Kinematic and Dynamic Modeling Based on Trajectory Tracking Control of Mobile Robot with Mecanum Wheels

Corresponding email: hassan.m.alwan@uotechnology.edu.iq

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.6908

Alwan, H.M., Nikolaevic, V.A., Hasan, S.F., Vladmerovna, K.O., 2024. Kinematic and Dynamic Modeling Based on Trajectory Tracking Control of Mobile Robot with Mecanum Wheels. International Journal of Technology. Volume 15(5), pp. 1473-1486

| Hassan M. Alwan | Mechanical Engineering Department, University of Technology, Alsinaa street, 10066, Baghdad, Iraq |

| Volkov A. Nikolaevic | High School of Automation and Robotics, Peter the Great St. Petersburg Polytechnic University, 29, Polytekhnicheskaya street, St. Petersburg, 195251, Russia |

| Sameh F. Hasan | Mechanical Engineering Department, University of Technology, Alsinaa street, 10066, Baghdad, Iraq |

| Kochneva O. Vladmerovna | High School of Automation and Robotics, Peter the Great St. Petersburg Polytechnic University, 29, Polytekhnicheskaya street, St. Petersburg, 195251, Russia |

The

trajectory tracking is important to make the WMR move autonomously from the

starting point to the destination along a predefined time. Implementing of trajectory tracking control

is a fundamental part to accomplish its application tasks. In this article a

new method by using a hybrid controller has been presented to solve the problem

of the trajectory tracking of four mecanum wheeled mobile robot. Proposed

controller is depending on modeling of robot kinematic and dynamic equations.

The novelty in this work is that, an optimal control system self-tuning

parameters based on an optimization algorithm for these models of the mobile

robot is utilized. The optimal control type that is used in this work is the

Linear Quadratic Regulator (LQR) controller. LQR is used to control the

actuator torque that is required in each wheel to achieve the robot task. The parameters

of the LQR controller are tuned by using Ant Colony Optimization (ACO). For

results simulation, MATLAB/ Simulink is used for circular and infinity shape

trajectories. Results show that when the robot follows a circular trajectory, the

values of position trajectory error values are reduced to small value (ex=3.218

*10-5m) and (ey= 2.224*10-5m) in xo

and yo directions, respectively and remained almost at these values

until the end of the simulation time. The maximum orientation error is (=

0.103rad), and convergent to zero after two seconds of the mobile robot

movement. Also when the robot follows an infinity shape trajectory, the

position trajectory error values are (ey) and (

) are

reduced to small value -4.078 *10-4m and 3.174*10-4rad

respectively, while, (ex) is reduced to 5.263*10-4 m

after about 15 seconds.

Ant colony optimization; Linear quadratic regulator controller; Robot kinematics: Trajectory tracking; Wheeled mobile robot

The researches about the control of trajectory

tracking of the mobile robot (WMR) are increased dramatically. In their review paper (Abed,

Lutfy, and Al-Doori, 2021) presents various trajectory planning strategies for mobile

robots using different optimization methods proposed in last year. In

their study (Song, Tang, and Li, 2024) addressed the issue of guiding a mobile robot

through a dynamic environment by combining the enhanced ant colony optimization

ACO with the dynamic window approach DWA algorithm. (Amouri, Cherfia, and Merabti,

2021) proposed

a new method to develop kinematic and dynamic models to improve the trajectory tracking accuracy. A new dynamic window algorithm DWA is proposed

by Wang, Ma, and Zhu (2022) to set the initial direction angle and

then improve its evaluation function during implementation of the trajectory

tracking to increase the efficiency and flexibility of the algorithm. A non-singular

terminal sliding mode

control (NTSMC) was used by Sun et al. (2020) for the mobile robot trajectory

tracking. Mathematical models of the mobile robot firstly, have been obtained with taking into account the uncertainty effect. An optimal robust control strategy is designed

by (Chai et al., 2024) based on the modified backstepping method to

achieve stable, accurate and real-time trajectory tracking for the wheeled

mobile robot in the presence of unavoidable disturbances. PID and LQR controllers have been

proposed by Amudhan

et al. (2019) to use in path controlling of a four wheeled

omnidirectional robot. Circular and rectangular shapes trajectories

have been followed in the performance examination of proposed controllers.

Yuan et al., (2019) have bee applied theoretically

and experimentally the extended state observer (ESO) relaying on the sliding

mode control (SMC) for the trajectory tracking of FMWMR. ESO-SMC based on both

kinematic and dynamic models of the WMR was applied with taking into account

the effect of the uncertainty and the disturbance. Morales et al. (2018) presented

the performance analysis of FMWMR experimentally by using linear quadratic

regulator (LQR) controller. Control of trajectory tracking of the omnidirectional WMR was solved by

using the model predictive control (MPC) based on only the mobile robot

kinematic model (Wang et

al., 2018). A modified active disturbance

rejection control (ADRC) built by (Azar et al., 2023) which includes a nonlinear state error feedback

controller and nonlinear tracking differentiator (TD) for the estimation error

correction during the trajectory tracking. In work done by Malayjerdi,

Kalani, and Malayjerdi, (2018), hybrid controller consisting of self – tuning fuzzy

PID controller based on the kinematic model of FMWMR was

utilized. In their

work, (Keek, Loh, and Chong, 2018) fractional order

proportional-integral (FOPI) controller utilized experimentally for the

trajectory tracking of the FMWMR was implemented. (Khadanga et al. 2018) and Gao et al. (2017) studied the wheeled mobile robot trajectory tracking controller design. For the problem of mobile robot’s path planning

under the known environment, a path planning method of mixed artificial

potential field (APF) and ant colony optimization (ACO) based on grid map is

proposed by (Chen and Liu, 2019) to explore a new and better path to receive

stronger stability and environmental adaptability. The

kinematics and dynamics models and proposed Backstepping controller algorithm

have been derived for the trajectory tracking of the robot. Both

mathematical models for WMR were derived based on the wheels velocities and

robot mass centre point velocities. Hussein (2023) presented a new

hybrid controller based on both kinematic and dynamic models of a non-holonomic

wheeled mobile robot. The gains parameters of the hybrid controller were tuned

by applying a modified version of a grey wolf optimization. Cui et al. (2012) proposed and simulated results to show the

effectiveness of the backstepping-based controller with proven global stability

by selecting a Lyapunov

function and introducing a virtual control input for the built dynamical model.

In their paper (El-Shorbagy

and Hassanien, 2018) a comprehensive

review of PSO as a well-known population-based optimization technique used in

the field of WMR. They start by a brief

introduction to the behaviour of the PSO, and then introduced the other

representation, convergence properties and the applications of PSO. The aim of

their study (Heryanto and Kusumoputro, 2021) was to propose an inner loop control algorithm

for UAV using a neural network–based DIC system. The experimental results

showed that the neural network–based DIC could follow the manoeuvres of the

testing trajectory dataset with excellent performance, as indicated by an

overall mean squared error (MSE). (Mehenge et al., 2023) work introduces a three-wheel holonomic

omnidirectional robot designed for mobile applications. This platform with

three omnidirectional wheels and DC motors, controlled by EMS 30A H-Bridge and

Arduino Mega 2560, it aligns kinematic calculations with mathematical models,

promising efficiency for diverse mobile manipulation robot applications. The main contribution of (Mohammed,

Al-Khafaji, and Abbas, 2023) paper is to develop an innovative algorithm

to accurately detect and identify the shape and color of objects and find their

location. The proposed algorithm utilizes the HSV color model to distinguish

between different object colors and shapes. After that, a series of filters are

applied to reduce the noise of these images to make the process of discovering

the shape and coordinates of the objects successful. (Wang et al. 2021) review a collision avoidance researches under unknown

environments for WMR including various types of controllers. In their approach (Pramujati

et al., 2023) introduces a model-based

control scheme consists of two systems for controlling the position of a

suspended cable-driven parallel robot. Three trajectories are generated to test

the compliance of the controller with its position. The error compensation scheme

is introduced to increase the positional accuracy of the previous controller,

especially on the z-axis. Williams and Wu (2010) have established a novel method of

obstacle-avoidance motion planning for mobile robots in dynamic environments,

wherein the obstacles are moving with general velocities and accelerations, and

their motion profiles are not preknown. A hybrid system is presented in which a

global deliberate approach is applied to determine the motion in the desired

path line (DPL).

Rusdinar et al. (2021) developed a mobile robot with a UVC light

system installed at the top and bottom to emit UVC light. This robot can be operated

automatically as it has a magnetic line sensor and employs a fuzzy inference

system algorithm for its movement. The experiment showed that UVC light has

good sterilization and disinfection performance.

Finally, it can be concluded that despite many methods are applied in the literature for designing the trajectory

tracking control strategy of the WMR for example: Fuzzy logic controller (Rahman, Hassan, and Ihsan, 2022), Adaptive Neuro-Fuzzy Inference System ;(ANFIS) (Tilahun

et al. 2023), Proportion integral differential (PID)(Saleh, Hussain, and Klim, 2018), linear quadratic regulator (LQR) (Uddin, 2018), model predictive control (MPC), etc, but they have drawbacks such as

large computational burden and long convergence time when dealing with under

actuated system. In addition, sliding model control (SMC) is

another effective method, but the chattering phenomenon limits its application.

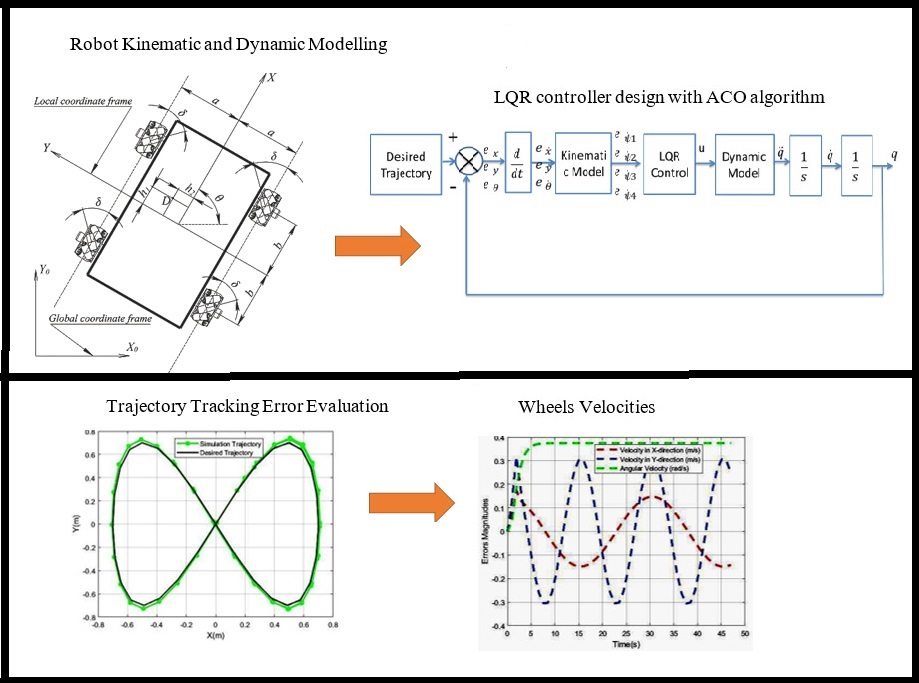

In this

work, hybrid controllers based on kinematics and dynamics are designed to solve

the trajectory tracking problem of a four mecanum wheeled mobile robot. The

type of the optimal control is the Linear Quadratic Regulator controller (LQR).

LQR is applied to design the controlled torques required by actuators and parameters of LQR controller are tuned by

using Ant Colony Optimization (ACO).

In

this scenario, the mobile robot is viewed as a complete mechanism with the angular velocities of its wheels serving as inputs

and the

robot’s linear and angular velocities as

outputs. In this context

the Jacobian matrix of inverse

kinematics can be expressed as (Equation 1):

FMWMR inverse kinematic equation

in robot local coordinate system is expressed as below (Equation

2):

Where: is the Matrix of angular

velocities of all robot mecanum wheels. Taking

in account that

is the robot velocities in

global coordinate system,

equation of inverse kinematic can be written as follow in global coordinate

system (Equation

3):

Where matrix of robot local coordinates system rotation with

reference to global coordinates system, and will be presented (Equation 4):

The forward kinematic jacobian matrix is pseudo-inverse of (J)(Zeidis et al. 2019), its

formula was written as:

The forward kinematics equation

in robot local coordinates system is written (Equation 5):

In the Lagrange formulation, the dynamic model of the robot includes the motion of the system resulting from the inertia of the entire robot mechanism and external forces. As illustrated in Figure (1a), point C represents the centre of the robot’s local coordinate frame, and (D) is the mass centre of the entire robot mechanism.

Velocity of local coordinate system origin point of the FMWMR (point C) in robot local coordinate system is evaluated according to the theory in as (Equation 7):

Since the

robot cannot change its vertical position (z-axis), so its potential energy is

equal to zero. The kinetic energy of the whole robot mechanism includes the

kinetic energy of the four mecanum wheels and robot platform. In this

case L is only kinetic

energy of the robot and has been written as (Equation 9):

Where: mr: mass of robot

platform , mwi: mass of i wheel, Ir: Robot mass moment of

inertia about its centre of mass

point, Iwi: moment of inertia

of i wheel. The Lagrange equation derived from the total energy of the whole

robot will present the dynamic model and can be written as

(Equation 10):

The

general form of the robot dynamic equation can be written (Equation

11):

Mass and

inertia matrix

Matrix of carioles and

centripetal effect

Controller design for trajectory tracking

In this section, a control system with self-tuning parameters based on

an optimization algorithm is utilized for both robot models. The type of the

optimal control that is used in this work is the Linear Quadratic Regulator

controller (LQR). It is used to design the controlled torques generated by the

wheels motors. The parameters of the LQR controller are tuned by using Ant

Colony Optimization (ACO) and this matter is presented in the next subsections.

3.1. Linear quadratic regulator controller

(LQR)

LQR controller used in this work is adopted

to make an optimal control signal for the motors torques.

3.2. Ant colony optimization (ACO)

Pei,

Wang, and Zhang (2012) states

that, ACO type

of optimization is an intelligent heuristic algorithm which was developed in

1992 by Marco Dorigo which simulates from the ant foraging behaviour. The

communication between ants is relying on the pheromones and the pheromones are

proportional inversely with length of the path. During the searching of the

ants for the food in an unknown environment, ants have been moved threw a path

containing a high pheromone concentration. Concentration of pheromone is

directly proportional with the numbers of the ants that walking on this path.

Ants behaviours display the principle in which adopted to select an optimal path.

To enhance path planning efficiency, heuristic function and tabu list (tabuk)

are adopted into an artificial ant colony model. Within a time (t), ant k moves

from a current node i to an unvisited node j regarding the distance information

received from the target point and pheromone intensity during this path. In the

case of more than one unvisited node, the transition probability (

) between the nodes will be evaluated by the

ant K in accordance with the formula that shown (Equation 29) :

where U

represents the next node of ant k, is an expectation heuristic factor,

is a

pheromone heuristic factor,

is a pheromone concentration on the path ij at a period of time (t),

(t) is an expected heuristic functio a (Equation 30):

where is a Euclidean distance between

any two adjacent nodes. After finishing the path search by all ants, pheromone

was evaporated. The formula that describes the increasing of the pheromone on

the path (Equations 31 and 32):

where () represents the rate of the pheromone

evaporation, and (t) is the time of the iterations. Value of

depends on the pheromone addition which has been

done by an ant (K) after its movement on (ij) path during iteration time

(t). Mathematical model of

can be

defined as (Equation 33):

Where (N)

represents the intensity of the pheromone that added by the ant (K) and (LK)

represents the length of the path that was tracking by the ant (K) during one

iteration. There is no fixed rule to choose the ant's

number as well as the Max. number of iteration. The selection number is

considered to be acceptable because the higher number of iterations and ants

required more program execution time. Also, it is needed a computer with high

specifications.The basic

parameters for the ACO have been chosen as

follow:

Ants

Number: 30

In this work, ACO is adopted in selection of optimal values of (Q) and (R) matrices elements. In simulation work, a closed loop controller (Figure 2) has been implemented. This loop is a trajectory tracking controller based on minimizing the pose error to zero. We used LQR controller where the gains were obtained by using Anti Colony Optimization ACO to control the motors torques.

Figure 2 Controller architecture

The proposed controller has been

examined in two options of WMR movement. In first

option WMR follows a circular shape trajectory and in second option it follows

an infinity shape trajectory. The results have been simulated by using MATLAB

2019 software. The parameters of robot are taken as follow:

Figure 3 The first proposed circular Shape Trajectory followed

by the WMR

After two seconds of the WMR task starting, the

values of position trajectory error values are reduced to small value (ex=3.218 *10-5m) and (ey=

2.224*10-5m) in xo and yo directions,

respectively and remained almost at these values until the end of the

simulation time. The maximum orientation error is (= 0.103rad),

and convergent to zero after two seconds of the mobile robot movement. Figure

4a shows the robot linear and angular velocities in global coordinate system

during the circular trajectory. As shown

in Figure 4a the robot velocities behaviour is smooth during the simulation

time. The value of the linear velocities is fluctuated about ±0.4 m/s and robot

rotation velocity is 0.4 rad/s. Generated torques from robot mecanum wheels

motors can be evaluated at any time. The torques values have been shown in Figure

4b.

In the second option, the equations

of the infinity shape trajectory followed by the WMR are described as

(Equations 39 and 40):

Figure 4 Velocities and torques generated in all wheels when the WMR follows a circular shape trajectory

Figure 5 The second proposed Infinity Shape Trajectory followed by WMR

It has been seen, in the

two cases, simulation results show higher precision of trajectory tracking

because the position tracking errors (x,y) are less than 10-3m and acceptable comparing with most of

published researches.

Figure 6

Velocities and torques generated in all wheels when the WMR follows an infinity

shape trajectory

In this work, an

optimal control system is applied based on the kinematics and dynamics of the

four mecanum wheeled mobile robot for the trajectory tracking.

MATLAB software is used for results simulation of the proposed controller in

two cases. In the first case the robot followed a circular shape trajectory and

in the second case followed an infinity shape trajectory. The most important points are presented as: LQR controller with a

self-tuning parameters based on ACO are applied to control the robot motors

torques. In the first case,

the values of the trajectory errors in xo and yo

directions are ex=4.645*10-4m and ey = 7.382*10-5

m respectively and these values converge to zero after two seconds. In second case, maximum

absolute values of the trajectory error (ex), (ey) and are 0.05 (m) , 0.01 (m), and 0.08 (rad) respectively. After about three seconds, (ey) and

are reduced to small value -4.078 *10-4 (m) and 3.174*10-4

(rad) respectively, while (ex) is reduced to 5.263*10-4

(m) after about 15 sec. The magnitudes of

the torques are between ( ± 1.5 ) N/m.

Authors are pleased to express special appreciations and thanks to “Mechanical Engineering Department at University of Technology, Baghdad, Iraq” and “High School of Automation and Robotics at Peter the Great Saint Petersburg Polytechnic University” for their help and support during the research period.

Abed, M.S., Lutfy, O.F.,

Al-Doori, Q.F., 2021. A Review on Path Planning Algorithms for Mobile Robots. Engineering

and Technology Journal, Volume 39(5), pp. 804–820

Alwan, H.M., 2020. Kinematic Modeling and simulation of

Holonomic Wheeled Mobile Robot with Mecanum Wheels. Journal of Mechanical

Engineering Research and Developments, Volume 43(5), pp. 451–459

Amouri, A., Cherfia, A., Merabti,

H., 2022. Nonlinear Model Predictive Control of a Class of Continuum Robots

Using Kinematic and Dynamic Models. FME Transactions, Volume 50(2), pp.

339–350

Amudhan, A.N., Sakthivel, P.,

Sudheer, A.P., Kumar, T.S., 2019. Design of Controllers for Omnidirectional

Robot Based on the System Identification Technique for Trajectory

Tracking. Journal of Physics:

Conference Series, Volume 1240(1), p. 012146

Azar, A.T., Abed, A.M.,

Abdul-Majeed, F.A., Hameed, I.A., Jawad, A.J.M., Abdul-Adheem, W.R., Ibraheem,

I.K., Kamal, N.A., 2023. Design and Stability Analysis of Sliding Mode

Controller for Non-Holonomic Differential Drive Mobile Robots. Machines, Volume 11, p. 470

Chai, B.,

Zhang, K., Tan, M., Wang, J., 2024. An Optimal Robust Trajectory Tracking

Control Strategy for the Wheeled Mobile Robot. International Journal of

Control, Automation and Systems, Volume 22(3), pp. 1050–1065

Chen, G., Liu, J., 2019. Mobile

Robot Path Planning Using Ant Colony Algorithm and Improved Potential Field

Method. Computational Intelligence and Neuroscience Journal, Volume 12,

pp. 1–10

Cui, Q.Z., Li, X., 2012.

Backstepping Control Design on the Dynamic of Omni-Directional Mobile

Robot. Journal of Applied Mechanics

and Materials, Volume 203, pp. 51–56

El-Shorbagy, M.A., Hassanien,

A.E., 2018. Particle Swarm Optimization from Theory to Applications. International Journal of

Rough Sets and Data Analysis, Volume 5(2), pp. 1–14

Gao, Z., Yang, Y., Du, Y., Zhang,

Y., Wang, Z., Xu, W., 2017. Kinematic Modeling and Trajectory Tracking Control

of a Wheeled Omni-directional Mobile Logistics Platform. In: Asia-Pacific

Engineering and Technology Conference (APETC), pp. 169–175

Hasan, S.F., Alwan, H.M., 2022.

Local Path Planning of a Four Mecanum Wheeled Mobile Robot Based on New

Modified Ultrasonic Sensors with Experimental Implementation. International

Journal of Mechanical Engineering, Volume 7(1), pp. 4621–4627

Hasana, S.F., Alwan, H.M., 2021.

Modelling and Control of Wheeled mobile Robot with Mecanum Wheels. Engineering and Technology journal,

Volume 39(A), pp. 779–789

Heryanto, M.A., Kusumoputro, B.,

2021. Attitude and Altitude Control of Quadcopter Maneuvers

using Neural Network–Based Direct Inverse Control. International

Journal of Technology, Volume 12(4), pp. 843–853

Hussein, R.M., 2023. Design a New

Hybrid Controller Based on an Improvement Version of Grey Wolf Optimization for

Trajectory Tracking of Wheeled Mobile Robot. FME Transactions, Volume

51(2), pp. 140–148

Keek, J.S., Loh, S.L., Chong, S.H., 2018. Fractional-Order

Proportional-Integral (FOPI) Controller for Mecanum-Wheeled Robot (MWR) in

Path-Tracking Control. International Journal of Mechanical Engineering and

Technology (IJMET), Volume 9(11), pp. 325–337

Khadanga,

R.K., Padhy, S., Panda, S., Kumar, A., 2018. Design and Analysis of Tilt Integral Derivative Controller for Frequency

Control in an Islanded Microgrid: A Novel Hybrid Dragonfly and Pattern Search

Algorithm Approach. Arabian Journal

for Science and Engineering, Volume 43 (6), pp. 1–12

Malayjerdi,

E., Kalani, H., Malayjerdi, M., 2018. Self-Tuning

Fuzzy PID Control of a Four-Mecanum Wheel Omni-directional Mobile Platform. 26th

Iranian Conference on Electrical Engineering(ICEE), Volume 2018, pp.

816–820

Mehenge, R., Satoskar, N., Shidhore, A., Arshath, N.M., 2023. Kinematic and Optimal design of a Three-wheeled Holonomic

Omnidirectional Robot Platform for Mobile Manipulation Tasks. Global

Journal of Engineering and Technology Advances, Volume 17(1), pp. 45–54

Mohammed, M.M., Al-Khafaji, M.M.,

Abbas, T.F., 2023. Smart Robot Vision for A Pick and Place Robotic System. Engineering

and Technology Journal, Volume 41(6), pp. 756–770

Morales, S., Magallanes, J.,

Delgado, C., Canahuire, R., 2018. LQR Trajectory Tracking Control of an

Omnidirectional Wheeled Mobile Robot. In: IEEE 2nd Colombian

Conference on Robotics and Automation (CCRA), pp. 1–5

Pei, Y., Wang, W., Zhang, S., 2012. Basic Ant Colony

Optimization. In: International

Conference on Computer Science and Electronics Engineering, Hangzhou,

pp. 665–667

Pramujati, B., Syamlan, A.T.,

Nurahmi, L., Tamara, M.N., 2023. Study on the Application of

Model-based Control Algorithm for a Suspended Cable-Driven Parallel

Robot. International Journal of Technology. Volume 14(4), pp. 854–866

Rahman, A., Hassan, N., Ihsan,

S.I., 2022. Fuzzy Logic Controlled Two Speed Electromagnetic Gearbox

for Electric Vehicle. International Journal of Technology. Volume 13(2), pp.

297–309

Rusdinar, A., Purnama, I., Fuadi, A.Z., Adiluhung, H., Wicaksono, M.,

Risnanda, Ningrum, R.A., 2021. Automated Ultraviolet C Light Mobile Robot for

Room Sterilization and Disinfection. International Journal of Technology,

Volume 12(4), pp. 854–864

Saleh, A., Hussain, M., Klim, S.,

2018. Optimal Trajectory Tracking Control for A Wheeled Mobile

Robot Using Fractional Order PID Controller. Journal of University of

Babylon, Vvolume 26, pp. 292–306

Song, B.,

Tang, S., Li, Y., 2024. A New

Planning Integrating Improved ACO and DWA Algorithms for Mobile Robots in

Dynamic Environments. Mathematical and Biosciences and Engineering Journal,

Volume 21(2), pp. 2189–2211

Sun, Z., Xie, H., Zheng, J., Man,

Z., He, D., 2020. Path-following Control of Mecanum-Wheels Omnidirectional

Mobile Robots Using Nonsingular Terminal Sliding Mode. Mechanical Systems

and Signal Processing, Volume 147, p. 107128

Tilahun, A.A., Desta, T.W., Salau, A.O., Negash, L.,

2023. Design of an Adaptive Fuzzy Sliding Mode Control with Neuro-Fuzzy System

for Control of a Differential Drive Wheeled Mobile Robot. Cogent Engineering,

Volume 10(2), p. 2276517

Uddin, N., 2018. Trajectory

Tracking Control System Design for Autonomius Two-Wheeled Robot. Journal Infotel, Volume 10(3), pp. 90–97

Wang, C., Liu, X., Yang, X., Hu,

F., Jiang, A., Yang, C., 2018.

Trajectory Tracking of an Omni-Directional Wheeled Mobile Robot Using a Model

Predictive Control Strategy. Applied Science, Volume 8(2), p. 231

Wang, H., Ma, X., Zhu, L., 2022. Obstacle Avoidance Path Planning of Mobile Robot Based

on Improved DWA. Journal of Physics: Conference Series, Volume

2383(1), p. 012098

Wang, Y., Li, X., Zhang, J., Li,

S., Xu, Z., Zhou, X., 2021. Review of Wheeled Mobile Robot Collision Avoidance

under Unknown Environment. Science Progress Journal, Volume 104(3), pp.

1–26

Williams, R.L., Wu, J., 2010.

Dynamic Obstacle Avoidance for An Omnidirectional Mobile Robot. Journal of

Robotics, Volume 2010, p. 901365

Yuan, Z., Tian, Y., Yin, Y.,

Wang, S., Liu, J., Wu, L., 2019. Trajectory Tracking Control of a Four Mecanum

Wheeled Mobile Platform: an Extended State Observer-Based Sliding Mode

Approach. IET Control Theory & Applications, Volume 14(3), pp.

415–426

Yuan, Z., Tian, Y., Yin, Y.,

Wang, S., Liu, J., Wu, L., 2019. Trajectory Tracking Control of a Four Mecanum

Wheeled Mobile Platform: an Extended State Observer-Based Sliding Mode

Approach. IET Control Theory & Applications, Volume 14(3), pp.

415–426

Zeidis, I., Zimmermann, K., 2019.

Dynamic of Four Wheeled Mobile Robot with Mecanum Wheels. Journal of Applied Mathematics and

Mechanics, Volume 3, pp. 1–22