Extraction and Characterization of Micro-fibrillated Cellulose from Rice Husk Waste for Biomedical Purposes

Corresponding email: m.chalid@ui.ac.id

Published at : 05 Feb 2024

Volume : IJtech

Vol 15, No 2 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i2.6698

Nurhayati., Irianto, H.E., Riastuti, R., Pangesty, A.I., Nugraha, A.F., Todo, M., Jumahat, A., Chalid, M., 2024. Extraction and Characterization of Micro-fibrillated Cellulose from Rice Husk Waste for Biomedical Purposes. International Journal of Technology. Volume 15(2), pp. 342-352

| Nurhayati | 1. Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia, 2. Research Center for Marine and Land Bioindustry, National Research |

| Hari Eko Irianto | Research Center for Marine and Land Bioindustry, National Research and Innovation Agency, Lombok 83352, Indonesia |

| Rini Riastuti | Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia |

| Azizah Intan Pangesty | 1. Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia, 2. Research Center for Biomedical Engineering, Faculty of Engineering, |

| Adam F. Nugraha | 1. Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia, 2. Center for Sustainability and Waste Management, Universitas Indones |

| Mitsugu Todo | Research Institute for Applied Mechanics, Kyushu University, Kasuga-koen 6-1, Kasuga-shi, Fukuoka 816-8580, Japan |

| Aidah Jumahat | 1. Faculty of Mechanical Engineering, Universiti Teknologi MARA, Shah Alam 40450, Malaysia, 2. Institute for Infrastructure Engineering Sustainable and Management, Universiti Teknologi MARA, Shah Alam |

| Mochamad Chalid | 1. Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia, 2. Center for Sustainability and Waste Management, Universitas Indones |

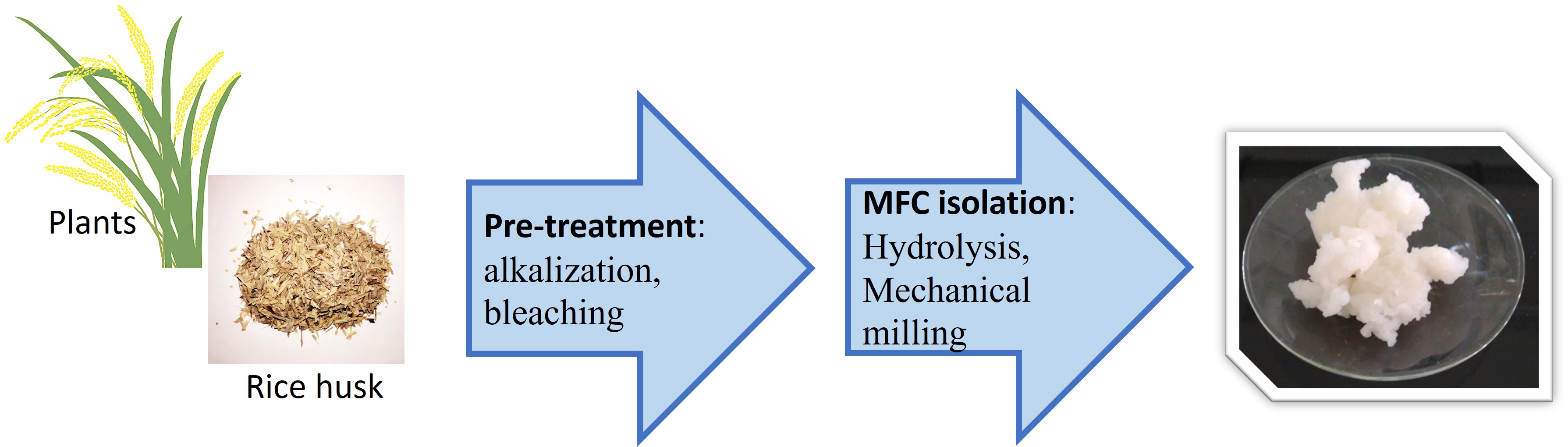

This study aimed to report the extraction of micro-fibrillated cellulose

(MFC) from rice husk (RH) through a series of processes including alkalization,

bleaching, chemical hydrolysis, and mechanical treatment. The chemical

structure, morphology, and crystallinity were assessed using Fourier Transform

Infrared spectroscopy (FTIR), Scanning Electron Microscope (SEM), and X-ray

diffraction (XRD). The results showed that alkalization was more effective in

removing unwanted substances such as silica, hemicellulose, and lignin compared

to bleaching. Chemical or mechanical treatment was more targeted towards

removing the amorphous phase while fibrillating MFC. Further mechanical

treatment significantly enhanced the crystallinity index (CI) of MFC, reaching

87.47%, while chemical treatment remained at 78.54%. The mechanical treatment

led to a larger void size due to rigorous fibrillation, resulting in increased

water retention during extraction compared to chemically treated MFC with a

negatively charged surface. Crystal extraction through mechanical treatment

disrupted the hydrogen bond, transforming cellulose crystal from triclinic to monoclinic

The comprehensive evaluation of MFC extracted from RH showed

its potential for biomedical application.

Acid hydrolysis; Mechanical treatment; Micro-fibrillated cellulose; Rice husk

Exploration

of bio-based materials is a process for addressing global challenges such as

the lack of petroleum, climate change, and unmanageable waste. Cellulose, a

member of the polysaccharide family, is the most prevalent organic component

generated from biomass. This material has diverse applications in industries,

including textiles (Felgueiras et al., 2021), food (Suryanti

et al., 2023;

The use of environmentally

friendly and sustainable biomedical materials has become increasingly important

in healthcare studies and development. Rice husk (RH) waste, the outer covering

of rice grains resulting from the milling process, constitutes a natural fiber

comprising cellulose, hemicellulose, lignin, and other compounds such as wax,

pectin, and silica (Johar, Ahmad, and Dufresne, 2012).

Studies showed that RH contained cellulose (25-35%), lignin (26-31%),

hemicellulose (18-21%), and silica (15-17%) (Rezanezhad,

Nazarnezhad, and Asadpour, 2013).

An extensive study

has been conducted on the isolation of cellulose from biomass/natural fibers

(Ng et al. 2015). This process aimed to remove lignin, hemicellulose, and other

non-cellulose compounds that naturally encapsulate cellulose. Alkalization and

bleaching are the most commonly used chemical treatments. These treatments not

only remove non-cellulose components but also defibrillate cellulose fibers

into micro-sized (Yuanita et al., 2015).

Menawhile, mechanical treatment through grinding is a straightforward,

energy-efficient process that requires simple equipment. Uetani and Yano (2011) explored the isolation of

nano-fibrillated cellulose using a modified blender. In the mechanical grinding

method, shear forces from the blades break hydrogen bonds, reducing cellulose

cell wall size to the nanoscale (Abdul-Khalil et

al., 2014). Therefore, this study aimed to compare the effect of

chemical and mechanical treatments on the characteristics of micro/nano-fibrillated

cellulose as a biomedical material. The resulting material from processed RH

holds potential applications in various medical fields, including surgical

paper, wound coverings, bone patch devices, and drug delivery systems.

2.1. Materials

RH (Oryza sativa L.) was obtained from a

local rice field in Wonogiri, Central Java, Indonesia. Sodium hydroxide (NaOH,

99.9%), Sodium chlorite (NaClO2, 25%), and acetic acid (CH3COOH,

99%) were procured from Merck, while sulfuric acid (H2SO4,

96.1%) was obtained from Mallinckrodt AR.

2.2. Treatment Preparation

In this study, virgin

RH was subjected to sequential treatments by alkalization, bleaching, and

hydrolysis or mechanical methods, to obtain the treated RH as RH_Al, RH_Al-Bl,

and RH_Al-Bl-Ch or RH_Al-Bl-Mc, respectively. The following section provides

the details for each process.

2.2.1. Pre-treatment

MFC extraction from RH comprised 2 primary

steps, namely pretreatment (washing, crushing, alkalization) and MFC isolation

using either mechanical or chemical methods. Pre-treatment began with washing

RH fibers in flowing water to remove visible debris, followed by soaking RH and

drying it at room temperature for 24 hours. The soaked fibers were then crushed

through a 40-mesh sieve and alkalinized in a 5 w/w% NaOH solution at a 1:25 w/v

ratio for 2 hours while stirring at approximately 80°C. After draining and

rinsing with distilled water, alkalized RH fibers were bleached for 2 hours at

70°C using 1.7% NaClO2 in a buffer of 100 ml of 0.2 M acetic acid

and 0.291 g NaOH. According to Iwamoto, Nakagaito,

and Yano (2007), this bleaching process was repeated 5 times until the

sample was cloudy white. Finally, the obtained product was rinsed with

distilled water to remove residual lignin, hemicellulose, and chlorine ions.

Observations were conducted at each step, including RH, fibers after alkaline

treatment (RH_Al), as well as fibers after alkaline and bleaching treatments

(RH_Al-Bl).

2.2.2. MFC Isolation

Following the removal of lignin, hemicellulose, and

other impurities, the pre-treatment was followed by isolating MFC through acid

hydrolysis (RH_Al-Bl-Ch) and mechanical milling, (RH_Al-Bl-Mc). In this study,

MFC results from both methods were compared to identify the most effective.

Acid hydrolysis treatment was performed by adding 60% v/v sulfuric acid to the

pre-treated RH fibers in distilled water (1/25 of w/v) and mixing at 45°C

(Syafri et al. 2011). After 45 minutes, the hydrolysis was terminated by adding

cold distilled water (about 15°C). For the mechanical milling treatment, water

(98/2 of w/w) was added to the pre-treated RH fibers in a blender, and the

blade was rotated between 11,000 - 12,000 rpm at room temperature for 20

minutes (Johar, Ahmad, and Dufresne, 2012).

2.2.3. Characterizations

RH at each treatment stage was evaluated by using a Field

Emission Scanning Electron Microscopes (FE-SEM) Quanta 650 EDAX EDS Analyzer at

varying magnifications of 100 and 500 times. Crystallinity percentage was

determined through hydrogen bonding analysis, using FTIR spectroscopy (Perkin

Elmer 90325) and X-ray diffraction (XRD) with a Philips XRD. FTIR was also

adopted to investigate the chemical structure, while XRD data was analyzed to

assess polymorphism and the allomorph of the extracted MFC. The crystallinity

ratio (CrR) and hydrogen bond energy (EH) for specific OH stretching bands in

cellulose fibers were calculated by comparing absorbance peaks at 1372 cm-1

(A1372) and 2900 cm-1 (A2900) (Nelson

and O’Connor 1964). Gaussian deconvolution peak separation methods were

applied to XRD data to obtain the crystallinity index (CI) of cellulose fibers,

calculated using the Segal Equation (Park et al., 2010).

3.1. Physical Appearance

This study adopted alkalization, bleaching, hydrolysis, and mechanical treatment methods to extract MFC and separate it from unwanted impurities. These methods yielded distinct physical changes, particularly in color and texture.

Figure 1 Physical appearance of isolated husk rice

fibers for (a) RH, (b) RH_Al, and (c) RH_Al-Bl

Figure 1 shows the

significant morphological changes observed during MFC isolation process. A

noticeable color shift was discovered in each phase, showing a reduction in

impurities such as lignin, hemicellulose, and silica, hemicellulose, and

silica. RH_Al sample maintained a dark color compared to RH, suggesting the

presence of lingering lignin. In contrast, RH_Al-Bl sample was white, showing

the effective removal of lignin during the bleaching steps.

3.2. Morphology Evolution

Figure

2a–e shows the SEM images at 100 and 500

Figure 2 SEM

images with 100x (left) and 500x (right) magnification of each sample; (a) RH,

(b) RH_Al (c) RH_Al-Bl (d) RH_Al-Bl-Ch, (e) RH_Al-Bl-Mc

Figures 2d (chemical) and 2e (mechanical) showed that surface patterns,

namely RH_Al-Bl-Ch had spiky surfaces, while RH_Al-Bl-Mc was smoother

3.3. Chemical Structure Analysis

The chemical structure of

the samples was observed through FTIR spectra (Figure 3a). The peak at

approximately 1555 cm-1, attributed to lignin according to Wyman et al. (2004), diminished as expected

in RH_Al sample compared to RH, and it became broader and disappeared in

samples RH_Al-Bl.

A similar pattern was

observed for the slight bump around 800 cm-1, showing silica in RH

samples, which was removed in RH_Al, RH_Al-Bl, and RH_Al-Bl-Ch or RH_Al-Bl-Mc.

The valley of 1260 cm-1 in FTIR signal, represented another

impurity, such as hemicellulose, coexisting with the prominent cellulose peak

at 1300 cm-1. This valley weakened and split from RH_Al to further

treated samples, signifying the effective removal of silica during the initial

alkalization.

Figure 3 a) FTIR spectra absorbance; b) Absorbance ratio of

hemicellulose, lignin, silica.

Figure

3b compiles the impurity content in the RH sample, using absorbance ratios to

provide a detailed assessment of impurities. The ratios at 800 cm-1, 1260 cm-1, and 1555 cm-1 represent silica, hemicellulose, and lignin,

respectively, with the as-received RH sample serving as the reference. Figure

3b shows a significant reduction in all impurities, at least 45%, starting from

alkalization treatment. Alkalization substantially reduced silica content, with

the entire elimination being performed through bleaching. Hemicellulose and

lignin ratios also decreased after alkalization and further decreased due to

mechanical or chemical treatment.

Chemical or mechanical treatments were applied to

further reduce impurities and extract MFC. The primary objective is to remove

the amorphous region and unbundle micro and nanofibrils of cellulose network

using different strategies. Chemical treatment uses sulfuric acid, following

the same principle as alkalization, to isolate and fibrillate cellulose by

hydrolyzing the glucoside bonds in lignin and hemicellulose chains (Jamalpoor and Hosseini 2015).

3.4. Crystallinity

Behavior

3.4.1. Hidrogen bond energy (EH) and bond distance (R)

In discussing sample crystallization behavior, FTIR

absorption peaks in the 1700-850 cm-1 range aid in assessing cellulose polymorphism. A shift in C-C and C-O

vibration peaks showed the conversion of cellulose allomorph from type I to II.

According to Carrillo et al. (2004), when

cellulose type I is more dominant than type II, the absorption at 1420 and 1155

cm-1 would change to

approximately 1430 and 1162 cm-1, respectively. Therefore, the absorption at approximately 1430 and 1162 cm-1 in all sample spectra

showed the presence of cellulose I.

Absorption at 893 cm-1 for cellulose type I changed to approximately 897 cm-1. The 895-905 cm-1 range was in line with higher wavenumbers

indicating cellulose type I, consistent with Yue

(2011), and attributed to glucose residue rotation around the glycosidic

bond (Jamalpoor and Hosseini 2015).

Furthermore, all fibers had an absorption peak at 1315 cm-1, confirming the minor presence of cellulose

type II. FTIR analysis reinforces cellulose I dominance in both untreated and

treated RH samples.

EH and R analysis offered another method to distinguish cellulose

types. Cellulose type I had 3 hydrogen bonding arrangements, namely

intramolecular hydrogen bonds O(6)H···O(2) and O(3)H···O(5), as well as

intermolecular hydrogen bond O(6)H···O’(3) with FTIR absorption peaks around

3455-3410 cm-1, 3375-3340 cm-1, and 3310-3230 cm-1, respectively.

Meanwhile, cellulose type II had 4 hydrogen bond arrangement, similar to type

I, with the addition of an intermolecular hydrogen bond: O(2)H···O’(2) or

O(6)H···O’(3) (Poletto et al., 2011). Table 1 provides EH and R values for each sample. Compared to EH value of

the as-received RH, all treated samples had lower hydrogen bond energy,

consistent with Poletto et al., (2011).

Table 1 Values of EH and R for each

sample

|

Intramolecular O(2)H···O(6) |

Intramolecular O(3)H···O(5) |

Intermolecular O(2)H···O'(2) | ||||

|

Sample Name |

3460-3405 c |

3375-3340 c |

3310-3230 c | |||

|

EH (kJ/mol) |

R (Å) |

EH (kJ/mol) |

R (Å) |

EH (kJ/mol) |

R (Å) | |

|

RH |

17.692 |

2.796 |

24.452 |

2.775 |

28.839 |

2.761 |

|

RH_Al |

18.483 |

2.793 |

23.229 |

2.778 |

30.134 |

2.757 |

|

RH_Al-Bl |

15.750 |

2.802 |

23.158 |

2.779 |

30.565 |

2.755 |

|

RH_Al-Bl-Ch |

15.750 |

2.802 |

23.229 |

2.778 |

26.394 |

2.768 |

|

RH_Al-Bl-Mc |

11.651 |

2.815 |

20.856 |

2.786 |

28.911 |

2.761 |

The relative

hydrogen bond distances examined in this study range from 2.755 to 2.815 Å.

According to Tasker et al., the hydrogen bond distance of Cellulose I was 2.75

Å. Consequently, the proximity of the distance to this value showed the

refinement of cellulose in the sample (O’Sullivan

1997). Additionally, as stated by Poletto et

al., (2011), higher crystallinity

leads to denser cellulose packing and shorter distances, resulting in increased

hydrogen energy between cellulose molecules.

Nelson and O’Connor (1964)

proposed the ratio between FTIR absorbance bands at 1372 and 2900 cm-1 as CrR, which is

proportional to the crystallinity degree of cellulose. CrR values for RH,

RH_Al, RH_Al-Bl, RH_Al-Bl-Ch, and RH_Al-Bl-Mc were 0.79, 1.73, 2.17, 3.03, and

5.67, respectively. The values gradually increase along with the treatment

process, with RH_Al-Bl-Mc having the highest. This suggested that mechanical

treatment was more powerful compared to chemical treatment in removing the

amorphous region.

3.4.2. Crystallinity Index (CI)

XRD was used

to complement the other characterization and further evaluate the crystallinity

behavior of cellulose. Figure 8

shows XRD diffraction of untreated and treated RH. From

XRD diffraction data, several peaks were identified, where peak one at =14.5°

is

(100) and

(10), peak two at

=17.0° is

(010) and

(110), peak

three at

=22.5° is

or (002) and

(012), as well as peak four at

=34.0° is

and

(004) (Hult et al., 2003; Wada and Okano, 2001). XRD peaks were

processed by Gaussian deconvolution separation to further determine the

crystallinity index, the d-spacing, crystallite size, and Z-values.

In this study, Z-values function

developed by Wada

and Okano (2001) was used to determine cellulose crystal structure, identifying it

as either triclinic or monoclinic

allomorph. The most intense

crystalline peak was discovered at 22.62° on the (002) lattice plane for all

the samples. Lionetto et al. and Harahap et al. investigations also identified

the same peak within different scanning angles (

) (Harahap et al., 2023; Lionetto et al.,

2012).

Figure 4 a) XRD

spectra; b) CI for each samplex

Figure 4a shows a decreasing

amorphous trench between peak (002) and peak (010) during each treatment phase,

moving towards the baseline, while CI is reversely increasing. Quantitatively,

Figure

4b showed a continuous rise in CI in the treatment process, with mechanical

treatment showing superiority compared to the chemical counterpart. CI of MFC

shows a tightly packed structure, hypothetically improving thermal stability

and mechanical properties, making it desirable for composite applications (Poletto et al.,

2011).

Table 2 Crystallite size (L) from each sample

|

Sample Name |

L (110) (nm) |

L (nm) |

L (002) (nm) |

L (004) (nm) |

L (100) (nm) |

L (010) (nm) |

L (110) (nm) |

L ( (nm) |

|

RH |

6.91 |

2.33 |

1.79 |

7.99 |

|

|

|

|

|

RH_Al |

5.73 |

2.27 |

1.51 |

8.83 |

|

|

|

|

|

RH_Al-Bl |

5.65 |

2.21 |

6.74 |

10.13 |

|

|

|

|

|

RH_Al-Bl-Ch |

6.36 |

1.01 |

7.52 |

5.28 |

|

|

|

|

|

RH_Al-Bl-Mc |

|

|

|

|

6.97 |

0.67 |

5.77 |

3.03 |

The

crystallite size of the samples decreases during the treatment process, as

shown in Table 2. When cellulose fiber was more distanced,

smaller crystal sizes were observed, often associated with a change in crystal

structure. The desirable triclinic structure of crystal in RH

for MFC isolation is prone to hydrogen bonding breakdown. However, when the

triclinic structure loses integrity, it will rearrange to create a monoclinic

structure of

This suggested that the final mechanical

treatment entirely transformed cellulose crystal from

The transformation was also shown in Table 2, where the crystallographic

family was diverted from triclinic structure

to monoclinic structure

3.5. Biomedical

Potential

This study presents the potential

of MFC extracted from RH as a

biomedical material for innovative applications (Varshney et al., 2022). The successful

removal of unwanted substances such as silica, hemicellulose, and lignin

through alkalization and bleaching treatments showed the suitability for

medical applications where purity and biocompatibility were crucial (Islam et al.,

2018).

The pristine MFC structure achieved through these processes presents a clean

surface, minimizing adverse reactions when interacting with biological systems (Sunasee, Hemraz,

and Ckless, 2016). Finally, the impurity-free nature of MFC positions it as a

promising candidate for wound healing and tissue engineering, where seamless

integration with the natural processes of the body is essential.

The substantial increase in CI of

MFC due to rigorous mechanical treatment is essential with potential biomedical

implications. This heightened CI signifies a more ordered and aligned cellulose

structure, enhancing mechanical strength and stability, particularly beneficial

for regenerative medicine scaffolds (Mauck and Burdick, 2015). The unique voids observed in

mechanically treated MFC, showing increased water retention, offered

opportunities for controlled drug delivery systems. These interconnected voids

serve as therapeutic agent reservoirs. This controlled release mechanism holds

promise for precise and sustained pharmaceutical delivery to enhance patient

outcomes (Sun

et al., 2019). Further mechanical processes elevate CI of MFC to 87.47%. This

improved mechanical strength and stability, crucial for biomedical applications

(Seddiqi

et al., 2021). Mechanically treated negatively charged surfaces aid

interactions with positively charged cells and medical materials, supporting

its usage in wound healing and as a medical adhesive. Additionally, mechanical

treatment shifts cellulose crystal structure from triclinic to monoclinic

, while reducing MFC crystallite size, potentially affecting mechanical

properties and reactivity.

In

conclusion, this study delved into the evolution of MFC crystallinity through a

multi-stage extraction process, comprising alkalization, bleaching, and either

chemical or mechanical treatment. Alkalization proved effective in removing

silica and hemicellulose from RH while bleaching primarily eliminated the bulky

lignin structure. These procedures not only heightened MFC purity, assessed

both visually and chemically using FTIR, but also improved crystallinity,

scrutinized through XRD. Successful efforts were made to eliminate the

amorphous phase through both chemical and mechanical treatments, substantiated

by SEM images showcasing fibrillation. This fibrillation was accompanied by a decrease

in EH, an increase in R, and a slight reduction in crystallite size and width.

Smaller MFC widths resulting from mechanical treatment led to higher surface

energy, rendering the surface more water-attractive. Furthermore, cellulose

crystals in MFC, extracted using both methods, predominantly had cellulose ,

transitioning to

specifically pronounced after mechanical treatment due to

hydrogen bond rearrangement. These discoveries firmly established MFC as a

highly promising biomedical material with versatile potential across various

medical applications.

This research was

funded by Universitas Indonesia with grant number

NKB-678/UN2.RST/HKP.05.00/2021. The authors are grateful to Aldhi Saputro for

the laboratory activity.

Abdul-Khalil, H.P.S., Davoudpour, Y., Islam,

M.N., Mustapha, A., Sudesh, K., Dungani, R., Jawaid, M., 2014. Production and Modification

of Nanofibrillated Cellulose Using Various Mechanical Processes: A Review. Carbohydrate

Polymers, Volume 99, pp. 649–665

Carrillo, F., Colom, X., Suñol, J.J., Saurina, J.,

2004. Structural FTIR analysis and thermal characterization of lyocell and

viscose-type fibers. European Polymer Journal, Volume 40(9), pp. 2229–2234

Chen, Z., Xu, Y., Shivkumar, S., 2018. Microstructure

and Tensile Properties of Various Varieties of Rice Husk. Journal of the

Science of Food and Agriculture, Volume 98(3), pp. 1061–1070

Choi, K., Nam, J.D., Kwon, S.H., Choi, H.J.,

Islam, M.S., Kao, N., 2019. Microfibrillated Cellulose Suspension and its Electrorheology.

Polymers, Volume 11(12), p. 2119

Felgueiras, C., Azoia, N.G., Gonçalves, C., Gama,

M., Dourado, F., 2021. Trends on the Cellulose-Based Textiles: Raw Materials

and Technologies. Frontiers in Bioengineering and Biotechnology, Volume 9, p. 608826

Galera-Manzano, L.M., Ruz

Cruz, M.Á., Moo Tun, N.M., Valadez González, A., Mina Hernandez, J.H., 2021.

Effect of Cellulose and Cellulose Nanocrystal Contents on the Biodegradation,

Under Composting Conditions, of Hierarchical Pla Biocomposites. Polymers,

Volume 13(11), p. 1855

Harahap, M., Daulay, N., Zebua, D., Gea, S.,

2023. Nanofiber Cellulose/Lignin from Oil Palm Empty Fruit Bunches and the

Potential for Carbon Fiber Precursor Prepared by Wet-spinning. International

Journal of Technology, Volume 14(1), pp. 152–161

Hu, L., Zhong, Y., Wu, S., Wei, P., Huang, J.,

Xu, D., Zhang, L., Ye, Q., Cai, J., 2021. Biocompatible and Biodegradable Super-toughness

Regenerated Cellulose via Water Molecule-assisted Molding. Chemical

Engineering Journal, Volume 417, p. 129229

Hult, E.L., Iversen, T., Sugiyama, J., 2003.

Characterization of the Supermolecular Structure of Cellulose in Wood Pulp Fibers.

Cellulose, Volume 10(2), pp. 103–110

Islam, M.S., Kao, N., Bhattacharya, S.N., Gupta,

R., Choi, H.J., 2018. Potential Aspect of Rice Husk Biomass in Australia for Nanocrystalline

Cellulose Production. Chinese Journal of Chemical Engineering, Volume

26(3), pp. 465–476

Iwamoto, S., Nakagaito, A.N., Yano, H., 2007.

Nano-fibrillation of Pulp Fibers for the Processing of Transparent Nanocomposites.

Applied Physics A: Materials Science and Processing, Volume 89(2), pp.

461–466

Jamalpoor, A., Hosseini, M., 2015. Biaxial Buckling

Analysis of Double-orthotropic Microplate-systems Including in-plane Magnetic Field

Based on strain gradient theory. Composites Part B: Engineering, Volume 75,

pp. 53–64

Johar, N., Ahmad, I., Dufresne, A., 2012.

Extraction, preparation, and characterization of cellulose fibers and

nanocrystals from rice husk. Industrial Crops and Products, Volume 37(1),

pp. 93–99

Lionetto, F., Del-Sole, R., Cannoletta, D.,

Vasapollo, G., Maffezzoli, A., 2012. Monitoring wood degradation during

weathering by cellulose crystallinity. Materials, Volume 5(10), pp. 1910–1922

Ludueña, L., Fasce, D., Alvarez, V.A., Stefani,

P.M., 2011. Nanocellulose from Rice Husk Following Alkaline Treatment to Remove

Silica. BioResources, Volume 6(2)

Mauck, R.L., Burdick, J.A., 2015. From Repair to

Regeneration: Biomaterials to Reprogram the Meniscus Wound Microenvironment. Annals

of Biomedical Engineering, Volume 43(3), pp. 529–542

Mu, R., Hong, X., Ni, Y.,

Li, Y., Pang, J., Wang, Q., Xiao, J., Zheng, Y., 2019. Recent Trends and

Applications of Cellulose Nanocrystals in Food Industry. Trends in Food

Science and Technology, Volume 93, pp. 136–144

Nelson, M.L., O’Connor, R.T., 1964. Relation of Certain

Infrared Bands to Cellulose Crystallinity and Crystal Lattice Type. Part II. A New

Infrared Ratio for Estimation of Crystallinity in Celluloses I and II. Journal

of Applied Polymer Science, Volume 8(3) , pp. 1325–1341

O’Sullivan, A.C., 1997. Cellulose: The Structure Slowly

Unravels. Cellulose, Volume 4(3), pp. 173–207

Pandey, A. 2021. Pharmaceutical and Biomedical Applications

of Cellulose Nanofibers: a Review. Environmental Chemistry Letters,

Volume 19(3), pp. 2043–2055

Park, B.D., Gon Wi, S., Ho Lee, K., Singh, A.P.,

Yoon, T.H., Soo-Kim, Y., 2003. Characterization of Anatomical Features and Silica

Distribution in Rice Husk using Microscopic and Micro-analytical Techniques. Biomass

and Bioenergy, Volume 25(3), pp. 319–327

Park, S., Baker, J.O., Himmel, M.E., Parilla,

P.A., Johnson, D.K., 2010. Cellulose Crystallinity Index: Measurement Techniques

and Their Impact on Interpreting Cellulase Performance. Biotechnology for

Biofuels, Volume 3, pp. 1–10

Poletto, M., Pistor, V., Zeni, M., Zattera, A.J.,

2011. Crystalline Properties and Decomposition Kinetics of Cellulose Fibers in Wood

Pulp Obtained by Two Pulping Processes. Polymer Degradation and Stability,

Volume 96(4), pp. 679–685

Rajinipriya, M., Nagalakshmaiah, M., Robert, M., Elkoun,

S., 2018. Importance of Agricultural and Industrial Waste in the Field of

Nanocellulose and Recent Industrial Developments of Wood Based Nanocellulose: A

Review. American Chemical Society (ACS) Sustainable Chemistry and

Engineering, Volume 6(3), pp. 2807–2828

Rezanezhad, S., Nazarnezhad, N., Asadpour, G.,

2013. Isolation of Nanocellulose from Rice Waste via Ultrasonication. Lignocellulose,

Volume 2(1), pp. 282–291

Rochardjo, H.S.B., Fatkhurrohman,

AK., Yudhanto, F., 2021. Fabrication of Nanofiltration Membrane Based on

Polyvinyl Alcohol Nanofibers Reinforced with Cellulose Nanocrystal using

Electrospinning Techniques. International Journal of Technology, Volume 12(2),

pp. 329–338

Seddiqi, H., Oliaei, E., Honarkar, H., Jin, J.,

Geonzon, L.C., Bacabac, R.G., Klein-Nulend, J., 2021. Cellulose and its Derivatives:

Towards Biomedical Applications. Cellulose, Volume 28(4), pp. 1893–1931

Sun, B., Zhang, M., Shen, J., He, Z., Fatehi, P.,

Ni, Y., 2019. Applications of Cellulose-based Materials in Sustained Drug

Delivery Systems. Current Medicinal Chemistry, Volume 26(14), pp.

2485–2501

Sunasee, R., Hemraz, U.D., Ckless, K., 2016.

Cellulose Nanocrystals: a Versatile Nano Platform for Emerging Biomedical Applications.

Expert Opinion on Drug Delivery, Volume 13(9), pp. 1243–1256

Suryanti, V., Kusumaningsih, T., Safriyani, D., Cahyani,

I.S., 2023. Synthesis and Characterization of Cellulose Ethers from Screw Pine

(Pandanus tectorius) Leaves Cellulose as Food Additives. International

Journal of Technology, Volume 14(3), pp. 659–668

Uetani, K., Yano, H., 2011. Nanofibrillation of Wood

Pulp Using a High-speed Blender. Biomacromolecules, Volume 12(2), pp.

348–353

Väisänen, S., Pönni, R.,

Hämäläinen, A., Vuorinen, T., 2018. Quantification of Accessible Hydroxyl

Groups in Cellulosic Pulps by Dynamic Vapor Sorption with Deuterium Exchange. Cellulose,

Volume 25(12), pp. 6923–6934

Varshney, S., Mulpuru, V., Mishra, N., Gupta,

M.K., 2022. Microwave-irradiated Novel Isolation of Nanocellulose from Waste Rice

Husk via Modified Chemo-mechanical Route: Characterization, in-silico Prediction,

and its Antibacterial Activity. Materials Technology, Volume 37(13), pp.

2608–2622

Wada, M., Okano, T., 2001. Localization of and

Phases in Algal Cellulose Revealed by Acid Treatments. Cellulose,

Volume 8(3), pp. 183–188

Wyman, C., Decker, S., Himmel, M., Brady, J.,

Skopec, C., Viikari, L., 2004. Hydrolysis of Cellulose and Hemicellulose. Polysaccharides:

Structural Diversity and Functional Versatility, Volume 1, pp. 1023–1062

Yuanita, E., Pratama, J.N., Mustafa, J.H., Chalid,

M., 2015. Multistage Preparation for Microfibrillated Celluloses Based on

Arenga Pinnata “ijuk” fiber. Procedia Chemistry, Volume 16, pp. 608–615

Yue, Y., 2011. A Comparative Study of Cellulose I

and II Fibers and Nanocrystals. Louisiana State University and Agricultural

and Mechanical College