Process of Solving Multi-Response Optimization Problems Using a Novel Data Envelopment Analysis Variant-Taguchi Method

Corresponding email: wanrop.kh@ksu.ac.th

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.7134

Wichapa, N., Pawaree , N., Nasawat, P., Chourwong, P., Sriburum, A., Khanthirat, W., 2024. Process of Solving Multi-Response Optimization Problems Using a Novel Data Envelopment Analysis Variant-Taguchi Method. International Journal of Technology. Volume 15(6), pp. 2038-2059

| Narong Wichapa | Department of Industrial Engineering, Faculty of Engineering and Industrial Technology, Kalasin University, Kalasin, 46000, Thailand |

| Narathip Pawaree | Department of Industrial Management, Faculty of Technology, Udon Thani Rajabhat University, Udon Thani, 41000, Thailand |

| Pariwat Nasawat | Department of Logistics and Process Engineering, Faculty of Industrial Technology, Rajabhat Rajanagarindra University, 24000, Thailand |

| Prawach Chourwong | Department of Logistics and Process Engineering, Faculty of Industrial Technology, Rajabhat Rajanagarindra University, 24000, Thailand |

| Anucha Sriburum | Department of Industrial Engineering, Faculty of Engineering and Industrial Technology, Kalasin University, Kalasin, 46000, Thailand |

| Wanrop Khanthirat | Department of Industrial Engineering, Faculty of Engineering and Industrial Technology, Kalasin University, Kalasin, 46000, Thailand |

Multi-response

optimization (MRO) is important to modern manufacturing that requires

simultaneous consideration of multiple performance metrics to achieve high

efficiency and quality. Therefore, this study presents an innovative hybrid

method that combines the Data Envelopment Analysis Variant (DEAV) model with

Taguchi to address the challenges associated with MRO. The DEAV model improves

traditional DEA by incorporating multiple attribute decision-making (MADM)

principles to offer a comprehensive evaluation framework. Taguchi uses

efficiency scores from the DEAV model to enable optimal parameter determination

through Taguchi optimization. Moreover, the hybrid method was validated using

two examples, including optimization of a fish scale scraping machine and the

CNC turning process of ST37 steel. The results showed that the DEAV-Taguchi

method produced more efficient and reliable outcomes than existing methods,

significantly improving key performance metrics such as surface roughness and

material removal rate. The main contribution of this study was the development

of a robust optimization framework that balanced multiple conflicting

objectives in manufacturing processes. Future studies are expected to apply the

method to different materials and processes, expand experimental designs, and

assess the economic and environmental impacts of optimized parameters. The

DEAV-Taguchi method also offers a significant advancement in MRO, providing a

versatile and effective solution for modern manufacturing optimization.

CNC turning optimization; Data envelopment analysis variant; Multi-response optimization; Manufacturing processes; Taguchi method

Multi-response optimization (MRO) is very important in contemporary manufacturing processes due to the usefulness in simultaneous consideration of multiple performance metrics to achieve both efficiency and high quality. However, conventional optimization methods have frequently failed to adequately address the complexities associated with balancing multiple conflicting objectives. This is despite the need to optimize manufacturing processes, specifically in high-precision environments, in order to enhance product quality, reduce costs, and increase efficiency (Soori, Arezoo, and Dastres, 2023; Abdelaoui, Jabri, and Barkany, 2023; Sulaiman et al., 2022; Yang et al., 2019). Therefore, there is a need to develop new, promising, and efficient methods to address MRO challenges in order to ensure the effective management of the issues identified. The introduction of innovative strategies for MRO can lead to better handling of the complexities and conflicting objectives inherent in modern manufacturing processes which are required to improve efficiency and quality.

Design of Experiments (DOE) is

a systematic method developed in the early 20th century by Sir

Ronald Fisher to study the relationships between factors affecting process and

output. The method is considered important for improving process efficiency and

product quality by enabling structured experimentation and analysis of different

factors. An example is the method introduced by Genichi Taguchi which is

considered robust and emphasizes improving quality through design rather than

inspection. It uses orthogonal arrays to study a large number of variables with

a minimal number of experiments, leading to reduced costs and time (Taguchi, 1986). The focus of the method on

minimizing variability through the use of signal-to-noise (S/N) ratios also

ensures specific effectiveness in optimizing manufacturing processes.

Furthermore, its ability to optimize parameters with fewer experimental runs compared

to traditional methods leads to cost-effectiveness and efficiency (Kantasiri et al., 2024; Chen et al., 2024;

Lestari et al., 2024; Sulaiman et al., 2022).

Multi-Attribute Decision Making

(MADM) methods which are an example of Multi-Criteria Decision Making (MCDM)

have been integrated into DOE to tackle complex optimization problems related

to multiple conflicting objectives or responses. For example, Grey Relational

Analysis (GRA), the Technique for Order of Preference by Similarity to Ideal

Solution (TOPSIS), Data Envelopment Analysis Ranking (DEAR), and Complex

Proportional Assessment (COPRAS) have also been effectively used to solve MRO

problems (Shivakumar and Panchangam, 2024; Kumar et

al., 2024; Pawaree, Phokha, and

Phukapak, 2024; Kannan et al., 2023; Sriburum, Wichapa, and Khanthirat,

2023; Liu et al., 2023; Yang et al., 2023; To-on, Wichapa, and

Khanthirat, 2023; Kamath et al., 2022; Yaser and Shunmugesh, 2019;

Vellaiyan, Amirthagadeswaran, and Sivasamy, 2018;

Zavadskas, Turskis, and Kildien?, 2014;

Liao and Chen, 2002). These MADM methods facilitate the evaluation and

prioritization of multiple alternatives based on a set of criteria, aiding

process of making more informed decisions. Moreover, the combination of MADM

with DOE has led to the provision of a more robust optimization solution that

balances multiple performance metrics and subsequently enhances overall

manufacturing efficiency.

The integration of Taguchi

method into MADM has proven effective in solving MRO problems. For example, (Kumar, Kumar, and Rajkumar, 2022) combined

Taguchi and GRA to optimize CNC end-milling parameters for AISI H11 tool steel,

achieving optimal surface roughness and MRR. A research by (Zhujani et al., 2024) also applied

Taguchi-based DOE method combined with GRA and Analysis of Variance (ANOVA) to

determine the optimal machining parameters for turning Inconel 718, a

high-strength nickel-based superalloy widely used in the aerospace industry.

Moreover, a research by (Sristi, Zaman, and Dhar, 2022)

conducted a comparative study of different hybrid Taguchi-based MADM methods

for optimizing hard-turning parameters. The study utilized COPRAS, TOPSIS, and

GRA to optimize parameters such as cooling environment, cutting speed, and feed

rate. The optimal process parameters obtained from all three methods were

consistent, showing the effectiveness of these methods in improving

machinability and process performance. A research by (Sriburum,

Wichapa, and Khanthirat, 2023) also utilized a novel TOPSIS linear

programming (modified TOPSIS) model based on Taguchi method for solving MRO

problems in the fish scale scraping machine. The study reported improvements in

fish scaling removal efficiency and reduction in fish damage, emphasizing the

utility of combining the modified TOPSIS with Taguchi for optimizing complex

processes.

Kamath et al., (2022)

evaluated the effect of process parameters on the face milling machining

process during process of machining Al/TiB2 metal matrix composite. This was

achieved using Taguchi-DEAR method to evaluate performance metrics, including

MRR and surface roughness. A research by (Moganapriya

and Rajasekar, 2023) also explored the use of titanium aluminum

nitride/tungsten carbide-coated inserted in dry turning, optimizing machining

variables to improve flank wear, MRR, and surface roughness using a

DEAR-Taguchi method. The application of Taguchi L16 design and ANOVA showed the

significant influence of feed per tooth on the outcomes. Moreover, the

combination of GRA and DEAR with Taguchi method produced an optimal cutting

regime that enhanced surface roughness and material removal rate, with feed per

tooth having the most substantial impact on performance metrics. Several MADM

methods have successfully addressed MRO problems, but each method has

advantages and disadvantages. A critical drawback identified in almost all was

related to data normalization which could adversely affect the reliability of

the results. The computational complexity of MADM methods could also increase

significantly when processing large datasets. Therefore, new MADM methods

needed to be developed in order to overcome these primary limitations.

The Data Envelopment Analysis

(DEA) model developed by (Charnes, Cooper, and

Rhodes, 1978) can evaluate the relative efficiency of decision-making

units (DMUs). This efficiency is often calculated as the ratio of the weighted

sum of outputs to the weighted sum of inputs. Moreover, the linear programming

model, called the CCR, has the ability to determine the optimal weights for

each DMU in order to ensure none of the efficiency scores exceeds one. DEA

offers several advantages and the most important is the ability to measure

efficiency without requiring data normalization, thereby simplifying the

preprocessing step. As a linear programming model, DEA can be solved using

different solvers, making the process computationally efficient. It provides a

comprehensive measure of efficiency by comparing multiple inputs and outputs

across DMUs without needing a predefined functional form (Fan et al., 2017, Wang,

Nguyen, and Wang, 2016). However, the traditional DEA model,

specifically the CCR, is not suitable for addressing MADM problems due to the

inability to distinguish among efficient units (Li et

al., 2022; Shi et al., 2021; Shi, Wang, and Zhang, 2019; Li et al.,

2018). The model provides an efficiency score of one to all DMUs on the

efficient frontier, leading to the classification of multiple units as equally

efficient. This lack of discrimination hinders the establishment of a clear

ranking order among efficient units, causing some challenges in the process of

ranking all DMUs precisely. A promising method is to integrate the concepts of

DEA into MADM in order to overcome this limitation and develop an effective

tool for solving MRO problems in the context.

The concept inspired the

conduct of this study to present an innovative method that combined the

principles of DEA and MADM towards producing the novel Data Envelopment

Analysis Variant (DEAV) specifically designed for MRO problems. The DEAV model

combined with Taguchi method was proposed and evaluated using two numerical

examples in order to deliver a robust solution for MRO challenges. This

advanced method aimed to offer a comprehensive framework for MRO. Therefore,

the contributions of this study are stated as follows:

1) The introduction of the

DEAV model produced through the inclusion of MADM principles as an enhancement

to the traditional DEA. The model provided weights to each criterion through

decision-makers or established methods such as Analytic Hierarchy Process

(AHP), Best-Worst Method (BWM), Criteria Importance Through Inter-criteria

Correlation (CRITIC), and Entropy to provide a flexible and adaptable

framework.

2) The combination of the

DEAV model with Taguchi method as a comprehensive optimization framework to

effectively balance multiple conflicting objectives. The Taguchi method

utilizes efficiency scores from the DEAV model to obtain optimal parameters

through optimization process.

3) The method was

subsequently validated through two examples, including optimization of a fish

scale scraping machine and the CNC turning process of ST37 steel. The DEAV-

Taguchi method showed significant improvements in

key performance metrics such as surface roughness and material removal rate,

outperforming existing methods.

4) The method was confirmed

to be adaptable for other MRO or MADM problems, showing versatility across

different industrial settings. It was suggested that future studies should

apply the method to different materials and processes, expand experimental designs,

and assess economic and environmental impacts.

The remainder of this study is organized as

follows: Section 2 focuses on the methodology designed to determine the optimal

machining parameters. Section 3 presents the results which show the

effectiveness of the proposed method. Lastly, Section 4 provides a summary of

the key results with an emphasis on the practical implications for

manufacturing optimization and the potential of the method to address MRO

problems.

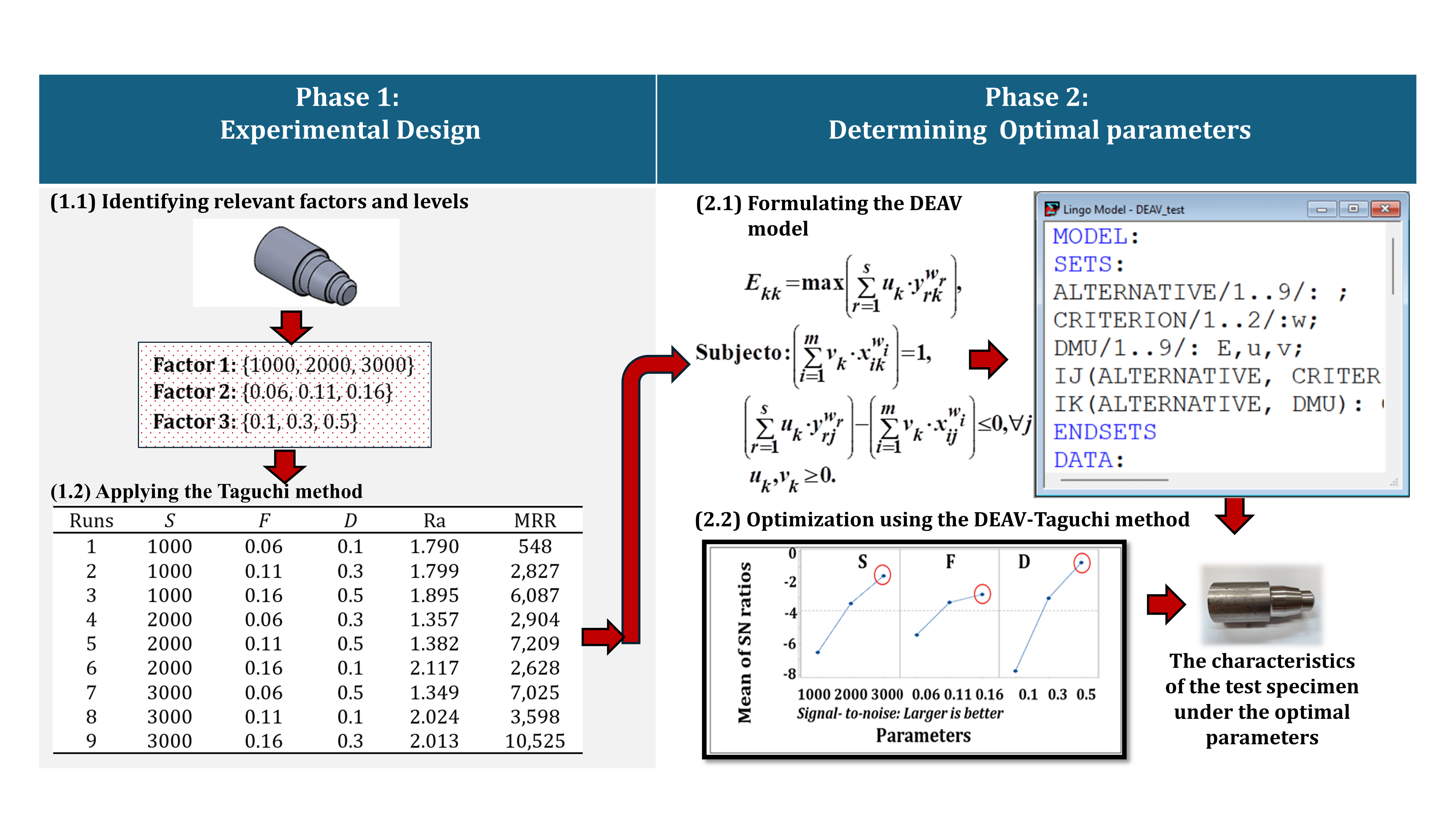

Figure 1 The proposed framework of the study

2.1. Phase1: Experimental design

The

experimental design used in this study was further divided into the following

two sub-steps.

2.1.1. Identifying

the relevant factors and subsequent levels

The sub-step focused on

determining the critical variables influencing the outcome of process and

specifying different values, conditions, or levels. This was important to

design the experiments that precisely captured the effects of each factor on

response variables.

2.1.2. Applying Taguchi method

The sub-step focused on

implementing a systematic method to efficiently plan the experiments with the

aim of identifying the optimal conditions. The method emphasized the reduction

of variability and enhancement of quality through the application of orthogonal

arrays to examine a large number of variables with a minimal number of

experiments.

2.2. Phase 2: Determining the optimal parameters

Process

of determining the optimal parameters was also divided into the following two

sub-steps.

2.2.1. Formulating

a DEAV model

The DEAV model was used to convert responses obtained into a single output. The concepts of the original DEA model required evaluating the efficiency score for each run according to the criterion. In the decision matrix, each set of runs was treated as a set of DMUs, and responses were categorized as inputs and outputs. Moreover, the efficiency of DMUs was assessed by comparing the inputs and outputs to a frontier. This was achieved by using linear programming to calculate efficiency scores and identify optimal DMUs and inefficiencies. The aim was to determine the optimal weights that maximize the efficiency score (Ekk) for each DMU. A score of 1 shows efficiency while values below 1 suggest an improvement in DMU by reducing inputs or increasing outputs. The DEAV model incorporated MADM concepts and required weights for each criterion which were determined by decision-makers or through methods such as AHP, BWM, CRITIC, and Entropy. The definitions of indices, parameters, objective functions, and constraints are provided in the following sections.

Consider a set of DMUs, denoted as DMUj, each characterized by a set of inputs xij for i = 1,…, m and a set of outputs yri for r =1,…,s. Let uk? represent the weights assigned to the output k evaluated while vk? is the weights assigned to the input k evaluated. The DEAV model is an advanced method for evaluating the performance of DMUs by incorporating multiple inputs and outputs. Therefore, this study focuses on transforming the non-linear DEAV into a linear programming model to enhance computational efficiency and applicability. The novel linear programming model for DEAV was formulated through a series of steps. Initially, the non-linear form was expressed through Equation (1).

The linear programming DEAV model applied

a sophisticated method to assess the performance of DMUs, using both inputs and

outputs to provide a comprehensive evaluation of the efficiency. The aim was to

maximize the efficiency score Ekk, which was the weighted sum

of the variables uk, wr, and yrk.

The model can be applied to a variety of MADM problems due to the ability to

continuously assign importance weights to criteria, which is fundamental to

MADM. Sensitivity analysis was subsequently used to determine the criteria

weights for both inputs and outputs (wr and wi)

in the DEAV model.

2.2.2. Determining

the optimal parameters using a novel DEAV - Taguchi method

This step discusses the

development of Taguchi method from the results obtained from the DEAV model to

optimize the parameters of the proposed machines. The aim was to provide a

detailed and structured method to enhance the performance of machines. At the

initial stage, the efficiency scores for each experimental run were calculated

using the DEAV model to serve as the basis for further analysis. Subsequently,

Taguchi method was applied using Minitab statistical software to provide a

robust analysis of the experimental data. The primary response parameters

considered were two types, including "Larger is better" and

"Smaller is better" which were analyzed using signal-to-noise (S/N)

ratios and considered important in Taguchi method for identifying optimal

settings. Specifically, the factor for "Smaller is better" was

calculated through Equation (3) while the factor for "Larger is

better" was determined according to Equation (4).

Where, y

represents response, and n denotes the number of replications. Moreover,

the Ekk response derived from the proposed DEAV model was

calculated based on the objective that larger values were preferable as shown

in Equation (4).

Figure 2 The step-by-step process of using the DEAV -Taguchi method

The validity of the proposed method was evaluated using two numerical examples. The first example was the fish scale scraping machine problem investigated by (Sriburum, Wichapa, and Khanthirat, 2023) while the second was a case study of the CNC turning process of ST37 steel. The detailed calculation steps for the examples are provided in Sections 3.1 and 3.2, respectively.

3.1. The fish scale scraping machine problem

The fish scale scraping machine problem investigated by (Sriburum, Wichapa, and Khanthirat, 2023) addressed the MRO challenge, with a particular emphasis on enhancing efficiency while minimizing damage to the fish. Based on the principles of the DEAV model in Equation (2), the efficiency was regarded as the output (y1) while the resulting fish damage was considered the input (x1). Table 1 presents the dataset for this study with a focus on the nine DMUs or runs and each is defined by three factors, including speed (S: rpm), time (T: seconds), and capacity (C: kg) assessed at three different levels.

Table 1 The dataset for the MRO problem of a fish scale scraping machine

Experiment | Speed (rpm) | Time (seconds) | Capacity (kg) | x1 | y1 | Ekk |

1 | 50 | 180 | 20 | 1.200 | 3.800 | 0.9704 |

2 | 50 | 240 | 25 | 1.467 | 4.400 | 0.9444 |

3 | 50 | 300 | 30 | 2.000 | 3.800 | 0.7517 |

4 | 60 | 180 | 25 | 1.467 | 4.933 | 1.0000 |

5 | 60 | 240 | 30 | 1.733 | 4.733 | 0.9012 |

6 | 60 | 300 | 20 | 3.000 | 3.800 | 0.6137 |

7 | 70 | 180 | 30 | 1.533 | 4.533 | 0.9377 |

8 | 70 | 240 | 20 | 3.000 | 3.933 | 0.6244 |

9 | 70 | 300 | 25 | 3.800 | 4.000 | 0.5595 |

The linear programming model could be solved using different optimization software. However, Lingo software was used in this study to determine all the efficiency scores (Ekk) for the fish scale scraping machine problem, as presented in Table 2.

Table 2 The details of the Lingo code for the fish scale scraping machine problem

Lingo code for the DEAV model |

MODEL: SETS: ALTERNATIVE/1..9/: ; CRITERION/1..2/:w; DMU/1..9/: E,u,v; IJ(ALTERNATIVE, CRITERION): X; ENDSETS DATA: X= 1.200 3.800 1.467 4.400 2.000 3.800 1.467 4.933 1.733 4.733 3.000 3.800 1.533 4.533 3.000 3.933 3.800 4.000; N_inputs=1;

w= 0.50, 0.50; !w={wi,wr);

ENDDATA MAX = @SUM(DMU (K): E(K)); @FOR(DMU(K):E(K) = @SUM(CRITERION(J)|j#GT# N_inputs :u(K)*(X(K,J)^w(J) )) ); !Constraints; @FOR(DMU(K): @SUM(CRITERION(J)|J#LE#N_inputs :v(K)*(X(K, J)^w(J) )) = 1 ); @FOR(DMU(K): @FOR(ALTERNATIVE(I): @SUM(CRITERION(J)|j#GT#N_inputs :u(K)*(X(I, J)^w(J) )) <= @SUM(CRITERION(J)|J#LE# N_inputs :@SUM(CRITERION(J):v(K)*(X(I, J)^w(J))) ))); @FOR(DMU(K): u(K)>=0); END |

The Lingo code solved was used to present the Ekk values in the final column of Table 1. This was followed by the application of Minitab statistical software to derive the optimal parameters, leading to the S/N Ratios of the Ekk response listed in Table 3.

Table 3 Response table for S/N Ratios of the Ekk response for the fish scale scraping machine problem

Experiment | Speed (rpm) | Time (seconds) | Capacity (kg) |

1 | -1.0790 | -0.2732 | -2.8642 |

2 | -1.7148 | -1.8304 | -1.8470 |

3 | -3.2312 | -3.9213 | -1.3138 |

Delta | 2.1522 | 3.6481 | 1.5504 |

Rank | 2 | 1 | 3 |

The higher delta value presented in the table shows that process parameters have a more significant impact on the multi-response performance indicator. Consequently, the delta statistics showed that the Ekk response was most influenced by the time (T) followed by speed (S), and then capacity (C). It is important to state that the main effects plot for S/N ratios are shown in Figure 3. The method ensured the selected parameters achieved the maximum desired outcomes, offering a robust framework for optimizing the fish scale scraping machine.

Figure 3 The main effects plot for S/N ratios of the Ekk for the fish scale scraping machine

Figure 3 shows that the optimal parameters to achieve the desired Ekk are a speed of 50 rpm, a time of 180 seconds, and a capacity of 30 kg. Moreover, the ANOVA results for the Ekk response are presented in the following Table 4.

Table 4 ANOVA for S/N ratios for Ekk response for the fish scale scraping machine

Source | DF | Seq SS | Adj SS | Adj MS | F | P |

Speed | 2 | 7.3354 | 7.3354 | 3.6677 | 25.55 | 0.038 |

Time | 2 | 20.1053 | 20.1053 | 10.0527 | 70.03 | 0.014 |

Capacity | 2 | 3.7228 | 3.7228 | 1.8614 | 12.97 | 0.072 |

Residual Error | 2 | 0.2871 | 0.2871 | 0.1435 |

|

|

Total | 8 | 31.4506 |

|

|

|

|

Source | DF | Seq SS | Adj SS | Adj MS | F | P |

The efficiency scores Ekk for each run, derived from the DEAV model calculations, were subjected to ANOVA. The analysis showed that the factors of speed (S), time (T), and capacity (C) significantly influenced the Ekk response at P-values less than 0.05, showing strong statistical significance. Moreover, a detailed comparison of the proposed method with other MADMs such as TOPSIS-LP (Sriburum, Wichapa, and Khanthirat, 2023), TOPSIS (Hwang et al., 1981), WASPAS (Zavadskas et al., 2012), and ARAS (Zavadskas and Turskis, 2010), COPRAS (Zavadskas, Kaklauskas, and Šarka, 1994), and MOORA with the full multiplicative form (Brauers and Zavadskas, 2010) is presented in Table 5.

Table 5 ANOVA for S/N ratios for Ekk response for the fish scale scraping machine

Methods | Original parameters | Optimal parameters |

Proposed | S2: F1: D2 | S1: F1: D3 |

TOPSIS-LP | S2: F1: D2 | S1: F1: D3 |

TOPSIS | S2: F1: D2 | S1: F1: D3 |

WASPAS | S2: F1: D2 | S1: F1: D3 |

ARAS | S1: F1: D1 | S1: F1: D3 |

COPRAS | S1: F1: D1 | S1: F1: D3 |

MOORA | S2: F1: D2 | S1: F1: D3 |

The comparison showed that the optimal parameters identified were consistent (S1:F1:D3) across the majority of MADM methods. The consistency confirmed the robustness and reliability of these methods in optimizing the parameters for the fish scale scraping machine. Moreover, the ranking alternatives of the DEAV model were evaluated against different MADM methods using the original parameters, specifically the decision matrix from Table 1, with weights wR1= 0.50 and wR2 = 0.50 in Table 6 and Figure 4.

Table 6 The ranking comparison of the proposed DEAV model against established MADM methods

Run | DEAV | Rank | TOPSIS | Rank | WASPAS | Rank | ARAS | Rank | TOPSIS | Rank | WASPAS | Rank |

1 | 0.9704 | 2 | 0.8088 | 4 | 0.8814 | 2 | 0.8351 | 1 | 1.0000 | 1 | 1.9263 | 2 |

2 | 0.9444 | 3 | 0.8568 | 2 | 0.8546 | 3 | 0.7204 | 3 | 0.8528 | 3 | 1.8245 | 3 |

3 | 0.7517 | 6 | 0.6408 | 6 | 0.6825 | 6 | 0.4547 | 6 | 0.5351 | 6 | 1.1558 | 6 |

4 | 1.0000 | 1 | 0.9004 | 1 | 0.9067 | 1 | 0.8033 | 2 | 0.9471 | 2 | 2.0455 | 1 |

5 | 0.9012 | 5 | 0.7964 | 5 | 0.8205 | 5 | 0.6584 | 5 | 0.7727 | 5 | 1.6613 | 5 |

6 | 0.6137 | 8 | 0.2961 | 8 | 0.5701 | 8 | 0.3358 | 8 | 0.3898 | 8 | 0.7705 | 8 |

7 | 0.9377 | 4 | 0.8527 | 3 | 0.8495 | 4 | 0.7067 | 4 | 0.8344 | 4 | 1.7987 | 4 |

8 | 0.6244 | 7 | 0.2994 | 7 | 0.5817 | 7 | 0.3530 | 7 | 0.4093 | 7 | 0.7975 | 7 |

9 | 0.5595 | 9 | 0.0394 | 9 | 0.5347 | 9 | 0.3260 | 9 | 0.3756 | 9 | 0.6403 | 9 |

Figure 5 The Spearman correlation coefficients for the fish scale scraping machine problem

Figure 5 shows the Spearman correlation coefficients for the comparison between the DEAV model and other well-known MADM methods. The results provided a strong correlation in ranking alternatives between the DEAV model and other MADM methods. These were specifically observed through the 0.950 recorded with TOPSIS, 0.983 with both ARAS and COPRAS, and a perfect 1.00 with WASPAS and MOORA. The high values showed that the DEAV model produced rankings considered significantly consistent with those generated by established MADM methods, thereby validating the effectiveness and reliability in multi-criteria decision-making contexts.

3.2. The case study of the CNC turning process applied to ST37 steel

Computer Numerical Control (CNC) turning introduced in the 1950s has been widely used for producing precise and complex components across different industries. The technology enables high-precision and repeatable manufacturing processes by automating the control of machining tools through programmed instructions. This capability is specifically important in industries such as aerospace, automotive, and electronics, where stringent demands for precision and consistency are predominant. In aerospace, CNC turning manufactures components with tight tolerances which are important for safety and performance, while in automotive, it produces engine parts and transmission components with high precision. The electronics industry also benefits from CNC turning by producing intricate device components that require meticulous accuracy. This is due to the ability of CNC machine to enhance efficiency, reduce human error, and allow for the production of complex geometries unachievable with manual methods. Consequently, technology is a cornerstone of modern manufacturing, driving technological advancements and significantly improving product quality.

ST37 steel is a commonly used material in different industrial settings and considered the ideal subject for this study due to the extensive use and the complexity of the machining process. CNC turning of ST37 steel requires multiple responses, including surface roughness and material removal rate. These responses are critical to the overall performance and cost-effectiveness of the manufacturing process and are considered part of the challenging MRO problems. Therefore, some important steps are required to solve problem which include (1) preparing the ST37 steel specimens, (2) identifying the relevant factors with levels and responses, (3) applying Taguchi method for experimental design, and (4) determining the optimal parameters for machining using a novel DEAV-Taguchi method.

3.2.1. The results of the experiment conducted using Taguchi method

Table 7 The details of the other experimental results based on Taguchi method

Runs | S | F | D | Ra | MRR |

1 | 1000 | 0.06 | 0.1 | 1.790 | 548 |

2 | 1000 | 0.11 | 0.3 | 1.799 | 2,827 |

3 | 1000 | 0.16 | 0.5 | 1.895 | 6,087 |

4 | 2000 | 0.06 | 0.3 | 1.357 | 2,904 |

5 | 2000 | 0.11 | 0.5 | 1.382 | 7,209 |

6 | 2000 | 0.16 | 0.1 | 2.117 | 2,628 |

7 | 3000 | 0.06 | 0.5 | 1.349 | 7,025 |

8 | 3000 | 0.11 | 0.1 | 2.024 | 3,598 |

9 | 3000 | 0.16 | 0.3 | 2.013 | 10,525 |

Figure 7 The main effects plot for S/N ratios of the MRR response

The optimal parameters to achieve the desired Ra were found in Figure 6 to be a speed of 2000 rpm, a feed rate of 0.06 mm/rev, and a depth of cut of 0.5 mm. Meanwhile, the values to achieve the desired MRR were recorded to be 3000 rpm, 0.16 mm/rev, and 0.5 mm respectively in Figure 7. The ANOVA results for both responses are also presented in Tables 8 and 9, respectively.

Table 8 ANOVA for S/N ratios for the Ra response

Source | DF | Seq SS | Adj SS | Adj MS | F | P |

Speed | 2 | 2.5275 | 2.5275 | 1.26374 | 97.37 | 0.010 |

Feed rate | 2 | 10.2382 | 10.2382 | 5.11912 | 394.42 | 0.003 |

Dept of cut | 2 | 7.6113 | 7.6113 | 3.80567 | 293.22 | 0.003 |

Residual Error | 2 | 0.0260 | 0.0260 | 0.01298 |

|

|

Total | 8 | 20.4030 |

|

|

|

|

S | 2 | 2.5275 | 2.5275 | 1.26374 | 97.37 | 0.010 |

Table 9 ANOVA for S/N ratios for the MRR response

Source | DF | Seq SS | Adj SS | Adj MS | F | P |

Speed | 2 | 140.396 | 140.396 | 70.198 | 61.71 | 0.016 |

Feed rate | 2 | 97.103 | 97.103 | 48.551 | 42.68 | 0.023 |

Dept of cut | 2 | 219.880 | 219.880 | 109.940 | 96.65 | 0.010 |

Residual Error | 2 | 2.275 | 2.275 | 1.138 |

|

|

Total | 8 | 459.653 |

|

|

|

|

S | 2 | 140.396 | 140.396 | 70.198 | 61.71 | 0.016 |

The factors of speed (S), feed rate (F), and depth of cut (D) were found to have a significant effect on both the Ra and MRR responses, with P-values less than 0.05. This showed that the determination of the optimal parameters for the two conflicting responses presented a significant challenge due to the need to balance opposing objectives. Therefore, the MRO problem was planned to be solved through the proposed method. This was achieved by using the DEAV model to integrate the two responses for each experimental run into efficiency scores. Subsequently, the Minitab statistical software version 19 was applied to optimize the parameters for the CNC turning machine for ST37 steel based on Taguchi method. The detailed calculation steps of the proposed method are presented in the following section.

3.2.2. Determining the optimal parameters using the DEAV model with the sensitivity analysis and Taguchi method

The initial decision matrix was obtained as shown in Table 10. The purpose of the matrix was to be used in calculating the efficiency scores of the DMUs or runs using the following steps:

Table 10 The initial decision matrix for the case study

Runs | Ra (µm) | MRR (mm3/min) |

1 | 1.790 | 548 |

2 | 1.799 | 2,827 |

3 | 1.895 | 6,087 |

4 | 1.357 | 2,904 |

5 | 1.382 | 7,209 |

6 | 2.117 | 2,628 |

7 | 1.349 | 7,025 |

8 | 2.024 | 3,598 |

9 | 2.013 | 10,525 |

(1) The efficiency scores of each DMU using the DEAV model

Sensitivity analysis was used to ascertain the weight of each criterion. This was achieved through the application of the weight adjustment method across nine scenarios to examine the impact of different weight distributions on the criteria. The scenarios are presented as follows:

Scenario#1: Allocation of 90% to the Ra response and 10% to the MRR response.

Scenario#2: Allocation of 80% to the Ra response and 20% to the MRR response.

Scenario#3: Allocation of 70% to the Ra response and 30% to the MRR response.

Scenario#4: Allocation of 60% to the Ra response and 40% to the MRR response.

Scenario#5: Equal allocation of 50% to the Ra response and 50% to the MRR response.

Scenario#6: Allocation of 40% to the Ra response and 60% to the MRR response.

Scenario#7: Allocation of 30% to the Ra response and 70% to the MRR response.

Scenario#8: Allocation of 20% to the Ra response and 80% to the MRR response.

Scenario#9: Allocation of 10% to the Ra response and 90% to the MRR response.

The DEAV model was used to integrate the two responses into a single efficiency score for each run. These efficiency scores were analyzed using the Taguchi method in Minitab version 19 to determine the optimal parameters for the CNC turning process. Model (2) was used to calculate the efficiency of each DMU, which in this context was represented by each run. The DEAV model was implemented using Lingo software with relevant parameters, including the Ra, MRR, and the weights for each response, integrated into the Lingo code. An example of the efficiency calculation for Scenario#5 presented in Table 11 shows the step-by-step process and methods used to determine the efficiency scores of each DMU within the given scenario. This was necessary to clarify how the input and output variables were processed and the application of the criteria weights determined through sensitivity analysis to generate the final efficiency scores.

Table 11 The details of the Lingo code for Scenario#5

Lingo code for the DEAV model |

MODEL: SETS: ALTERNATIVE/1..9/: ; CRITERION/1..2/:w; DMU/1..9/: E,u,v; IJ(ALTERNATIVE, CRITERION): X; ENDSETS DATA: X= 1.790, 548 1.799, 2827 1.895, 6087 1.357, 2904 1.382, 7209 2.117, 2628 1.349, 7025 2.024, 3598 2.013, 10525; N_inputs=1; w= 0.50, 0.50; !w={wi,wr); ENDDATA MAX = @SUM(DMU (K): E(K)); @FOR(DMU(K):E(K) = @SUM(CRITERION(J)|j#GT# N_inputs :u(K)*(X(K,J)^w(J) )) ); Constraints; @FOR(DMU(K): @SUM(CRITERION(J)|J#LE#N_inputs :v(K)*(X(K, J)^w(J) )) = 1 ); @FOR(DMU(K): @FOR(ALTERNATIVE(I): @SUM(CRITERION(J)|j#GT#N_inputs :u(K)*(X(I, J)^w(J) )) <= @SUM(CRITERION(J)|J#LE# N_inputs :@SUM(CRITERION(J):v(K)*(X(I, J)^w(J))) ))); @FOR(DMU(K): u(K)>=0); END |

Table 12 The ranking comparison of the proposed DEAV model against established MADM methods

Runs | Parameters | Ra (µm) | MRR (mm3/min) | Ekk |

1 | S1: F1: D1 | 1.790 | 548 | 0.2420 |

2 | S1: F2: D2 | 1.799 | 2,827 | 0.5482 |

3 | S1:F3: D3 | 1.895 | 6,087 | 0.7838 |

4 | S2:F1: D2 | 1.357 | 2,904 | 0.6398 |

5 | S2: F2: D3 | 1.382 | 7,209 | 0.9988 |

6 | S2: F3: D1 | 2.117 | 2,628 | 0.4873 |

7 | S3: F1:D3 | 1.349 | 7,025 | 0.9980 |

8 | S3: F2: D1 | 2.024 | 3,598 | 0.5831 |

9 | S3: F3: D2 | 2.013 | 10,525 | 1.0000 |

The execution of the Lingo code led to the determination of the efficiency scores (Ekk) for Scenario #5 in Table 12. This was followed by the application of the larger-is-better criterion of Taguchi to identify the optimal parametric conditions. The S/N Ratios of the Ekk response are presented in Table 13.

Table 13 Response table for S/N Ratios of the Ekk response

Experiment | S | F | D |

1 | -6.5537 | -5.4072 | -7.7515 |

2 | -3.3782 | -3.3054 | -3.0335 |

3 | -1.5676 | -2.7869 | -0.7145 |

Delta | 4.9862 | 2.6203 | 7.0370 |

Rank | 2 | 3 | 1 |

The higher delta value presented in the table shows that process parameters have a more significant impact on the multi-response performance indicator. Consequently, the delta statistics showed that the Ekk response was most influenced by the depth of cut (D), followed by speed (S), and then feed rate (F). It is important to state that the main effects plot for S/N ratios are shown in Figure 8. The method ensured the selected parameters achieved the maximum desired outcomes, offering a robust framework for optimizing the CNC turning process of ST37 steel.

Figure 8 The main effects

plot for S/N ratios of the Ekk

The analysis showed that the optimal

parameters to achieve the desired Ekk were a speed of 3,000

rpm, a feed rate of 0.16 mm/rev, and a depth of cut of 0.5 mm. Moreover, the

ANOVA results for the Ekk response are presented in Table 14.

Table 14 ANOVA for S/N ratios for the Ekk response

|

Source |

DF |

Seq SS |

Adj SS |

Adj MS |

F |

P |

|

Speed |

2 |

38.224 |

38.2242 |

19.1121 |

83.82 |

0.012 |

|

Feed rate |

2 |

11.552 |

11.5525 |

5.7762 |

25.33 |

0.038 |

|

Depth of cut |

2 |

77.158 |

77.1575 |

38.5788 |

169.20 |

0.006 |

|

Residual Error |

2 |

0.456 |

0.4560 |

0.2280 |

|

|

|

Total |

8 |

127.390 |

|

|

|

|

|

S |

2 |

38.224 |

38.2242 |

19.1121 |

83.82 |

0.012 |

The efficiency scores Ekk

for each run, derived from the DEAV model calculations, were subjected to

ANOVA. The analysis showed that the factors of speed (S), feed rate (F),

and depth of cut (D) significantly influenced the Ekk

response at P-values less than 0.05, showing strong statistical significance.

(1)

Sensitivity analysis

Sensitivity analysis is a

method widely used to ensure the reliability and stability of solutions.

Therefore, a comprehensive two-phase sensitivity analysis was adopted in this

study. In the first phase, nine scenarios were developed to model different weights

of criteria with a reflection of the emphasis on the Ra value over the MRR

value. This was achieved using the weight adjustment method as stated in Step

(1) to examine the impact of different weight distributions on the criteria.

The same calculation steps applied to evaluate the Ekk as in Scenario #5 were used for other scenarios with the results

presented in Table 15.

Table 15 The

efficiency scores (Ekk) for all scenarios

|

Ekk |

|||||||||

|

Sc.#1 |

Sc.#2 |

Sc. #3 |

Sc. #4 |

Sc. #5 |

Sc.#6 |

Sc.#7 |

Sc. #8 |

Sc. #9 |

|

|

1 |

0.6007 |

0.4788 |

0.3816 |

0.3042 |

0.2420 |

0.1780 |

0.1309 |

0.0963 |

0.0708 |

|

2 |

0.7046 |

0.6621 |

0.6221 |

0.5846 |

0.5482 |

0.4753 |

0.4121 |

0.3573 |

0.3098 |

|

3 |

0.7260 |

0.7404 |

0.7551 |

0.7701 |

0.7838 |

0.7376 |

0.6941 |

0.6531 |

0.6146 |

|

4 |

0.9106 |

0.8341 |

0.7640 |

0.6998 |

0.6398 |

0.5407 |

0.4570 |

0.3863 |

0.3265 |

|

5 |

0.9810 |

0.9859 |

0.9909 |

0.9958 |

0.9988 |

0.9262 |

0.8589 |

0.7965 |

0.7386 |

|

6 |

0.6042 |

0.5728 |

0.5431 |

0.5150 |

0.4873 |

0.4263 |

0.3729 |

0.3262 |

0.2854 |

|

7 |

1.0000 |

1.0000 |

1.0000 |

1.0000 |

0.9980 |

0.9208 |

0.8497 |

0.7840 |

0.7234 |

|

8 |

0.6492 |

0.6323 |

0.6159 |

0.5999 |

0.5831 |

0.5240 |

0.4710 |

0.4233 |

0.3804 |

|

9 |

0.7263 |

0.7871 |

0.8531 |

0.9246 |

1.0000 |

1.0000 |

1.0000 |

1.0000 |

1.0000 |

The efficiency values of all scenarios were

subsequently utilized to calculate the optimal parameters and predicted Taguchi

results for each case using Minitab version 19. Therefore, Table 16 presents

the optimal parameters with the predicted responses of alternatives for the

nine scenarios. Table

16 focuses on selecting the most suitable experimental outcomes, with a clear

prioritization of MRR over Ra. Optimization strategy aims to maximize MRR,

achieving 10,603 mm³/min while maintaining Ra at 1.851 µm. Moreover, the

optimal parameters identified were a speed of 3000 rpm, a feed rate of 0.16

mm/rev, and a depth of cut of 0.5 mm. These "optimal parameters" were

determined through the Taguchi method, targeting the best settings to enhance

overall machining efficiency and performance. The predicted values labeled

"Predict Taguchi results" were further obtained using Minitab version

19 to forecast the outcomes based on the determined parameter settings.

Table 16 A

comprehensive comparison of the optimal parameters across nine distinct

scenarios

|

Scenarios |

Original parameters |

Optimal parameters |

Predict Taguchi results |

|

|

Ra (µm) |

MRR (mm3/min) |

|||

|

Scenario#

1 |

S3: F1: D3 |

S2: F1: D3 |

1.165 |

4,879 |

|

Scenario#

2 |

S3: F1: D3 |

S3: F2: D3 |

1.578 |

8,734 |

|

Scenario#

3 |

S3: F1: D3 |

S3: F2: D3 |

1.578 |

8,734 |

|

Scenario#

4 |

S3: F1: D3 |

S3: F3: D3 |

1.851 |

8,766 |

|

Scenario#

5 |

S3: F3: D2 |

S3: F3: D3 |

1.851 |

10,603 |

|

Scenario#

6 |

S3: F3: D2 |

S3: F3: D3 |

1.851 |

10,603 |

|

Scenario#

7 |

S3: F3: D2 |

S3: F3: D3 |

1.851 |

10,603 |

|

Scenario#

8 |

S3: F3: D2 |

S3: F3: D3 |

1.851 |

10,603 |

|

Scenario#

9 |

S3: F3: D2 |

S3: F3: D3 |

1.851 |

10,603 |

The optimal

parameters S3:F3:D3 were selected when the importance weight of the MRR

criterion was equal to or greater than for the Ra criterion. However, in a

situation where the Ra criterion had more significance, the optimal parameters

were changed. For example, in Scenario #3, the optimal parameters shifted to

S3:F2:D3 when 70% weight was on the Ra response and 30% on the MRR response. In

scenarios where the Ra response was significantly prioritized over the MRR

criterion, such as in Scenario #1, the optimal parameters were adjusted to a

speed of 2000 rpm, a feed rate of 0.06 mm/rev, and a depth of cut of 0.5 mm.

This showed the choice of parameters mainly depended on the required surface

finish quality for specific applications.

The

second phase was focused on using different MADM methods for a comparative

analysis through the application of the data obtained from the DEAV model in

Section 3.2.2.1. The decision matrix from Table 5 with weights assigned as wRa = 0.50 and wMRR = 0.50 were used for the

analysis. The detailed comparison of the proposed method with other MADM such

as TOPSIS (Hwang et al., 1981),

WASPAS (Zavadskas et al., 2012), and

ARAS (Zavadskas and Turskis, 2010), COPRAS (Zavadskas,

Kaklauskas, and Šarka, 1994), DEAR (Liao and

Chen, 2002; Kamath et al., 2022),

and MOORA with the full multiplicative form (Brauers

and Zavadskas, 2010) is presented in Table 17. This was necessary to

determine the effectiveness and robustness of the proposed solution.

Table 17 A

comprehensive comparison of the optimal parameters across various MADM methods

|

Methods |

Original

parameters |

Optimal

parameters |

|

|

Proposed |

S3: F3: D2 |

S3: F3: D3 |

|

|

TOPSIS |

S3: F3: D2 |

S3: F3: D3 |

|

|

WASPAS |

S3: F3: D2 |

S3: F3: D3 |

|

|

ARAS |

S3: F3: D2 |

S3: F3: D3 |

|

|

COPRAS |

S3: F3: D2 |

S3: F3: D3 |

|

|

DEAR |

S3: F3: D2 |

S3: F3: D3 |

|

|

MOORA |

S3: F3: D2 |

S3: F3: D3 |

The comparison showed

that the optimal parameters identified were consistent (S3:F3:D3) across the

majority of MADM methods. This consistency further confirmed the robustness and

reliability of the methods in optimizing the parameters for the CNC turning

process of ST37 steel. The uniformity across different MADM methods also

suggests the parameters are optimal to achieve the desired performance metrics.

The

ranking alternatives of the DEAV model were compared with different MADM

methods using the original parameters, specifically the decision matrix from

Table 10, with weights wRa = 0.50 and wMRR = 0.50. The

results obtained from the comparison process are presented in Table 18 while

the Spearman correlation coefficients are shown in Figure 9.

Table 18 The

ranking comparison of the proposed DEAV model against established MADM methods

|

Run |

DEAV |

Rank |

TOPSIS |

Rank |

WASPAS |

Rank |

ARAS |

Rank |

COPRAS |

Rank |

MOORA |

Rank |

|

1 |

0.2420 |

9 |

0.0936 |

9 |

0.3005 |

9 |

0.3225 |

9 |

0.3505 |

9 |

0.3102 |

9 |

|

2 |

0.5482 |

7 |

0.2415 |

7 |

0.4790 |

7 |

0.4541 |

7 |

0.5052 |

7 |

0.7028 |

7 |

|

3 |

0.7838 |

4 |

0.5395 |

4 |

0.6434 |

4 |

0.6298 |

4 |

0.7130 |

4 |

1.0048 |

4 |

|

4 |

0.6398 |

5 |

0.3070 |

5 |

0.5794 |

5 |

0.5528 |

5 |

0.6119 |

5 |

0.8202 |

5 |

|

5 |

0.9988 |

2 |

0.6803 |

2 |

0.8241 |

3 |

0.7972 |

2 |

0.8997 |

2 |

1.2805 |

2 |

|

6 |

0.4873 |

8 |

0.2010 |

8 |

0.4212 |

8 |

0.3991 |

8 |

0.4448 |

8 |

0.6247 |

8 |

|

7 |

0.9980 |

3 |

0.6642 |

3 |

0.8254 |

2 |

0.7957 |

3 |

0.8970 |

3 |

1.2794 |

3 |

|

8 |

0.5831 |

6 |

0.2970 |

6 |

0.4908 |

6 |

0.4670 |

6 |

0.5235 |

6 |

0.7475 |

6 |

|

9 |

1.0000 |

1 |

0.8254 |

1 |

0.8268 |

1 |

0.8728 |

1 |

1.0000 |

1 |

1.2820 |

1 |

Figure 9 The Spearman

correlation coefficients for optimizing CNC turning of ST37 steel

(3)

Experimental validation

A

confirmation test was conducted using the optimal parameters identified by the

proposed method, which were a speed of 3000 rpm, a feed rate of 0.16 mm/rev,

and a depth of cut of 0.5 mm. The results showed that the predicted Ra and MRR

values were 1.851µm and 10,603 mm3/min as presented in Table 14. The

optimal parameters were tested in 12 replications and the results were close to

the actual experiment within 95% confidence level as shown in Table 19.

Table 19 Confirmation

test at 95% confidence interval (CI).

|

Responses |

95% CI |

Means |

Predicted |

|

|

Low |

High |

|||

|

Ra |

1.752 |

1.858 |

1.805 |

1.851 |

|

MRR |

10611 |

10763 |

10,687 |

10,603 |

Figure 9 The Spearman

correlation coefficients for optimizing CNC turning of ST37 steel

In conclusion, MRO was found to be important

in modern manufacturing, where achieving efficiency and quality required

considering multiple performance metrics simultaneously. The need for

innovative strategies was due to the fact that traditional optimization methods

often struggled to balance conflicting objectives. This study presented a novel

hybrid method for MRO by combining the DEAV model with Taguchi method. The DEAV

model was used to improve on traditional DEA by incorporating MADM principles,

offering a comprehensive evaluation of performance metrics. Taguchi method was

later used to optimize parameters based on the efficiency scores of the DEAV

model.

The

proposed method was a systematic process initiated through the identification

of relevant factors, determination of the critical variables influencing

process outcomes, and the subsequent respective levels. Taguchi method was

applied to design experiments using orthogonal arrays in order to efficiently

study the effects of multiple variables. Subsequently, the DEAV model was

formulated to convert response values into a single efficiency score for each

experimental run. Optimization was achieved by analyzing these efficiency

scores using Taguchi method to identify optimal parameters based on

signal-to-noise (S/N) ratios. The method was later validated through numerical

examples by optimizing a fish scale scraping machine and the CNC turning

process of ST37 steel.

The

results showed that the DEAV-Taguchi method provided more efficient and

reliable outcomes than existing methods. Specifically, it significantly

improved scaling efficiency by 15% and reduced fish damage by 10% for the fish

scale scraping machine. For the CNC turning process of ST37 steel, the method

enhanced surface roughness by 10.33% through a reduction from 2.013 µm

to 1.805 µm and increased the material removal rate (MRR) by 1.54% from 10,525

mm3/min to 10,687 mm³/min.

This

study contributed a robust and adaptable optimization framework that integrates

DEA and MADM principles with the systematic Taguchi method, effectively

addressing MRO complexities and demonstrating versatility across different

manufacturing processes. However, the findings were limited to specific

applications, such as a fish scale scraping machine and CNC turning of ST37

steel, suggesting a need for further experiments to validate broader

applicability across materials and processes. Economic impacts of optimized

parameters were also not fully explored, signalling the need for future

research to assess these dimensions for improved practical value. The

integration of MADM and Taguchi required careful consideration of inherent

limitations, urging future studies to address potential biases for greater

reliability. Key recommendations include validating the method with diverse

materials and processes, expanding experimental designs to better understand

parameter interactions, and assessing economic and environmental impacts to

enhance sustainability insights. Additionally, combining the DEAV model with

other optimization and weighting techniques (e.g., CRITIC, Entropy, AHP, BWM)

could increase adaptability and robustness, expanding the model's relevance in

MADM scenarios by supporting more nuanced, criteria-based decision-making for

complex industrial applications.

The author wishes to extend heartfelt

gratitude to Kalasin University, Udonthani Rajabhat University, and Rajabhat

Rajanagarindra University for their invaluable support and resources, which

were instrumental in conducting this study. Additionally, the author expresses

sincere appreciation to the reviewers for their thoughtful feedback and

constructive suggestions, which significantly enriched the quality and rigor of

this research.

Conflict of Interest

The

authors declared that there was no known competing financial interests or

personal relationships capable of influencing the results reported in this

study.

| Filename | Description |

|---|---|

| R1-IE-7134-20240717160642.jpg | --- |

Abdelaoui, F.Z.E., Jabri, A., Barkany, A. E., 2023. Optimization Techniques for Energy Efficiency In Machining Processes—A Review. The International Journal of Advanced Manufacturing Technology, Volume 125(7), pp. 2967–3001

Brauers, W.K.M., Zavadskas, E.K., 2010. Project Management by MULTIMOORA As an Instrument for Transition Economies. Technological and Economic Development of Economy, Volume 16(1), pp. 5–24. https://doi.org/10.3846/TEDE.2010.01

Charnes, A., Cooper, W.W., Rhodes, E., 1978. Measuring The Efficiency of Decision-Making Units. European Journal of Operational Research, Volume 2(6), pp. 429–444. https://doi.org/10.17485/IJST%2F2012%2FV5I12%2F30612

Chen, W.H., Huang, T.H., Luo, D., Jin, L., Maduabuchi, C., Lamba, R., Hoang, A. T., 2024. Optimization of a Unileg Thermoelectric Generator by the Combination of Taguchi Method and Evolutionary Neural Network for Green Power Generation. Applied Thermal Engineering, Volume 248, p. 123204.

https://doi.org/10.1016/j.applthermaleng.2024.123204

Fan, Y., Bai, B., Qiao, Q., Kang, P., Zhang, Y., Guo, J., 2017. Study On Eco-Efficiency of Industrial Parks in China Based on Data Envelopment Analysis. Journal of Environmental Management, Volume 192, pp.107–115.

.https://doi.org/10.1016/j.jenvman.2017.01.048

Hwang, C.L., Yoon, K., Hwang, C.L., Yoon, K., 1981. Methods For Multiple Attribute Decision Making: Lecture Notes in Economics and Mathematical Systems. Springer-Berlin, Heidelberg, Volume186, pp. 58–191.

https://doi.org/10.1016/0377-2217%2888%2990267-6

Kamath, G. B., Subramaniam, K., Devesh, S., Chavan, V., Mohan, N., Bhat, R., Wijerathne, H. T., 2022. Multi-Response Optimization of Milling Process Parameters for Aluminium-Titanium Diboride Metal Matrix Composite Machining Using Taguchi-Data Envelopment Analysis Ranking Approach. Engineered Science, Volume 18, pp. 271–277. http://dx.doi.org/10.30919/es8d680

Kannan, S., Varatharajulu, M., Hariharasakthisudhan, P., Logesh, K., 2023. Identification of the Effect of Strontium and Ytterbium Addition Over Magnesium Zinc Alloy During the Drilling Process with ARAS And WASPAS Techniques. Materials Chemistry and Physics, Volume 309, p. 128320. https://doi.org/10.1016/j.matchemphys.2023.128320

Kantasiri, T., Kasemsiri, P., Pongsa, U., Posi, P., Chindaprasirt, P., 2024. Optimization of Concrete Containing Waste Crumb Rubber Mix Design for Thermal Insulating Applications Using Taguchi Method. Construction and Building Materials, Volume 434, p. 136636. https://doi.org/10.1016/j.conbuildmat.2024.136636

Kumar, R., Kumar, S., A?bulut, Ü., Gürel, A.E., Alwetaishi, M., Shaik, S., Saleel, C.A., Lee, D., 2024. Parametric Optimization of an Impingement Jet Solar Air Heater for Active Green Heating in Buildings Using Hybrid CRITIC-COPRAS Approach. International Journal of Thermal Sciences, Volume 197, p. 108760.

https://doi.org/10.1016/j.ijthermalsci.2023.108760

Kumar, R.S., Kumar, S.D., Rajkumar, S., 2022. Multi-Response Optimization of AISI H11 Using Taguchi and Grey Relational Analysis. Materials Research Express, Volume 9(10), p. 106508. https://doi.org/10.1088/2053-1591%2Fac95fe

Lestari, W.D., Adyono, N., Faizin, A.K., Haqiyah, A., Sanjaya, K.H., Nugroho, A., Kusmasari, W., Ammarullah, M.I., 2024. Optimization Of 3D Printed Parameters for Socket Prosthetic Manufacturing Using the Taguchi Method and Response Surface Methodology. Results in Engineering, Volume 21, p. 101847. https://doi.org/10.1016/j.rineng.2024.101847

Li, F., Zhu, Q., Chen, Z., Xue, H., 2018. A Balanced Data Envelopment Analysis Cross-Efficiency Evaluation Approach. Expert Systems with Applications, Volume 106, pp. 154–168. https://doi.org/10.1108/dta-01-2020-0003

Li, M.J., Lu, J.C., Chen, L., 2022. A Method to Determine the Integrated Weights of Cross-Efficiency Aggregation. Soft Computing, Volume 26(14), pp. 6825–6837. https://doi.org/10.1007/s00500-022-06926-y

Liao, H.C., Chen, Y.K., 2002. Optimizing Multi-Response Problem in the Taguchi Method by DEA-Based Ranking Method. International Journal of Quality & Reliability Management, Volume 19(7), pp. 825–837. https://doi.org/10.1108/02656710210434766

Liu, M., Duan, C., Li, G., Cai, Y., Wang, F., Li, L., 2023. Multi-Response Optimization of Ni-Based Laser Cladding via Principal Component Analysis and Grey Relational Analysis. Optik, Volume 287, p.171122. https://doi.org/10.1016/j.ijleo.2023.171122

Moganapriya, C., Rajasekar, R., 2023. Dry Machining Characteristics of Coated Inserts and Multi-Response Optimization Through DEAR-Taguchi Method. Materialwissenschaft und Werkstofftechnik, Volume 54(6), pp. 751–760. https://doi.org/10.1002/mawe.202200166

Pawaree, N., Phokha, S., Phukapak, C., 2024. Multi-Response Optimization of Charcoal Briquettes Process for Green Economy Using a Novel TOPSIS Linear Programming and Genetic Algorithms Based on Response Surface Methodology. Results in Engineering, Volume 22, p. 102226. https://doi.org/10.1016/j.rineng.2024.102226

Shi, H., Wang, Y., Zhang, X., 2019. A Cross-Efficiency Evaluation Method Based on Evaluation Criteria Balanced on Interval Weights. Symmetry, Volume 11(12), p. 1503. https://doi.org/10.3390/sym11121503

Shi, H.L., Chen, S.Q., Chen, L., Wang, Y.M., 2021. A Neutral Cross-Efficiency Evaluation Method Based on Interval Reference Points in Consideration of Bounded Rational Behavior. European Journal of Operational Research, Volume 290(3), pp. 1098–1110. https://doi.org/10.1016/j.ejor.2020.08.055

Shivakumar, M.R., Panchangam, M.K., 2024. Multi-Response Optimization of Reinforcement Parameters of Aluminum Alloy Composites by Taguchi Method and Grey Relational Analysis. Heliyon, Volume 10(9), p. e30183.

https://doi.org/10.1016/j.heliyon.2024.e30183

Soori, M., Arezoo, B., Dastres, R., 2023. Machine Learning and Artificial Intelligence in CNC Machine Tools: A Review. Sustainable Manufacturing and Service Economics, Volume 2, p. 100009. https://doi.org/10.1016/j.smse.2023.100009

Sriburum, A., Wichapa, N., Khanthirat, W., 2023. A Novel TOPSIS Linear Programming Model Based on the Taguchi Method for Solving the Multi-Response Optimization Problems: A Case Study of a Fish Scale Scraping Machine. Engineered Science, Volume 23, p. 882.

https://doi.org/10.30919/es882

Sristi, N.A., Zaman, P.B., Dhar, N.R., 2022. Multi-Response Optimization of Hard Turning Parameters: A Comparison Between Different Hybrid Taguchi-Based MCDM Methods. International Journal on Interactive Design and Manufacturing, Volume 16(4), pp.1779–1795. https://doi.org/10.1007/s12008-022-00849-6

Sulaiman, S., Alajmi, M.S., Isahak, W.N.W., Yusuf, M., Sayuti, M., 2022. Dry Milling Machining: Optimization of Cutting Parameters Affecting Surface Roughness of Aluminum 6061 using the Taguchi Method. International Journal of Technology, Volume 13(1), pp. 291–319. https://doi.org/10.14716/ijtech.v13i1.4208

Parr, W. C., 1989. Introduction to Quality Engineering: Designing Quality Into Products and Processes. Technometrics, Volume 31(2), pp.255–256. https://doi.org/10.1080/00401706.1989.10488520.

To-on, P., Wichapa, N., Khanthirat, W., 2023. A Novel TOPSIS Linear Programming Model Based on Response Surface Methodology for Determining Optimal Mixture Proportions of Lightweight Concrete Blocks Containing Sugarcane Bagasse Ash. Heliyon, Volume 9(7), p. e17755. https://doi.org/10.1016/j.heliyon.2023.e17755

Vellaiyan, S., Amirthagadeswaran, K.S., Sivasamy, D. B., 2018. Taguchi-Grey Relation Based Multi-Response Optimization of Diesel Engine Operating Parameters with Water-in-Diesel Emulsion Fuel. International Journal of Technology, Volume 9(1), pp. 68–77. https://doi.org/10.14716/IJTECH.V9I1.1374

Wang, C.N., Nguyen, X. T., Wang, Y.H., 2016. Automobile Industry Strategic Alliance Partner Selection: The Application of a Hybrid DEA and Grey Theory Model. Sustainability, Volume 8(2), p. 173. https://doi.org/10.3390/SU8020173

Yang, B., Zhang, G., Ran, Y., Yu, H., 2019. Kinematic Modelling and Machining Precision Analysis of Multi-Axis CNC Machine Tools Based on Screw Theory. Mechanism and Machine Theory, Volume 140, pp. 538–552.

https://doi.org/10.1016/J.MECHMACHTHEORY.2019.06.021

Yang, W.C., Yang, J.Y., Kim, R.C., Om, M.S., Kim, U.H., Ri, W.S., Sok, S.H., 2023. Multi-Attribute Optimization and Influence Assessment Methodology of Casting Process Parameters Combined with Integrated MADM and Taguchi Method. The International Journal of Advanced Manufacturing Technology, Volume 129(1), pp. 681–695. https://doi.org/10.1007/s00170-023-12275-3

Yaser, E.K.M., Shunmugesh, K., 2019. Multi-Objective Optimization of Milling Process Parameters in Glass Fiber-Reinforced Polymer Via Grey Relational Analysis and Desirability Function. Materials Today: Proceedings, Volume 11, pp. 1015–1023. https://doi.org/10.1016/J.MATPR.2018.12.032

Zavadskas, E. K., Turskis, Z., 2010. A new additive ratio assessment (ARAS) method in multicriteria decision?making. Ukio Technologinis Ir Ekonominis Vystymas, Volume 16(2), pp.159–172. https://doi.org/10.3846/tede.2010.10

Zavadskas, E.K., Turskis, Z., 2010. A New Additive Ratio Assessment (ARAS) Method in Multicriteria Decision?Making. Technological and economic development of economy, Volume 16(2), pp.159–172. https://doi.org/10.3846/TEDE.2010.10

Zavadskas, E.K., Turskis, Z., Antucheviciene, J., Zakarevicius, A., 2012. Optimization of Weighted Aggregated Sum Product Assessment. Elektronika ir Elektrotechnika, Volume 122(6), pp. 3–6. https://doi.org/10.5755/J01.EEE.122.6.1810

Zavadskas, E.K., Turskis, Z., Kildien?, S., 2014. State of the Art Surveys of Overviews on MCDM/MADM Methods. Technological and Economic Development of Economy, Volume 20(1), pp. 165–179. https://doi.org/10.3846/20294913.2014.892037

Zhujani, F., Abdullahu, F., Todorov, G., Kamberov, K., 2024. Optimization of Multiple Performance Characteristics for CNC Turning of Inconel 718 Using Taguchi–Grey Relational Approach and Analysis of Variance. Metals, Volume 14(2), p. 186. https://doi.org/10.3390/met14020186