Highly Efficient Technology for Making Bread Using an Ion-ozone Mixture

Corresponding email: yamadina88@mail.ru

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.4242

Iztayev, A., Tursunbayeva, S., Zhiyenbayeva, S., Iskakova, G., Matibayeva, A., Izteliyeva, R., Yakiyayeva, M., 2023. Highly Efficient Technology for Making Bread Using an Ion-ozone Mixture. International Journal of Technology. Volume 14(4), pp. 695-704

| Auyelbek Iztayev | Research Institute of Food Technologies, Faculty of Food Technology, Almaty Technological University, Almaty, 050012, Kazakhstan |

| Sholpan Tursunbayeva | Department "Technology of bread and processing industries", Faculty of Food Technology, Almaty Technological University, Almaty, 050012, Kazakhstan |

| Saule Zhiyenbayeva | Department "Technology of bread and processing industries", Faculty of Food Technology, Almaty Technological University, Almaty, 050012, Kazakhstan |

| Galiya Iskakova | Department "Technology of bread and processing industries", Faculty of Food Technology, Almaty Technological University, Almaty, 050012, Kazakhstan |

| Ainur Matibayeva | Department "Food technology", Faculty of Food Technology, Almaty Technological University, Almaty, 050012, Kazakhstan |

| Raushan Izteliyeva | Department "Food quality and safety", Faculty of Food Technology, Almaty Technological University, Almaty, 050012, Kazakhstan |

| Madina Yakiyayeva | Research Institute of Food Technologies, Faculty of Food Technology, Almaty Technological University, Almaty, 050012, Kazakhstan |

The

article examined the ways of using highly effective technologies for the

development of whole-wheat flour bread. Ion-ozone cavitation technology is

used, which allows time reduction for dough making and bread baking. The flour

used in the experiment is of various kinds of low-quality wheat: non-class

wheat, class III, class IV, and class V wheat . During the experiments, the

amino acid composition of wheat was determined, which has a large impact on the

quality of the test. To obtain a high-quality dough, wheat grains of various

lower classes were treated with ion-ozone cavitation treatment. The treatment

was carried out using a universal ion-ozone cavitation installation,

producing both ozone and molecular ions from oxygen contained in atmospheric

air and processed using overpressure of crops. The experiment result shows that

the method of processing with ion-ozone cavitation technology allows the improvement

of the rheological properties of the dough, the reduction of baking time by 2

times, and the improvement of the quality of bread from whole-ground

low-quality soft wheat flour. The obtained bread products in comparison with

the control sample had higher organoleptic indices; according to several

physico-chemical and organoleptic indices, a sample of bread from whole-wheat

wheat of class III appeared in a more favorable light.

Bread; Ion; Ozone; Processing; Wheat

The production of bread and bakery products is one of the main issues in

the production of food. It shares 15.3% of the total production of the food

industry. The greatest demand among the population is bread and bakery products

from wheat flour of the first grade, rye bread, and products from wheat flour

of the highest grade. Previously, the 3rd class grain, from which baking flour

is obtained, was in a total volume of 80%; now it is only 20%. The problem is

not the quality of bread, because the baking industry is ready and is trying to

produce quality bread. The problem lies in the quality of flour and grain. In

fact, it is not profitable for agricultural producers to produce high-quality

grain (Satsaeva et al., 2016;

Baymagambetova et al., 2014).

Wheat is

one of the main sources of calories in daily human nutrition. According to US

standards, T. durum wheat belongs to class I, which corresponds to GOST R 52554–2006 (GOST R 52554–2006, 2006). Hard-grain wheat of

type II, II, III. Class IV in the American standard corresponds to the

botanical species T. aestivum, while soft-wheat corresponds to separate

class IV and VI. The optimal chemical

composition and structure of the food matrix of whole wheat grains can

contribute to preventive action and reduce the risks of chronic diseases. It

was also suggested that, in addition to the effects of dietary fiber, the

synergistic effect of some bioactive compounds helps to protect health and

maintain the normal functioning of the body (Kokhmetova et al., 2014; Chakraverty and Singh, 2004).

Whole

wheat flour is the main source of protein and starch that can be present in

bread while retaining the fully original nutritional value of wheat and

enriching the composition of bread with macro- and micronutrients as well. In

whole-wheat flour, all anatomical components of the grain, such as the

endosperm, the germ, and the shell layers, are present in the same proportions

as in the grain. Such flour contains significantly more dietary fiber,

vitamins, and minerals compared with varietal types of flour (Kalinina and Fatkullin 2016; Yakiyayeva et

al., 2016; Slavin, 2004).

Studies by scientists from different countries show that consuming whole grain

foods can reduce the risk of cardiovascular disease, various types of cancer,

and type 2 diabetes, and possibly improve body weight regulation. The

technology of preparing bread on cavitation-activated water, accompanied by

hydration structuring of gluten proteins, allows the increase of the specific

volume of bread, increases its elasticity, slows down the hardening, and

reduces the use of baking improvers (Meleshkina, 2018; Mei et al., 2016; Maemerov, 2004).

The use of deep processing of whole meal flour from promising varieties

of low-grade wheat and cavitation processing of dough improves the quality,

nutritional and biological values, and safety of finished products and reduces

the technological process of production. Organoleptic and physico-chemical were

used as indicators to prove the quality and nutritional value of the products

and were examined in the Accredited Food Safety Testing Laboratory.

To accomplish the tasks, first of all, an analysis of the technique and

technology of bakery products from low-grade wheat was carried out. Ways were

identified to intensify the production of bakery products based on ion-ozone

cavitation technology for making dough from low-grade wheat in order to improve

quality, reduce the technological process of production, increase labor

productivity, and improve the socio-economic indicators of bakery enterprises.

Safety studies of raw materials and developed bakery products are carried out

in accredited food safety laboratories.

Whole-ground wheat grain of the following classes was determined as an

object of research: III, IV, V, as well as non-class wheat. Grain sampling was

carried out according to GOST

13586.3–2015 (GOST

13586.3–2015, 2015). The mass fraction of protein in terms of dry matter

was determined according to GOST

10846–91 (GOST

10846–91, 2009). The total amino acid composition was determined

according to GOST 32195–2013 (GOST 32195–2013, 2013). The amino acid rate was calculated by comparing the amino acid

composition of the grain protein with the scale of the adequacy of the content

of essential amino acids in the “ideal protein” according to the UNO/WHO

(United Nations Organization/World Health Organization) as applied to human

needs in adulthood. The limiting amino acid was determined by amino acid -

lysine.

Research and baking of bread products were carried out on the

basis of scientific laboratories of Almaty Technological University.

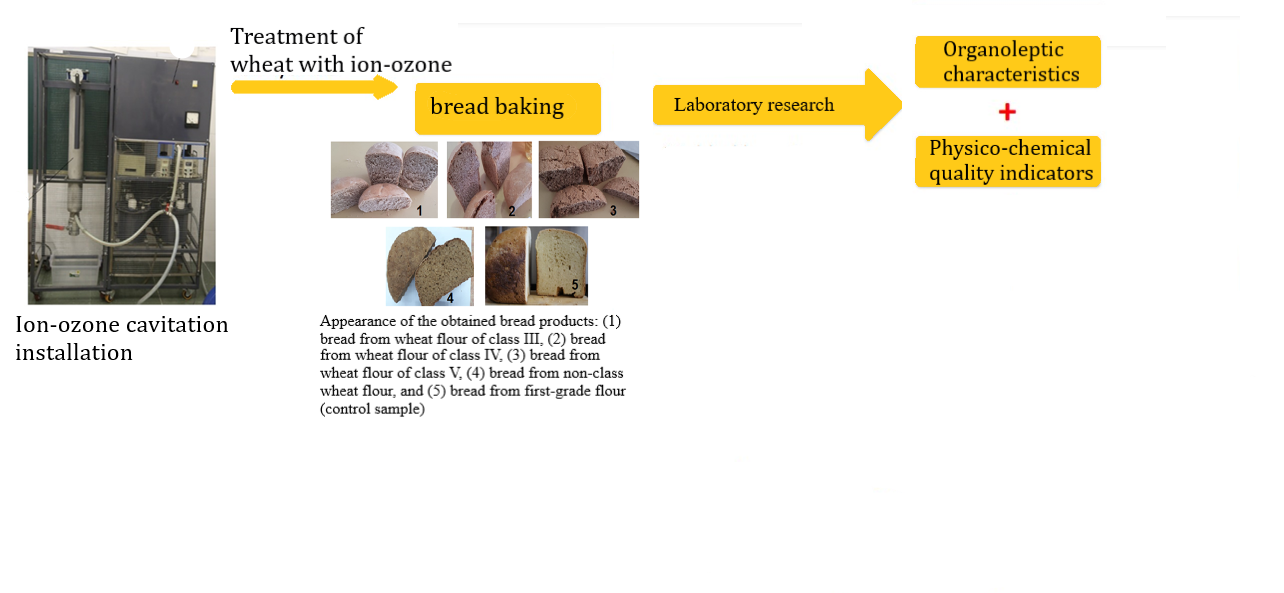

Before grinding, wheat of low grades was processed in

an ion-ozone cavitation installation

(Figure 1)

In order to receive ions in

this installation, oxygen is passed through an ion chamber, in which quiet

electric charges act. This process charges oxygen with negative ions. Enriched

oxygen enters and grain processing takes place. Oxygen molecules take away

electrons and become negatively charged ions and they are significantly ten

times more chemically active than uncharged oxygen molecules. The negative ions

resulted contribute to the improvement of biochemical and vitamin properties of

the product.

Figure 1 Ion-ozone cavitation installation: (1) ion-ozone

generator; (2) cavitation capacity

The smallest values can be noted for lysine (19.8 ± 0.3 mg/1 g protein), tryptophan (10.1 ± 0.3 mg/1 g protein), and threonine (18.7 ± 0.3 mg/1 g protein)

Figure 2 Appearance of the obtained bread products: (1) bread

from wheat flour of class III, (2) bread from wheat flour of class IV, (3)

bread from wheat flour of class V, (4) bread from non-class wheat flour, and

(5) bread from first-grade flour (control sample)

The organoleptic characteristics of

the obtained bread samples are shown in Figure 3.

|

Quality indicators |

Bread from first-grade flour (control sample) |

Bread from wheat flour of class III |

Bread from wheat flour of class IV |

Bread from wheat flour of class V |

Bread from non-class wheat flour |

|

Humidity, % |

47.4 ± 0.12 |

49.7 ± 0.06 |

48.8 ± 0.07 |

47.4 ± 0.07 |

45.6± 0.14 |

|

Acidity, degrees |

3.6 ± 0.08 |

3.4 ± 0.02 |

3.4 ± 0.09 |

3.5 ± 0.11 |

3.6 ± 0.08 |

|

The specific volume of bread, cm3/100 g |

188.4 ± 0.31 |

179.6 ± 0.54 |

169.4 ± 0.22 |

165.2 ± 0.91 |

158.3 ± 0.43 |

|

The porosity of the crumb, % |

64.3 ± 0.20 |

67.3 ± 0.13 |

66.0 ± 0.41 |

63.4 ± 0.13 |

59.7 ± 0.35 |

In the process of baking bread with innovative highly effective technology, the number of essential amino acids, such as isoleucine, leucine, lysine, and threonine increase; and the organoleptic and physico-chemical parameters are improved in accordance with the class of wheat. The correct choice of the optimal dosage ratio of rye and wheat bran in the test was confirmed by a series of parallel experiments that showed convergence of the results. The best in almost all investigated indicators compared to the control bread sample is wheat bread of class III. The results allow us to recommend a more thorough study of this topic and a further introduction to the production of technology for producing wheat from class III wheat using ion-ozone cavitation technology. An assortment of bakery products from class III, IV, and V wheat flour and non-class wheat flour was developed based on the ion-ozone cavitation dough preparation technology. The economic effect was achieved by reducing the duration of the production process from 3 to 6 hours, reducing the number of equipment due to the exclusion of fermentation and proofing processes (dough mixers, bowls, fermentation tanks, proofer), increasing the yield of bread by 8-10% and increase labor productivity by more than 2-3 times. The resulting bakery products will allow solving the future issues of improving the health of the nation as a whole by creating products with high nutritional and biological value, based on the deep processing of fine whole meal flour from the wheat of low grades.

| Filename | Description |

|---|---|

| R4-IE-4242-20221012131718.docx | --- |

Baymagambetova, K.K., Nurpeisov, I.A.,

Gass, O.S., Sereda, G.A., Chudinov, V.A., Bekenova, L.V., Bishimbaeva N.K.,

2014. Ecological test of wheat precociolous lines obtained by biotechnology

methods. In: Plant biology

and biotechnology international conference materials, Almaty, Kazakhstan

Erkmen, O., 2001. Uses of Ozone to Improve the Safety and Quality of Foods. Journal Gida Teknolojisi, Volume

5(3), pp. 58–64

da Costa, D.G.N., Malkhamah, S.,

Suparma, L.B., 2018. Use of the Safety Factor and Margin of Safety in

Motorcyclist Accident Risk Management. International Journal of

Technology. Volume 9(4), pp. 737–750

Chakraverty, A., Singh, R.P., 2004. Postharvest

Technology and Food Process Engineering. CRC Press: Taylor & Francis

Group

GOST R

52554–2006., 2006. Wheat. Technical Conditions. Moscow, Standartinform. Available

online at: https://internet-law.ru/gosts/gost/2644?ysclid=liin6vbf 2a737726797,

Accessed on September 16, 2022

GOST

13586.3–2015., 2015. Grain. Acceptance Rules and Sampling Methods. Moscow,

Standartinform. Available online at: https://internet-law.ru/gosts/gost/ 60669/?ysclid=liin8r03d497693489,

Accessed on September 17, 2022

GOST

10846–91., 2009. Grain and Products of its Processing. Method for

Determination

of Protein.

Moscow, Standartinform. Available online at: https://internet-law.ru /gosts/gost/28268/?ysclid=liin9ky3oh360978630,

Accessed on September 16, 2022

GOST

32195–2013., 2013. Feeds, Compound Feeds. Method for Determination of Amino

Acids. Moscow, Standartinform. Available online at: https://internet-law.ru /gosts/gost/56066/?ysclid=liina9lgrv303163117,

Accessed on September 18, 2022

Iztayev, A., Yakiyayeva, M., Kulazhanov, T., Kizatova, M., Maemerov, M., Stankevych, G., Toxanbayeva, B., Chakanova, Zh., 2018. Controlling

the Implemented Mathematical Models of Ion-Ozon Cavitation Treatment for Long-Term Storage of Grain Legune Crops. Journal

of Advanced Research in Dynamical and Control Systems, Volume 10(13), pp. 672–680

Kalinina, I.V., Fatkullin, R.I., 2016.

Application of the Effects of Ultrasonic Cavitation

Effects as a Factor in the Intensification of the Extraction of Functional Ingredients.

Vestnik SUSUSeries Food and Biotechnology, Volume 4(1), pp. 64–70

Kalinina, I., Naumenko, N., Fatkullin, R.,

2018. Perspectives of Using of Ultrasonic Cavitation in Water Treatment

Technology for the Food Productions. IOP Conference Series:

Earth and Environmental Science, Volume 272, pp. 1–9

Kim, J.G., Yousef, A.E., Khadre, M.A.,

2003. Ozone and its Current and Future Application in the Food

Industry. Advances in Food and Nutrition

Research, Volume 45, pp. 167–218

Kokhmetova, A., Sapakhova, Z.,

Yessimbekova, M., Yeleshev, R., Morgounov, A., 2014. Principles and Methods of Selection of Grain Crops

at the Present Stage. Journal Vestnik of Agricultural Science of Kazakhstan,

Volume 1, pp. 3–19

Li, M., Peng, J., Zhu, K. X., Guo, X. N.,

Zhang, M., Peng, W., Zhou, H. M., 2013. Delineating the Microbial and

Physica-Chemical Changes During Storage of Ozone Treated Wheat

Flour. Journal Innovative Food Science & Emerging

Technologies, Volume 20, pp. 223–229

Maemerov, M.M., 2004. Increasing the Role

of Ozone as an Environmentally Friendly Method for Treating Plant Materials. In: Strategy of food and light industry development:

materials of international scientific-practical conference, Almaty,

Kazakhstan

Maemerov, M.M., Iztaev, A.I., Kulazhanov,

T.K., Iskakova, G.K., 2011. Scientific Bases of Ion-Ozone Technology o Grain Processing and Products of its

Processing. Almaty: LEM, Kazakhstan

Masudin, I., Fernanda, F.W., Widayat, W., 2018. Halal Logistics

Performance and Customer Loyalty: From the Literature Review to a Conceptual

Framework. International Journal of Technology. Volume 9(5), pp.

1072–1084

Mei, J., Liu, G., Huang, X., Ding, W.,

2016. Effects of ozone treatment on medium hard wheat (Triticum aestivum L.)

flour quality and performance in steamed bread making. CyTA-Journal of Food, Volume 14, pp. 449–456.

Meleshkina, E.P., 2018. Modern Requirements

for the Quality of Wheat and Wheat Flour. Journal Bread products, Volume 10,

pp. 14–15

Munarso, S.J., Kailaku, S.I., Arif, A.B., Budiyanto, A.,

Mulyawanti, I., Sasmitaloka, K.S., Setyawan, N., Dewandari, K.T., Widayanti,

S.M., 2020. Quality Analysis of Chili Treated with Aqueous Ozone Treatment and

Improved Transportation and Handling Technology. International Journal

of Technology. Volume 11(1), pp. 37–47

Sandhu, H.P., Manthey, F.A., Simsek, S.,

2011. Quality of Bread Made from Ozonated Wheat (Triticum aestivum L.) Flour. Journal of the Science of Food and

Agriculture, Volume 91, pp. 1576–1584

Satsaeva, I.K., Gasieva, V.A., Teboeva,

A.K., Farnieva, Ya.S., 2016. The Way to Improve the Quality and Safety of Bakery Products from Wheat Flour by Improving the Technology of Hop Yeast. Journal Vestnik KrasGAU,

Volume 2, pp. 118–124

Slavin, J., 2004. Whole Grains and Human

Health. Journal Nutrition Research Reviews,

Volume 17, pp. 99–110

Tursunbayeva, Sh.A., Iztayev, A.,

Magomedov, M., Yakiyayeva, M.A., Muldabekova, B.Zh., 2019. Study

of the Quality of Low-Classes Wheat and Bread Obtained by

the Accelerated Test Method. Periodico

Tche Quimica, Volume 16 (33), pp. 809–823

Tursunbayeva, Sh.A., Iztayev, A.I., Mynbayeva,

A.B., Alimardanova, M.K., Iztayev, B.A., Yakiyayeva M.A., 2021. Development

of a Highly Efficient Ion-Ozone Cavitation Technology for Accelerated Bread

Production. Scientific Reports, Volume 11(1),

p. 19129

Yakiyayeva, M., Iztaev, A., Kizatova, M.,

Maemerov, M., Iztaeva, A., Feydengold, V., Tarabaev, B., Chakanova, Zh., 2016. Influence

of Ionic, Ozone Ion-Ozone Cavitational Treatment on Safety of the Leguminous

Plants and Oil-Bearing Crops at the Storage. Journal of Engineering and Applied Sciences, Volume 11(6), pp. 1229–1234

Zapevalov, M.V., Kovalenko, N.V., Petrova, G.V., 2015. Post-Harvest

Grain Processing. Journal News of

the Orenburg State Agrarian University, Volume 3(53), pp. 80–83

Zhakatayeva, A., Iztayev, A., Muldabekova, B.,

Yakiyayeva, M., Hrivna, L., 2020. Scientific security

assessment of safety risk of raw sugar products. J. Periodico Tche Quimica, Volume 17(34), pp. 352–368.