Synthesis, Characterization, and Application of Poly(Styrene-Co-Glycidyl Methacrylate) as Reactive Diluents to Epoxy Resin

Corresponding email: da_ainakulova@kbtu.kz

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6920

Tulegenkyzy, A.D., Megat-Yusoff, P.S.M., Al Azzam, K.M., Kairatovna, B.L., Goyal, A., Eshmaiel, G., Negim, E.-S., Samy, M., Ravindran, B., 2024. Synthesis, Characterization, and Application of Poly(Styrene-Co-Glycidyl Methacrylate) as Reactive Diluents to Epoxy Resin. International Journal of Technology. Volume 15(4), pp. 903-916

| Ainakulova Dana Tulegenkyzy | School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole bi 59, 050000, Almaty, Kazakhstan |

| Puteri Sri Melor Megat-Yusoff | Mechanical Engineering Department, Universiti Teknologi PETRONAS, Bandar Seri Iskandar 32610, Perak, Malaysia |

| Khaldun Mohammad Al Azzam | Department of Chemistry, Faculty of Science, The University of Jordan, 11942 Amman, Jordan |

| Bekbayeva Lyazzat Kairatovna | National Nanotechnology Open Laboratory, Al-Faraby Kazakh National University, 71, Al-Faraby av., 050040, Almaty, Kazakhstan |

| Arpit Goyal | Civil Engineering Department, Thapar Institute of Engineering and Technology, Patiala, Punjab, India- 147001 |

| Ganjian Eshmaiel | Concrete Corrosion Tech LTD, 12 Humphrey Middlemore Drive, Birmingham, England B17 0JN |

| El-sayed Negim | 1 School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole bi 59, 050000, Almaty, Kazakhstan 2 School of Petroleum Engineering, Satbayev University, 22 Satbay |

| Moshera Samy | Polymers and Pigments Department, National Research Centre, 33 El Bouhoth St., Dokki, Giza 12622, Egypt |

| Balasubramani Ravindran | Department of Environmental Energy and Engineering, Kyonggi Unversity, Youngtong-Gu, Suwon 16277, Gyeonggi-Do, South Korea |

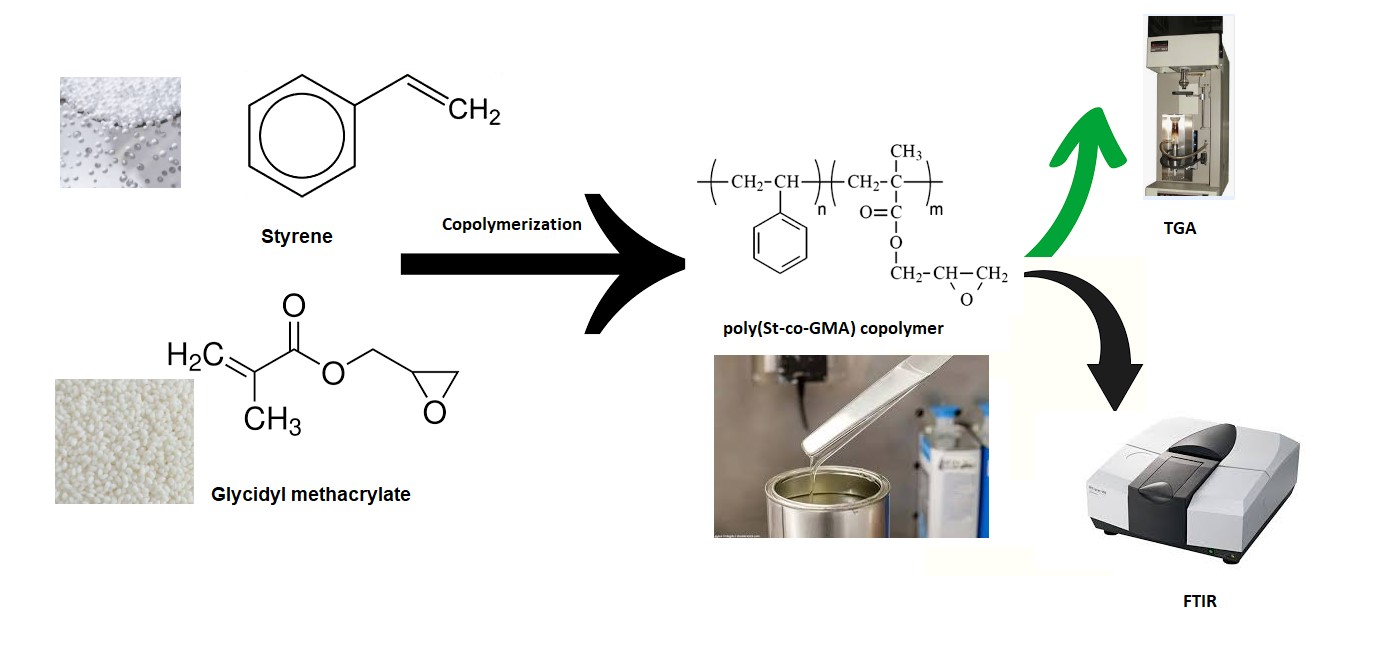

Anticorrosion coatings

are specialized products designed to protect metal surfaces from costly and

dangerous corrosion, acting as barriers against corrosive organisms. Therefore,

this study examined the physical and mechanical properties of epoxy resin in

the presence of reactive diluents. Reactive diluents were synthesized based on

styrene (St) and glycidyl methacrylate (GMA) through the free radical method

using benzoyl peroxide (BPO) as a catalyst with various feed ratios of St and

GMA. Diluents were characterized by Fourier Transform Infrared (FTIR)

spectroscopy and Thermogravimetric Analyzer (TGA). Epoxy resins and hardener

were at a ratio of 1:1, 1:0.5, and 1:0.3, respectively. The results showed that

reactive diluents [Poly(St-co-GMA)] had an excellent dilution effect on

epoxy resin with a decrease in epoxy resin viscosity from 8592 mPa-s to 1656,

680, and 430 mPa-s. Furthermore, the adhesion, tensile, and hardness properties

contained 70% GMA and 30% St at a hardener ratio of 1:0.3. The increase in the mechanical properties was attributed

to the reaction between modified epoxy resins with hardener.

Epoxy; Hardener; Mechanical properties; Reactive diluents; Styrene

Corrosion is a natural process that causes metal surfaces to degrade and fail, posing potential costs and hazards. These surfaces can be protected with anticorrosion coatings, which serve as barriers against corrosive organisms (Ainakulova et al., 2023; Ningrum et al., 2023; Devianto et al., 2023; Riyanto et al., 2023). Various anticorrosion coatings offer unique properties and application methods, among which the organic types are potentially helpful in preventing corrosion on metal surfaces (Msekh et al., 2018; Fu and Cheng, 2011). Some recently improved methods include epoxy polymers, characterized by excellent adhesion, chemical resistance, and durability properties. Most epoxy resins comprised aromatic rings and two heteroatoms, namely P, O, N, and S (Dagdag et al., 2020; Makhlouf, 2014). Hardener or cross-linking agent plays an important role in curing epoxy resins at room temperature. The mechanical properties of these resins depend on the type and characteristics of hardener, such as concentration and temperature (Najuma and Lity, 2014; Jain et al., 2006). Furthermore, reliable analytical methods that efficiently measure the groups in epoxy resins are crucial for synthesis and product quality control. The different application methods require low viscosities, particularly in coating industries. Meanwhile, reducing epoxy resin viscosities often entailed using organic solvents, which can harm both health and the environment (Pineda et al., 2016). The preliminary study focused on the exploration of alternative methods, such as reactive diluents rather than organic solvents. These diluents typically contained oxirane ring compounds, namely glycidyl methacrylate, benzyl glycidyl ether, 1, 4-butanediol diglycidyl ether, etc (Jingyu, Haichao, and Guoxin, 2022; Tran et al., 2020). Polymers with epoxide groups, such as glycidyl methacrylate (GMA), are categorized as epoxy resins (Tzoumani et al., 2022) and have been widely used in a variety of applications, including surface coatings, electrical laminates, adhesives, and molding compounds (Pramanik, Mendon, and Rawlins, 2012; Teh et al., 2007; Wang et al., 2005). Epoxy groups in polymers significantly impact the effective performance in diverse applications (Maruyama, 2001), which enable GMA-based copolymers to enhance coating adhesion, barrier properties, corrosion protection, and service life. Meanwhile, free radical solution polymerization offered advantages such as block copolymers with monomers (Asha et al., 2019). Azzahari et al. (2012) used free radical polymerization in toluene with BPO as an initiator to produce new copolymers from various feed compositions of GMA and tetrahydrofurfuryl acrylate (THFA). The thermal stability of copolymers rises as the THFA content increases. Srikanth et al. (2007) carried out a research to determine the methods needed to produce copolymers from different feed ratios of N-(acryloyloxymethyl) benzotriazole (AMBT) and GMA using the free radical solution polymerization process. Epoxy groups in acrylate anticorrosion coatings produced densely packed, cross-linked coatings, which enhanced corrosion protection due to the stronger chemical bonds. The result improved corrosion protection and prolonged service life for the coated metal substrates. Therefore, this study aimed to prepare Poly(St-co-GMA) copolymers as reactive diluents to reduce viscosity of epoxy resin as well as improve the physical and mechanical properties, including adhesion and thermal characteristics in the presence of an amine-based hardener at a ratio of 1:1, 1:0.5 and 1:0.3. During copolymerization process with GMA, styrene (St) played a critical role by increasing the rate of polymerization and improving the mechanical properties of epoxy resins such as thermal, mechanical, and chemical resistance (Mehmet, 2000). The prepared Poly(St-co-GMA) copolymers were characterized using Fourier Transform Infrared (FTIR) spectroscopy and Thermogravimetric Analyzer (TGA).

2.1. Materials

Epoxy resins ELM-NG 1000

and hardener ELM-NG 34H were supplied by Elcos Marketing LLP, Kazakhstan.

ELM-NG 1000 had an epoxy value ranging from 5.25 to 5.5 eq/Kg, with a weight

per epoxide, viscosity, and density of 182 g/eq, 8500 mPa-s at 25oC

and 1.16 gm/cm3, respectively. Meanwhile, ELM-NG

34H had an amine value and viscosity of 298 mgKOH/g and 254 mPa-s at 25oC.

Major chemicals, namely glycidyl methacrylate (GMA97%), St, xylene, and

benzoyl peroxide (BPO) were purchased from Sigma-Aldrich and used as received.

2.2. Synthesis of Poly(St-co-GMA) copolymer

Copolymerization

process included combining St and GMA with different feed monomer compositions,

namely M1= 70/30, M2= 50/50, and M3 = 30/70, using the free radical

polymerization method in the presence of xylene as a solvent. The solution

medium was put into a 500 mL three-necked flask system equipped with a stirrer,

reflux condenser, and thermometer. The catalyst BPO was added to the flask

while stirring mechanically at 500 to 600 rpm, maintaining a temperature of 65

2.3. Characterization of Poly[St-co-GMA]

copolymer

The

prepared Poly[St-co-GMA] copolymer was characterized using ALPHA FTIR

spectroscopy, Bruker. FTIR spectroscopy and TGA were used to identify and study

the functional groups of copolymers and the thermal properties, respectively.

The per-dried copolymers were tested using Perkin Elmer TGA (TGA/SDTA851e,

METTLER TOLEDO, Switzerland). Furthermore, the measurements were carried out at

room temperature and heating rates of 900°C and 10°C/min under the atmosphere.

2.4. Tests

The viscosity (mPa-s) of

epoxy resins and reactive diluents were measured at room temperature using a

Brookfield viscometer, according to ISO 12058-1 (ISO,

2018), at a speed of 5 and 50 rpm. Meanwhile,

epoxy value (eq/Kg) and weight per epoxide g/eq of resins were determined using

the titration method at room temperatures according to ASTM D1652. The

properties of reactive diluents and modified epoxy resins are shown in Tables 1

and 2, respectively.

Table 1 Properties of reactive diluents.

|

Reactive

diluents |

M1 |

M2 |

M3 |

Test

method |

|

Viscosity,

mPa-s |

10 |

14 |

35 |

ISO

12058-1 |

|

Epoxy

value, eq/Kg |

0.31-0.33 |

0.35-0.37 |

0.40-0.43 |

ASTM

D1652 |

|

Weight

per epoxide, g/eq |

130.5 |

138.6 |

142.5 |

ASTM

D1652 |

2.5. Mixing ratio

Epoxy

resins (E0, 90 %) were mixed with reactive diluents (10%) labeled M1, M2, and

M3 using a stirring stick or spatula for 10 minutes, which led to the formation

of epoxy resins denoted as EM1, EM2, and EM3. Additionally, the properties of

these epoxy resins are shown in Table 2.

ELM-NG

34H is a low-viscosity modified cycloaliphatic that functions as hardener when

mixed with epoxy resins in different ratios of 1.0:1.0, 0.5:1.0, and 0.3:1.0. To ensure proper blending, mix the

ingredients slowly and deliberately, making sure to scrape the container for

thorough incorporation.

Finally, apply the epoxy mixture to metal and concrete substrates, and allow it

to cure naturally at room temperature.

Table 2 Properties of epoxy resin mixed with reactive

diluents.

|

Modified

epoxy with reactive diluents |

EM1 |

EM2 |

EM3 |

Test

method |

|

Viscosity,

mPa-s |

430 |

680 |

1656 |

ISO

12058-1 |

|

Epoxy

value, eq/Kg |

4.4 –

4.9 |

4.10 –

4.8 |

4.1 –

5.2 |

ASTM

D1652 |

|

Weight

per epoxide, g/eq |

195 |

210 |

230 |

ASTM

D1652 |

2.6. Film preparation

Epoxy resin (E0) and mixtures with reactive diluents were mixed in a beaker with different hardener ratios of 1:1, 1:0.5, and 1:0.3 to ensure homogeneity. The resulting mixtures were poured into steel molds, forming specimens with dimensions of 7 mm x 7 mm x 7 mm, and allowed to dry at room temperature for 6 days (Negim et al., 2011). The process of mixing and casting is shown in Figure 1.

Figure 1 The process of mixing and casting for film

preparation.

2.7. Mechanical Tests

Steel

films of 12 cm x 6 cm x 1 mm were provided to evaluate mechanical properties

and chemical durability during curing. A cylindrical Mandrel Tester (ASTM D522)

(ASTM, 2001) was used

to assess the resistance of a coated product to cracking and detachment from a

metal substrate when subjected to bending under standard conditions. The

tubular impact (ASTM D2794) (ASTM, 2019) and the economic cross-hatch testers (ASTM D3359) (ASTM, 2001a) were used

to evaluate the film resistance to impact and adhesion of applied coatings,

respectively. Additionally, the adhesion strength measurements of epoxy and

diluted mixture were conducted using pull-out tests according to EN 1542

standard (Krzywinski and Sadowski, 2019).

3.1. Copolymerization

An overview of

copolymerization process of Poly)St-co-GMA( is shown in

Figure 2. This reaction mechanism comprised three distinct steps, initiation

(I), propagation (II), and termination (III), conducted at a temperature of 80oC

for 1 hour.

Several factors, such as monomer reactivity, initiator selection, reaction conditions, and kinetics, must be considered to successfully copolymerize St and GMA. The reactivity ratio of the monomers determined the composition and structure of copolymer. The initiator, typically a free radical, must be compatible with the monomers, desired reaction and decomposition temperatures, solubility, and reactivity. Copolymerization process relied on specific reaction conditions, namely temperature, solvent, and time. The temperature, solvent and reaction time must be suitable for reactivity, compatible, and adequate to complete the process. According to Tzoumani et al. (2022), reaction kinetics played a crucial role in determining the composition and molecular weight distribution of copolymer (Tzoumani et al., 2022).

3.2. FTIR spectral

analysis of Poly(St-co-GMA)

Figure 3 shows FTIR absorption spectra of

GMA, where peaks in 942.18 cm-1 to 814.57 cm-1 were

attributed to the oxirane ring in the structure (Zhao et al., 2018). The intensive peak at 1716.38 cm-1 represents the stretching

vibration of C=O in carbonyl groups. In addition, the peak at 1154.49

Figure 3 FTIR spectra for poly GMA, M1 and M2. Copolymerization process included combining St and GMA with different feed monomer compositions, namely M1= 70/30, and M2= 50/50

3.3. Thermal

properties of Poly(St-co-GMA)

TGA

was used to examine the thermal stabilities, including the impact of various St

and GMA ratios on weight loss in copolymer. TGA thermograms of Poly(St-co-GMA)

with various ratios are in Supplementary 1 (S1). Meanwhile, Table 3 shows the

initial decomposition and maximum polymer degradation temperatures (PDTmax), as

well as weight loss (%) after thermal decomposition.

TGA

curves showed that copolymers experienced three-step degradation processes for

M1, M3 and two steps for M2. The temperature range in the first stage was

between 0°C and 170°C, while the weight loss (%) increased with higher GMA

content, attributed to bound water or impurities. M3 and M1 showed the highest

and lowest weight loss of 29% and 9%, respectively. In the second stage, weight

loss for M1 and M3 started at 170°C and continued to 340°C, while for M2, it

extended from 210oC to 900oC, corresponding to the ester

decomposition and loss of CO2 (Negim et al., 2014; Vitaliy et al., 2003). The analysis led to a

higher weight loss for M2 than M3 and M1. The weight loss for the third stage

started at 340°C and continued to 900°C for M1 and M3. However, an increase in

the GMA ratio caused a decrease and an increase in the weight loss for M3 (19%)

and M1 (29%) due to GMA decomposition. Copolymer, with increased GMA content,

showed exceptional thermal stability and versatility, making it suitable for

various applications. The maximum polymer degradation (PDTmax) was

related to the temperature where the highest rate of weight loss occurred, and it

increased as GMA content in copolymer decreased. Meanwhile, M1 and M3 showed the highest and lowest PDTmax of 400oC,

and 180oC, respectively.

High thermal degradation resistance in materials offered several

advantages, namely structural integrity and performance stability, which made

it suitable for high-temperature applications such as automotive components,

electronic devices, and aerospace, ensuring longevity and reliability.

According to Ramezani

et al. (2023), thermal degradation is a process where the mechanical properties of a

material, such as strength and toughness, deteriorate.

High thermal degradation resistance enabled a material to maintain the

properties even under increased temperatures, improving durability and safety.

This extends the shelf life of the material, reducing the need for frequent

repairs, thereby leading to cost savings and increased efficiency. High thermal

degradation resistance enhanced stability, mechanical properties, extended shelf

life, and thermal cycling resistance. The degradation process is important in

demanding environments under elevated temperature conditions (El-Gamal et al., 2023).

Table 3 Thermal properties of Poly)St-co-GMA( at different feed ratios

|

Sample (%) |

Temperature (°C) |

Weight loss (%) |

PDTmax (°C) |

|

M1 |

0 -170 |

9 |

400 |

|

170 -340 |

26 | ||

|

340 -900 |

29 | ||

|

M2 |

0 -210 |

12 |

320 |

|

210 -900 |

55 | ||

|

M3 |

0-180 |

21 |

180 |

|

180 -330 |

40 | ||

|

330 -900 |

16 |

3.4. Applications with epoxy

3.4.1. Viscosity

Viscosity of epoxy resin

(E0) mixed with 10% reactive diluents of varying composition ratios was

measured at different speeds (5 and 50 rpm) and 25oC, as shown in

Table 4. The results depicted that as the viscosity of E0 decreased, the

spindle speed increased, a phenomenon attributed to the orientation of polymers

in the flow direction and chain deformation (Devrani et al., 2017). Viscosity of epoxy resin decreased when mixed with reactive diluents,

from 8592 mPa-s to 430 mPa-s, 680 mPa-s, and 1656 mPa-s for EM1, EM2, and EM3,

respectively. However, viscosity of epoxy resin increased with a higher ratio

of GMA in reactive diluents. The increase was attributed to the dilution effect

of reactive diluents on epoxy resin and the subsequent increase in weight per

epoxide (g/eq) between cross-linking points (Malburet et al., 2023; Rudawska and Frigione, 2022; Jagtap and More,

2021; Negim et al., 2021; Ozeren and Ozkul, 2018). Viscosity and thixotropic

index are important factors when applying epoxy resins spatially to metal and

concrete substrates. The thixotropic index is a ratio of viscosities at low and

high speeds by a factor of ten. The effect of reactive diluents with different

compositions on Thixotropic index (TI) of epoxy resin is shown in Table 5. TI

of epoxy resin (E0) was 3.58, decreasing to less than 1 when epoxy resin was

diluted with reactive diluents. Furthermore, TI of diluted epoxy resin

increased with a higher ratio of GMA in reactive diluents.

Table

4 Viscosity and

thixotropic index of epoxy resin mixed with reactive diluents.

|

Sample code |

E0 |

EM1 |

EM2 |

EM3 |

|

Viscosity at 5 rpm (mPa-s) |

8592 |

430 |

680 |

1656 |

|

Viscosity at 50 rpm (mPa-s) |

2400 |

1400 |

1150 |

1700 |

|

Thixotropic index (TI) |

3.58 |

0.31 |

0.59 |

0.97 |

3.4.2. Adhesion

The adhesion strength of epoxy resin to

concrete and metal substrates is an important parameter in surface bonding (Naderi, 2008). The effect of reactive diluents with

different compositions on the adhesion strength of epoxy on these surfaces is

shown in Table 5. It was reported that as hardener ratio increased from 0.3 %

to 1.0%, the adhesion strength of epoxy resins mixed with reactive diluents

decreased. The decrease was attributed to the type and ratios of hardener (Vidil et al., 2016; Negim et

al., 2011). The mixed epoxy resin with reactive

diluents increased the adhesion strength compared to the reference epoxy resin

(E0). The rise was due to the presence of epoxy ring in GMA and

increased cross-linking resulting from the interaction between the rings from

epoxy resin and reactive diluents with hardener (Thakor et al., 2021). However, the adhesion strength of epoxy mixture on the concrete and

metal substrates increased with the content of GMA in reactive diluents due to

the increasing epoxy ring in the mixture. EM3 containing 70% GMA had the

highest adhesion strength of 3.34 MPa and 5.12 MPa for metal and concrete mixed

with 0.3% hardener. Meanwhile, EM1 mixed with reactive diluents containing 30%

GMA had the lowest adhesion strength of 2.6 MPa and 3.6 MPa for metal and

concrete mixed with 0.3% hardener.

Table 5

The effect of reactive diluents composition on the adhesion of concrete and

metal substrates.

|

Sample code |

E0 |

EM1 |

EM2 |

EM3 | ||||||||

|

|

Adhesion,

MPa | |||||||||||

|

Epoxy: hardener ratios |

1:0.3 |

1:0.5 |

1:1 |

1:0.3 |

1:0.5 |

1:1 |

1:0.3 |

1:0.5 |

1:1 |

1:0.3 |

1:0.5 |

1:1 |

|

Concrete |

3.33 |

2.82 |

2.45 |

3.6 |

3.12 |

2.58 |

3.91 |

3.4 |

3.1 |

5.12 |

4.58 |

4.35 |

|

Metal |

2.19 |

1.51 |

1.93 |

2.6 |

2.3 |

2.1 |

2.72 |

2.53 |

2.4 |

3.34 |

2.86 |

2.7 |

3.4.3. Tensile strength and elongation at break

Tensile strength of both

pure and modified epoxy resin (E0) with reactive diluents containing different

amounts of GMA is shown in Figure 4. An increase in hardener ratio from 0.3 to

1.0 % correlates to higher tensile strength. Vidil et al. (2016) stated that this was

attributed to the cross-linking between epoxy and hardener. Comparing epoxy E0

mixed with a hardener in the ratio of 1:0.3 had lower tensile strength than

1:1. For modified epoxy, namely EM1 – EM3, reactive diluents affected the

tensile strength of the films. EM3 had the highest GMA content and maximum

tensile strength of 65.3 MPa when mixed with the hardener ratio of 1:1, while

EM1, with the lowest GMA content, had a minimum tensile strength of 57.2 MPa

under the same condition. This disparity was due to the higher cross-linking

observed in sample EM3 compared to EM1 (Huang et al., 2017). Figure 4 shows that tensile

strength increased with increasing viscosity due to the rise in molecular

weight as well as the cross-link of epoxy mixture and hardener (Jie et al., 2022).

Figure 4 Tensile strength of pure

epoxy (E0) and modified epoxies (EM1-EM3) at different hardener ratios

Figure 5 shows that the elongation at the

break of pure and modified epoxy decreased with increasing hardener ratios and

GMA content in reactive diluents due to side effects (Rahman et al., 2012).

Figure

5 Elongation at break

of pure epoxy (E0) and modified epoxies (EM1-EM3) at different hardener ratios.

3.4.4. Hardness

The effect of hardener

ratio and GMA content in reactive diluents on the hardness of epoxy films is

shown in Table 6. The hardness of epoxy films increased with increasing

hardener ratios and GMA content in reactive diluents attributed to the rising

cross-link between epoxy ring (epoxy resin & GMA) and hardener (Szewczak and Maciej, 2020). EM1 with 30% GMA content

and a hardener ratio of 1:0.3 had a lower hardness (78) than EM3 containing 70%

GMA and a hardener of 1:1. Generally, the hardness of epoxy films depended on

different factors, including hardener ratios, diluent type, solvent, and

concentrations (Ozeren and

Ozkul, 2018; Syrmanova et al., 2016; Villanueva et al., 2009). Table 6 shows that

increasing hardener ratios and GMA concentrations in reactive diluents enhanced

the impact resistance and flexibility of cured epoxy-coated films.

Table 6 Mechanical properties

of epoxy resin mixed with different reactive diluents.

|

Sample code |

E0 |

EM1 |

EM2 |

EM3 | ||||||||||

|

Mechanical

properties | ||||||||||||||

|

Epoxy: hardener |

1:0.3 |

1:0.5 |

1:1 |

1:0.3 |

1:0.5 |

1:1 |

1:0.3 |

1:0.5 |

1:1 |

1:0.3 |

1:0.5 |

1:1 | ||

|

Impact test |

P |

P |

F |

F |

P |

P |

F |

P |

P |

P |

P |

P | ||

|

Cylindrical Mandrel |

P |

F |

F |

P |

P |

F |

P |

P |

P |

P |

P |

P | ||

|

Cross Hatch |

p |

F |

F |

P |

P |

F |

P |

P |

P |

P |

P |

P | ||

|

Hardness |

75 |

79 |

80.5 |

78 |

79.5 |

81.9 |

84 |

86.9 |

88.7 |

85 |

86.5 |

89.6 | ||

In conclusion, Poly(St-co-GMA) copolymer, one of reactive diluents for

epoxy resin, was successfully synthesized with various ratios of monomers

(70:30, 50:50, and 30:70 w/w) using free the radical solution polymerization

method to improve the physical and mechanical properties of epoxy resin in the

presence of an amine-based hardener at ratios of 1:1, 1:0.5 and 1:0.3. The incorporation of GMA epoxy groups improved the adhesion of anticorrosion coatings,

barrier properties, thermal stability, and service life. Meanwhile,

mixed epoxy resins enhanced adhesion and tensile strength. Reactive diluents

and hardener with ratios of 30:70 and 1:0.3 had the highest mechanical

properties. The hardness of epoxy films, impact resistance, and flexibility

increased with higher hardener ratios and GMA concentration in reactive

diluents, enhancing mechanical and physical properties. The results provided

insights into optimizing the solvents used in the coating industries,

potentially changing it to solvent-free coatings with exceptional mechanical

properties and reduced environmental pollution. The knowledge and use of

Poly(St-Co-GMA) for various epoxy resin applications improved further by these

initiatives.

This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AP 19676595 Development of high electrically conductive paint for corrosion prevention in concrete structures). Authors also thank to Assoc. Prof. Dr. Anwar Usman from Universiti Brunei Darussalam for his contribution to analyze, finalize and fine tuning this article.

| Filename | Description |

|---|---|

| R1-CE-6920-20240628103021.docx | --- |

Ainakulova, D., Muradova, S., Khaldun, M.A.A., Bekbayeva, L.,

Megat-Yusoff, P., Mukatayeva, Z., Ganjian, E., Negim, E.-S., 2023. Analytical

Review of Conductive Coatings, Cathodic Protection, and Concrete. Kompleksnoe

Ispolzovanie Mineralnogo Syra = Complex Use of Mineral Resources, Volume

329(2), pp. 92–102

American Society for Testing and Materials (ASTM), 2001a. ASTM D3359. Standard Test Methods for Rating Adhesion by Tap Test

American Society for Testing and Materials

(ASTM), 2001b. ASTM D522. Standard Test Methods for Mandrel Bend Test of

Attached Organic Coatings

American Society for

Testing and Materials (ASTM), 2019. ASTM D2794. Standard Test Methods for Resistance of Organic

Coatings to The Effects of Rapid Deformation (Impact)

American Society for Testing and Materials (ASTM), 2019. ASTM D1652. Standard Test Method for

Epoxy Content of Epoxy Resins

Asha, A.B., Srinivas, S., Hao, X., Narain, R., 2019. Enzyme-Responsive

Polymers: Classifications, Properties, Synthesis Strategies, and Applications. Smart

Polymers and their Applications, Volume 2019, pp. 155–189

Azzahari, A.D., Yahya, R., Hassan, A., Sheikh, Md.R.K., 2012. Synthesis

and Characterization of New Copolymers from Glycidyl Methacrylate and

Tetrahydrofurfuryl Acrylate: Determination of Reactivity Ratios. Fibers and

Polymers, Volume 13(5), pp. 555–563

Dagdag, O., Hsissou, R., El-Harfi, A., Berisha, A., Safi, Z., Verma, C.,

Ebenso, E. E., Ebn-Touhami, M., El-Gouri, M., 2020. Fabrication of Polymer

Based Epoxy Resin As Effective Anti-Corrosive Coating For Steel: Computational

Modeling Reinforced Experimental Studies. Surfaces and Interfaces,

Volume 18, p. 100454

Devianto, H., Nurdin, I., Widiatmoko, P., Silvia, D.,

Prakarsa, C., 2023. Tobacco Extract for

Inhibition of Carbon Steel Corrosion in H2S-contained NaCl Solution. International

Journal of Technology, Volume 14(5), pp. 1167-1176

Devrani, S., Sharma, R., Rajesh, M., Kapoor, A., 2017. Exploring Viscoelastic Characteristics of Polymer-Water

Solutions by Viscometric Analysis. Asian Journal of Chemistry, Volume

29(9), pp. 1953–1958

El-Gamal, R., Song, C., Rayan, A.M., Liu, C., Al-Rejaie, S., ElMasry, G.,

2023. Thermal Degradation of Bioactive Compounds During Drying Process of

Horticultural and Agronomic Products: A Comprehensive Overview. Agronomy,

Volume 13(6), p. 1580

Fu, A.Q., Cheng, Y.F., 2011. Characterization of The Permeability of a

High Performance Composite Coating to Cathodic Protection and its Implications

on Pipeline Integrity. Progress in Organic Coatings, Volume 72(3), pp.

423–428

Hermán, V., Takacs, H., Duclairoir, F., Renault, O.,

Tortai, J. H., Viala, B., 2015. Core

Double–Shell Cobalt/Graphene/Polystyrene Magnetic Nanocomposites Synthesized By

In Situ Sonochemical Polymerization. RSC Advances, Volume 5(63), pp.

51371–51381

Huang, Y., Tian, Y., Li, Y., Tan, X., Li, Q., Cheng, J., Zhang, J., 2017.

High Mechanical Properties of Epoxy Networks with Dangling Chains and Tunable

Microphase Separation Structure. RSC Advances, Volume 7(77), pp.

49074–49082

International Organization for Standardization (ISO), 2018. ISO 12058-1. International Standard: Determination of

Viscosity Using a Falling-Ball Viscometer

Jagtap, A.R., More, A., 2021. Developments in Reactive Diluents: A Review.

Polymer Bulletin, Volume 79(8), pp. 5667–5708

Jain, R., Kukrejia, P., Naryla, A.K., Chaudhary, V.K., 2006. Studies of

The Curing Kinetics and Thermal Stability of Epoxy Resins Using a Mixture of

Amines and Anhydrides. Journal of Applied Polymer Science, Volume 100,

pp. 3919–3925

Jie, J., Qingwen, S., Ran, Z., Zhi, S., Jiani, W.,

2022. Viscosity, Mechanical Properties, and

Phase-Separated Morphology of Waterborne Epoxy Asphalt. Construction and

Building Materials, Volume 334, p. 127074

Jingyu, L., Haichao, Z., Guoxin, S., 2022. Renewable Green Reactive

Diluent for Bisphenol a Epoxy Resin System: Curing Kinetics And Properties. RSC

Advances, Volume 12, pp. 31699–31710

Krzywinski, K., Sadowski, L., 2019. The Effect of Texturing of the Surface of Concrete Substrate on the

Pull-Off Strength of Epoxy Resin Coating. Coatings, Volume 9,

p. 143.

Makhlouf, A.S.H., 2014. Protective Coatings for Automotive, Aerospace and

Military Applications: Current Prospects And Future Trends. In Handbook of

Smart Coatings for Materials Protection, pp. 121–131

Malburet, S., Bertrand, H., Richard, C., Lacabanne, C., Dantras, E.,

Graillot, A., 2023. Biobased Epoxy Reactive Diluents Prepared from Monophenol

Derivatives: Effect on Viscosity and Glass Transition Temperature of Epoxy

Resins. RSC Advances, Volume 13(22), pp. 15099–15106

Maruyama, T., 2001. FT-IR Analysis of BSA Fouled on Ultrafiltration and

Microfiltration Membranes. Journal of Membrane Science, Volume 192(1-2),

pp. 201–207

Mehmet, D., 2000. Styrene Polymers and Copolymers. Applied Polymer

Science: 21st Century, pp. 93–106

Msekh, M.A., Cuong, N.H., Zi, G., Areias, P., Zhuang, X., Rabczuk, T.,

2018. Fracture Properties Prediction of Clay/Epoxy Nanocomposites With

Interphase Zones Using A Phase Field Model. Engineering Fracture Mechanics,

Volume 188, pp. 287–299

Naderi, M., 2008. Adhesion of Different Concrete Repair Systems Exposed to

Different Environments. The Journal of Adhesion, Volume 84(1), pp.

78–104

Najuma, A.R., Lity, A.V., 2014. The Effect of Various Hardeners on The

Mechanical and Thermal Properties of Epoxy Resin. International Journal of

Engineering Research & Technology, Volume 3(1), pp. 2662–2665

Negim, E.-S., Bekbayeva, L., Irmukhametova, G.,

Kalugin, S., Alfergani, A., 2021. The Effect of

Poly (Propylene Glycol – G – Styrene) on The Physicomechanical Properties of

Unsaturated Polyester Resin. Egyptian Journal of Chemistry, Volume

65(4), pp. 715–722

Negim, E.S.M., Nurpeissova, Zh.A., Mangazbayeva, R.A., Khatib, J.M.,

Williams, C., Mun, G.A., 2014. Effect of pH on the Physic-Mechanical Properties

and Miscibility of Methyl Cellulose/Poly(Acrylic Acid) Blends. Carbohydrate

Polymers, Volume 101, pp. 415-422

Negim, S. M., Bahruddin, S., Mahyuddin, R., Idiris, M.S., 2011. Effects of

TDI and FA-703 on Physico-Mechanical Properties of Polyurethane Dispersion. Journal of Applied

Polymer Science, Volume121(1), pp. 8–13

Ningrum, E.O., Khoiroh, I., Nastiti, H.I., Affan, R.A., Karisma, A.D.,

Agustiani, E., Surono, A., Suroto, H., Suprapto, S., Taji, L.S., Widiyanto, S.,

2023. Surface Coating Effect on Corrosion Resistance of Titanium Alloy Bone

Implants by Anodizing Method. International Journal of Technology.

Volume 14(4), pp. 749-760

Ozeren, E.E., Ozkul, M.H., 2018. Effects of Epoxy, Hardener, and Diluent

Types on The Hardened State Properties of Epoxy Mortars. Construction and

Building Materials, Volume 187, pp. 360–370

Pineda, A.F.E., Garcia, F.G., Simoes, A.Z., Silva, E.L.D., 2016.

Mechanical Properties, Water Absorption And Adhesive Properties of Diepoxy

Aliphatic Diluent-Modified DGEBA/Cycloaliphatic Amine Networks on 316 L

Stainless Steel. International Journal of Adhesion and Adhesives, Volume

68, pp. 205–211

Pramanik, M., Mendon, S.K., Rawlins, J.W., 2012. Determination of Epoxy

Equivalent Weight of Glycidyl Ether Based Epoxides via Near Infrared

Spectroscopy. Polymer Testing, Volume 31(5), pp. 716–721

Rahman, M.M., Hosur, M., Zainuddin, S., Jajam, K.C., Tippur, H.V.,

Jeelani, S., 2012. Mechanical Characterization of Epoxy Composites Modified

with Reactive Polyol Diluent And Randomly-Oriented Amino-Functionalized MWCNTs.

Polymer Testing, Volume 31(8), pp. 1083–1093

Rajiv, P., Deepa, A., Vanathi, P., Vidhya, D., 2017. Screening for Phytochemicals and FTIR Analysis of Myristica

Dactyloids Fruit Extracts. International Journal of Pharmacy and

Pharmaceutical Sciences, Volume 9(1), pp. 315–318

Ramezani, M., Mohd-Ripin, Z., Pasang, T., Jiang, C-P.,

2023. Surface Engineering of Metals:

Techniques, Characterizations and Applications. Metals, Volume 13(7), p.

1299

Riyanto, Jazuli, M.M., Sahroni, I., Musawwa, M.M., Cahyandaru, N.,

Wahyuni, E.T., 2023. A Simple Technique for the Corrosion Inhibition of

Underwater Cannonball from a Shipwreck. International Journal of Technology,

Volume 14(4), pp. 843–853

Rudawska, A., Frigione, M.. 2022. Effect of Diluents on Mechanical

Characteristics of Epoxy Compounds. Polymers, Volume 14(11), p. 2277

Srikanth, A.P., Sunitha, T.G., Raman, V., Nanjundan,

S., Rajendran, N., 2007. Synthesis,

Characterization and Corrosion Protection Properties of

Poly(N-(acryloyloxymethyl) benzotriazole-co-glycidyl methacrylate) Coatings on

Mild Steel. Materials Chemistry and Physics, Volume103(2–3), pp. 241–247

Syrmanova, K., Negim, E., Kaldybekova, J., Tuleuov,

A.M., 2016. Epoxylitane Compositions Modification

with Using Thermoplastic Polyurethane. Oriental Journal of Chemistry,

Volume 32(1), pp. 1–7

Szewczak, A., Maciej S., 2020. Physico-Mechanical and Rheological

Properties of Epoxy Adhesives Modified by Microsilica and Sonication Process.

Materials, Volume 13(23), p. 5310

Teh, P.L., Mariatti, M., Akil, H.M., Yeoh, C.K., Seetharamu, K.N.,

Wagiman, A.N.R., Beh, K.S. 2007. The Properties of Epoxy Resin Coated Silica

Fillers Composites. Materials Letters, Volume 61(11-12), pp. 2156–2158

Thakor, S.G., Rana, V.A., Vankar, H.P., Pandit, T.R., 2021. Dielectric

Spectroscopy and Structural Characterization of Nano-Filler-Loaded Epoxy Resin.

Journal of Advanced Dielectrics, Volume 11(2), pp. 2150011

Tran, A.D., Koch, T., Knaack, P., Liska, R., 2020. Radical Induced

Cationic Frontal Polymerization For Preparation of Epoxy Composites. Composites Part A: Applied

Science and Manufacturing, Volume 132, p.

105855

Tzoumani, I., Soto-Beobide, A., Iatridi, Z., Voyiatzis, G.A., Bokias, G.,

Kallitsis, J.K., 2022. Glycidyl Methacrylate-Based Copolymers as Healing Agents

of Waterborne Polyurethanes. International Journal of Molecular Sciences,

Volume 23(15), pp. 8118–8139

Vidil, T., Tournilhac, F., Musso, S., Robisson, A., Leibler, L., 2016.

Control of Reactions and Network Structures of Epoxy Thermosets. Progress in

Polymer Science, Volume 62, pp. 126–179

Villanueva, M., Fraga, I., Rodríguez-Añón, J.A., Proupín-Castiñeiras, J., 2009.

Study of the Influence of a Reactive Diluent on the Rheological Properties of

an Epoxy-Diamine System. Journal of Thermal Analysis and Calorimetry,

Volume 98(2), pp. 521–525

Vitaliy, V.K., Maria, G.C., Luigi, L., Zauresh, S.N., Grigoriy, A.M.,

Rauash, A.M., 2003. Phase Behaviour of Methylcellulose-Poly(Acrylic Acid)

Blends and Preparation of Related Hydrophilic Films. Polymer International,

Volume 52(1), pp. 62–67

Wang, H., Han, W., Tian, H., Wang, Y., 2005. The Preparation and

Properties of Glass Powder Reinforced Epoxy Resin. Materials Letters, Volume

(1), pp. 94–99

Zhao, J., Wang, S., Zhang, L.,

Wang, C., Zhang, B., 2018. Kinetic, Isotherm, and Thermodynamic Studies for

Ag(I) Adsorption Using Carboxymethyl Functionalized Poly(Glycidyl

Methacrylate). Polymers, Volume 10(10), pp. 1090–1110