Development of Patient-Specific Adaptive Assistive Devices for Brachial Plexus Injury

Corresponding email: halim471@uitm.edu.my

Published at : 05 Feb 2024

Volume : IJtech

Vol 15, No 2 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i2.6708

Rashid, H., Haremy, C.M., Othman, A.D., Hashim, N.M., Izmin, N.A.N., Abdullah, A.H., 2024. Development of Patient-Specific Adaptive Assistive Devices for Brachial Plexus Injury. International Journal of Technology. Volume 15(2), pp. 404-413

| Helmi Rashid | School of Mechanical Engineering, College of Engineering, Universiti Teknologi MARA (UiTM), 40450 Shah Alam, Selangor, Malaysia |

| Chyesia Moses Haremy | Biomechanical & Clinical Engineering (BioMeC) Research Group, School of Mechanical Engineering, College of Engineering, Universiti Teknologi MARA (UiTM), 40450 Shah Alam, Selangor, Malaysia |

| Ahmad Dzuharuddin Othman | School of Mechanical Engineering, College of Engineering, Universiti Teknologi MARA (UiTM), 40450 Shah Alam, Selangor, Malaysia |

| Natiara Mohamad Hashim | Faculty of Medicine, Universiti Teknologi MARA (UiTM), Sungai Buloh Campus, 47000 Sungai Buloh, Selangor, Malaysia |

| Nor Aiman Nor Izmin | Interdisciplinary Graduate School of Engineering Sciences, Kyushu University, 6-1 Kasuga-koen Kasuga-Shi, Fukuoka, 816-8580 Japan |

| Abdul Halim Abdullah | Biomechanical & Clinical Engineering (BioMeC) Research Group, School of Mechanical Engineering, College of Engineering, Universiti Teknologi MARA (UiTM), 40450 Shah Alam, Selangor, Malaysia |

Injury to the brachial plexus prevents the arm, wrist, and

hand from communicating with the spinal cord in whole or in part. The

'patient's upper arm limb appears to be completely incapable of performing any

type of independent movement. The aim of this project is to design and develop

a customized adaptive assistive device for patients with brachial plexus injury

and to fabricate the prototype using 3D printing technology. The development of

the device involved adapting the mechanical engineering design process,

including conceptual design and finite element analysis, to predict the

performance of the design and to select the best printing materials. The

patient's left arm was 3D scanned to create a customized part that perfectly

fit the patient. The 3D model of the prototype was developed using Autodesk

Fusion 360 and Autodesk TinkerCAD. Two different materials, namely Polylactic

Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS), were considered in the

computational analysis. Results show that the maximum von Misses stress of PLA

is observed at 2.464 MPa, slightly higher than the ABS material (2.451 MPa),

indicating a greater stress tolerance imposed on the material's strength.

However, PLA has a smaller maximum displacement than ABS, at 0.019 mm and 0.030

mm, respectively. The PLA material was chosen for 3D printing based on several

considerations, including mechanical qualities, cost, printing time,

durability, and data evaluation. The adaptive device for brachial plexus injury

was successfully delivered to the patient and demonstrated the capability to

assist in arm movement.

Adaptive assistive device; Brachial plexus injury; Finite element analysis; Patient-specific; 3D printing

An injury to the brachial plexus, the network of nerves that carries impulses from the spinal cord to the shoulder, arm, and hand, is referred to as a brachial plexus injury (BPI), sometimes known as a brachial plexus lesion (National Institute of Neurological Disorders and Stroke, 2008). Injury to the brachial plexus prevents the arm, wrist, and hand from communicating with the spinal cord in whole or in part. Frequently, brachial plexus injuries also leave the area completely numb (Johns Hopkins Medicine, n.d.). Brachial plexus injuries are a major indication of shoulder arthrodesis (Sousa et al., 2013). An injury that suddenly affects these nerves, commonly referred to as a brachial plexus injury, can cause various symptoms such as pain, weakness, numbness, or limited movement in the shoulder, arm, and/or hand (Cleveland Clinic, n.d.).

An assistive device is a device that allows a patient or

user with a disability to perform any daily activity with little to no

assistance from others (Mazlan et al., 2021; Oliver, 2019).

Most patients with illnesses or impairments who receive rehabilitation use

assistive devices. These devices not only reduce

their reliance on caregivers but also enhance their level of functioning and

participation in the community (Levesque and Doumit, 2020). To ensure

the safety of users while using assistive devices, it is crucial to design them

with their limitations in mind. Muscles, which constitute 45% of body weight,

are the predominant type of tissue in the body (Volpi et al., 2022).

With the aid of the nervous system, the muscular system provides the capacity

for movement and performing everyday activities. Due to a lack of product

development experience, medical personnel are having problems creating suitable

assistive equipment that could benefit them. Even engineers who are skilled in

product development lack the medical knowledge necessary to diagnose any issue

that could endanger the patient further (Abas et al., 2023;

Devin et al., 2023; Cutti et al., 2023). The study,

analysis, design, and production of an adaptive assistive device for a patient

with a brachial plexus injury are the focus of this project.

This adaptive aid was created for Patient A, a programmer

with a left arm brachial plexus injury. Due to his left arm's brachial injury,

he finds it challenging to carry out his duties, such as utilising a laptop or

computer while resting his hand on a table. The patient has a history of

brachial plexus damage stretching a few years ago. He is unable to

spontaneously raise his left arm like other individuals. The primary goal of

this study is to develop an orthosis that will allow the patient to raise his left

arm independently without assistance from the other hand. The left limb of the

patient will be 3D scanned to determine how the limb should be shaped for the

device.

The design will be

carried out using commercial computer-aided design (CAD) software, using the 3D

scanned limb as a reference for dimensions (AutoDesk Fusion 360). Before

modelling it in a CAD programme, a few design concepts will be created by

referring to the various adaptive assistive devices that are available to

create the best design under the direction of an expert in rehabilitation. The

study will only concentrate on the Fused Deposition Modelling method of 3D

printing (FDM). In order to achieve the maximum accuracy for the mechanical

properties, the 3D Printing settings will be as follows: 0.1mm layer height,

20% infill, 3 shell layers, and 4 top/bottom layers. For the analysis, only the

commercial program AutoDesk Fusion 360 will be used to simulate Finite Element

Analysis (FEA). Different kinds of materials will not be tested experimentally.

Other options include using 3D Printing technology, which is significantly more

affordable, produces devices more quickly, and allows for patient-specific customisation

(Jonnala,

Sankineni, and Kumar, 2023).

The project starts

with the problem identification from the patient consultation. The concepts can

be filtered by using the Pugh method. The final selection of engineering design

was modelled using CAD software. A static finite element analysis was performed

to predict the product performance before 3D printing fabrication.

2.1. Patient Consultation

In this stage, meeting with the patient was essential to identify and understand the problems before proceeding to generate ideas and concepts to develop a suitable device. The literature review and benchmarking were extensively explored to better understand. Thus, various ideas and concepts were successfully interpreted and generated based on different types of assistive devices (Ahmed and Al-Shammari, 2023; Scherb et al., 2023; Rashid et al., 2012). Figure 1 shows the process flow in this project. The project was initiated by patient consultation with the rehabilitation specialist to identify the problems. The process is followed by a 3D scanning process to capture digitization data of the patient for patient-specific device development. The idea and several concepts were then generated before coming out with a preliminary design. The detailed design was created and analysed computationally before proceeding to the fabrication and testing of the product. In the analysis stage, stress concentration and safety factors were part of the criteria to be considered for the pass-and-fail statement.

Figure 1 Project flow in developing the patient-specific adaptive assistive device

2.2. Conceptual Design

Several ideas to solve the

problem were sketched to get better pictures of the solution. Figure 2 illustrates the

proposed solution, which consists of (a) a harness and (b) an upper and lower

arm holder. The purpose of the holder is to fit the patient's arm securely,

preventing any movement or loosening.

Additionally,

a harness utilizing a customized

strap has been proposed to support the fixation to the patient's body.

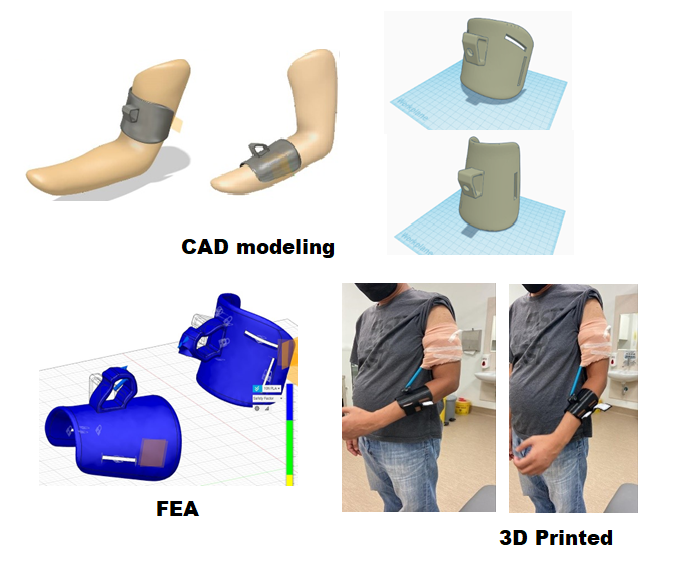

2.3. CAD Design and Modeling

3D scanning technology was

adapted to capture the shape of the 'patient's arm. The scanning process was

conducted at the Hospital Al-Sultan Abdullah, UiTM, under observation by a rehabilitation specialist

using a handheld 3D scanner machine (Shining 3D, China). Figure 3(a) shows the

3D scanning process on the left arm (affected arm) of the patient, while Figure

3(b) indicates the raw images of the scanned data. The arm model was

reconstructed and smoothened using Meshmixer software to obtain a precise and

identical shape of the patient's left arm. To ensure that the design seems proportionate, the arm holder

must resemble the geometry of the left arm. CAD software is used to

design all parts of the device. Figure 4 illustrates the final design of the

arm orthosis, which consists of two parts: (a) the upper arm holder and (b) the

lower arm holder. After designing the arm using Autodesk Fusion 360, the file

is converted to .stl files and then imported to the AutoDesk TinkerCAD

software, as shown in Figure 5. This is for designing the slot for the

resistance band and straps for the harness to be tied together.

Figure 2 Sketches of the proposed assistive device, which consists of the (a) harness and (b) upper and lower holder

Figure 3 (a) 3D scanning process on the left arm of the patient with the

observation by the rehabilitation specialist, and (b) raw images of 3D scanned

data

2.4. Finite Element Analysis

Computational analysis is the fundamental approach to predicting a 'product's strength, material selection, and optimized design, which is widely used in medical science and engineering design (Hamza et al., 2023; Faadhila et al., 2022; Ahmad et al., 2020, Nor-Izmin et al., 2020; Abdullah et al., 2012). A static finite element analysis was performed to predict the 'product's performance before proceeding to 3D printing fabrication. This provided optimum parameter setting and design. The Autodesk Fusion 360 software was used for the static stress analysis on both upper and lower arm holders to observe the force-loading effects in the resistance band slot area of the holder. Two different materials, namely Polylactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS), were evaluated to predict the suitability of these materials for the device.

Figure 4 Designing the (a) upper arm holder and (b) lower arm holder using AutoDesk Fusion 360

Figure 5 Designing the slot for the resistance band and strap

harness for (a) the upper arm and (b) the lower arm holder using AutoDesk

TinkerCAD

Figure 6 illustrates the loading

and boundary conditions conducted in this study. The boundary condition

(constraints) was set on the four-hole slots on the corners for the upper arm

holder and two-hole slots on the corners (labeled in red line) for the lower

arm holder where the strap of the harness is tied. Constraints are applied to a

model to prevent it from moving in response to applied loads. A 10N structural

load/force (labeled blue arrow) was applied onto the slot of the resistance

band where the weight of the upper arm and lower arm react toward each other.

The blue labels indicate the loading condition, while the red labels show the

constraints. The resulting von Mises stress, displacement, and safety factors

were the main focus of this simulation to assess the design's validity in

real-world conditions (Farah, Anderson, and Langer, 2016).

Figure 6

Loading and boundary conditions setting in the analysis

2.5. Fabrication of the Assistive Device

In

the fabrication procedure, both the upper and lower arm holders were created

using a 3D printer capable of working with PLA and ABS materials. The selection

of these materials was based on their widespread availability and common use in

the development of adaptive devices and prototypes, as highlighted in previous

studies (Wahid

et al., 2022; Mazlan et al., 2021). The design

model was generated using Autodesk Fusion360 CAD software and then exported in

stereolithography (.stl) format to the slicing software Ultimaker Cura.

Subsequently, the file was converted into a g-code file for the Creality

Ender-3 V2 after the slicing process. For both arm orthosis components, a

thickness of 5mm and an infill density of 20% were selected for 3D printing

manufacturing. These parameter settings were informed by prior research (Wahid et al.,

2022; Mazlan et al., 2021; Hamzah et al., 2019) while

considering printing cost and orthosis weight. Safety factors and the

weight-to-performance ratio were crucial in achieving a promising product. It's

worth noting that increasing infill values will raise the young modulus and

product weight (Mazlan et al., 2023).

Additionally, PLA filament, chosen for its ease of printing and higher

stiffness compared to ABS, exhibits a tensile strength greater than 37 MPa. The

upper arm holder required 12 hours for printing, while the lower arm holder

took 14 hours.

3.1. Comparison

between PLA and ABS Materials

The performance

of both materials was compared on the resulting von Mises stress, displacement,

and safety factor, as shown in Table 1 (a), (b), and (c), respectively. The

maximum von Misses stress of PLA is observed to be higher in comparison to the

ABS material, indicating a greater tolerance of stress imposed on the

material's strength. However, PLA has a smaller maximum displacement than ABS,

at 0.019 mm and 0.030 mm, respectively. The reaction forces and reaction

moments are often produced by applied force actions. Structure failure can

occur when reaction forces exceed action forces, resulting in fracture and

corrosion. When comparing the two materials in Table 1(a), PLA had lower

maximum reaction forces than ABS, indicating that PLA opposes less force from

the applied force from the detachable arm orthosis, which is also influenced by

gravity force. The most common approach to express a safety factor is as a ratio

between a measurement of the maximum load that will not cause the stated type

of failure and a comparable measurement of the maximum load that is expected to

be applied. The factor of safety is the most straightforward and extensively

utilized strategy in handling variability and uncertainty in engineering design

(Nigro

and Arch, 2023; Moreland, 2009). The application of safety

considerations to ensure that a building can fulfill its intended function

reduces the chance of failure to an acceptable level (Amitrano et al., 2023; Sarma

et al., 2020). Both materials have the same safety factor

of 15, which is relatively high and considerably above one, indicating that

neither material will fail under the current conditions. As a result, PLA is

superior to ABS as a suitable material for producing this arm orthosis. One of

the reasons for choosing PLA is to save cost, and the failure difference

between PLA and ABS does not affect the design of arm orthosis and the

'patient's comfort when using the arm orthosis.

3.2.

Prototype of the Assistive Device

The

prototype of the patient-specific assistive device was successfully developed

and printed. Although the finite element analysis had been conducted earlier,

issues of fit- to-patient and comfort are subjective and need to be tested on

the patient. Therefore, the prototype of the device was essential to observe

the highlighted issues. Design changes, revisions, and improvements were made

to each 3D-printed prototype. The patient's feedback and observations are

critical for obtaining the greatest quality 3D-printed arm orthosis. Table 2

illustrates the changes implemented as a result of patient feedback and

observations during multiple attempts. Furthermore, Figure 7 depicts the

fitting process with the patient, which directly contributes to the enhancement

and modification of the device.

Table 1 Variation of (a) von Mises Stress, (b) Displacement, and (c) Safety factor for the assistive device at different material properties, namely PLA (left) and ABS (right)

Table 2 Changes and modifications of the design model based on the patient feedback

Figure 7

Patient fitting and testing the functionality of the device

A

patient-specific adaptive assistive device for brachial plexus injury has been

successfully developed. Computational analysis was employed to assess the

strength of the arm orthosis under various parameter settings before proceeding

with 3D printing fabrication. This device works in tandem with resistance bands

secured to the arm holders. The final concept design was chosen through a

rigorous conceptual evaluation method. The overall analysis, using different

materials of the same thickness under the same load, indicated that PLA

exhibited the highest stress and the lowest maximum displacement. Subsequently,

the device was fabricated using 3D printing technology, with the choice of

material based on the prior analysis. The resistance band acted as an elastic

force, enabling the patient to perform daily activities more easily. One

notable limitation is that the developed prototype has not undergone

quantitative testing on the patient in this manuscript. At this stage, the

project's focus has been on creating a prototype that offers an ideal fit for

the patient and is functional. Further research is recommended to assess the

performance of the printed product, ensuring the project's continuity and

refinement.

This study was funded by the Universiti Teknologi

MARA through the research grant No. 100-RMC 5/3/SRP (037/2021). We would like

to express our appreciation and gratitude to the College of Engineering, UiTM

and AA3D Technology Sdn. Bhd. for their technical assistance and support.

| Filename | Description |

|---|---|

| R1-ME-6708-20230929144848.docx | Table of Correction |

Abas, M., Habib, T., Noor, S.,

Zimon, D., Wozniak, J., 2023. Application of Multi-criteria Decision-making

Methods in the Selection of Additive Manufacturing Materials for Solid Ankle

Foot Orthoses. Journal of Engineering Design, Volume 34(8), pp. 616–643

Abdullah, A.H., Rashid, H.,

Mahmud, J., Othman, M.F., Ibrahim, M.W.A.-J. 2012. Effects of Screw Materials

in Anterior Cruciate Ligament Reconstruction using Finite Element Analysis. Procedia

Engineering, Volume 41, pp. 1614–1619

Ahmad, M.A., Zulkifli, N.N.M.E.,

Shuib, S., Sulaiman, S.H., Abdullah, A.H., 2020. Finite Element Analysis of

Proximal Cement Fixation in Total Hip Arthroplasty. International Journal of

Technology, Volume 11(5), pp. 1046–1055

Ahmed, R.M., Al-Shammari, M.A.,

2023. EMG-Based Control of Active Ankle-Foot Prosthesis. Journal of

Engineering, Volume 29(9), pp. 31–44

Amitrano, F., Coccia, A., Pagano,

G., Biancardi, A., Tombolini, G., Daddio, G., 2023. Effects of Ankle-Foot

Orthosis on Balance of Foot Drop Patients. Studies in Health Technology and

Informatics, Volume 302, pp. 1029–1030

Cleveland Clinic, (n.d.).

Brachial Plexus Injuries. Available online at

https://my.clevelandclinic.org/health/diseases/22822-brachial-plexus-injury,

Accessed on January 25, 2023

Cutti, A.G., Morosato, F.,

Gentile, C., Gariboldi, F., Hamoui, G., Santi, M.G., Teti, G., Gruppioni, E.,

2023. A Workflow for Studying the Stump–Socket Interface in Persons with

Transtibial Amputation through 3D Thermographic Mapping. Sensors, Volume

23(11), p. 5035

Devin, K.M., Tang, J., Moser, D.,

Jiang, L., 2023. Assessing Socket Fit Effects on Pressure And Shear at

aTranstibial Residuum/Socket Interface. Applied Bionics and Biomechanics,

Volume 2023, p. 3257059

Faadhila, A., Rahman, S.F.,

Whulanza, Y., Supriadi, S., Tampubolon, J.Y., Wicaksana, S.I., Rahyussalim,

A.J., Kurniawati, T., Abdullah, A.H., 2022. Design of a Transforaminal Lumbar

Interbody Fusion (TLIF) Spine Cage. International Journal of Technology,

Volume 13(8), pp. 1663–1671

Farah, S., Anderson, D.G.,

Langer, R., 2016. Physical and Mechanical Properties of PLA, And Their

Functions in Widespread Applications — A Comprehensive Review. Advanced Drug

Delivery Reviews, Volume 107, pp. 367–392

Hamza, S., Heidari, M.,

Ahmadizadeh, M., Dashtizadeh, M., Chitt, M., 2023. Modification of Horizontal

Wind Turbine Blade: A Finite Element Analysis, International Journal of

Technology, Volume 14(1), pp. 5–14

Hamzah, S.R., Nor-Izmin, N.A.,

Tardan, G., Abdullah, A.H., 2019. Design and Analysis of Adjustable Headrest

for Total Body Involvement Cerebral Palsy, International Journal of Recent

Technology and Engineering, Volume 8(1), pp. 3208–3211

Johns Hopkins Medicine, (n.d.).

Brachial Plexus Injury. Available online at https://www.hopkinsmedicine.org/

health/conditions-and- diseases/ brachial-plexus-injuries, Accessed on January 25,

2023

Jonnala,

U.K., Sankineni, R., Kumar, Y.R., 2023. Design and

Development of Fused Deposition Modeling (FDM) 3D-Printed Orthotic Insole by

Using Gyroid Structure. Journal of the Mechanical Behavior of Biomedical

Materials, Volume 145, p. 106005

Levesque, L., Doumit, M. 2020.

Study of Human-Machine Physical Interface for Wearable Mobility Assist Devices.

Medical Engineering & Physics, Volume 80, pp. 33–43

Mazlan, M.A., Anas, M.A.,

Nor-Izmin, N.A., Abdullah, A.H. 2023. Effects of Infill Density, Wall Perimeter

and Layer Height in Fabricating 3D Printing Products. Materials, Volume

17, p. 695

Mazlan, M.A., Hashim, N.M.,

Zakaria N.A.C., Abdullah, A.H. 2021. 3D Printed Assistive Writing Device for

Phocomelia Patient. Malaysian Journal of Medicine and Health Sciences,

Volume 17(13), pp. 7–11

Moreland, D.W., 2009. Mechanical

Systems Safety. In: Safety Design for Space Systems, Musgrave, G.E.,

Larsen, A.M., Sgobba, T., (ed.), Elsevier Science

National Institute of

Neurological Disorders and Stroke, 2008. NINDS Brachial Plexus Injuries, 2008

Nigro, L., Arch, E.S., 2023.

Design and Mechanical Testing of a Novel Dual-Stiffness Ankle-Foot Orthosis. Journal

of Medical Devices, Volume 17(3), p. 034501

Nor-Izmin, N.A., Hazwani, F.,

Abdullah, A.H., Todo, M., 2020. Risk of Bone Fracture in Resurfacing Hip

Arthroplasty at Varus and Valgus Implant Placements. International Journal

of Technology, Volume 11(5), pp. 1025–1035

Oliver, M., 2019. Assistive

Technology in Polytrauma Rehabilitation. Physical Medicine and

Rehabilitation Clinics, Volume 30(1), pp. 217–259

Rashid, H., Ariffin, M.K.M., Noh,

M.H.M., Abdullah, A.H., Hamid, A.H.A., Jusoh, M.A.M., Othman, A., 2012. Design

Review of Scissors Lifts Structure for Commercial Aircraft Ground Support

Equipment Using Finite Element Analysis. Procedia Engineering, Volume

41, pp. 1696–1701

Sarma, T., Saxena, K.S., Majhi,

V., Pandey, D., Sahai, N., 2020. Development Of Active Ankle Foot Orthotic

Device. Materials Today: Proceedings, Volume 26(2), pp. 918–921

Scherb, D., Steck, P., Wechsler,

I., Wartzack, S., Miehling, J., 2023. The Determination of Assistance-as-Needed

Support by an Ankle–Foot Orthosis for Patients with Foot Drop. International

Journal of Environmental Research and Public Health, Volume 20(17), p. 6687

Sousa, R.,

Pereira, A., Massada, M., Trigueiros, M., Lemos, R., Silva, C., 2011. Shoulder

Arthrodesis in Adult Brachial Plexus Injury: What is The Optimal Position? Journal

of Hand Surgery, Volume 36(7), pp. 541–547

Volpi, M., Paradiso, A.,

Costantini, M., Swieszkowski, W., 2022. Hydrogel-based Fiber Biofabrication

Techniques for Skeletal Muscle Tissue Engineering. ACS Biomaterials Science

& Engineering, Volume 8(2), pp. 379–405

Wahid, A.M.A., Tardan, G.,

Pangesty, A.I., Rashid H., Abdullah, A.H., 2022. Development of Ankle-Foot

Orthosis with the Integration of IoT Controller. International Journal of

Emerging Technology and Advanced Engineering, Volume 12(5), pp. 49–55