Design and Performance Analysis of Portable Vertical Burner Biomass Pellet for Green Tea Drying Process

Corresponding email: makbul.hajad@ugm.ac.id

Published at : 01 Dec 2025

Volume : IJtech

Vol 16, No 6 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i6.7776

| Sugeng Harianto | Department of Agricultural and Biosystems Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Makbul Hajad | Department of Agricultural and Biosystems Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Bambang Purwantana | Department of Agricultural and Biosystems Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Joko Nugroho Wahyu Karyadi | Department of Agricultural and Biosystems Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Nina Amelia | Department of Agricultural and Biosystems Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Muhammad Akhsin Muflikhun | Department of Mechanical and Industrial Engineering, Faculty of Engineering, Universitas Gadjah Mada, Yo gyakarta, 55284, Indonesia |

| Suchada Rianmora | School of Manufacturing Systems and Mechanical Engineering, Sirindhorn International Institute of Technology, Thammasat University, Phatumthani, 12120, Thailand |

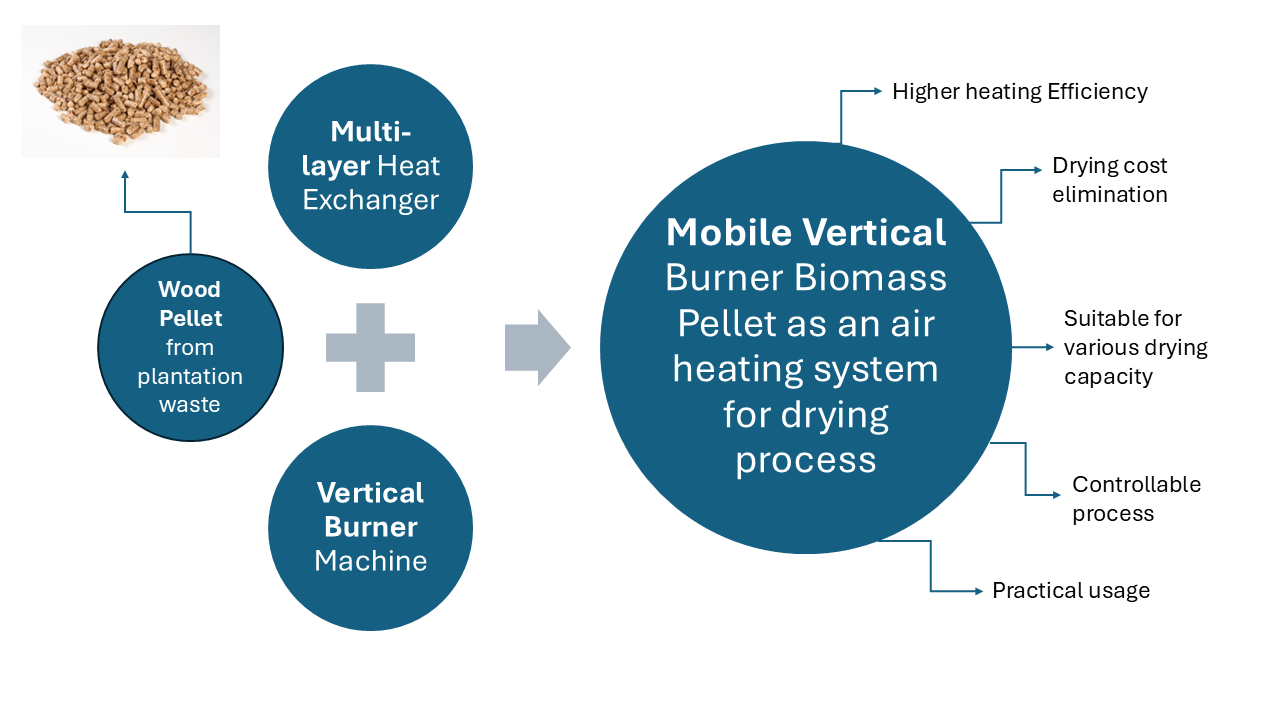

This study aimed to design a portable vertical biomass pellet burner as an alternativesolution to reduce energy costs in tea production, specifically for drying green tea using a ball tea dryer machine. The design combines a burner chamber unit with a multilayer heat exchanger to improve performance, and development was based on the drying air requirements of the process. The study used a Randomized Block Design (RBD) with two variables—feeding rate (5, 7, and 9 kg/h) and drying airflow (895.23, 1028.55, and 1103.47 CFM)—each tested at three levels.The performance was measured by the rate of temperature rise, drying air heating efficiency, and energy cost efficiency. The results showed that the burner design could meet the required airflow rate of up to 1150 CFM and reach temperatures of up to 120?C. To achieve the desired drying conditions, the optimal biomass pellet feeding rate was 7 kg/h, which costs approximately $0.09 per kilogram of dried tea—cheaper than using Liquid Petroleum Gas (LPG), which costs approximately $0.13/kg. The findings also revealed that both the airflow rate and feeding rate significantly affect the temperature increase rate and heating efficiency. Overall, this portable vertical biomass pellet burner can reduce green tea drying costs at ball tea drying stations by 30.28% compared with LPG usage.

Biomass pellet; Design improvement; Green tea drying; Performance analysis; Vertical burner

| Filename | Description |

|---|---|

| R3-ME-7776-20251107151827.pdf | --- |

Agbulut,

U., Gurel, A. E., & Bicen, Y. (2021). Prediction of daily global solar

radiation using different machine learning algorithms: Evaluation and

comparison. Renewable and Sustainable Energy Reviews, 135, 110–114. https://doi.org/https://doi.org/10.1016/j.rser.2020.110114

Ahn, J., & Jang, J. H. (2018). Combustion

characteristics of a 16 step grate-firing wood pellet boiler [1st International

Conference on Bioresource Technology for Bioenergy, Bioproducts Environmental

Sustainability]. Renewable Energy, 129, 678–685. https://doi.org/https://doi.org/10.1016/j.renene.2017.06.015

Al-attab,

K. A., & Zainal, Z. A. (2011). Design and performance of a pressurized

cyclone combustor (pcc) for high and low heating value gas combustion. Applied

Energy, 88(4), 1084–1095. https://doi.org/https://doi.org/10.1016/j.apenergy.2010.10.041

Alianto,

B., Rahim, G., Santoso, M., Nasruddin, N., & Nugroho, Y. (2025). Experiment

and modeling of smoke ventilation in a compartment using coconut husks as solid

fuels. International Journal of Technology, 16(2), 411–422. https://doi.org/https://doi.org/10.14716/ijtech.v16i2.6278

Alita,

D., Putra, A. D., & Darwis, D. (2021). Analysis of classic assumption test

and multiple linear regression coefficient test for employee structural office

recommendation. Indonesian Journal of Computing and Cybernetics Systems, 15(3),

295–306. https://doi.org/10.22146/ijccs.65586

Attanayake, D. D., Sewerin, F., Kulkarni,

S., Dernbecher, A., Alonso, A. D., & Van Wachem, B. (2023). Review

of modelling of pyrolysis processes with cfd-dem. Flow, Turbulence and

Combustion, 111, 355–408. https://doi.org/10.1007/s10494-023-00436-z

Balakheli,

M. M., Chahartaghi, M., Sheykhi, M., Hashemian, S. M., & Rafiee, N. (2020).

Analysis of different arrangements of combined cooling, heating and power

systems with internal combustion engine from energy, economic and environmental

viewpoints. Energy Conversion and Management, 203, 112253. https://doi.org/10.1016/j.enconman.2019.112253

Bardant,

T. B., Haq, M. S., Setiawan, A. A. R., Harianto, S., Waluyo, J., Mastur, A. I.,

Lestari, A. D., Sulaswatty, A., Sujarwo, S., Rinaldi, N., & Wiloso, E. I.

(2019). The renewability indicator and cumulative degree of perfection for

gamboeng tea; part 2, exergy calculation of tea factory. Jurnal Kimia Terapan Indonesia, 20(2), 79–89. https://doi.org/10.14203/jkti.v20i2.400

Buchner, D., Schraube, C., Carlon, E., von

Sonntag, J., Schwarz, M., Verma, V., & Ortwein, A. (2015). Survey of

modern pellet boilers in austria and germany: System design and customer

satisfaction of residential installations. Applied Energy, 160, 390–403. https://doi.org/10.1016/j.apenergy.2015.09.055

Burmawi,

B., Mulyanef, M., & Saputra, A. P. (2021). Analisa unjuk kerja dari heat

exchanger tipe shell and tube menggunakan air sebagai fluida panas dan fluida

dingin. Menara Ilmu, 15(1). https://doi.org/10.31869/mi.v15i1.2341

Carlon, E., Schwarz, M., Golicza, L.,

Verma, V. K., Prada, A., Baratieri, M., Haslinger, W., & Schmidl, C.

(2015). Efficiency and operational behaviour of small-scale pellet

boilers installed in residential buildings. Applied Energy, 155, 854–865. https://doi.org/10.1016/j.apenergy.2015.06.025

Chabane, F., Moummi, N., & Benramache,

S. (2013). Thermal efficiency analysis of a single-flow solar air heater

with different mass flow rates in a smooth plate. Frontiers in Heat and Mass

Transfer, 4(1). https://doi.org/10.5098/hmt.v4.1.3006

Chakraborty,

A., & Goswami, D. (2017). Prediction of slope stability using multiple

linear regression (mlr) and artificial neural network (ann). Arabian Journal of

Geosciences, 10(17). https://doi.org/10.1007/s12517-017-3167-x

Choi,

S. H., & Manousiouthakis, V. I. (2020). On the carbon cycle impact of

combustion of harvested plant biomass vs. fossil carbon resources. Computers

and Chemical Engineering, 140, 106942. https://doi.org/10.1016/j.compchemeng.2020.106942

Cifriadi,

A., Sugita, P., Wismogroho, A. S., Kemala, T., Nikmatin, S., Widayatno, W. B.,

Amal, M. I., Jayadi, F., Firdharini, C., & Kinasih, N. A. (2025).

Development and characterization of biomass-based biocarbon fillers for natural

rubber composites. International Journal of Technology, 16(3), 982–992. https://doi.org/10.14716/ijtech.v16i3.6809

Dale,

V. H., Kline, K. L., Parish, E. S., Cowie, A. L., Emory, R., Malmsheimer, R.

W., Slade, R., Smith, C. T., Wigley, T. B. B. E. N., Bentsen, N. S., Berndes,

G., Bernier, P., Brandao, M., Chum, H. L., Diaz-Chavez, R., Egnell, G.,

Gustavsson, L., Schweinle, J., Stupak, I., & Wellisch, M. (2017). Status

and prospects for renewable energy using wood pellets from the southeastern

united states. GCB Bioenergy, 9(8), 1296–1305. https://doi.org/10.1111/gcbb.12445

Deng,

M., Li, P., Shan, M., & Yang, X. (2020). Optimizing supply airflow and its

distribution between primary and secondary air in a forced-draft biomass pellet

stove. Environmental Research, 184, 109301. https://doi.org/10.1016/j.envres.2020.109301

Di-Giacomo, G., & Taglieri, L. (2009).

Renewable energy benefits with conversion of woody residues to pellets.

Energy, 34(5), 724–731. https://doi.org/10.1016/j.energy.2008.08.010

Enagi,

I. I., Al-attab, K. A., Zainal, Z. A., & Teoh, Y. H. (2022). Palm biodiesel

spray and combustion characteristics in a new micro gas turbine combustion

chamber design. Energy, 254, 124335. https://doi.org/10.1016/j.energy.2022.124335

Farokhi,

M., & Birouk, M. (2019). A hybrid edc/flamelet approach for modelling

biomass combustion of grate-firing furnace. Combustion Theory and Modelling,

23(4), 716–747. https://doi.org/10.1080/13647830.2019.1587177

Islam,

M. M., Wathore, R., Zerriffi, H., Marshall, J. D., Bailis, R., & Grieshop,

A. P. (2021). In-use emissions from biomass and lpg stoves measured during a

large, multi-year cookstove intervention study in rural india. Science of the

Total Environment, 758, 143698. https://doi.org/10.1016/j.scitotenv.2020.143698

Jandacka,

J., & Holubc?k, M. (2020). Emissions production from small heat sources

depending on various aspects. Mobile Networks and Applications, 25(3), 904–912.

https://doi.org/10.1007/s11036-020-01519-1

Johansson,

L. S., Leckner, B., Gustavsson, L., Cooper, D., Tullin, C., & Potter, A.

(2004). Emission characteristics of modern and old-type residential boilers

fired with wood logs and wood pellets. Atmospheric Environment, 38(25),

4183–4195. https://doi.org/10.1016/j.atmosenv.2004.04.020

Jolvis-Pou, K. R., Paul, S. K., &

Malakar, S. (2019). Industrial processing of ctc black tea. In

Caffeinated and cocoa based beverages (pp. 131–162). Woodhead Publishing. https://doi.org/10.1016/b978-0-12-815864-7.00004-0

Kayo,

C., Tojo, S., Iwaoka, M., & Matsumoto, T. (2014, December). Evaluation of

biomass production and utilization systems. CRC Press. https://doi.org/10.1016/B978-0-12-404609-2.00014-3

Klepacka,

A. M., & Florkowski, W. J. (2022). An opportunity for renewable energy:

Wood pellet use by rural households. In Handbook of climate change mitigation

and adaptation (pp. 1087–1120). Springer. https://doi.org/10.1007/978-3-030-72579-2_110

Kumar,

A., Alsadoon, A., Prasad, P. W. C., Abdullah, S., Rashid, T. A., Pham, D. T.

H., & Nguyen, T. Q. V. (2021). Generative adversarial network (gan) and

enhanced root mean square error (ermse): Deep learning for stock price movement

prediction. Multimedia Tools and Applications, 81(3), 3995–4013. https://doi.org/10.1007/s11042-021-11670-w

Kumar, K. R., Dashora, K., Kumar, S.,

Dharmaraja, S., Sanyal, S., Aditya, K., & Kumar, R. (2023). A review

of drying technology in tea sector of industrial, non-conventional and

renewable energy based drying systems. Applied Thermal Engineering, 224,

120118. https://doi.org/10.1016/j.applthermaleng.2023.120118

Lee, Y. W., Ryu, C., Lee, W. J., &

Park, Y. K. (2011). Assessment of wood pellet combustion in a domestic

stove. Journal of Material Cycles and Waste Management, 13(3), 165–172. https://doi.org/10.1007/s10163-011-0014-0

Lestari, P. W., Harianto, S. P.,

Prawira-Atmaja, M. I., Andriyani, M., Shabri, S., Maulana, H., & Putri, S.

H. (2022). Identifikasi sifat fisik produk samping dari mesin ball tea pada

pengolahan teh hijau. Teknotan: Jurnal Industri Teknologi, 16(2), 85. https://doi.org/10.24198/jt.vol16n2.4

Mahmoud, M., Ramadan, M., Naher, S.,

Pullen, K., & Olabi, A. G. (2021). The impacts of different heating

systems on the environment: A review. Science of the Total Environment, 766,

142625. https://doi.org/10.1016/j.scitotenv.2020.142625

Mihaescu,

L., Enache, E., Pisa, I., & Pop, E. (2021). Design and experimental testing

of a horizontal flame burner for agricultural waste pellets. In Innovative

renewable waste conversion technologies. Springer Reference. https://doi.org/10.1007/978-3-030-81431-1_8

Mirzayanti,

Y. W., Marlinda, L., Irawan, H., Al Muttaqii, M., Ma’sum, Z., Asri, N. P.,

& Chern, J. M. (2024). Performance of in-situ stirring batch reactor

transesterification of nannochloropsis sp microalgae into biodiesel.

International Journal of Technology, 15(4), 859–869. https://doi.org/10.14716/ijtech.v15i4.6678

Nunes,

L. J. R., Matias, J. C. O., & Catal˜ao, J. P. S. (2016). Wood pellets as a

sustainable energy alternative in portugal. Renewable Energy, 85, 1011–1016. https://doi.org/10.1016/j.renene.2015.07.065

Ozsoysal,

O. A. (2010). Effects of combustion efficiency on an otto cycle. International

Journal of Exergy, 7(2), 232. https://doi.org/10.1504/ijex.2010.031242

Pelka,

G., Jach-Nocon, M., Paprocki, M., Jachimowski, A., Lubo´n, W., Nocon, A.,

Wygoda, M., Wyczesany, P., Pachytel, P., & Mirowski, T. (2023). Comparison

of emissions and efficiency of two types of burners when burning wood pellets

from different suppliers. Energies,

16(4), 1695. https://doi.org/10.3390/en16041695

Prayoga, A. R., Zuki, M., & Dany, Y.

(2021). Contribution of motion study to standard time at ball tea

station (case study pt mitra kerinci, south solok). Jurnal Agroindustri, 11(2),

92–107. https://doi.org/10.31186/j.agroindustri.11.2.92-107

Racero-Galaraga,

D. A., Sofan-German, S. J., Arteaga-Ramos, J. P., & Mendoza-Fandino, J. M.

(2024). Energy optimization of sugarcane bagasse by oxidative torrefaction: A

multiple linear regression method. International Journal of Technology, 15(6),

1697–1711. https://doi.org/10.14716/ijtech.v15i6.7155

Roy,

M. M., Dutta, A., & Corscadden, K. (2013). An experimental study of

combustion and emissions of biomass pellets in a prototype pellet furnace.

Applied Energy, 108, 298–307. https://doi.org/10.1016/j.apenergy.2013.03.044

Sener, R., & Gul, M. Z. (2021). Optimization

of the combustion chamber geometry and injection parameters on a light-duty

diesel engine for emission minimization using multi-objective genetic

algorithm. Fuel, 304, 121379. https://doi.org/10.1016/j.fuel.2021.121379

Sharma,

S., & Sheth, P. N. (2016). Air–steam biomass gasification: Experiments,

modeling and simulation. Energy Conversion and Management, 110, 307–318. https://doi.org/10.1016/j.enconman.2015.12.030

Sugandi, W. K., Sita, K., Herwanto, T.,

& Habsari, S. (2022). Energy analysis on the processing of green

tea. Jurnal Teknik Pertanian, 11(2), 206. https://doi.org/10.23960/jtepl.v11i2.206-217

Teixeira,

J. C., Vasconcelos, B., & Ferreira, M. E. (2009). Simulation of a small

scale pellet boiler. Proceedings of the ASME 2009 International Mechanical

Engineering Congress and Exposition (IMECE 2009). https://doi.org/10.1115/IMECE2009-11133

Thabari,

J. A., Auzani, A. S., Nirbito, W., Muharam, Y., & Nugroho, Y. S. (2023).

Modeling of coal spontaneous fire in a large-scale stockpile. International

Journal of Technology, 14(2), 257–266. https://doi.org/10.14716/ijtech.v14i2.5367

Toscano,

G., Duca, D., Amato, A., & Pizzi, A. (2014). Emission from realistic

utilization of wood pellet stove. Energy, 68, 644–650. https://doi.org/10.1016/j.energy.2014.01.108

Wang, C., Zhang, L., & Liu, J. (2013).

Cost of non-renewable energy in production of wood pellets in china.

Earth Science, 7(2), 199–205. https://doi.org/10.1007/s11707-013-0358-y

Yi,

J., Li, X., He, J., & Duan, X. (2020). Drying efficiency and product

quality of biomass drying: A review. Drying Technology, 38(15), 2039–2054. https://doi.org/10.1080/07373937.2019.1628772

Yokohama, S. (2008). The asian biomass handbook. Japan Institute of Energy.

Zhou, A. Z., Xu, H., Tu, Y., Zhao, F., Zheng, Z., & Yang, W. (2019). Numerical investigation of the effect of air supply and oxygen enrichment on biomass combustion in the grate boiler. Applied Thermal Engineering, 156, 550–561. https://doi.org/10.1016/j.applthermaleng. 2019.04.05