Heuristic Approach to Planning Complex Multi-Stage Production Systems

Corresponding email: kapiton.pospelov@spbpu.com

Published at : 29 Dec 2023

Volume : IJtech

Vol 14, No 8 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i8.6833

Pospelov, K.N., Vatamaniuk, I.V., Lundaeva, K.A., Gintciak, A.M., 2023. Heuristic Approach to Planning Complex Multi-Stage Production Systems. International Journal of Technology. Volume 14(8), pp. 1790-1799

| Kapiton N. Pospelov | Peter the Great St. Petersburg Polytechnic University, 29 Polytechnicheskaya st., St. Petersburg, 195251, Russia |

| Irina V. Vatamaniuk | Peter the Great St. Petersburg Polytechnic University, 29 Polytechnicheskaya st., St. Petersburg, 195251, Russia |

| Karina A. Lundaeva | Peter the Great St. Petersburg Polytechnic University, 29 Polytechnicheskaya st., St. Petersburg, 195251, Russia |

| Aleksei M. Gintciak | Peter the Great St. Petersburg Polytechnic University, 29 Polytechnicheskaya st., St. Petersburg, 195251, Russia |

The

paper describes an algorithm for finding a quasi-optimal production plan for

complex production systems that involve moving products through a chain of

linked processes with varying resource sets. The general problem of optimizing

a network of manufacturing enterprises is considered: a set of enterprises

producing homogeneous products is modeled during a process consisting of a set

of sequential operations arranged in a strict sequence. Standard methods for solving

production planning problems are considered. According to the analytical

review, most planning tasks in such systems are resolved using original

techniques. For this reason, a universal heuristic algorithm was

proposed. An algorithm with two branches is also proposed for two cases: for

the case of a known constraint in the system and for an alternative case. The

algorithm is focused on application in production systems in which the acquisition

of empirical data is complicated by the large volume, heterogeneity, and

limited reliability of data. In such systems, quasi-optimization in accordance

with the proposed algorithm will allow for obtaining a satisfactory result with

the permissible and required computing power. The algorithm can be

classified as a greedy algorithm. It is partly based on local optimization and

performs well for production with a long cycle and a small number of products.

For this reason, the approach is recommended for heavy industry, shipbuilding,

aircraft manufacturing, and other productions with a long cycle.

Greedy algorithm; Heuristic techniques; Optimization algorithms; Production planning; Quasi-optimization

Selecting the scenario with the best load and resource distribution that satisfies various optimization criteria is necessary to achieve optimal production performance in a complex production system. To tackle the challenge of establishing an optimal production plan, one effective technique is the automation of production schedules. The introduction of ready-made digital solutions for schedule management is an expensive and difficult option in terms of adaptation to the conditions of a particular enterprise. Therefore, it is recommended to develop algorithms and software requirements tailored to optimize the production plan, considering the specific technological processes and resource constraints of the enterprise in question (Zakharenkov, Mrochek, and Mrochek, 2018). Mathematical techniques deployed to tackle uncomplicated tasks like assignments, workshop tasks, or other discrete and combinatorial optimization problems, can be considered conventional means to resolve production planning problems (Lee, Kim, and Kim 2023; Bengio, Lodi, and Prouvost, 2021). Such methods include linear optimization methods (Yazdani, Khezri, and Benyoucef, 2021), the Hungarian algorithm (Laha and Gupta, 2016), the branch-and-bound algorithm (Li and Qi, 2022), probability theory and simulation methods (Costas et al., 2023); stochastic optimization methods, for instance, swarm-based algorithms, are applicable to certain specific tasks (Zukhruf, Frazila, and Widhiarso, 2020). However, given the complexity of the problem within the framework presented, none of these methods is appropriate.

This

paper examines the general optimization problem for a network of manufacturing

enterprises: a set of enterprises producing similar products is modeled during

a process consisting of a set of consecutive operations arranged in a strict

sequence. The complexity of the task is heightened by diverse resource sets

linked to various processes and distinct resource requirements for different

products, rendering standard allocation solutions and simple linear

optimization algorithms impractical. In addition, when tackling a general task

of this nature, it is crucial to take production constraints – procedures that

are the chain's most ineffective link – into account. In some practical

instances of equivalent systems, the constraints are apparent, while in others,

they necessitate an analysis of the production processes.

At the same time, it is evident that the

mathematical formalization of production processes simplifies the real system

to a certain extent. Hence, the precision of the analytical solution to the

optimization issue in this scenario might not satisfy the decision-makers

requirements in regard to the balance between the result accuracy and

calculation expenses. Therefore, simplifying calculations is an essential task

when designing an algorithm to solve an optimization problem. Solutions

considering this aspect allow for a quasi-optimal (nearly optimal, although not

entirely precise) outcome.

This task is pertinent to enterprises that

undertake a few typical but time-consuming orders, specifically in heavy

industry, shipbuilding, and aircraft construction.

The aim of this study is to present an

algorithm to resolve an optimization issue in a system consisting of orders

placed across multiple enterprises and undergoing several production

procedures. This algorithm is founded on formulating a general optimization

problem and utilizing established mathematical optimization techniques for

production planning. The presented method is oriented to

problem-solving in the universal case of multistage production, which

substantiates the theoretical significance of the study: most of the studied

heuristic algorithms (Halim, Hidayat, and

Aribowo, 2021; Paramita, Karimah, and Yatmo, 2021; Maulidya et al., 2020) are adapted at the moment to solve specific planning

problems.

2.1. Research objective

In general, there are two subtypes of optimization

tasks in production systems with multiple sequential processing operations:

1. In the first instance, the system's constraint is

known; this paper does not address it because its definition is linked to the

techniques of the theory of constraints (Kiran, 2019). In this case, it is essential to consider loading

the system constraint as much as possible.

2. In the latter instance, the constraint is

uncertain, and thus, it is crucial to consider the potential for its discovery

when addressing the issue at hand.

Thus, in the general case, the

problem is formally stated as follows: a specific set of orders N (in

this scenario, referred to as the "order", which is the entity that

passes through the production process from input to output) needs to be

optimally assigned to M productions based on a criterion, such as (1).

is a set of

completion dates for the production processes of the set of N orders.

The element of the set is the

completion date of a particular order.

The problem is typically framed as a single-criterion

optimization problem. Additionally, other optimization criteria can be

introduced, such as maximizing the number of products completed by a given

deadline or optimizing the workload of a specific enterprise within the M

set. These criteria can either replace or supplement the original criterion to

form a multi-criteria optimization task.

The production process comprises P separate

procedures that must be executed in a strict sequence. The procedures and their

execution sequence remain identical, regardless of the enterprise. In general,

transitions between enterprises are not allowed (i.e., it is impossible to

perform pi procedure at one enterprise and p i+1

procedure at another one).

Each enterprise in the M set is characterized

by a set of R resources having a capacity equal to P. Each

enterprise resource is linked one-to-one to the procedure performed at this

enterprise.

For each N set order, an S set is

created containing the essential resources to perform the procedures with a

corresponding P-capacity. Each element in this set is linked one-to-one

to the procedure performed for this order.

For each order, an L set is also established to

determine the duration of the procedures (the capacity of the set is P).

Based on the elements of this set, the objective function max is calculated.

If the system has a known constraint, system (2) takes the form (3):

is the procedure that is restrictive in

nature, assuming a standardized implementation across all enterprises; any deviations from this

standard require adjustments to the system (3).

It is permitted to switch

from system (3) to system (2) even in the case of a known system constraint to

achieve a quasi-optimal state since it is not always possible to achieve full

loading of the constraint. The duration of operations (and the ensuing change

in resource requirements) cannot typically be changed to meet the system (3)

requirements.

2.2. Existing solutions

In

order to formulate the optimization problem in practice and select the optimal

equation, the entire production process is taken into account collectively, and

each of its sections (procedures) is considered separately (Guseinov, Kurbanov, and Melikov, 2014).

The

methods of production process algorithmization are one of the tools for

formalizing the system, which enables proceeding to a series of much smaller

local subtasks with reference to the overall goal of system optimization. The

process algorithmization requires identifying critical actions that are

essential to the overall production process, as well as structuring and

decomposing processes, defining required operations, and establishing their

relationships with one another (Zhuravleva and Sakovich, 2023; Karimov, 2021).

The

algorithm developed under this method for the production process must include a

clear sequence of actions and a list of all resources utilized at each stage to

ensure the attainment of specified production targets. In developing algorithms

for multi-stage processes, the following steps can be distinguished (Dolganov and Zuev, 2015):

1.

Technology analysis, decomposition of multi-stage processes, determination of

the purpose of each subprocess, its sequence, relationship, and place in

achieving the overall goal of the system;

2.

Determination of the required resources, encompassing details concerning their

characteristics such as the capacity of production sites, equipment

accessibility, constraints in processing applications, and additional pertinent

factors.

3.

Calculation of the size of production sites in relation to the types of

products manufactured;

4.

Analysis of applications accepted for processing, estimated duration of

production (based on historical data on completed projects, resource

employment, etc.), required resources, and appropriate production sites;

5.

Calculation of the personnel performing basic technological operations.

The

system is described as a set of production units (divisions, product processing

operations) that are primarily used to analyze resources and their consumption.

The chain links are interconnected by technological dependencies on the work

complexity and the amount of output (Danilov, Ryzhova, and Voinova,

2010).

Shipbuilding

industry optimization can be considered an example of resolving this issue.

Such production sites assemble several product units at the same time. When

drawing up a production plan, it is challenging to create groups of products

from the current order portfolio that are then best assembled simultaneously in

the designated order at the company's assembly sites while also taking into

account the lowest achievable assembly-related costs (Sidorenko

and Khobotov, 2009).

In

addition, similar issues can be resolved using information modeling (Lebedeva and Sompol’tseva, 2020). The product information model is the basis for

building an automated production management system. Designing databases that

contain technological data, including information on necessary equipment and

tools, regulatory and technical documentation, and the procedure for

technological operations, is essential for building information models. Product

information models are used to determine the timing, planning, and need for the

purchase of materials. Possible production scenarios are also generated based

on the manufactured structure's information model, taking into account the

available production capacities (Lebedeva and Sompol’tseva,

2020). It is advisable to use

information models of products when creating a production plan to calculate the

required resource costs and allocate production areas based on orders. It is

possible to identify the optimal strategy for loading the enterprise by comparing

data on the specifics of the applications that were received with the current

utilization of resources.

Additionally,

it is suggested that automated production preparation systems for the

shipbuilding industry be introduced. These systems would be based on the

division of the hull into blocks and sections and the method chosen for forming

the hull on the slipway. A typical technological process of ship assembly is

selected for the incoming application on the basis of databases on common

sections and blocks (Surkov, 2005).

The

analysis of the sources thus reveals that the existing solutions are specific

and are applied to particular production conditions or optimization

functions. An example of such a

solution is a batch scheduling model for a three-stage hybrid Flowshop

producing products with a hierarchical assembly structure, applicable to a

hierarchical shop floor production structure (Maulidya et al., 2020). A similar example is the

development of an algorithm that has as its basis an optimization function for

minimizing the total production time (Halim, Hidayat, and

Aribowo, 2021). A separate area of

research is algorithms for collective production and cooperation (Paramita, Karimah,

and Yatmo, 2021), which are not considered

in this paper due to their inappropriateness to the task at hand. In this

regard, the

creation of

a single

versatile algorithm

might be

of utmost

importance. It also confirms the need for additional

algorithmization so that formal methods of task assignment and optimal

scheduling are applied adaptively, taking into account the specifics of a

particular task.

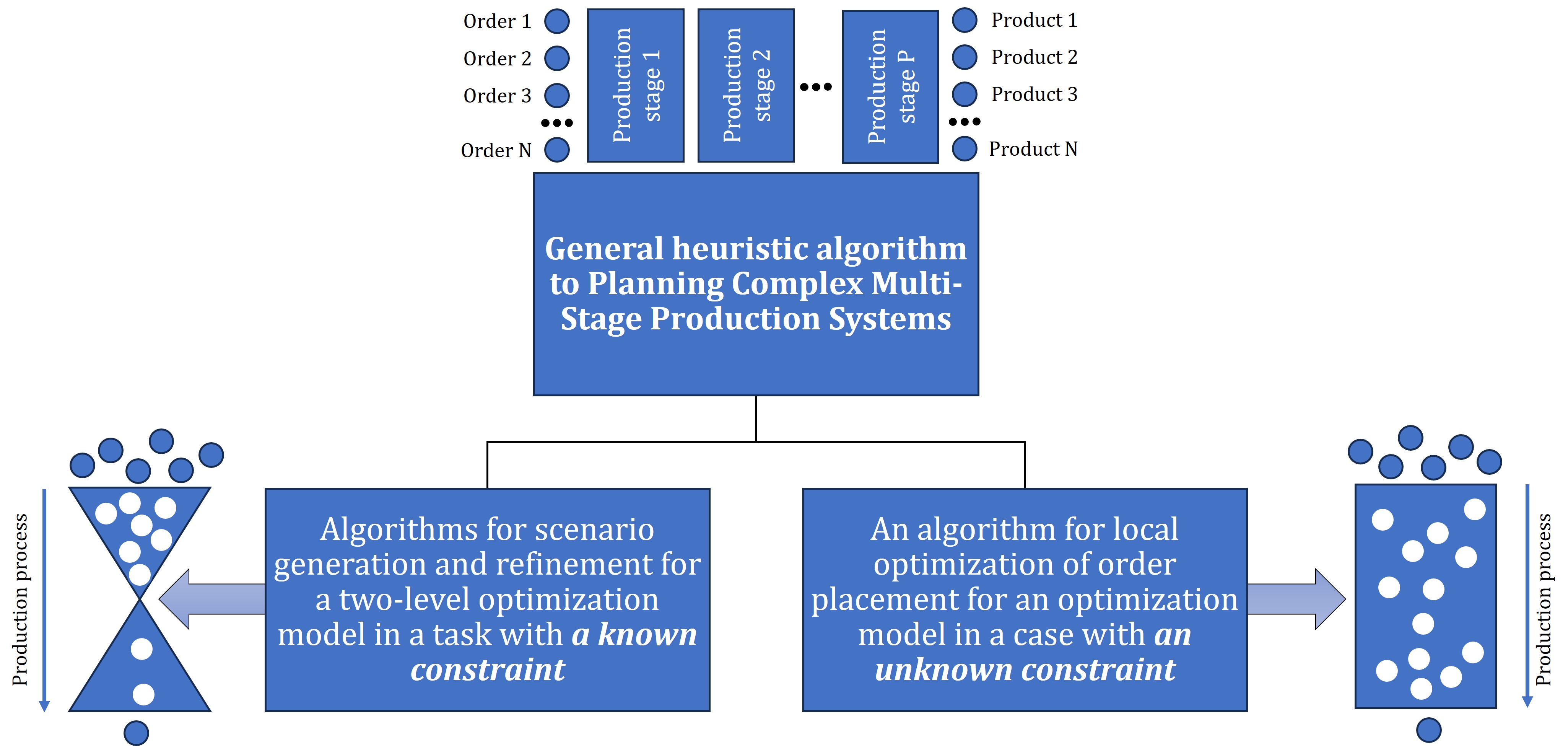

The suggested algorithm handles two variations of

the general problem (with a known or unknown constraint) by adapting to the

conditions. In the case of a known constraint, the optimization model is a

two-level one: at the first level, scenarios are generated based on the

intention to maximize the load of the constraint procedure; at the second

level, the scenarios are refined to form an integral production program. When

the constraint is unknown, a quasi-optimal scenario is formed through

sequential local optimization. This approach minimizes the complexity of the

algorithm implementation. Figure 1 shows the algorithm in broad strokes.

Figure

1 General algorithm for

resolving the optimization issue

A two-level algorithm implies the following

steps:

1. Make a list of potential order assignment

scenarios for enterprises including variations in the processing order and the

method used to select a production site for each order. At this point, only the

constraint procedure – the system's bottleneck – is taken into account.

2. Rank scenarios for assigning performers in

ascending order of the calculated penalty function. When an order is not

fulfilled (not included in the scenario), the penalty is assigned. The penalty

function can also consider the order priority if there is an order

prioritization system. The use of the penalty function is a well-known

technique for finding quasi-optimal states within production planning tasks (Laha and Gupta, 2016).

3. Calculate the schedule for all procedures of

the first few scenarios with the lowest values of the penalty function. At the

same stage, the value of the penalty function's value should be updated subject

to the calculated performer schedules by work groups. It is likely that when

considering scenarios, the penalty functions will change, and the scenario that

was suboptimal at the upper level will become optimal. To achieve this, some

scenarios are refined.

4. Select the best scenario based on the penalty

function recalculation results.

Figure 2 shows the algorithms for the

subprocesses of scenario generation and refinement for a two-level optimization

algorithm.

Figure

2 Algorithms for scenario

generation and refinement for a two-level optimization model in a task with a

known constraint

Let us focus on the areas where it is possible to

specify and improve the two-level algorithm. The penalty function may consider

additional factors (such as the workload of enterprises, the geographic

distance between the business and the customer, etc.) when finalizing and

supplementing data. In addition, the order processing procedure and the

principle of assigning an enterprise to it can both be decided randomly and

based on calculations of the production site’s loads, specializations for

certain orders, etc.

When a

constraint is unknown, a heuristic algorithm for finding a global optimum

through local optimization of order placement is adopted. In order to solve

these issues, heuristic algorithms are used (Ongcunaruk

and Ongcunaruk, 2021; Utama et

al., 2019), since

this enables obtaining a satisfactory result in the absence of sufficient data

and the impossibility of their accurate processing. Low data quality appears

likely when taking into account the complexity of the model system under

consideration.

A

quasi-optimal scenario for the order production in this situation is achieved

by generating many different scenarios, both by chance and by some empirical

dependence (it is allowed to arrange the processing sequence in ascending or

descending order of some order characteristics, for instance, planned labor

intensity). The optimization criterion may also take the form of a penalty

function akin to the description provided for the two-level branch of the

algorithm.

Figure 3 An algorithm for local optimization of order placement

for an optimization model in a case with an unknown constraint

Turning to the discussion,

we highlight the main features of the algorithm, including its limitations, and

describe its primary application areas. We conclude the discussion by noting

the main alternative methods for addressing the presented problems.

It

should be noted that the algorithm in the second variation, based on local

optimization, performs well for production with a long cycle and a small number

of products. In the case of a large number of products, the complexity of the

greedy algorithm increases significantly, which leads to a nonlinear increase

in computational time. For this reason, the approach is recommended for heavy

industry, shipbuilding, aircraft manufacturing, and other productions with a

long cycle. At the same time, prior

research indicates that greedy algorithms for solving such problems are

applicable (Wang et al., 2023).

The

proposed method is focused on the universal case of multi-stage production,

taking into account the principles of the Theory of Constraints, which is an

extension and addition to the existing base of methods. Nevertheless, it also has a number of limitations.

In particular, it implies a fundamental difficulty in determining the

approximation of the quasi-optimal solution to the global optimum, which is a

separate future research problem that has not yet been solved in this paper.

Another limitation is the applicability of the algorithm to production with a

long cycle and a small number of products, which was mentioned above.

The

algorithm has undergone testing for optimization issues in a heavy industry

enterprise. The results obtained enable the creation of sets of scenarios close

to optimal with satisfactory computational time.

In

network tasks, a range of optimization methods can be employed to improve

efficiency. These include adapted methods for solving assignment problems,

workshop tasks, and the branch-and-bound method.

Based

on the results of the formulation of the production process optimization

problem, an algorithm is suggested that can be applied to both problems with

known constraints and problems with unknown constraints. The algorithm is

focused on quasi-optimization, which limits the effectiveness of its

application to the degree of approximation to the globally optimal result. At

the same time, it is not possible to reliably assess this degree at the current

stage - the development of available methods for such determination is the

topic of further research. This particular model for solving production

planning issues is appropriate for heavy industry enterprises characterized by

parallel and long-term manufacturing of high-tech complex products. According

to the analytical review, most planning tasks in such systems are resolved

using original techniques. In certain instances, tasks are accomplished using

empirical patterns, and the production plan is developed manually. Automating

the creation of quasi-optimal scenarios within this industry can prove highly

beneficial and efficient, serving as a valuable tool for generating production

program scenarios and as a component of decision support systems. The algorithm

was tested on the task of compiling a medium-term (5-10 years) production

schedule for a heavy industry enterprise. The main limitation in its practical application,

except for the above-mentioned limitation of approaching the global optimum, is

the speed of computation, which increases strongly with the increase of both

production objects and producing subjects or procedures. In this regard, a

further research task is to speed up the computation both at the level of the

algorithm and in practical program implementation. If this task is solved, it

will be possible to talk about the possibility of applying the algorithm in a

wider range of tasks, including mass production tasks.

The

research is funded by the Ministry of Science and Higher Education of the

Russian Federation (contract No. 075-03-2023-004 dated 13.01.2023).

Bengio, Y., Lodi, A.,

Prouvost, A., 2021. Machine Learning for

Combinatorial Optimization: A Methodological Tour D’horizon. European Journal of Operational Research, Volume 290(2), pp. 405–421

Costas, J., Puche, J., Ponte, B., Gupta, M. C., 2023. An Agent-Based Simulator for Quantifying the Cost of Uncertainty in Production

Systems. Simulation Modelling Practice and Theory, Volume 123, p. 102660

Danilov, G.V., Ryzhova, I.G., Voinova, E.S., 2010. Analysis and Optimization of the Enterprise's

Production Capacity Structure. Scientific and Technical News of the

St. Petersburg State Polytechnic University. Economic Sciences, Volume

4(102), pp. 87–90

Dolganov, K.B., Zuev, V.A., 2015. Features of Creating

a Distribution Center Simulation Model. IMMOD, Volume 2015, pp. 110–114

Guseinov, I.A., Kurbanov, Z.G., Melikov, E.A., 2014. Control of Non-Stationary Multi-Stage Processes in the

Petrochemical Industry. News of the Russian Academy of Sciences. Theory and

Control Systems. Volume 4, p. 90

Halim, A.H., Hidayat, N.P.A., Aribowo, W., 2021. Single Item

Batch-scheduling Model for a Flow Shop with m Batch-processing Machines to

Minimize Total Actual Flow Time. International Journal of Technology, Volume 13(4), pp. 816–826

Karimov, J.H., 2021. Procedures for Optimizing Global Goals of a Multistage Process Control System. Universum Technical Sciences, Volume 11–1 (92), pp. 48–52

Kiran, D.R., 2019.

Chapter 28 - Theory of Constraints. Production Planning and Control. Butterworth-Heinemann

Laha, D., Gupta,

J.N.D., 2016. A Hungarian Penalty-Based Construction Algorithm to

Minimize Makespan and Total Flow Time in No-Wait Flow Shops. Computers &

Industrial Engineering, Volume 98, pp. 373–383

Lebedeva E.G., Sompol’tseva, A.A., 2020. Analysis of the Development of

Technological Processes in the Manufacture of Ship Structures. Marine Smart Technologies, Volume 4-1, pp. 61–68

Lee, J., Kim, B.,

Kim, S.H., 2023. A Matheuristic Algorithm for Block Assignment

Problem in Long-Term Production Planning in the Shipbuilding Industry. Computers &

Industrial Engineering, Volume 184, p. 109603

Li, Y., Qi, X., 2020.

A Geometric Branch-And-Bound Algorithm for the Service Bundle Design Problem. European

Journal of Operational Research, Volume 303(3), pp. 1044-1056

Maulidya, R.,

Suprayogi, Wangsaputra, R., Halim, A.H., 2020. A Batch Scheduling Model for a

Three-stage Hybrid Flowshop Producing Products with Hierarchical Assembly

Structures. International Journal of Technology, Volume 11(3), pp. 608–618

Ongcunaruk, W., Ongkunaruk, P., 2021. A Construction Heuristic for the

Bin-Packing Problem with Time Windows: A Case Study in Thailand. International

Journal of Technology. Volume 12(2), pp. 390–400

Paramita, K.D., Karimah, A., Yatmo, Y.A., 2021. Collective Strategies and Spatialities of Neighborhood

Food Coproduction during COVID-19 Pandemic. International Journal of

Technology. Volume 12(6), pp. 1228–1238

Sidorenko, A.M., Khobotov, E.N., 2009. Production Planning with Parallel

Assembly of Products. News

of the Moscow State Technical University Named After, Volume 3, pp. 100–109

Surkov, K.M., 2005. Automated Development of Technological Processes for Ship Hull Assembly. News of the Astrakhan

State Technical University, Volume 2, pp. 182–187

Utama, D.M., Widodo, D.S., Wicaksono, W., Ardiansyah, L.R., 2019. A New

Hybrid Metaheuristics Algorithm for Minimizing Energy Consumption in the Flow

Shop Scheduling Problem. International Journal of Technology.

Volume 10(2), pp. 320–331

Wang Y., Han Y., Wang Y., Li J., Gao K., Liu Y., 2023. An

Effective Two-Stage Iterated Greedy Algorithm for Distributed Flowshop Group

Scheduling Problem with Setup Time. Expert Systems with Applications, Volume 233, p. 120909

Yazdani, M.A.,

Khezri, A., Benyoucef, L., 2021. A Linear Multi-Objective Optimization Model

for Process and Production Planning Generation in a Sustainable Reconfigurable

Environment. IFAC-Papers OnLine, Volume 54 (1), pp.

689–695

Zakharenkov, K.V., Mrochek, Zh. A., Mrochek, T.V.,

2018. Algorithm for Solution of Multicriterion Problem of Production Planning of Pipes and Shaped Products. System Analysis and Applied Information Science, Volume 4 (9), pp. 4–10

Zhuravleva, N.A., Sakovich, O.I.,2023. Algorithmization of Production

Processes in Freight Rail Service Sales. News of the Scientific Research

Results, Volume 1, pp.

114–124

Zukhruf, F., Frazila, R.B., Widhiarso, W., 2020. A Comparative Study on

Swarm-based Algorithms to Solve the Stochastic Optimization Problem in

Container Terminal Design. International Journal of Technology, Volume 11(2), pp. 374–387