Development of an Innovative Thermal Cracking of Mixed-Plastic Waste Without Catalyst as an Alternative Fuel Source

Corresponding email: janterps@unimed.ac.id

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.6905

Simanjuntak, J.P., Zainon, M.Z., Zulkifli, N.W.M., Tambunan, B.H., Sihombing, J.L., Riduwan, 2024. Development of an Innovative Thermal Cracking of Mixed-Plastic Waste Without Catalyst as an Alternative Fuel Source. International Journal of Technology. Volume 15(5), pp. 1539-1549

| Janter P. Simanjuntak | Mechanical Engineering Department, State University of Medan, Jl. Willem Iskandar Pasar V Medan Estate, Medan 20221, North Sumatra, Indonesia |

| Mohd Zamri Zainon | Department of Mechanical Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia |

| Nurin Wahidah Bint Mohd Zulkifli | Department of Mechanical Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia |

| Bisrul H. Tambunan | Mechanical Engineering Department, State University of Medan, Jl. Willem Iskandar Pasar V Medan Estate, Medan 20221, North Sumatra, Indonesia |

| Junifa L. Sihombing | Department of Chemistry, Faculty of Mathematics and Natural Sciences, State University of Medan, Jl. Willem Iskandar Pasar V Medan Estate, Medan 20221, North Sumatra, Indonesia |

| Riduwan | Usaha Kecil Menengah, Program Kemitraan dan Bina Lingkungan PT. Kawasan Industri Medan, Medan 20371, North Sumatra, Indonesia |

The

growing consumption of plastic is a major contributor to the substantial

increase in waste, emphasizing the urgent need for the adoption of sustainable

and effective practices in management and resource reclamation. Therefore, this

study aimed to investigate the production of pyrolytic

distilled oil (PDO) from five types of mixed-plastic waste using

pyrolysis and distillation process without catalysts. Pyrolysis was conducted

at a temperature range of 300 to 450

with a fixed heating rate of 10

/min

for 60 minutes, while distillation was performed at 120

to 350

. The

distilled pyrolytic oil obtained was characterized using analytical techniques

with gas chromatography-mass spectrometry (GC-MS) and Carbon/Hydrogen/Nitrogen

(CHN) analyses to determine its chemical content and heating value. The effect

of pyrolysis and distillation temperature on product yield and hydrocarbon

content was also examined. The results showed that the predominant compounds

obtained were aromatic hydrocarbon groups, including styrene, benzene,

naphthalene, and xylene. Other compounds included non-aromatic hydrocarbon

groups, such as alkane and alkene. In addition, the chemical content was found

to be comparable to that of product obtained from the use of common pyrolysis

using catalysts. In this study, the

heating values observed were in the range of

30.835 – 33.004 MJ/kg. However, the heating value of the product

was still low and needed to be improved using another treatment. Comparison

with previous reports showed that temperature in this study was not significant

to the chemical content and heating value of the obtained distillate oil.

Low temperature; Non-catalyst; Plastic waste; Pyrolysis; Pyrolytic oil

Fossil fuels, such as coal, oil, and gas, are primary global energy sources that have been widely used for over a century. Despite the importance of these fuels, their extensive use has led to several detrimental effects, including climate change, air pollution, and resource depletion. Consequently, there is a pressing need to reduce their usage and support initiatives aiming for zero fossil fuels by 2050 (Holechek et al., 2022). These detrimental effects are likely to persist on Earth when decisive actions are not taken to mitigate human dependence. Climate change, caused by the greenhouse gases emitted from burning fossil fuel-derived energy, has significantly impacted the planet. The impacts include rising sea levels, more frequent and intense weather events, and increased extinction rates for plants and animals (Haines et al., 2006).

According to

previous studies, mitigating human reliance on fossil fuels necessitates a

transformative shift towards cleaner and more sustainable energy sources,

including wind, solar, and geothermal power (Owusu

and Asumadu-Sarkodie, 2016). This transition is expected to reduce

environmental impact and create new economic opportunities and jobs within the

renewable energy sector. Several studies have shown that continued dependence

on the use of fossil fuels is unsustainable and poses a significant threat to

Earth.

In line with

several reports, plastic waste has become a significant environmental concern

due to its widespread use, improper disposal, and slow degradation (Vriend et al., 2021). In addition, it

comprises discarded plastic, such as packaging, bags, bottles, straws, and

other single-use variants. The waste typically causes several environmental

problems, including land and water pollution, where it ends up in landfills,

taking centuries to degrade (Sari et al., 2022).

This condition often leads to its accumulation in landfills, contributing to

soil contamination and the release of harmful chemicals. The consequences

extend to marine pollution, where it accumulates in the oceans and water

bodies, posing a severe threat to marine life.

Compared to other countries, Indonesia

also needs a mix of energy sources to meet its future demands while reducing

its dependence on fossil fuels. This approach requires increasing the use of

renewable sources, improving energy efficiency, and exploring new technologies

to support a more sustainable system of producing liquid biofuel (Simanjuntak, Tambunan, and Sihombing, 2023; Simanjuntak et

al., 2022). In

Indonesia, two crucial sources of liquid fuel production are organic and

inorganic materials. Organic materials, typically sourced from plants or

biomass, serve as a highly environmentally friendly alternative and are often

referred to as green fuel.

A typical example of organic materials is palm oil, which serves as an

ideal and highly productive source of biofuel for internal combustion engines (Prihadiyono et al., 2022). Algae plants

also have the potential to serve as a renewable energy source due to their high

productivity and ability to grow in diverse environment (Sardi et al., 2022; Jamilatun et al., 2020). In

addition, inorganic

materials, such as plastic waste, have high productivity and can be used for

industrial and construction purposes. Various plastic materials can be

processed into liquid fuels with properties similar to diesel (Suhartono et al., 2023). The quality of

liquid fuels can be improved by mixing organic and inorganic materials (Kusrini et al., 2018). Plastic

has been reported to possess the potential to be used as building material,

thereby reducing concrete production costs. Previous reports showed that it

could also be used as aggregate substitute for cement in concrete. The

aggregate acts as filling materials that contribute to the structural strength

of concrete (Purnomo, Baskoro, and Muslim, 2023).

Plastic waste can be a potential source for

future energy mixes through the use of pyrolysis. This method comprises heating

the waste to high temperatures in the absence of oxygen, leading to the

breakdown of the constituent long polymer chains and the production of a liquid

fuel known as pyrolysis oil (Sharma et al., 2014).

The liquid product obtained can be used as a fuel substitute or blended with

bio-oil for internal combustion engines (Awang et

al., 2021), electricity generation, or feedstock for the production

of chemicals. Another effective method of using plastic waste is gasification (Ahmed and Gupta, 2010), which comprises heating

in the presence of oxygen and steam to produce a gas mixture called syngas.

This product can be burned for heat and electricity or processed into biofuels,

such as ethanol or methanol.

Based on

findings, pyrolysis and gasification have the potential to convert plastic into

useful energy sources while also reducing the amount of waste being accumulated

in landfills or the environment. However, there are also some challenges

associated with its use as an energy source. These include potential emissions

of harmful pollutants during the conversion process, the need for careful

handling to prevent contamination with other materials, and the cost of

building and operating the necessary infrastructure (Verma

et al., 2016).

According to

previous studies, pyrolysis is a promising solution for addressing the issue of

mixed-plastic waste. This process comprises the thermal decomposition of

organic materials in an oxygen-deprived environment, leading to the production

of valuable by-products, including fuel, gases, and char (Papari, Bamdad, and Berruti, 2021). Pyrolysis of mixed-plastic waste holds

significant potential as it can generate a valuable energy source, serving as a

sustainable alternative to fossil fuels. This transition not only mitigates

greenhouse gas emissions but also contributes to the advancement of the

circular economy (Siddiqui and Redhwi, 2009).

However, it presents inherent challenges, such as the substantial variability

in substrate composition and the imperative need for optimal operating

conditions to ensure the production of high-quality fuels (Kasar, Sharma, and Ahmaruzzaman, 2020; Al-Salem et

al., 2017). The

complexity of managing diverse waste streams necessitates comprehensive study

efforts to explore the technical feasibility, economic viability, and

environmental impact associated with the pyrolysis process.

Plastic

waste holds great promise in the petrochemical industry through the pyrolysis

process, leading to the release of several valuable industrial materials. In

this study, data from previous research by Soni et al., (2021) is

referenced, which demonstrates that plastic waste, categorized by its recycling

code, contains a range of chemical components.

The values

presented represent the proximate analysis of a single sample obtained from

different types. The high volatile fraction and low ash content showed that

co-pyrolysis process can contribute to optimal pyrolysis production, yielding a

high heating value for fuels.

The current trend in plastic pyrolysis studies focuses

on achieving high yields of products with high quality and low energy

consumption, collectively referred to as high efficiency. This efficiency can

be enhanced by using catalysts, which allow for lower operational temperatures (Peng et al., 2022). However, most studies

employing catalysts have been conducted on individual types of plastic. The use

of these materials presents challenges, such as feeding issues and difficulties

in process control. Despite the drawbacks, the primary benefit of using

catalysts is the higher production of bio-oil (Kim,

2004).

Previous reports have explored pyrolysis without catalysts, particularly when

processing single types of plastic. These reports have demonstrated the

possibility of achieving comparable yields at moderate temperatures (Miskolczi et al., 2004).

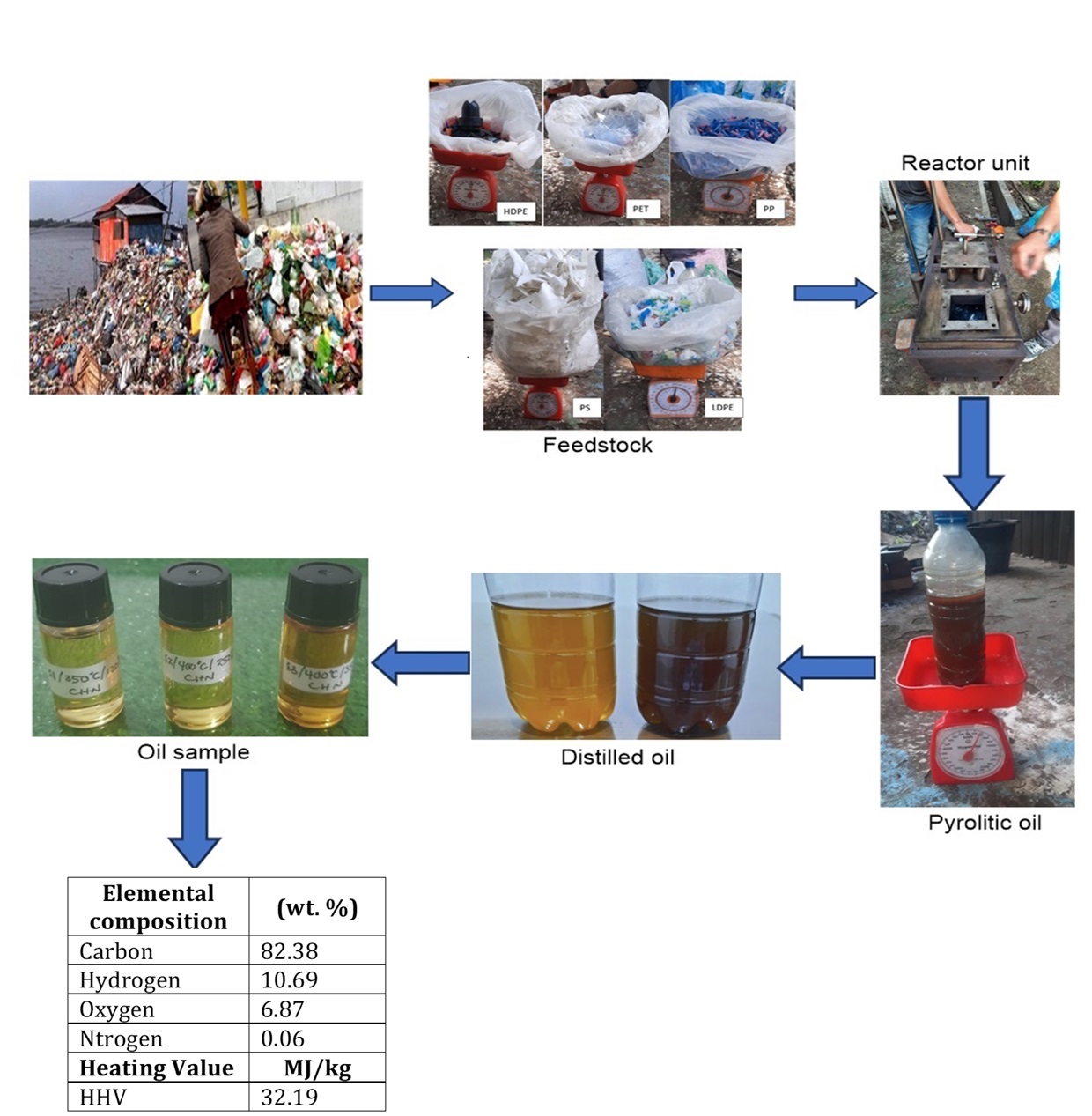

2.1. Materials

This study involved the utilization of

a mixed feedstock comprising five types of plastic waste. The plastic materials

were collected

from the trash bin around the study site, which was sorted, cleaned, and dried

before being put into the pyrolysis apparatus. The feedstock included polyethylene

terephthalate (PET), low-density polyethylene (LDPE), high-density polyethylene

(HDPE), polypropylene (PP), and polystyrene (PS) derived from mineral beverage water bottles, grocery plastic bags, detergent bottle caps, beverage pipettes, and food wrapping of Styrofoam

respectively. The feedstock was chopped manually to achieve a standardized size of

approximately 3 cm x 3 cm. The proximate analysis of the material used was

presented in Table 1.

Table 1 Proximate

Analysis of Plastic (%)

|

Plastics |

C |

H |

N |

S |

O |

Cl |

|

HDPE |

85.40 |

15.04 |

0.00 |

0.52 |

2.77 |

0.14 |

|

PVC |

38.53 |

5.04 |

0.013 |

0.176 |

0.00 |

56.25 |

|

PS |

92.59 |

8.13 |

0.00 |

0.00 |

2.24 |

0.00 |

|

LDPE |

77.60 |

21.55 |

0.00 |

0.003 |

0.00 |

0.00 |

|

PET |

77.00 |

13.00 |

0.20 |

n.a |

5.00 |

n.a |

2.2. Method

Approximately 200 grams of each type of

plastic was introduced into the pyrolysis reactor and heated to the desired

temperature without oxygen using an LPG combustor. During the heating process,

the mixed plastic was degraded into lighter molecules in the form of vapor.

After passing through the condenser, the vapor reached its saturation

temperature and condensed into liquid. Subsequently, a distillation process was

used to separate the liquids according to the density of molecules which

resulted in pyrolytic distilled oil (PDO), exhibiting properties similar to

fossil-based liquid fuels.

Operating temperature for this process

ranged from 300 to 450 , while the heating rate and residence

time were 10

and

60 minutes, respectively. The schematic of the process is presented in Figure

1. The procedure began with pyrolysis, followed by the cooling of the pyrolytic

vapor in the condenser until all vapor transformed into condensate. After pyrolysis process was

completed, the reactor was allowed to cool down and the condensate was

extracted from the condenser. In addition, distillation was conducted within the

same reactor, generating pyrolytic oil as the final product.

The type of distillate or pyrolytic oil

obtained was based on the operating temperature utilized during the process. A total of six samples were

prepared for characteristic testing using only CHN and GC-MS methods to analyze the

product yield in terms of chemical and molecule components. According to Ghodke (2021), there were six methods for characterizing

pyrolytic oil. However, in this study, the CHN-GCMS was selected due to the

cost-effectiveness and time consumed during the characterization process using

multiple methods.

Pyrolysis process comprised

the thermal decomposition of inorganic materials in the absence of oxygen.

During the process, the plastic feedstock was subjected to decomposition based

on the application of heat. The absence of oxygen prevented combustion, leading

to the formation of various products, including gases, liquids or PPO, and

solids. These products could then be further processed or refined for various

applications, such as fuel production, chemical synthesis, or waste management.

The equation (1) below shows a simplified representation of pyrolysis reaction.

Figure 1 Schematic pyrolysis system of five types of plastic waste

The

plastic pyrolytic oil (PPO) product, derived from pyrolysis of a mixture of

five types of plastic, occurred within a temperature range of 300 to 450 oC. The

procedure yielded predominantly liquid oil, constituting an intricate

amalgamation of hydrocarbons, along with a solid residue identified as char.

This char primarily consisted of mixed carbon, and the quantity generated was

dependent on the type of plastic and the specific pyrolysis conditions

employed. The yield of each product was intricately linked to several factors,

including the composition of the mixed plastic, the temperature range applied,

the heating rate, and various other parameters. In addition, the choice of the

pyrolysis reactor and the conditions under which the procedure was conducted

significantly influenced the final product outcomes.

In this study, the yield of PPO from the five

mixed plastics reached 45% by weight of the feedstock at a temperature of

approximately 400oC. This finding was consistent with the results of other

reports, who achieved a yield of up to 69% when pyrolyzing mixed plastic at

approximately 500oC (Genuino et al., 2022).

Figure 2 shows the appearance of pyrolytic distilled products (PDO), revealing

a strong dependence on the applied distillation temperature. A total of six

samples (S1-S6) each with a volume of 10 ml, and subjected to different

pyrolysis and distillation temperature, were tested. The specific conditions

for each sample were 1) S1 pyrolyzed at 350 oC and distilled at 120 oC,

2) S2 pyrolyzed at 400 oC and distilled at 250 oC, 3) S3

pyrolized at 400 oC and distilled at 350 oC, 4) S4

pyrolyzed at 300 oC without distillation from the gasoline-like

port, 5) S5 pyrolyzed at 300 oC without distillation from the

diesel-like port, and 6) S6 pyrolyzed at 380 oC and distilled at 180 oC. Lower distillation temperature (<200 oC) led to the production

of products with bright colors, while higher temperature (>200 oC) produced a

yellowish hue. This observation was in line with the findings of a previous

report (Wiriyaumpaiwong and Jamradloedluk, 2017).

3.1. Chemical characterization

of plastic distilled oil

The chemical characterization

of the plastic distilled oil was conducted at the National Study and Innovation

Agency, Indonesia (BRIN). The samples were subjected to total CHN

(carbon/hydrogen/nitrogen) and analyzed using an Exeter Analytical (Chelmsford,

MA) CE-440 Elemental Analyzer. Subsequently, the oxygen content was determined

through mass balance closure. Table 2 presented the elemental composition and

heating value of the PDO obtained from the five mixed types of plastic. Table 3

provided a comparison of the results with those from another study that used a

catalyst. The chemical content was found

to be comparable to the common pyrolysis processes using catalysts. However, it

was noteworthy that the heating value was lower compared to the report by Sharma et al. (2014). This disparity could be

attributed to the higher oxygen content in the PDO produced in this study.

Table 2 Elemental composition and heating value of PDO of five

mixed plastics (wt %)

|

Sample Name |

Carbon (%) |

Hydrogen (%) |

Nitrogen (%) |

Oxygen (%) |

HHV (MJ/kg) |

|

S1 |

85.633 |

10.540 |

0.019 |

3.808 |

33.004 |

|

85.171 |

10.385 |

0.077 |

4.367 |

32.768 | |

|

S2 |

80.302 |

10.123 |

0.061 |

9.514 |

31.221 |

|

79.029 |

10.081 |

0.041 |

10.849 |

30.835 | |

|

S3 |

82.951 |

11.521 |

0.052 |

5.476 |

32.903 |

|

83.325 |

11.545 |

0.054 |

5.076 |

33.025 | |

|

S4 |

82.190 |

10.032 |

0.078 |

7.700 |

31.692 |

|

82.133 |

10.244 |

0.060 |

7.563 |

31.818 | |

|

S5 |

81.278 |

10.680 |

0.057 |

7.985 |

31.869 |

|

81.607 |

10.785 |

0.067 |

7.541 |

32.032 | |

|

S6 |

83.266 |

11.328 |

0.061 |

5.345 |

32.863 |

|

81.719 |

11.071 |

0.043 |

7.167 |

32.255 | |

|

Average |

82.384 |

10.695 |

0.056 |

6.866 |

32.190 |

|

Carbon

(%) |

Hydrogen

(%) |

Nitrogen

(%) |

Oxygen

(%) |

HHV

(MJ/kg) |

Reference |

|

81.24 |

14.69 |

0.13 |

3.95 |

34.54 |

Quesada et al.

(2019) |

|

74.90 |

1.70 |

2.78 |

8.6 |

32.12 |

Santella et al. (2016) |

|

82.38 |

10.69 |

0.06 |

6.87 |

32.19 |

This work (Non-catalyst) |

3.2. Gas

chromatography-mass spectroscopy (GC–MS)

Figures 3 and 4 depicted the molecular

fraction successfully recorded by GC-MS for the six samples (S1–S6). The data

exhibited a consistent and relatively similar pattern, suggesting that the

impact of temperature on pyrolysis products was not highly significant. The

GC-MS analysis revealed two distinct hydrocarbon groups, which were aromatics,

including benzene, toluene, xylene, styrene, and naphthalene, and a

non-aromatic group comprising C1-C10 alkanes, C11-C20 alkanes, and C1-C10

alkenes. Table 4 provided comparative data on pyrolysis results with and

without the use of a catalyst. From Table 4 it was evident that the pyrolysis

process without a catalyst had a similar product of liquid hydrocarbon with

pyrolysis without a catalyst.

According to these data, the PDO

yields were predominantly composed of aromatic hydrocarbons. The GC–MS analysis

revealed that the pyrolysis liquid oils from the 6 samples mainly consisted of

aromatic hydrocarbons with a minor presence of aliphatic hydrocarbon compounds

similar to the findings of Miandad et al.

(2017). Specifically, styrene, derived from the cracking of polystyrene

(PS), was the dominant aromatic compound, which was consistent with the study

conducted by Shah and Jan (2015). The production of aromatics

from the pyrolysis of polyethylene (PE) could involve Diels-Alder reaction and

dehydrogenation mechanisms (Miandad et al., 2019).

This study identified a high percentage of BTX components (benzene, toluene,

xylene), styrene monomers, and other mono-aromatic compounds, highlighting

their potential application in the petrochemical industry. In addition, these

mono-aromatic compounds could be blended into the gasoline pool to enhance the

fuel's octane number (Jaafar et al., 2022).

Table 4 Comparison of the chemical composition of liquid products identified by GC–MS

|

Component name | |||||

|

Naphthalene |

Benzene |

Toluene |

Xylene |

Styrene |

References |

|

17.20 |

28.8 |

28.80 |

n.a |

n.a |

Aisien,

Otuya, and Aisien (2021) *) |

|

0.21 |

1.10 |

1.49 |

n.a |

64.31 |

Shah

and Jan (2015) *) |

|

0.63 |

4.00 |

15.30 |

8.80 |

24.50 |

Miandad

et al. (2017) *) |

|

2.90 |

4.50 |

24.00 |

3.40 |

54.0 |

Onwudili,

Insura, and Williams, (2009) **) |

|

2.5 |

5.28 |

10 |

1.75 |

30 |

This work**) |

*) Catalyst

*) Non-catalyst

For polystyrene, the

raw material’s highly aromatic nature resulted in the predominant production of

aromatic products during pyrolysis. Conversely, for PET, LDPE, and HDPE, the

generated oil mainly comprised aliphatic hydrocarbons, including alkanes and

alkenes (Budsaereechai, Hunt, and Ngernyen, 2019).

The hydrocarbon groups ranging from C4–C11 represented light fraction petroleum

fuels, while carbon numbers from C12–C20 indicated medium fraction diesel

fuels. The thermal degradation of polyalkene mixed plastics occurred through

random cutting, producing a diverse range of hydrocarbon fragments with varying

carbon atom numbers. The weakest C-C bonds in the polyalkene structure

underwent random cutting reactions during degradation, leading to the formation

of carbon double bonds (C=C) in the resulting structure. Consequently, the

pyrolysis oil obtained showed a notable concentration of alkenes. This thermal

degradation process, induced by random cutting reactions, resulted in the

formation of a diverse array of hydrocarbon species. However, due to the

presence of CH3 side chains in the PET structure, several

hydrocarbons were also formed alongside those observed in the pyrolysis of

other polyalkenes (Siddiqui and Redhwi, 2009)."

The pyrolysis oil content, dominated by aromatic monobenzene, as well as non-aromatic alkanes and C1-C10 alkenes, indicated that plastic samples had undergone a cracked process to produce short-chain hydrocarbons. Furthermore, these compounds also produced content, such as Benzoic acid, n-Pentadecanol, 1-Tetradecanol, and some >C21 components, including Behenic alcohol, and Hentriacontane (Carbonic acid, decyl undecyl ester). The heavy oil content of compounds with >C21 was primarily obtained from the degradation of HDPE, which was mostly found in sample S6.

In

conclusion, valuable industrial products could be obtained from five mixed

plastic waste through pyrolysis and distillation processes without a catalyst.

This waste included polyethylene terephthalate (PET), low-density polyethylene

(LDPE), high-density polyethylene (HDPE), polypropylene (PP), and polystyrene

(PS) from mineral water bottles, grocery bags, detergent bottle caps, beverage

pipette, and Styrofoam food wrapping respectively. The chemical content was

found to be comparable to the common pyrolysis utilizing a catalyst. The

heating values achieved ranged from 30.835 to 33.004 MJ/kg. However, this

heating value was relatively low and required improvement through the

oxygenation process or blending with biodiesel, kerosene, and other fuels with higher

heating values.

The authors

are grateful tp the Directorate General of Higher Education, Ministry of

Education, for financial support, which was facilitated by the Institute for

Study and Community Service Universitas Negeri Medan, Directorate of Study,

Technology, and Community Service, Report, Innovation, and Culture, under

contract number SP DIPA No. 023.17.1.690523/2023 4th revision, March

31, 2023. In addition, the authors are grateful to 2 final-year diploma students,

and workshop employees for their valuable contribution to this study.

| Filename | Description |

|---|---|

| R2-CE-6905-20240917141713.pdf | --- |

Ahmed, I., Gupta, A., 2010. Chemical Energy

Recovery from Polystyrene Using Pyrolysis and Gasification. In: 48th

AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace

Exposition, p. 804

Aisien, E.T., Otuya, I.C., Aisien, F.A., 2021. Thermal and Catalytic

Pyrolysis of Waste Polypropylene Plastic Using Spent FCC Catalyst. Environmental

Technology & Innovation, Volume 22, p. 101455

Al-Salem, S.M., Antelava, A., Constantinou, A.,

Manos, G., Dutta, A., 2017. A Review on Thermal and Catalytic Pyrolysis of

Plastic Solid Waste (PSW). Journal of Environmental Management, Volume

197, pp. 177–198

Awang, M.S.N., Mohd Zulkifli, N.W., Abbas, M.M.,

Amzar Zulkifli, S., Kalam, M.A., Ahmad, M.H., Mohd Yusoff, M.N.A., Mazlan, M.,

Daud, W.M.A.W., 2021. Effect of Addition of Palm Oil Biodiesel in Waste Plastic

Oil on Diesel Engine Performance, Emission, and Lubricity. ACS Omega,

Volume 6(33), pp. 21655–21675

Budsaereechai, S., Hunt, A.J., Ngernyen, Y., 2019.

Catalytic Pyrolysis of Plastic Waste for the Production of Liquid Fuels for

Engines. RSC Advances, Volume 9(10), pp. 5844–5857

Genuino, H.C., Ruiz, M.P., Heeres, H.J., Kersten,

S.R.A., 2022. Pyrolysis of Mixed Plastic Waste (DKR-350): Effect of Washing

Pre-treatment and Fate of Chlorine. Fuel Processing Technology, Volume

233, p. 107304

Ghodke, P.K., 2021. High-Quality Hydrocarbon Fuel

Production from Municipal Mixed Plastic Waste Using a Locally Available

Low-Cost Catalyst. Fuel Communications, Volume 8, p.100022

Haines, A., Kovats, R.S., Campbell-Lendrum, D.,

Corvalán, C., 2006. Climate Change and Human Health: Impacts, Vulnerability,

and Mitigation. The Lancet, Volume 367(9528), pp. 2101–2109

Holechek, J.L., Geli, H.M., Sawalhah, M.N., Valdez,

R., 2022. A Global Assessment: Can Renewable Energy Replace Fossil Fuels by

2050? Sustainability, Volume 14(8), p. 4792

Jaafar, Y., Abdelouahed, L., El Hage, R., El

Samrani, A., Taouk, B., 2022. Pyrolysis of Common Plastics and Their Mixtures

to Produce Valuable Petroleum-like Products. Polymer Degradation and

Stability, Volume 195, p. 109770

Jamilatun, S., Budhijanto, Rochmadi, Yuliestyan,

A., Aziz, M., Hayashi, J., Budiman, A., 2020. Catalytic Pyrolysis of Spirulina

platensis Residue (SPR): Thermochemical Behavior and Kinetics. International

Journal of Technology, Volume 11(3), pp. 522–531

Kasar, P., Sharma, D.K., Ahmaruzzaman, M., 2020.

Thermal and Catalytic Decomposition of Waste Plastics and Its Co-processing

with Petroleum Residue Through Pyrolysis Process. Journal of Cleaner

Production, Volume 265, p. 121639

Kim, J.S., 2004. Pyrolysis of Plastic Wastes Using

the Non-Catalytic Hamburg-Process and a Catalytic Process Using the

Cycled-Spheres-Reactor. Environmental Engineering Research, Volume 9,

pp. 31–37

Kusrini, E., Supramono, D., Degirmenci, V.,

Pranata, S., Bawono, A.A., Ani, F.N., 2018. Improving the Quality of Pyrolysis

Oil from Co-firing High-density Polyethylene Plastic Waste and Palm Empty Fruit

Bunches. International Journal of Technology, Volume 9(7), pp. 1498–1508

Miandad, R., Barakat, M.A., Rehan, M., Aburiazaiza,

A.S., Ismail, I.M.I. Nizami, A.S., 2017. Plastic Waste to Liquid Oil Through

Catalytic Pyrolysis Using Natural and Synthetic Zeolite Catalysts. Waste

Management, Volume 69, pp. 66–78

Miandad, R., Rehan, M., Barakat, M.A., Aburiazaiza,

A.S., Khan, H., Ismail, I.M., Dhavamani, J., Gardy, J., Hassanpour, A., Nizami,

A.S., 2019. Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based

Biorefineries. Frontiers in Energy Research, Volume 7, p. 27

Miskolczi, N., Bartha, L., Deak, G., Jover, B.,

2004. Thermal Degradation of Municipal Plastic Waste for Production of

Fuel-like Hydrocarbons. Polymer Degradation and Stability, Volume 86(2),

pp. 357–366

Onwudili, J.A., Insura, N., Williams, P.T., 2009.

Composition of Products from The Pyrolysis of Polyethylene and Polystyrene in a

Closed Batch Reactor: Effects of Temperature and Residence Time. Journal of

Analytical and Applied Pyrolysis, Volume 86(2), pp. 293–303

Owusu, P.A., Asumadu-Sarkodie, S., 2016. A Review

of Renewable Energy Sources, Sustainability Issues and Climate Change

Mitigation. Cogent Engineering, Volume 3(1), p. 1167990

Papari, S., Bamdad, H., Berruti, F., 2021.

Pyrolytic Conversion of Plastic Waste to Value-added Products and Fuels: A

review. Materials, Volume 14(10), p. 2586

Peng, Y., Wang, Y., Ke, L., Dai, L., Wu, Q., Cobb,

K., Zeng, Y., Zou, R., Liu, Y., Ruan, R., 2022. A Review on Catalytic Pyrolysis

of Plastic Waste to High-value Products. Energy Conversion and Management,

Volume 254, p. 115243

Prihadiyono, F.I., Lestari, W.W., Putra, R., Aqna,

A.N.L., Cahyani, I.S., Kadja, G.T.M., 2022. Heterogeneous Catalyst based on

Nickel Modified into Indonesian Natural Zeolite in Green Diesel Production from

Crude Palm Oil. International Journal of Technology, Volume 13(4), pp.

931–943

Purnomo, H., Baskoro, H., Muslim, F., 2021. Stress

and Strain Behavior of Confined Lightweight Concrete using Sand Coated

Polypropylene Coarse Aggregate. International Journal of Technology,

Volume 12, pp. 1261–1272

Quesada, L., Calero, M., Martin-Lara, M.A., Perez,

A., Blazquez, G., 2019. Characterization of Fuel Produced by Pyrolysis of

Plastic Film Obtained of Municipal Solid Waste. Energy, Volume 186,

p.115874

Santella, C., Cafiero, L., De Angelis, D., La

Marca, F., Tuffi, R., Ciprioti, S.V., 2016. Thermal and Catalytic Pyrolysis of

A Mixture of Plastics from Small Waste Electrical and Electronic Equipment

(WEEE). Waste Management, Volume 54, pp. 143–152

Sardi, B., Ningrum, R.F., Ardianyah, V.A.,

Qadariyah, L., Mahfud, M., 2022. Production of Liquid Biofuels from Microalgae

Chlorella sp. via Catalytic Slow Pyrolysis. International Journal of

Technology, Volume 13(1), pp. 147–156

Sari, M.M., Andarani, P., Notodarmojo, S., Harryes,

R.K., Nguyen, M.N., Yokota, K., Inoue, T., 2022. Plastic Pollution in the

Surface Water in Jakarta, Indonesia. Marine Pollution Bulletin, Volume

182, p. 114023

Shah, J., Jan, M.R., 2015. Effect of Polyethylene

Terephthalate on The Catalytic Pyrolysis of Polystyrene: Investigation of The

Liquid Products. Journal of the Taiwan Institute of Chemical Engineers,

Volume 51, pp. 96–102

Sharma, B.K., Moser, B.R., Vermillion, K.E., Doll,

K.M., Rajagopalan, N., 2014. Production, Characterization and Fuel Properties

of Alternative Diesel Fuel from Pyrolysis of Waste Plastic Grocery Bags. Fuel

Processing Technology, Volume 122, pp. 79–90

Siddiqui, M.N., Redhwi, H.H., 2009. Pyrolysis of

Mixed Plastics for the Recovery of Useful Products. Fuel Processing

Technology, Volume 90(4), pp. 545–552

Simanjuntak, J.P., Al-attab, K.A., Daryanto, E.,

Tambunan, B.H., 2022. Bioenergy as an Alternative Energy Source: Progress and

Development to Meet the Energy Mix in Indonesia. Journal of Advanced

Research in Fluid Mechanics and Thermal Sciences, Volume 97, pp. 85–104

Simanjuntak, J.P., Tambunan, B.H., Sihombing, J.L.,

2023. Potential of Pyrolytic Oil from Plastic Waste as an Alternative Fuel

Through Thermal Cracking in Indonesia: A Mini Review to Fill the Gap of the

Future Research. Journal of Advanced Research in Fluid Mechanics and Thermal

Sciences, Volume 102(2), pp. 196–207

Soni, V.K., Singh, G., Vijayan, B.K., Chopra, A.,

Kapur, G.S., Ramakumar, S.S.V., 2021. Thermochemical Recycling of Waste

Plastics by Pyrolysis: A Review. Energy & Fuels, Volume 35(16), pp.

12763–12808

Suhartono, Romli, A., Hari Prabowo, B., Kusumo, P.,

Suharto, 2023. Converting Styrofoam Waste into Fuel Using a Sequential Pyrolysis

Reactor and Natural Zeolite Catalytic Reformer. International Journal of

Technology, Volume 14(1), pp. 185–194

Verma, R., Vinoda, K.S., Papireddy, M., Gowda,

A.N.S., 2016. Toxic Pollutants from Plastic Waste-A Review. Procedia

Environmental Sciences, Volume 35, pp. 701–708

Vriend, P., Hidayat, H., van Leeuwen, J., Cordova,

M.R., Purba, N.P., Lohr, A.J., Faizal, I., Ningsih, N.S., Agustina, K., Husrin,

S., Suryono, D.D., 2021. Plastic Pollution Research in Indonesia: State of

Science and Future Research Directions to Reduce Impacts. Frontiers in

Environmental Science, Volume 9, p. 187

Wiriyaumpaiwong, S.,

Jamradloedluk, J., 2017. Distillation of Pyrolytic Oil Obtained from Fast

Pyrolysis of Plastic Wastes. Energy Procedia, Volume 138, pp. 111–115