Energy Optimization of Sugarcane Bagasse by Oxidative Torrefaction: A Multiple Linear Regression Method

Corresponding email: stivensofan@unisinu.edu.co

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.7155

Racero-Galaraga, D.A., Sofan-German, S.J., Arteaga-Ramos, J.P., Mendoza-Fandiño, J.M., 2024. Evaluation of Laplacian Spatial Filter Implementation in Detecting Driver Vigilance Using Linear Classifier. International Journal of Technology. Volume 15(6), pp. 1697-1771

| Diego A. Racero-Galaraga | Universidade Federal de São Carlos - Campus de Sorocaba Programa de Pós-Graduação em Planejamento e Uso de Recursos Renováveis, Rodovia João Leme dos Santos (SP-264), 18052-780, Itinga District - Soro |

| Stiven Javier Sofan-German | University of Sinú-Elías Bechara Zainúm, Electromechanical Engineering Program, Cra. 1w No. 38-153, Barrio Juan XXIII, 230004, Monteria – Colombia |

| Juan P. Arteaga-Ramos | Universidade Estadual paulista - Campus de Guaratingueta Programa de Pós-Graduação em engenharia, Av. Dr. Ariberto Pereira da Cunha, 333 - Pedregulho, Guaratinguetá - SP, 12516-410, Brasil |

| Jorge M. Mendoza-Fandiño | University of Cordoba, Department of Mechanical Engineering, Cra. 6 #77-305, 230004, Monteria - Colombia |

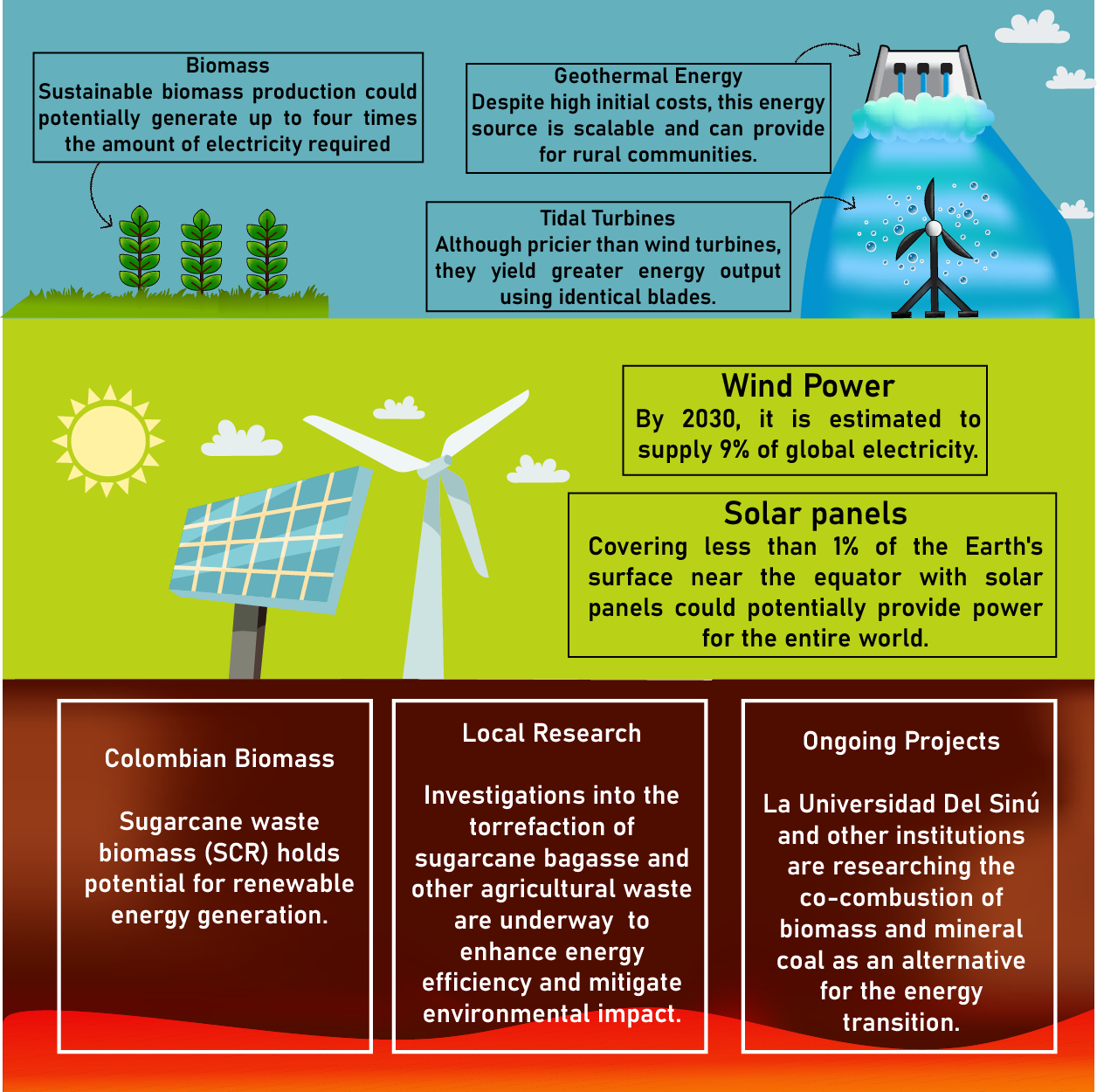

Biomass is widely recognized as a promising substitute for fossil fuels due to zero CO2 emissions, global availability, storage capacity, and immediate response to demand. Therefore, this research aimed to develop and apply a multiple linear regression model to predict the calorific value in oxidative torrefied sugarcane bagasse. An innovative method was used to enhance the efficiency of torrefaction process, focusing on predicting the calorific value through temperature and oxygen concentration. Detailed analyses of collected data were carried out in the RStudio software environment, which showed the capacity of the model to explain calorific value of sugarcane bagasse, achieving a coefficient of determination R2 of 88.29%. The results showed that the model enhanced the understanding of biomass torrefaction processes and provided valuable tools for optimization, promoting more efficient and sustainable practices in energy generation from agricultural residues such as sugarcane bagasse. The novelty of this research was in presenting a specific and rigorous method to address a significant challenge in the field of renewable energy, offering tangible results that could have a significant impact on the industry.

Biomass; Multiple linear regression model; RStudio; Sugarcane bagasse; Torrefaction

The persistent expansion of

energy consumption in recent decades is contributing to the depletion of fossil

fuel resources, high environmental pollution, and increased climate change (Hu et al., 2018). To replace fossil fuel,

renewable energy sources offer a significant solution for a sustainable future (Germán et al., 2023). Therefore, research

has been conducted to develop renewable energy sources and other efficient

technologies to prevent potential global energy and environmental crises (Kartal and Özveren, 2022). In this context,

biomass offers several advantages as a suitable alternative to fossil fuels (Lamandasa et al., 2021;

Prihantini et al., 2021; German et

al., 2023). These include zero CO2 emissions, global availability

according to demand, and storage capacity (Kalak,

2023).

Biomass is an incredibly

adaptable material that can be converted into biofuels and biochemical products

through various thermochemical conversion technologies, such as pyrolysis (Cen et al., 2021; Huang et al., 2020),

gasification (Fan et al., 2020) and

combustion (Tu et al., 2018).

However, thermochemical use of biomass is constrained by high moisture content,

low calorific value, volumetric energy density, and significant hygroscopicity (Xu et al., 2021). These challenges lead to

reduced conversion efficiency, alongside high costs associated with the

collection, storage, and transportation of biomass (Chen,

Peng, and Bi, 2015).

Among the available biomass

options, lignocellulosic has been proven effective as the most preferred due to

both technical and social factors (Fandiño et al.,

202). This preference is based on several factors, including lack of

competition with food resources, higher energy density, lower requirements for

fertilizers, water, pesticides, and rapid growth (Verdugo

et al., 2022). Consequently, it is essential to explore new

methods for efficiently using biomass from sectors such as agro-industry and

the paper industry, as well as improving the inherent characteristics (Gutiérrez et al., 2022).

Several preprocessing methods

such as torrefaction have shown potential to address some of the limitations

associated with the use of raw biomass in pyrolysis, gasification, or

combustion processes (Parkhurst, Saffron, and

Miller 2016; van der Stelt et al., 2011). Torrefaction or mild

pyrolysis, is a thermochemical process occurring in the range of 200 to 300°C

at atmospheric pressure, with limited or no oxygen presence (Thengane et al., 2020). This process is

conducted in a non-oxidizing environment at temperatures ranging from 200 to

300°C (Chen et al., 2021).

Torrefaction can also be carried out with a limited amount of oxygen in the gas

phase (oxidative torrefaction) (Devaraja et al.,

2022), thereby potentially reducing costs due to the exothermic

oxidation reactions of biomass leading to widespread application in the

industry (Leontiev et al., 2018).

Although research has examined the applications of torrefaction and enhanced

biomass, information on system integration and practical applications in the

industry remains insufficient (Kusrini et al.,

2018). There has been a significant increase in commercial advancement

and adoption of biomass torrefaction technology recently, as shown by a

significant increase in the number of operational demonstration plants (Hazra et al., 2023; Koppejan et al., 2012;

Wilén et al., 2014).

The widespread adoption has

shown the need to develop a model that predicts the properties of torrefied

biomass or improves torrefaction conditions (Adeleke

et al., 2020). This will facilitate the design of large-scale

torrefaction equipment and optimize the process overall (Liu et al., 2023). Torrefaction technology requires

development to create predictive models that can be used for assessing the

viability of the process. For example, (Watts et

al., 2023) used a regression model to determine the optimal torrefaction

temperature using thermogravimetric data. This shows the need for idea

identification of variations among the parameters influencing oxidative

torrefaction.

Various regression methods that

are available vary based on the type of variables and the assumed functional

relationship. Among these methods, linear regression is the most fundamental

and powerful in terms of information (Mahbobi and

Tiemann, 2015). Linear regression assumes that the relationship between

two variables is linear or can be linearized through some transformation. In

this context, the observed data show a potential linear relationship among

variables. However, multiple linear regression is considered the fit model

since the Higher Heating Value (HHV) is the dependent variable, while

temperature and oxygen concentration serve as independent variables. This model

assumes that more than one independent variable influences or correlates with

the value of the dependent variable (Granados,

2016).

Angelique (Conag et al., 2019), proposed a new

predictive model for the HHV based on components of Sugarcane Residue (SCR),

which were both raw and torrefied due to the inadequacy of existing models.

Although moisture correlated negatively with the HHV of fuels, it is often

excluded in conventional models. Despite the negative contribution of moisture

because of combustion, its removal was observed to require additional energy

which affected HHV. The model was established through multivariate linear

regression with experimental and bibliographic data, achieving a minimum R2 of

0.90, with a mean absolute error of less than 6% and a mean bias of less than

1%. This model aimed to anticipate the potential use of SCR as a renewable

energy source (Conag et al., 2019).

Wei-Hsin

Chen et al. investigated the production of biocarbon and the yield of sugarcane

bagasse torrefaction. The experiment was carried out using bilinear

interpolation (BLI), inverse distance weighting interpolation (IDW), and

regression analysis for predictions. The results showed that torrefied biomass

at 275°C for 60 minutes or at 300°C for 30 minutes or more was suitable for

biocarbon generation, as a low-carbon impact alternative to coal with low

energy efficiency at 300°C. All three methods were suitable for predicting

yield, with IDW showing an error below 5%. Therefore, second-order regression

analysis was recommended for more accurate predictions (Chen

et al., 2017).

(Oladosu

et al., 2024) conducted an experiment using a tubular furnace for torrefaction,

exploring the effects of temperature, retention time, moisture content, and

particle size on HHV as well as energy yield (EY) of Bambara groundnut shell

(BBGS). The results showed an optimal HHV of 21.78 MJ/kg with 1 mm particles, a

temperature of 260°C, 23 minutes retention, and 10% moisture. The model

obtained was applied to validate the input-output relationships using Response

Surface Methodology (RSM) and Bayesian Information Criterion (BIC) stepwise

regression, developing a regression model with a balance between

interpretability and solid predictive performance.

Ighalo

et al. (2020) explored an innovative method to predict HHV of biomass using a

linear regression algorithm (LRA) and stochastic gradient descent (SGD) in a

machine learning environment. The experiment was based on a dataset comprising

78 proximate and ultimate analyses. The results showed that LRA model had

higher accuracy compared to SGD. The evaluation was also carried out using

stratified cross-validation, stratified random splits, and holdout testing,

obtaining a coefficient of determination R2>0.999 in all cases. The research

suggested that LRA and SGD were highly accurate artificial intelligence models

for predicting biomass HHV (Ighalo et al.,

2020).

Qian

et al. (2018) developed regression models based on proximity to anticipate the

HHV of poultry waste (PW). The data of PW was obtained from literature to build

the models, which were validated with additional samples and compared with

previous models. The most accurate model integrated linear terms (all proximate

components), polynomial terms (quadratic and cubic terms of volatile matter),

and interaction effects (fixed carbon and ash). The results showed a higher R2

(91.62%) and lower estimation errors compared to previous models, serving as a

potential tool for predicting PW HHV without the need for expensive equipment (Qian et al., 2018).

Based on the

description, this research represents a significant contribution to the

existing knowledge on oxidative torrefaction of sugarcane bagasse and the

prediction of calorific value by developing and applying a multiple linear

regression model. By addressing the influence of temperature and oxygen

concentration, the analysis aims to explore biomass conversion mechanisms. This

offers a precise tool to optimize the processes, promote more efficient, and

sustainable practices in energy production from agricultural waste. Therefore,

the hypothesis states that both temperature and oxygen concentration during

oxidative torrefaction have a significant impact on the calorific value of

sugarcane bagasse. Therefore, this research aimed to develop a predictive model

for the calorific value of sugarcane bagasse following torrefaction process

using temperature and oxygen concentration as input parameters.

This

research presents a novel method by developing a predictive tool to estimate

the calorific value of sugarcane bagasse torrefied under controlled conditions

of temperature and oxygen concentration. Compared to previous reports, this

research integrates a detailed analysis of the correlation between specific

variables such as oxygen concentration and temperature, providing greater

precision in the estimation of energy value of the biofuel. Furthermore, the

use of mathematical models to represent the experimental data contributes

significantly to improving the understanding of torrefaction process which

serves as fundamental for future optimizations in the production of fuels from

biomass.

Experimental research

was conducted using sugarcane bagasse as biomass, subjected to an oxidative

torrefaction process. Initially, particle size was controlled within a range of (Abdulyekeen, Daud, and Patah,

2024) and 1 kg was used. The sample was dried at 105°C for 24 hours

according to the procedures of (Liborio et al.,

2023). This control of particle size and standardized drying process

ensured homogeneous initial conditions for biomass before torrefaction process,

thereby contributing to the consistency and reproducibility of experimental

results (He et al., 2023).

2.1. Experimental Setup

The reactor consisted of a sealed

chamber designed for torrefaction, supplied with inert gases such as nitrogen

and oxygen to create a controlled environment. The role of nitrogen (N2) in the

oxidative torrefaction process was essential to creating a controlled

environment within the reactor. Nitrogen acted as an inert gas that prevented

the undesired oxidation of biomass during the process. By introducing nitrogen

into the sealed chamber, an oxygen-free environment was created, preventing

spontaneous combustion and other undesired effects associated with the presence

of oxygen. This enables torrefaction to be conducted in a more controlled and

predictable manner, ensuring the quality and consistency of the final products

obtained from the process. Within this chamber, temperature and oxygen

concentration are monitored and regulated to ensure optimal conditions

throughout the process. Exhaust gases were also maintained, allowing thorough

monitoring of the products from torrefaction, as shown in Figure 1.

The

oxidative torrefaction process included controlling the flow of nitrogen,

acting as an inert gas, and oxygen (1). To regulate this flow, Pure nitrogen,

and synthetic air were used as a mixture of oxygen and nitrogen. Both gases

passed through a mixer before entering the reactor (2), where temperature was

monitored (3). The resulting gases were filtered to capture particulate matter.

Figure 1 Schematic diagram of the experimental setup.

2.2. Parameters

To conduct torrefaction, temperatures

ranging from 200 to 300°C were applied, alongside oxygen concentrations of 0%,

10%, and 20%, each for 30 minutes, as shown in Table 1. The 0% oxygen setting

showed pure nitrogen input, while 20% represented the atmospheric oxygen level,

and 10% denoted an intermediate mixture between these extremes. The variation

in these parameters facilitated subsequent biomass analysis using a

calorimetric bomb to obtain diverse HHV.

The

30 minutes time period was selected in the experimental protocol for

torrefaction of sugarcane bagasse to allow adequate assessment of how

torrefaction conditions vary during the period. This specific period, along

with variations in temperatures and oxygen concentrations, included a

significant range of torrefaction conditions. Furthermore, the duration was

considered sufficient to induce significant changes in the properties of

sugarcane bagasse, including HHV, while maintaining a practical and manageable

duration for the experiments.

Table 1 Temperatures and

Concentrations.

|

Temperature

°C |

Oxygen

concentration (%) | ||

|

200 |

0 |

10 |

20 |

|

220 |

0 |

10 |

20 |

|

240 |

0 |

10 |

20 |

|

260 |

0 |

10 |

20 |

|

280 |

0 |

10 |

20 |

|

300 |

0 |

10 |

20 |

2.3. Model

A

multiple linear regression model was used for this analysis, where the

dependent variable was HHV, while the independent variables consisted of

temperature and oxygen concentration per volume. Using the RStudio software

environment, comprehensive assessments were conducted, including the analysis

of collinearity among variables, inspection of regression residuals,

determination of the coefficient of determination (R2), coefficients associated

with the linear equation, as well as F-tests and other relevant statistical

diagnostics. This method allowed for a comprehensive and rigorous evaluation of

the relationship between predictor variables and the response variable within

the context of multiple linear regression model. In the context of the multiple

linear regression model, it was presumed that events follow a functional

structure defined by equation 1:

where:

· yj represents the

dependent variable, in this case, the calorific value of the torrefied

sugarcane bagasse for sample j.

· b0 is the independent

term or intercept, which shows the expected value of yj when

all independent variables xij are equal to zero.

· are the regression coefficients showing the expected

change in

respectively.

· represent the independent variables, in this case, the

experimental conditions such as oxygen concentration and temperature for sample

j.

· is the error or random disturbance term, which

captures the influence of factors not included in the model.

This formulation aims to capture the

linear relationship between predictor variables and the response variable,

thereby enabling a quantitative interpretation of the influence of temperature

and concentration on HHV.

The results obtained through the calorimetric bomb are presented

in Table 2, where values of HHV are recorded based on temperature and

concentration. The independent and dependent variables were initially assessed

for collinearity, as shown in Table 2. This was carried out to determine the

existence of linear relationship, an essential condition for the application of

the regression model. The analysis was based on a correlation matrix, the

content of which was visualized in Figure 2.

Table 2 Data obtained from the calorimetric bomb

|

Temperature °C |

Concentration % |

HHV (kJ/kg) |

|

200 |

0 |

18934 |

|

220 |

0 |

19493 |

|

240 |

0 |

20241 |

|

260 |

0 |

21328 |

|

280 |

0 |

21658 |

|

300 |

0 |

23827 |

|

200 |

10 |

18950 |

|

220 |

10 |

20381 |

|

240 |

10 |

21130 |

|

260 |

10 |

21493 |

|

280 |

10 |

24860 |

|

300 |

10 |

25841 |

|

200 |

20 |

19683 |

|

220 |

20 |

20716 |

|

240 |

20 |

21027 |

|

260 |

20 |

21602 |

|

280 |

20 |

24718 |

|

300 |

20 |

26988 |

Oxidative torrefaction could be more favorable because the presence of oxygen during the process was able to reduce energy loss, improve efficiency and profitability, modify biomass properties. This phenomenon contributed to high handling and energy density, offering an enhanced final product quality with lower formation of undesired compounds. According to Table 2, there was an increasing trend in HHV as torrefaction temperature rose. This suggested that higher temperatures led to greater biomass densification and decomposition, causing elevated fixed carbon content and calorific value. Additionally, HHV values were higher for lower oxygen concentrations (0% and 10%), compared to an oxygen concentration of 20%. This showed that the presence of oxygen during torrefaction contributed to partial oxidation of the biomass, which could reduce carbon content and calorific value. The analysis was based on a correlation matrix, as shown in Figure 2.

Figure 2 Correlation matrix among the variables

Figure 2 shows a

correlation matrix between the variables used in the research: oxygen

concentration (concen), temperature (temp), and Higher Heating Value (HHV_1).

Each component of the matrix is described below:

· Correlation

between concentration (concen) and temperature (temp): The correlation

coefficient was 0.0, showing that there was no significant linear relationship

between these two variables. This suggested that oxygen concentration did not

vary proportionally with temperature in the roasting process.

· Correlation

between temperature (temp) and Heating Value (HHV_1): The coefficient of 0.90

suggested a strong positive correlation, showing a corresponding increase in

temperature alongside heating value. This showed the importance of temperature

as a significant factor in optimizing torrefaction process to improve energy

content of bagasse.

· Correlation

between concentration (concen) and Heating Value (HHV_1): The coefficient of

0.27 showed a weak positive correlation, suggesting that oxygen concentration

has a minor influence on heating value compared to temperature.

The matrix included

a color code on the lower scale, ranging from -1 (perfect negative correlation)

to 1 (perfect positive correlation). The colors showed the magnitude and

direction of the correlations, where darker shades show a stronger relationship

and lighter represent weak or no correlations. Following this confirmation,

RStudio software was used, setting HHV as a function of temperature and

concentration, with the result shown in Table 3.

3.1. Residual Value

The initial

exploration of the summary of linear regression showed the assessment of

residuals. Based on Table 3 and Figure 3, the residuals showed a uniform

distribution, which tended to be symmetric. This suggested that the mean value

was close to zero, while the maximum and minimum values including 0.25 and 0.75

percentiles showed similarities with opposite signs. The observation suggested

that the model was appropriate as the residuals did not show significant

systematic patterns, thereby supporting the validity of the applied linear

regression.

Table 3 Distribution and evaluation of linear regression model residuals

|

Residues: |

Min |

1Q |

Median |

3Q |

Max |

|

|

-1611.42 |

-334.73 |

67.22 |

374.35 |

1309.66 |

Figure 3 Boxplot of the distribution of residual values

Figure 3 shows a boxplot of the residuals obtained from the

predictive model used in the research. This plot provided valuable information

for analyzing the distribution of the residuals, identifying possible outlier,

as well as evaluating the symmetry and dispersion of the errors.

· Median: The

central line within the box represented the median of the residuals, which was

close to 0. This showed that the model errors were balanced between

overpredictions and underpredictions, suggesting a good model fit.

· Box (IQR -

Interquartile Range): The box enclosed the interquartile range (IQR), which

represented 50% of the data. In this case, the residuals were mainly

concentrated between values of approximately -500 and 500. The concentration

was around the median showing that most of the model errors were within a

reasonable range.

· Whiskers:

The whiskers in the plot extended to the minimum and maximum values, excluding

outliers. In this case, the whiskers showed a dispersion that extended from

approximately -1500 to 1000, showing some limited variability in the residuals.

· Outliers: A

point outside the range of the whiskers was observed, which corresponded to an

outlier. This showed a specific data point where the model had a considerably

larger error, suggesting the need for a detailed review to determine a special

case or an error in the data. This boxplot showed that the model residuals were

properly distributed, with acceptable symmetry and a limited presence of

outliers. Most of the errors were concentrated near 0, which supported the

accuracy and stability of the proposed predictive model.

3.2. Coefficients

After analyzing the residuals and confirming the model accuracy, some coefficients were observed, as shown in Table 4.

Table 4 Coefficients of the

Linear Regression Model

|

Coefficients: |

Estimate |

Std.

Error |

t-value |

Pr(>|t|) |

|

|

(Intercept) |

5649.31 |

1546.893 |

3.652 |

0.00236 |

** |

|

Concentration |

77.108 |

25.301 |

3.048 |

0.00814 |

** |

|

Temperature |

61.623 |

6.048 |

10.189 |

3.90E-08 |

*** |

|

Signif. codes: |

0="***" |

0.001="**" |

0.01="*" |

0.05=" " |

1= |

The table shows the estimated coefficients for each variable in

the linear regression model, together with the standard error, t-value and

associated p-value. Significance levels are indicated by codes: *** for p <

0.001, ** for p < 0.01 and * for p < 0.05, while the absence of a symbol

indicates that p > 0.05, which means that the coefficient is not

statistically significant. These significance values reflect the strength of

the relationship between the predictor variables and the response variable in

the model; thus, coefficients with p less than 0.05 are considered

statistically significant, indicating a strong association in the context of

the fitted model.

In addition to providing the

coefficients

Table 5 Confidence Intervals for Estimation Coefficients with 95% Confidence Level

|

Reliability |

(Intercept) |

Concentration |

Temperature |

|

2.50% |

2352.19004 |

23.18087 |

48.73173 |

|

97.50% |

8946.43695 |

131.0358 |

74.51399 |

The are available, which are essentially used to

accept or reject the null hypothesis

is null, it will show the absence of a linear

relationship. Asterisks (*) show the significance level of a variable for the

linearity of the model. The concentration variable is highly significant, while

the temperature is significant, reaffirming non-collinearity.

The

analysis of and confidence intervals can reject the null hypothesis

as the values show a high

linear relationship. A relevant piece of information is the coefficient of

determination R2

3.3. ANOVA

In the analysis of

variance represented in Table 6, the being greater than 1 rejects the null

hypothesis, with a

showing significance in the overall model. This is further supported by the

significance of the

of

the independent variables.

3.4. Residuals

Analyzing the

residuals, the linearity of the model can be easily observed. For example,

plotting the residuals against the variable shows the distribution of values,

including some outliers, as presented in Figure 4.

Table 6 Analysis of Variance (ANOVA)

|

|

Df |

Sum Sq |

Mean Sq |

F value |

Pr(>F) |

|

|

Concentration |

1 |

7134834 |

7134834 |

9.2882 |

0.008142 |

** |

|

Temperature |

1 |

79744907 |

79744907 |

103.813 |

3.90E-08 |

*** |

|

Residuals |

15 |

11522387 |

768159 |

|

|

|

Figure 4 Distribution of residuals versus

temperature and concentration to assess model linearity

Another method to

assess the normality of the residuals is through a Q-Q Plot, as shown in Figure

5. This plot shows data distribution, indicating that the central data points

are more closely related to the line compared to the ends, namely outliers.

Figure 5 Q-Q plot to assess normality of residuals

Based on the

results, an oxidative torrefaction process can predict the HHV with temperature

and oxygen concentration at an 88.29% confidence level using the following

model, as shown in equation 2:

The results have significant practical

implications for the biomass industry, providing an accurate predictive tool

for optimizing the oxidative torrefaction processes of sugarcane bagasse. The

ability to predict calorific value of bagasse based on temperature and oxygen

concentration enables industry stakeholders to make informed decisions

regarding optimal operating parameters to maximize energy efficiency and the

quality of the final product. Furthermore, the results suggest essential areas

for future research, such as exploring other process variables that can

influence calorific value, as well as validating the proposed model in different

industrial contexts and with several types of biomass. This line of future

research can lead to further improvements in the efficiency and sustainability

of energy production from biomass, significantly contributing to the transition

towards cleaner and renewable energy sources.

Predicting the HHV of torrefied

biomass is essential for assessing efficiency, energy use, and optimizing

torrefaction processes to ensure the viability of biomass as a renewable energy

source. However, the ability of this model to predict the HHV of other

biomasses requires external validation using different experimental data to

show broader applicability.

In conclusion, this research applied a

multiple linear regression model to predict the HHV of sugarcane bagasse based

on oxidative torrefaction using temperature and concentration as predictor

variables. The results showed a significant relationship between HHV and

temperature, while the correlation with concentration was weaker. The model

showed good predictive capability, explaining 88.29% of the variability in HHV.

The examination of coefficients showed that both temperature and concentration

were significant variables in predicting HHV. The validity of the estimated

coefficients was supported by confidence intervals and significance values.

However, the unexplained portion, accounting for 11.71% could be attributed to

factors such as insufficient samples or the presence of outliers. The

regression assumptions were also satisfied, since F-test showed a p-value of

1.03????10?07, and the model achieved a confidence level of 95%. Although

the model showed accuracy in predicting HHV, there was a suggestion for improvement

by including other relevant parameters such as volatile materials and moisture.

Furthermore, the economic viability of oxidative torrefaction in the presence

of oxygen to reduce costs was discussed. These results supported the

application of oxidative torrefaction as an effective strategy to enhance the

calorific properties of sugarcane bagasse, potentially driving more sustainable

practices in energy generation from waste. The model presented in Equation 2

was developed based on data obtained from an experiment conducted within a 30 minute

torrefaction period. Although the design was the experimental setup, its

underlying principles and methodology could potentially be applied to other

cases with similar conditions. Extrapolating the model to significantly

different torrefaction durations or conditions could require additional

validation and adjustment. The coefficients and relationships established in

the model were not directly translated to scenarios beyond the scope of the

original experimental design. Therefore, careful consideration and possibly

recalibration of the model were recommended for application to other

torrefaction durations or conditions to ensure accuracy and reliability.

The authors are grateful to the Universidade

Federal de São Carlos - Campus de Sorocaba, Universidade Estadual Paulista -

Campus de Guaratingueta, Universidad del Sinú and University of Cordoba for

their support and collaboration in the development of this research.

Furthermore, the authors are grateful to thank these institutions for the

valuable support provided, fostering an environment conducive to the

advancement of knowledge.

Source of Financing

This

research received the financial support of the Universidad del Sinú - Elías

Bechara Zainúm in the framework of the internal project entitled "ANALYSIS

OF ENERGY YIELD AND EMISSIONS OF BIOMASS CO-COMBUSTION WITH MINERAL COAL AS AN

ALTERNATIVE FOR ENERGY TRANSITION", approved in the internal call UNISINÚ

INVESTIGA 2023 with code CI-00423-006. The financial support facilitated the

successful completion of the research and contributed to the advancement of

knowledge in the field of energy transition.

In

addition, the authors thank the Universidad de Córdoba, Montería, Colombia for

funding within the scope of the program for the maintenance and improvement of

indicators of the research groups approved in the internal call for the year

2023,” according to minutes No. FI-02-23.

Conflict of Interest

The authors declare no conflict of

interest.

Abdulyekeen, K.A., Daud, W.M.A.W., Patah, M.F.A, 2024.

Torrefaction of Wood and Garden Wastes from Municipal Solid Waste to Enhanced

Solid Fuel Using Helical Screw Rotation-Induced Fluidised Bed Reactor: Effect

of Particle Size, Helical Screw Speed and Temperature. Energy, Volume

293, p. 130759, https://doi.org/10.1016/j.energy.2024.130759

Adeleke,

A.A, Odusote, J.K., Ikubanni, P.P., Lasode, O.A., Malathi, M., Paswan, D, 2021.

Essential Basics on Biomass Torrefaction, Densification, and Utilization. International

Journal of Energy Research, Volume 45(2), pp. 1375–1395, https://doi.org/10.1002/er.5884

Cen,

K., Zhuang, X., Gan, Z., Ma, Z., Li, M., Chen, D., 2021. Effect of the Combined

Pretreatment of Leaching and Torrefaction on the Production of Bio-Aromatics

from Rice Straw via the Shape Selective Catalytic Fast Pyrolysis. Energy

Reports, Volume 7, pp. 732–739, https://doi.org/10.1016/j.egyr.2021.01.031

Chen,

W.H., Hsu, H.J., Kumar, G., Budzianowski, W.M., Ong, H.C., 2017. Predictions of

Biochar Production and Torrefaction Performance from Sugarcane Bagasse Using

Interpolation and Regression Analysis. Bioresource Technology, Volume

246, pp. 12–19, https://doi.org/10.1016/j.biortech.2017.07.184

Chen,

W.H., Lin, B.J., Lin, Y.Y., Chu, Y.S., Ubando, A.T., Show, P.L., Ong, H.C.,

Chang, J.S., Ho, S.H., Culaba, A.B., Pétrissans, A., Pétrissans, M., 2021.

Progress in Biomass Torrefaction: Principles, Applications, and Challenges. Progress

in Energy and Combustion Science, Volume 82, p. 100887, https://doi.org/10.1016/j.pecs.2020.100887

Chen,

W.H., Peng, J., Bi, X.T., 2015. A State-of-the-Art Review of Biomass

Torrefaction, Densification, and Applications. Renewable and Sustainable

Energy Reviews, Volume 44, pp. 847–866, https://doi.org/10.1016/j.rser.2014.12.039

Conag,

A.T., Villahermosa, J.E.R., Cabatingan, L.K., Go, A.W., 2019. Predictive HHV

Model for Raw and Torrefied Sugarcane Residues. Waste and Biomass

Valorization, Volume 10(7), pp. 1929–1943, https://doi.org/10.1007/s12649-018-0204-2

Devaraja,

U.M.A., Dissanayake, C.L.W., Gunarathne, D.S., Chen, W.H., 2022. Oxidative

Torrefaction and Torrefaction-Based Biorefining of Biomass: A Critical Review. Biofuel

Research Journal, Volume 9(3), pp. 1672–1696, https://doi.org/10.18331/BRJ2022.9.3.4

Fan,

Y., Tippayawong, N., Wei, G., Huang, Z., Zhao, K., Jiang, L., Zheng, A., Zhao,

Z., Li, H. 2020. Minimizing Tar Formation Whilst Enhancing Syngas Production by

Integrating Biomass Torrefaction Pretreatment with Chemical Looping

Gasification. Applied Energy, Volume 260, p. 114315, https://doi.org/10.1016/j.apenergy.2019.114315

Fandiño,

J.M.M., German, S.J.S., García, D.E.L., Guarín, A.M., Julio, J.D.R., 2021.

Caracterização Energética dos Resíduos da Agroindústria do Milho em um

Protótipo de Gaseificação Multizona (Energy Characterization of Corn

Agroindustry Waste in a Multi-Zone Gasification Prototype). Revista

Virtual de Quimica (Virtual Journal of Chemistry), Volume 14(1), pp. 61–67,

https://dx.doi.org/10.21577/1984-6835.20210099

Germán,

S.J.S, Fandiño, J.M.M, Julio, J.D.R., Gómez, R.D., 2023. CFD Simulation

Applying a Discrete Phase Model of Residual Corn Biomass Gasification in a

Concentric Tube Reactor. Journal of Southwest Jiaotong University,

Volume 58(5), pp. 390–405, https://doi.org/10.35741/issn.0258-2724.58.5.30

German,

S.J.S, Torres, J.D.A., Garcés, A.R., Oviedo, M.E.D., 2023. Evaluación

Energética de la Formación De Biogás Obtenido De Residuos Sólidos Urbanos Del

Relleno Sanitario Mediante El Modelo LandGEM (Energy Assessment of Biogas

Formation Obtained from Urban Solid Waste from the Landfill Using the LandGEM

Model). Research and Innovation in Engineering, Volume 11(2), pp.

16–27, https://doi.org/10.17081/invinno.11.2.6373

Granados,

R.M., 2016. Modelos de Regresión Lineal Múltiple. Universidad de Granada, https://www.ugr.es/~montero/matematicas/regresion_lineal.pdf

Gutiérrez,

A.S., Fandiño, J.M.M., Eras, J.J.C., German, S.J.S., 2022. Potential of

Livestock Manure and Agricultural Wastes to Mitigate the Use of Firewood for

Cooking in Rural Areas: The Case of the Department of Córdoba (Colombia). Development

Engineering, Volume 7, p. 100093, https://doi.org/10.1016/j.deveng.2022.100093

Hazra,

S., Morampudi, P., Prindle, J.C., Fortela, D.L.B., Hernandez, R., Zappi, M.E.,

Buchireddy, P., 2023. Torrefaction of Pine Using a Pilot-Scale Rotary Reactor:

Experimentation, Kinetics, and Process Simulation Using Aspen PlusTM.

Clean Technologies, Volume 5(2), pp. 675–695, https://doi.org/10.3390/cleantechnol5020034

He,

Y., Zhang, S., Liu, D., Xie, X., Li, B., 2023. Effect of Biomass Particle Size

on the Torrefaction Characteristics in a Fixed-Bed Reactor. Energies,

Volume 16(3), p. 1104, https://doi.org/10.3390/en16031104

Hu,

Q., Yang, H., Xu, H., Wu, Z., Lim, C.J., Bi, X.T., Chen, H., 2018. Thermal

Behavior and Reaction Kinetics Analysis of Pyrolysis and Subsequent In-Situ

Gasification of Torrefied Biomass Pellets. Energy Conversion and Management,

Volume 161, pp. 205–214, https://doi.org/10.1016/j.enconman.2018.02.003

Huang,

M., Ma, Z., Zhou, B., Yang, Y., Chen, D., 2020. Enhancement of the Production

of Bio-Aromatics from Renewable Lignin by Combined Approach of Torrefaction,

Deoxygenation Pretreatment, and Shape-Selective Catalytic Fast Pyrolysis Using

Metal-Modified Zeolites. Bioresource Technology, Volume 301, p. 122754, https://doi.org/10.1016/j.biortech.2020.122754

Ighalo,

J.O., Adeniyi, A.G., Marques, G., 2020. Application of Linear Regression

Algorithm and Stochastic Gradient Descent in a Machine-Learning Environment for

Predicting Biomass Higher Heating Value. Biofuels, Bioproducts and

Biorefining, Volume 14(6), pp. 1286–1295, https://doi.org/10.1002/bbb.2140

Kalak,

T., 2023. Potential Use of Industrial Biomass Waste as a Sustainable Energy

Source in the Future. Energies, Volume 16(4), p. 1783, https://doi.org/10.3390/en16041783

Kartal,

F., Özveren, U., 2022. Prediction of Torrefied Biomass Properties from Raw

Biomass. Renewable Energy, Volume 182, pp. 578–591, https://doi.org/10.1016/j.renene.2021.10.042

Koppejan,

J., Sokhansanj, S., Melin, S., Madrali, S., 2012. Status Overview of

Torrefaction Technologies. IEA Bioenergy Task, Volume 32, pp. 1–54, https://www.ieabioenergy.com/wp-content/uploads/2015/11/IEA_Bioenergy_T32_Torrefaction_update_2015b.pdf

Kusrini,

E., Supramono, D., Degirmenci, V., Pranata, S., Bawono, A.A., Ani, F.N., 2018.

Improving the Quality of Pyrolysis Oil from Co-Firing High-Density Polyethylene

Plastic Waste and Palm Empty Fruit Bunches. International Journal of

Technology, Volume 9(7), pp. 1498–1508, https://doi.org/10.14716/ijtech.v9i7.2531

Lamandasa,

C.I., Setiawan, A., Harjanto, S., Rhamdhani, M.A., 2021. Effect of Adding

Biomass from Palm Kernel Shell on Phase Transformation and Microstructure

during Carbothermic Reduction of Ilmenite. International Journal of

Technology, Volume 12(6), pp. 1139–1148, https://doi.org/10.14716/ijtech.v12i6.5232

Leontiev,

A., Kichatov, B., Korshunov, A., Kiverin, A., Medvetskaya, N., Melnikova, K.,

2018. Oxidative Torrefaction of Briquetted Birch Shavings in the Bentonite. Energy,

pp. 165, 303–313, https://doi.org/10.1016/j.energy.2018.09.103

Liborio,

D.O., Gonzalez, J.F., Arias, S., Mumbach, G.D., Alves, J.L.F., da Silva,

J.C.G., Silva, J.M.F., Barbosa, C.M.B.M., Carvalho, F.R., Soares, R.R., Simões,

D.A., Pacheco, J.G.A., 2023. Pyrolysis of Energy Cane Bagasse: Investigating

Kinetics, Thermodynamics, and Effect of Temperature on Volatile Products. Energies,

Volume 16(15), p. 5669, https://doi.org/10.3390/en16155669

Liu,

X., Yang, H., Yang, J., Liu, F., 2023. Prediction of Fuel Properties of

Torrefied Biomass Based on Back Propagation Neural Network Hybridized with

Genetic Algorithm Optimization. Energies, Volume 16(3), p. 1483, https://doi.org/10.3390/en16031483

Mahbobi,

M., Tiemann, T.K., 2015. Introductory Business Statistics with Interactive

Spreadsheets, https://opentextbc.ca/introductorybusinessstatistics/

Oladosu,

K.O., Babalola, S.A., Ajao, R.K., Erinosho, M.F, 2024. Torrefaction of Bambara

Groundnut Shell: Experimental Optimization and Prediction of the Energy

Conversion Efficiency Using Statistical and Machine Learning Approaches. International

Journal of Ambient Energy, Volume 45(1), p. 2277309, https://doi.org/10.1080/01430750.2023.2277309

Parkhurst,

K.M., Saffron, C.M., Miller, R.O., 2016. An Energy Analysis Comparing Biomass

Torrefaction in Depots to Wind with Natural Gas Combustion for Electricity

Generation. Applied Energy, Volume 179, pp. 171–181, https://doi.org/10.1016/j.apenergy.2016.05.121

Prihantini,

N.B., Maulana, F., Wardhana, W., Takarina, N.D., Nurdin, E., Handayani, S.,

Nasruddin, Haryani, G.S., 2021. Wild Mixed Culture Microalgae Biomass from UI

Agathis Small Lake Harvested Directly using an Ultrasound Harvesting Module as

Biofuel Raw Material. International Journal of Technology, Volume 12(5),

pp. 1081–1090, https://doi.org/10.14716/ijtech.v12i5.5226

Qian,

X., Lee, S., Soto, A., Chen, G., 2018. Regression Model to Predict the Higher

Heating Value of Poultry Waste from Proximate Analysis. Resources,

Volume 7, p. 39, https://doi.org/10.3390/resources7030039

Thengane,

S.K., Kung, K.S., Gupta, A., Ateia, M., Sanchez, D.L., Mahajani, S.M., Lim,

C.J., Sokhansanj, S., Ghoniem, A.F., 2020. Oxidative Torrefaction for Cleaner

Utilization of Biomass for Soil Amendment. Cleaner Engineering and

Technology, Volume 1, p. 100033, https://doi.org/10.1016/j.clet.2020.100033

Tu,

R., Jiang, E., Yan, S., Xu, X., Rao, S., 2018. The Pelletization and Combustion

Properties of Torrefied Camellia Shell Via Dry and Hydrothermal Torrefaction: A

Comparative Evaluation. Bioresource Technology, Volume 264, pp. 78–89, https://doi.org/10.1016/j.biortech.2018.05.009

Van

der Stelt, M.J.C., Gerhauser, H., Kiel, J.H.A., Ptasinski, K.J., 2011. Biomass

Upgrading by Torrefaction for the Production of Biofuels: A Review. Biomass

and Bioenergy, Volume 35(9), pp. 3748–3762, https://doi.org/10.1016/j.biombioe.2011.06.023

Verdugo,

A.S., Pleite, E.C, Panahi, A., Ghoniem, A.F., 2022. Kinetics Mechanism of Inert

and Oxidative Torrefaction of Biomass. Energy Conversion and Management,

Volume 267, p. 115892, https://doi.org/10.1016/j.enconman.2022.115892

Watts,

J., Potter, A., Mohan, V., Kumari, P., Thengane, S.K., Sokhansanj, S., Cao, Y.,

Kung, K.S., 2023. Proxy Quality Control of Biomass Particles Using

Thermogravimetric Analysis and Gaussian Process Regression Models. Biofuels,

Bioproducts and Biorefining, Volume 17(5), pp. 1274–1289, https://doi.org/10.1002/bbb.2504

Wilén,

C., Sipilä, K., Tuomi, S., Hiltunen, I., Lindfors, C., Sipilä, E., Saarenpää,

T.L., Raiko, M., 2014. Wood Torrefaction: Market Prospects and Integration with

The Forest and Energy Industry. VTT Technical Research Centre of Finland.

Number 165, p. 55, https://publications.vtt.fi/pdf/technology/2014/T163.pdf

Xu,

J., Huang, M., Hu, Z., Zhang, W., Li, Y., Yang, Y., Zhou, Y., Zhou, S., Ma, Z.,

2021. Prediction and Modeling of the Basic Properties of Biomass After

Torrefaction Pretreatment. Journal of Analytical and Applied Pyrolysis,

Volume 159, p. 105287, https://doi.org/10.1016/j.jaap.2021.105287