Investigating the Influence of Material Properties, Infiltration, and Climatic Conditions on Hygrothermal Risk of Building Envelopes

Published at : 05 Feb 2024

Volume : IJtech

Vol 15, No 2 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i2.6688

Ryan, B., Bristow, D.N., 2024. Investigating the Influence of Material Properties, Infiltration, and Climatic Conditions on Hygrothermal Risk of Building Envelopes. International Journal of Technology. Volume 15(2), pp. 383-393

| Bona Ryan | Department of Civil Engineering, University of Victoria, 3800 Finnerty Dr., Victoria, V8P 5C2, Canada |

| David N. Bristow | Department of Civil Engineering, University of Victoria, 3800 Finnerty Dr., Victoria, V8P 5C2, Canada |

Deterioration of

building envelopes due to poor moisture management is considered critical in the

sustainability of buildings where wood-frame constructions are widely used.

However, the integration of research outputs in building enclosure design

analysis considering the combined effects of internal and external parameters

is less exhaustively explored. This is partly due to the uniqueness of each

component material, the uncertainty of involved factors, and complex

interdependencies that influence the response of building envelopes throughout

their service lives. To address this issue, hygrothermal simulations and risk

assessment of key moisture indicators were performed on wall assemblies exposed

to different climatic conditions. The assessment focused on three major issues

concerning the moisture design of exterior walls: (1) selection of appropriate

materials for optimum performance, (2) effect of moisture infiltration, and (3)

different geographic locations. The proposed design methodology includes the

simulations and development of a design experiment method based on

full-factorial design. The proposed method demonstrates a quantitative appraisal

resulting in a clear presentation of moisture accumulation, considering

dependencies on various factors. Research findings showed several important

factors that affect the hygrothermal performance of wood-frame wall assemblies

and need to be considered in the design process. The relationship with the

external climate determines the optimal moisture response, given the dependency

of the component properties on the drying and wetting potential.

Building physics; Biodeterioration risk; Green and healthy building; Hygrothermal analysis; Wood-frame building envelopes

The concept of sustainable building design has

gained importance in recent decades, as manifested by green and healthy

building strategies (Wardhana, Berawi, and

Sari, 2023; Doan et al., 2021; Isa et al., 2018). Sustainable

design, which can be interpreted as creating a healthy built environment using

resource-efficient and ecologically based principles, has encouraged the

establishment of improved design criteria for modern buildings. Consequently,

modern buildings are becoming increasingly complex, such as in their

heat-air-moisture (HAM) design (Sehizadeh and Ge, 2016).

Functional variations have facilitated this complexity, the inclusion of

several ventilation systems, and the use of novel building materials. In this

sense, the moisture design of the building envelope plays a key role in

determining the performance of a building, considering the envelope’s features

as the first line of defense and the main interface of buildings with the

external environment.

The objective of this study is to investigate

the effect of material combinations and the corresponding risk of wood-frame

exterior wall designs using hygrothermal simulations and a design experiment

approach. The outputs from the simulations were processed and analyzed to

provide extensive information using the RHT index, moisture content (MC) in the

region of interest of wall components as response indicators, and Moisture

Index (MI) as a climate indicator. The findings presented in this paper help address

a number of concerns regarding the importance of the impact of components and

material layers on the overall moisture performance of wood-frame wall

constructions.

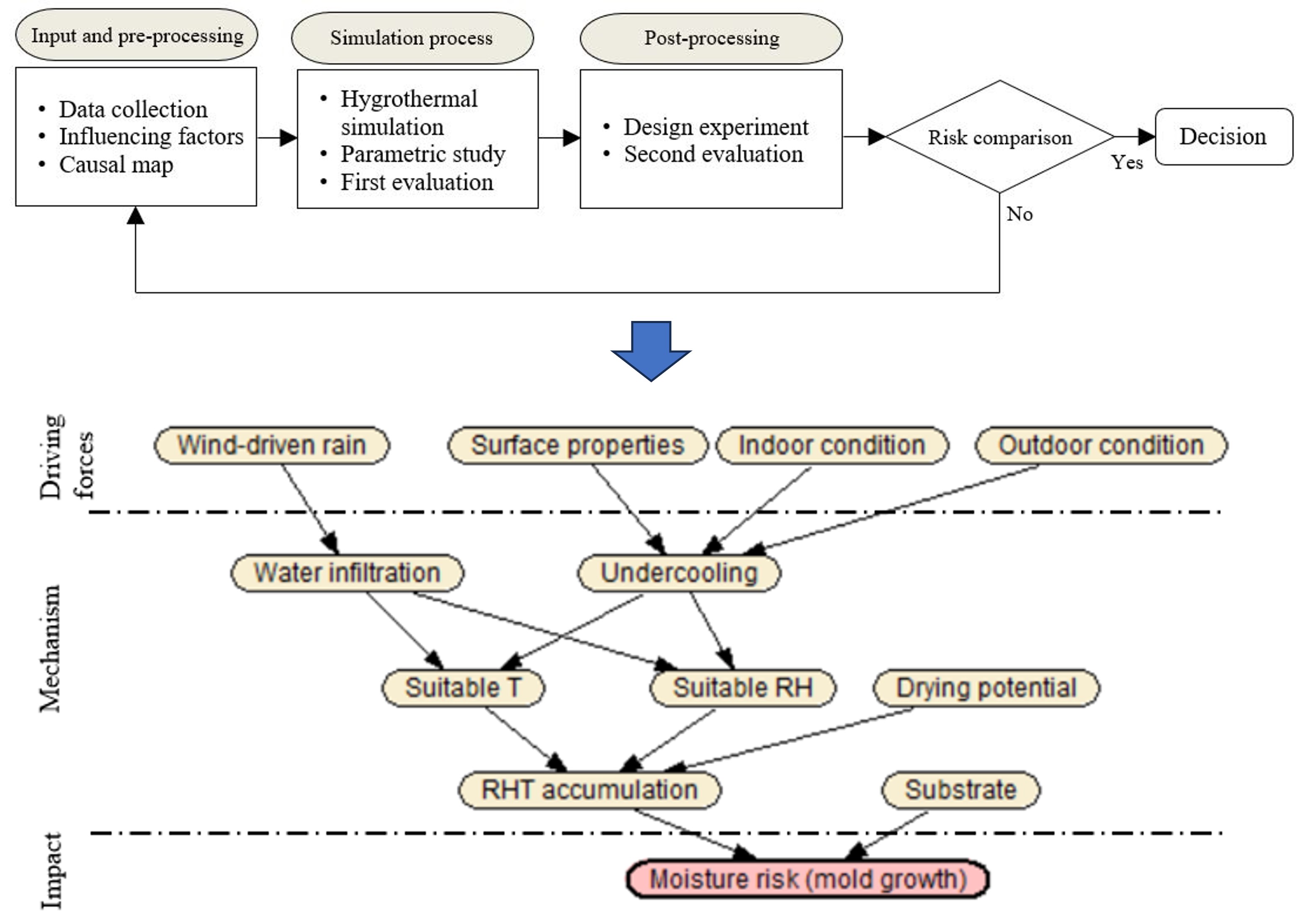

Figure 1 Methodology of hygrothermal risk assessment

To capture interdependencies, full factorial design was used to statistically filter out the significant parameters and significant interaction between parameters. The findings from the parametric study were further analyzed, exploring the characteristics of these parameters in subsequent analyses. A full factorial design is a type of sensitivity analysis whose design consists of two or more factors, each with discrete possible values or levels that take all possible combinations of those levels across all factors (Ryan, Koltsakis, and Manoleas, 2019). This analysis allows the users to study the effect of each factor in a model, as well as the effects of interactions between factors, on the response variable. The parametric study conducted in this research was classified as a multi-level full factorial with four factors. To evaluate the result of a factorial design, a graph of factor interaction plot was created. This analysis was performed with MATLAB (Supplementary File— S01).

2.1. Input and Pre-processing

2.1.1. Data collection

• Wall construction details

This study focused on wood-frame walls with two commonly used claddings in North America: brick veneer and stucco. The basic details of the construction of the wood-frame structure wall are based on the reference model (Lstiburek, 2002) and are shown in Figure 2. The wall configuration remained the same for all the simulations performed in this study, with certain parameters being varied for the parametric study.

• Boundary conditions and geographic location

The two main boundary conditions were the outdoor and indoor conditions. The outdoor boundary condition was defined by the specific weather data obtained from the reference year files (Cannon, 2016). The climate analysis module includes geographical location data and several major weather components, such as temperature, relative humidity, short- and long-wave radiation, wind velocity, wind direction, annual rainfall, cloud index, and air pressure, recorded on an hourly basis.

The hourly indoor climatic conditions (i.e., temperature and relative humidity) were derived from the standard year climate based on ASHRAE Standard 160 (ASHRAE, 2016) in heating-only mode, in which the indoor temperature is kept constant at 22°C during winter (heating season) and left to fluctuate during summer (cooling season). For indoor relative humidity, summer and winter settings were simulated using the ASHRAE simplified model, which depends on exterior climate conditions. A total exposure duration of three years was used for the simulation. The initial year of the simulation was considered a conditioning period and thus was not taken into account in the calculations of the response variable.

• Moisture entry due to moisture infiltration

Convective moisture entry induced by air movement through defects in the air control layer is a complex and multidimensional effect (Glass et al., 2017). In this study, the accidental moisture entry was modeled by a convective moisture source. The model allows a transient consideration of the vapor infiltration through air flow, depending on the specific air permeance of the component on the height of the connected airspace that accounts for the air pressure due to the stack effect. Component permeance estimates in the DIN 68800-2 (DIN, 2012) assume that moderately airtight buildings correspond to the air convection responsible for 250 g/m² of condensation in insulated wooden structures during winter. Therefore, this value was selected. Regarding the position of the convective moisture source describing the condensation layer, the oriented strand board (OSB) sheathing layer facing the cavity was selected for this purpose. The air pressure difference was obtained from the assumption of height for a single-family home (h = 5 m).

2.1.2. Determination of the influencing factors

The relevant physical processes were considered while selecting the influential parameters for this study. The design suggested keeping the insulation constant since this has been extensively explored. In Pallin (2012), the parameters responsible for the material behavior were examined with a specific purpose on the effect of layer properties on the energy performance. Based on the research, the important factors in moisture problems were driven by two mechanisms: wind-driven rain and undercooling.

A causal map (Ackermann and Alexander, 2016) is proposed to depict the major cause-effect in hygrothermal response and presented in the Supplementary File—S02. The vapor barrier properties, rain screen, moisture leakage resulting from vapor infiltration, and the diffusivity of the cladding material were identified as highly significant factors influencing moisture diffusion and undercooling processes. Therefore, the following parameters were investigated: 1) Vapor barrier permeance-varied between 0.1 perms and 20 perms (no vapor barrier) (ASHRAE, 2016; Mukhopadhyaya, 2003); 2) Rain screen-varied between 0 mm (no rain screen) and 25 mm; 3) Moisture leakage-varied between 0 g/m2 (no moisture leakage) and 250 g/m2 (moderate airtightness building) (DIN, 2012); and 4) The cladding material diffusion resistance factor-varied between 169 (typical value for brick) and 311 (typical value for regular PC stucco) (Fraunhofer IBP, 2022).

2.2. Simulation Process and Post-Processing

2.2.1. Hygrothermal simulation and parametric study

Hygrothermal simulations and subsequent analyses were performed to characterize the role of the specified material layers in the moisture performance. Simulations were performed using the hygrothermal simulation program WUFI® Pro V6.6. A parametric study was performed by investigating the effect of varying the component parameters and climatic conditions on the overall long-term moisture response of the wood-frame wall assembly. By doing so, the significance of individual factors and the interaction between these factors on the hygrothermal performance of the exterior wall could be understood.

The parametric analysis focused on three important issues concerning the moisture design of exterior walls: (1) materials properties, (2) effect of moisture infiltration, and (3) different geographic locations. A set of variable values was assigned within a certain range for each parameter. A total of 144 simulations were conducted at this stage, as shown in the Supplementary File—Table S03. Results in ASCII format were extracted and transformed in the post-processing stage for subsequent analyses.

3.1. Simulation Process

The typical outputs considered for the analyses were the RH and T graphs across the wall assembly over the simulation period (Supplementary File— S04). To determine the distributions of RH and T for each wall component and across the region of focus, the output data were extracted and plotted using the relevant indices.

3.1.1. RHT Index calculation

The RHT index (Kumaran et al., 2003; Mukhopadhyaya, 2003; Mukhopadhyaya et al., 2002) is a comparative metric able to quantify the hygrothermal response of specific part of the building envelope accumulatively over a long period. This index can be used for quantification of the localized hygrothermal response in terms of the amount (how much) and of the time (how long). The part of the wall component under consideration is called the ‘region of interest’ or ROI, which can be defined as a region of the wall's cross-section where the response is most severe. To calculate the RHT index at ROI, two values—RH and T—along specified time intervals are required. The generic definition of the RHT index is given as cumulative RH and T by the following expression:

where RH denotes relative humidity, T denotes temperature, and t denotes time step. and

are thresholds in which, at any time step, when either

the RHT value for that time step is zero. Figure 3 shows the wall cross-section and outputs at ROI.

Figure 3 RH and T investigation: (a) wall section with “ROI” of OSB sheathing board layer facing stud cavity; (b) RH and T variation with time at the ROI

The results of the simulations provide an opportunity to closely examine the RH and T conditions inside the wall assembly over a specified period. Based on the observation of the part with the most severe moisture response, the OSB layer (Figure 3) serves as the ROI for all simulations in this study. In this case, in Equation 1 user-defined threshold values of RHX 95% and were selected (ASHRAE, 2021), and a time step of one hour was used. The threshold value indicates the critical condition when mold onset begins as a function of the duration of moisture accumulation.

3.1.2. Study of parameter influence on hygrothermal performance

· Effect of water vapor leakage

Plots of moisture response of wall models subjected to the Montreal climate are illustrated in Figure 4. In essence, the graph shows the most severe hygrothermal response present in the wall assembly. In this particular case, the RHT index of the wall with 1 perm VB has increased by 180% from 438 to 1226, owing to accidental moisture entry.

In order to know the temporal behavior of moisture accumulation, the evolution of MC over time was investigated (Figure 4b). The graphs demonstrated the comparable impacts on the wall assembly's MC response as a result of accidental moisture intake. Due to leakage, there has been a higher intensity of moisture content at ROI, which has led to a situation where MC may approach 15% mass during wetting seasons. However, the results show that the peak MC is always below the threshold of wood decay, i.e., 25% (ASHRAE, 2021), thus indicating a good moisture response. Moreover, the wall assembly shows a good drying potential in which the sheathing board does not store liquid moisture for a long period and, therefore, gives an indication of good moisture management.

Figure 4 (a) RHT index at the ROI for stucco wall; and (b) Moisture content— MC (% mass) over simulation period with 1 perm vapor barrier, with leakage and with no leakage

· Effect of vapor barrier permeance

In the present study, the permeance of vapor barrier (VB) ranges from 0.1 to 20 perm. The highest value is associated with no vapor barrier plus coated gypsum board. As shown in Figure 5, The vapor permeance of VB has a considerable impact on the overall moisture response. A less-permeable VB can lessen the severity of the moisture response, whereas the VB with high permeance causes a severe moisture response (i.e., the highest RHT index).

In the case of the wall with no vapor barrier and coated interior gypsum only (corresponding to 4.7 perms), the layer brings a moisture response similar to those with 5 perm vapor barriers, thus verifying the model. It has been observed that the complete removal of the vapor barrier produces a much higher level of moisture response than the other cases. Therefore, the properties of vapor barrier have a significant effect on the moisture response, and a vapor permeance between [0.1:1.0 perm] would lead to an optimum moisture strategy in wall assemblies of the type represented in this study.

Figure 5 Moisture response due to different permeance of VB: (a) RHT index, and (b) MC

Results of moisture content show similar effects on the hygrothermal response for the wall assembly subject to varied vapor permeance, as shown in Figure 5b. The wall with a vapor barrier of 10 perms and those with complete removal of the vapor barrier has significantly higher moisture contents, above the decay threshold of 25%. The trend shows a slight increase over future time. However, the peak MC occurred for a relatively short period, where it decreased considerably during drying seasons.

· Effect of Exterior Cladding

Two cladding types, brick, and regular PC stucco, have been considered as cladding material. This part aimed to identify which of these two claddings provides sufficient moisture management. The results are presented in Figure 6. The graphs clearly demonstrate that the stucco cladding consistently shows a lower moisture response intensity (i.e., lower RHT index) for all vapor barrier permeances considered. Therefore, it is evident that for the conditions given in this study, the regular PC stucco provides an enhanced level of moisture performance (Figure 6a). After closely examining the cladding material characteristics, specifically those of stucco and brick (including heat capacity, dry density, air permeability, sorption properties, suction pressure, liquid diffusivity, and water vapor permeability), it was obvious that in this case, porosity and, consequently, water diffusivity, were the properties that differ most (Figure 6b).

In order to examine this effect, the exterior claddings with material whose diffusion resistance range from low extreme to high extreme were simulated. The result shows that the most optimum moisture response is provided by a certain range of cladding properties.

Figure 6 (a) RHT Index variation due to different permeance of vapor barrier with various configurations; (b) Varied porosity properties of cladding materials

· Effect of geographical locations

Three cities in North America, namely Montreal, Vancouver, and Miami, were chosen based on their moisture load characteristics. Moisture characteristics of a location can be expressed in terms of climate indices, e.g., the moisture index (MI). MI is calculated as a function of wetting potential (WI) and drying potential (DI) (Cornick et al., 2002). In contrast to DI, which is based on annual evaporation potential, WI is computed based on annual rainfall. More severe moisture loading is indicated by a higher MI value.

Montreal, situated on the Atlantic coast of southeastern Canada, falls under the category of a humid continental climate. It experiences warm and humid summers, along with cold winters. Vancouver, located in the southwest corner of Canada, is a coastal city with a moderate oceanic climate. It is considered one of the warmest cities in Canada according to the Köppen climate classification. Moving on to Miami, its climate is classified as tropical monsoon. It is characterized by long and warm summers, hot and muggy winters, and a noticeably drier winter (Gaur and Lacasse, 2022).

The change in the RHT index with respect to the change in MI is shown in Table 1. The hygrothermal response of the wall changed as the intensity of the climate load did. Likewise, the RHT increased when accidental moisture was introduced into the stud cavity. However, the moisture responses of the models in Miami and Vancouver showed major differences despite their similar MI. This indicates a nonlinear and complex relationship between hygrothermal behavior and climate conditions (Ryan and Bristow, 2023).

Table 1 Moisture Index for three locations and the corresponding RHT Index

City | Moisture Index (MI) [-] | RHT95 (S1-RS-NL) [-] | RHT95 (S1-RS-L) [-] |

Montreal, QC | 0.93 | 0 | 0 |

Miami, FL | 1.08 | 0 | 0 |

Vancouver, BC | 1.09 | 1637 | 2239 |

To investigate this phenomenon, the authors observed the changes in MC over time for the wall assemblies in different locations, as shown in Figure 7. The right-handed figures show moisture content, whereas the left-handed figures show the outdoor climate conditions of the associated location. A significant difference was observed in the MC of the assembly in Miami, where the pattern was more irregular with a lower amplitude. This response corresponds with the temperature conditions in Miami, which fluctuate less (narrow amplitude) over the seasons, and these conditions support the drying process of the wall assemblies. The results are in line with those expected in relation to the moisture load in the respective region, where Vancouver has the highest moisture risk.

Figure 7 Moisture response (% MC) of the wall assemblies in relation to the outdoor climate conditions (T and RH): (a) Montreal; (b) Vancouver; (c) Miami

3.2. Sensitivity through Full Factorial Design

The factorial design plot in Figure 8 illustrates how major effects may be determined from the response variable and are related to the factors represented by the steepness of the plot lines. If the plot lines are not parallel, an interaction exists. The graphs display mean values where the mean values of RHT index were presented on the vertical axis, while input variables of each factor were presented on the horizontal axis (i.e., VB permeance, rain screen, moisture leakage, and cladding type). For example, the plot line with dotted yellow color represents the factor interaction of the model with VB permeance VB = 20. Meanwhile, the dotted green color and solid blue color plots represent models with VB permeance VB=1 and VB = 0.1, respectively. Taking one point on the plot, e.g., VB = 20 and RS = 1, will give a mean value of the RHT index of that yellow-line model, which is 1.64 x 104.

Figure 8 Interaction plot of factorial design. VB permeance varied to [0.1:20 perm]; Rain screen varied to 0 = without RS and 1 = with RS; Moisture leakage varied to 0 = without leakage and 1=with leakage; Cladding type varied to 0 = stucco and 1 = brick

The interaction plot indicates that the vapor permeance and cladding parameters, followed by the moisture leakage parameter, have the greatest impact on the RHT index. The effect of moisture leakage in the form of moisture convection is significant in increasing moisture response and the corresponding biodeterioration risk, i.e., RHT index. Rain screen has relatively little influence. No strong interaction exists; however, the interaction of VB permeance–cladding type is the highest among all interactions.

The method applied in this study is an alternative to the analytical design method, e.g., the Dew Point Method (ASHRAE, 2016), which poses major limitations, such as only predicting condensation without knowing the magnitude and duration of moisture accumulation. Comparative sample calculation of this method is provided in the Supplementary File—S05.

The study investigated the biodeterioration risk

of exterior walls induced by moisture accumulation through hygrothermal

simulations. The findings from this study are summarized as follows. The effect

of moisture leakage in the form of moisture convection significantly increases

the moisture response and corresponding biodeterioration risk, i.e., the RHT

index. However, the proper drying capacity provided by the barrier membrane can

maintain moisture transport within good magnitude (below mold decay threshold)

and duration (short period of moisture storage). The effect of vapor barrier

permeance is very important where a certain range of VB permeance provides

optimum moisture responses. Together with cladding material, the interactive

effect of those layers is decisive in a way that higher water vapor permeance

and solar absorptivity of the exterior cladding can help dry out the water that

has leaked into the wall assembly. Moreover, the VB permeance will affect

moisture content in interior gypsum and cladding as moisture buffers. The

effect of rain screens on the studied walls however is not decisive.

Additionally, the moisture response of the exterior wall system was also

closely correlated to the climatic moisture load in the respective region. Thus,

careful analysis should be made in relation to climate conditions and their

impact on the wall parameters. This relationships with the external climate

determine the hygrothermal response, given the dependency of the component

properties on drying and wetting potential. As such, knowledge of the roles of

material layers on the overall moisture performance of building envelopes is

essential to support design analysis for optimum moisture management. Future work will include developing a probabilistic method of moisture

risk on building envelopes to account for uncertainties and applicability that

has generic model for quantifying the risks.

The authors are

grateful to the Building Owners and Managers Association of British Columbia

(BOMA BC) for supporting this research through a Mitacs Accelerate Grant.

| Filename | Description |

|---|---|

| R1-A-6688-20231010084959.docx | --- |

Ackermann, F., Alexander, J., 2016.

Researching Complex Projects: Using Causal Mapping to Take a Systems

Perspective. International Journal of Project Management, Volume 34(6),

pp. 891–901

ASHRAE, 2016. ANSI/ASHRAE Standard 160 -

Criteria for Moisture Control Design Analysis in Buildings

ASHRAE, 2021. 2021 ASHRAE® Handbook.

Fundamentals SI edition. ASHRAE, Peachtree Corners, GA

Cannon, A.J., 2016. Multivariate Bias

Correction of Climate Model Output: Matching Marginal Distributions and

Intervariable Dependence Structure. Journal of Climate, Volume 29(19),

pp. 7045–7064

Cornick, S., Dalgliesh, A., Said, N., Djebbar,

R., Tariku, F., Kumaran, M.K., 2002. Report from Task 4 of MEWS Project-Task

4-Environmental Conditions Final Report. Institute for Research in

Construction. Ottawa: National Research Council

DIN, 2012. DIN 68800-2 Wood preservation -

Part 2: Preventive Constructional Measures in Buildings. Germany: Deutsches

Institut Fur Normung E.V.

Doan, D.T., Wall, H., Ghaffarian Hoseini, A., Ghaffarianhoseini,

A., Naismith, N., 2021. Green Building Practice in the New Zealand Construction

Industry: Drivers and Limitations. International Journal of Technology,

Volume 12(5), pp. 946–955

Fraunhofer IBP, 2022. WUFI Pro v.6 databases. Available Online at: https://wufi.de/en/2015/03/10/assessment-of-mold-growth-risk/, Accessed on 30 March, 2023

Gaur, A., Lacasse, M., 2022. Climate Data to

Support the Adaptation of Buildings to Climate Change in Canada. Data,

Volume 7(4), p. 42

Glass, S.V., Gatland, S.D., Ueno, K., Schumacher,

C.J., 2017. Analysis of Improved Criteria for Mold Growth in ASHRAE Standard

160 by Comparison with Field Observations. ASTM International, West

Conshohocken, PA 19428-2959, pp. 1–27

Hussain, T., Shamraiz, M., Abrar, S.U., 2016.

Effect of Temperature and Vacuum on the Drying Rate and Various Parameters of

Wood Samples, using an Indigenously Designed and Developed Vacuum Drying

System. International Journal of Technology, Volume 7(5), pp. 795–809

Isa, N.K.M., Yunos, M.Y.M., Ibrahim, M.H.,

Ismail, K., Marzuki, M., 2018. An Exploration of Drivers and Strategies for

Encouraging the Delivery of Green Building Projects in Housing Development. International

Journal of Technology, Volume 9(8), pp. 1702–1714

Kumaran, M.K., Mukhopadhyaya, P., Cornick,

S.M., Lacasse, M.A., Rousseau, M., Maref, W., Nofal, M., Quirt, J.D., Dalgliesh,

W.A., 2003. An Integrated Methodology to Develop Moisture Management Strategies

for Exterior Wall Systems. In: Proceedings of the 9th Canadian

Conference on Building Science and Technology, pp. 45–62

Lstiburek, J., 2002. Moisture Control for

Buildings. ASHRAE Journal, Volume 44(2), pp. 36–41

Mukhopadhyaya, P., 2003. MEWS Project Produces

Long-Term Moisture Response Indicator. Construction Innovation, Volume

8(1), pp. 6–7

Mukhopadhyaya, P., Goudreau, P., Kumaran,

M.K., van Reenen, D., 2002. Influence of Material Properties on The

Hygrothermal Response of An Ideal Stucco Wall - Results from Hygrothermal

Simulations. 2002 Trondheim, Norway, pp. 611–618

Mukhopadhyaya, P., Kumaran, K., Tariku, F., van

Reenen, D., 2006. Application of Hygrothermal Modeling Tool to Assess Moisture Response of

Exterior Walls. Journal of Architectural Engineering, Volume 12(4), pp. 178–186

Pallin, S., 2012. Probabilistic Risk

Assessment of Energy Efficient Retrofitting Techniques, Chalmers University

of Technology

Ryan, B., Bristow, D.N., 2023. Climate Change

and Hygrothermal Performance of Building Envelopes: A Review on Risk

Assessment. International Journal of Technology, Volume 14(7), pp. 1461–1475

Ryan, B., Koltsakis, E., Manoleas, P., 2019.

Finite Element Modelling and Parametric Studies of Semi-Closed Thin-Walled

Steel Polygonal Columns for The Application on Steel Lattice Towers. CSID

Journal of Infrastructure Development, Volume 2(2), pp. 204–214

Sehizadeh, A., Ge, H., 2016. Impact Of Future

Climates on The Durability of Typical Residential Wall Assemblies Retrofitted to

The Passivehaus for the Eastern Canada Region. Building and Environment,

Volume 97, pp. 111–125

Wardhana, N., Berawi,

M.A., Sari, M., 2023. Parameters Comparison of Green Building and Healthy

Building. In: Proceedings of SECON’22. Lecture Notes in Civil

Engineering. Springer International Publishing, Cham, pp. 855–867

Yamamoto, H., Takada, S., 2022. Influence of

Variability in Hygrothermal Properties on Analytical Results of Simultaneous

Heat and Moisture Transfer in Porous Materials. Journal of Building Physics,

Volume 45(6), pp. 757–773