A Novel Kinetic Model of Enzymatic Biodiesel Production in a Recirculating Fixed Bed Reactor

Corresponding email: heri.hermansyah@ui.ac.id

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.6612

Soetandar, F., Hidayatullah, I.M., Utami, T.S., Yohda, M., Hermansyah, H., 2024. Novel Kinetic Model of Enzymatic Biodiesel Production in a Recirculating Fixed Bed Reactor. International Journal of Technology. Volume 15(3), pp. 780-791

| Frederick Soetandar | 1. Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java 16424, Indonesia, 2. Bioprocess Engineering Study Program, Faculty of Engineering, Universitas In |

| Ibnu Maulana Hidayatullah | 1. Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java 16424, Indonesia, 2. Bioprocess Engineering Study Program, Faculty of Engineering, Universitas In |

| Tania Surya Utami | 1. Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java 16424, Indonesia, 2. Bioprocess Engineering Study Program, Faculty of Engineering, Universitas In |

| Masafumi Yohda | 1. Division of Biotechnology and Life Science, Institute of Engineering, Tokyo University of Agriculture and Technology, Koganei, Tokyo 184-8588, Japan, 2. Institute of Global Innovation Research, Tok |

| Heri Hermansyah | 1. Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java 16424, Indonesia, 2. Bioprocess Engineering Study Program, Faculty of Engineering, Universitas In |

Entrapped

lipase derived from Candida rugosa can be used as an

alternative for

commercial heterogeneous catalysts in the

biodiesel synthesis process.

The inclination towards a

recirculating reactor with lipase-containing beds stems from its capability to

simultaneously improve both yield and reproducibility in the biodiesel

synthesis process. To

industrialize biodiesel production with entrapped lipase in a recirculating

reactor, optimization is essential, and this can be estimated using a kinetics

model. In this context, a kinetics model based on the Ping-Pong Bi-Bi mechanism

was developed for enzyme transesterification. Following this, experiments on biodiesel

synthesis were carried out in a fixed-bed reactor with a recirculated substrate, and a biodiesel concentration of

2177.231 mol/m3 was achieved from 917.804 mol/m3

triglyceride. In this study, 3 models, namely Model 1, 2, and 3, were developed

based on the Ping-Pong Bi-Bi mechanism,

and each has assumptions that determine its complexity. To validate these models, two sets of secondary data were taken and fitted into the respective model. The sum relative

error is used to express the differences between model and experimental data. Model 1, predicting

each component in transesterification, exhibited the highest error of 1.64,

while Model 3, assuming excess alcohol and incorporating a pseudo-steady-state

for di- and monoglyceride, yielded the lowest error. Despite these variations,

every model demonstrated good agreement in following each component profile

accurately, providing a more precise description of the reaction elements.

Biodiesel; Candida rugosa lipase; Enzyme kinetic; Modelling; Recirculating fixed-bed reactor; Transesterification

Homogeneous catalysts are commonly used in biodiesel production due to their relatively simpler production methodology. However, alternative approaches such as non-catalytic processes, including high-pressure methodology, acid-catalyzed esterification, and heterogeneous catalyst transesterification has been explored (Kalita et al., 2022; Feng et al., 2010; Demirbas, 2008). Among these methodologies, heterogeneous catalyst transesterification is an important advancement to mitigate the well-recognized limitations associated with homogeneous catalysts and non-catalytic routes (Monika, Banga, and Pathak, 2023; Wancura et al., 2021; Kareem et al., 2020). The development of heterogeneous catalysts holds the potential for low-cost and stable catalysts (Aisyah et al., 2023).

Recent advances in

heterogeneous catalyst studies present the opportunity to cost-effectively

incorporate enzymes as catalysts (Kalita et al.,

2022; Ng et al., 2022; Budžaki et al., 2018). Lipase,

particularly sourced from Candida rugosa, stands out as a recognized and

effective biocatalyst for transesterification, playing a crucial role in the

evolution of biodiesel production. The notable activity and ready availability

of Candida rugosa lipase (CRL) further emphasize its efficacy in the

transesterification process (Iuliano et al.,

2020; Yücel, Terzio?lu, and Özçimen, 2012). The use of recirculating

fixed-bed reactors is preferred over other types due to their enhanced

efficiency (Ani et al., 2018; Ren

et al., 2012). These reactors not only

reduce size requirements but also enable the reuse of heterogeneous catalysts

compared to batch processes (Aliyah et al., 2016). Despite these

advantages, addressing challenges related to reaction rates, catalyst cost, and

enzyme inhibition is imperative for enhancing the use of immobilized enzymes in

biodiesel production (Hermansyah et al.,

2023; Hidayatullah et al., 2018). To overcome these challenges,

the application of kinetic models becomes crucial in identifying correlations

among operational parameters (Hidayatullah et

al., 2021).

Various

kinetics models have been developed to illustrate the initial rate of ester

production by incorporating stepwise transesterification. These models are

designed to predict reactant, by-product, and product concentrations concerning

both time and substrate concentration (Rahma and Hidayat,

2023; Ezzati, Ranjbar, and Soltanabadi, 2021; Calabrò et al., 2010; Pessoa,

Magalhães, and Falcão, 2009; Xu, Du, and Liu, 2005). While

biodiesel synthesis often involves transesterification reactions, many models

simplify the process by assuming a single substrate, typically triglyceride

concentration (Fedosov et al., 2013;

Al-Zuhair, Ling, and Jun, 2007; Al-Zuhair, 2005). Although this simplification

aids in determining substrate consumption and product formation rates, it tends

to overlook by-product formation. Some models use empirical equations for

kinetics, lacking practicality in handling varying substrate concentrations.

Intermediate products are important to be put into kinetics to fully elucidate

the synthesis pathways (Muharam and Soedarsono,

2020). To address this, there is a need for a model showing stepwise

biodiesel production from triglycerides, emphasizing formation sequences including

enzymes.

In

this study, CRL was immobilized within calcium alginate beads to

serve as a biocatalyst in the reactor. A novel mathematical model was developed

to predict both the reaction yield and the intermediates generated during

transesterification. To illustrate changes in concentration relative to

residence time, enzymatic kinetics was integrated with plug flow mass balance.

The proposed kinetics model is closely in line with experimental data, capable

of representing each transesterification element (alcohol, biodiesel,

triglyceride, diglyceride, monoglyceride, and glycerol), and representing

enzymatic transesterification pathway following the Ping-Pong Bi-Bi mechanism. Subsequently,

3 models with different assumptions and complexity were proposed. Model 1

includes all triglyceride derivatives in the reaction and considers alcohol as

the limiting reactant. Model 2 is the simplified version of model 1 by assuming

pseudo-steady state for diglyceride and monoglyceride concentration. Model 3

assume excess alcohol, resulting in complete reactions and therefore assumes

diglyceride and monoglyceride concentration to be zero.

2.1. Materials

In this study, cooking palm oil was used as a triglyceride substrate, and was produced by PT. Salim Ivomas Pratama, Tbk. (Jakarta, Indonesia). The lyophilized CRL Type VII, bovine serum albumin (BSA), and all additional reagents were purchased from Merck & Co (Rahway, NJ, USA).

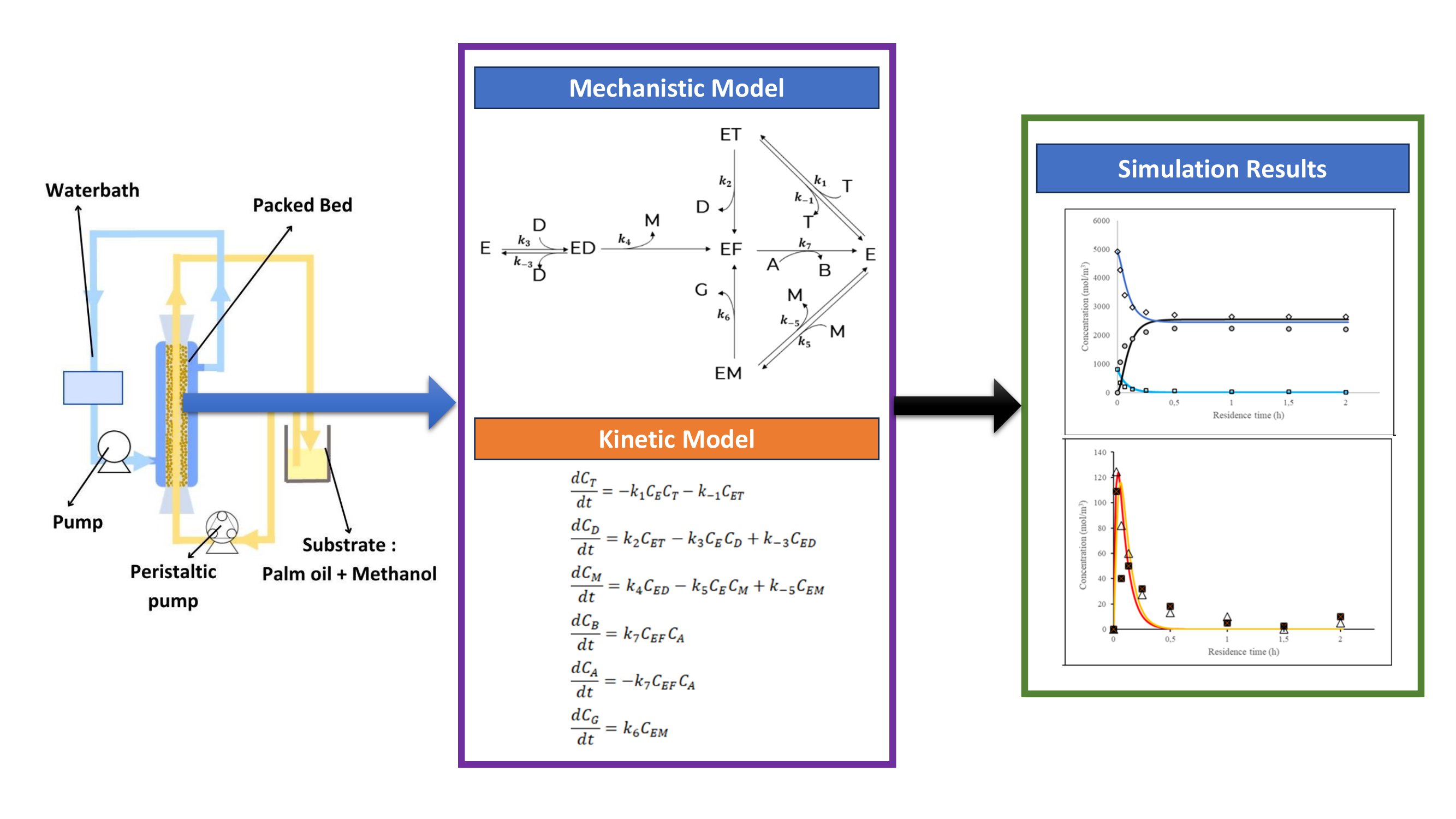

2.2. Reactor configuration and design

The reactor was configured to recirculate the substate mixture with dimensions of 15 cm in length and 1.1 cm in inner diameter. Immobilized enzymes were positioned within the reactor and secured using wire mesh. To maintain a consistent temperature of 37°C, the reactor jacket was enveloped with heated water from a water bath. This setup was linked to both a peristaltic pump and a water pump. The peristaltic pump introduced the mixed substrate into the reactor while the water pump circulated heated water to ensure the reactor temperature stability.

2.3. Enzyme Immobilization

The first step of the immobilization includes the production of sodium alginate solution. Subsequently, lipase solution was introduced to a sodium alginate solution to generate a 20 ml mixture containing 1.5% sodium alginate and 100 mg of lipase. Using a syringe, the enzyme mixture was extruded into a 2% CaCl2 solution. The resultant beads were left suspended in the CaCl2 solution for 1 hour. Then, the beads were transferred to a fresh 2% CaCl2 solution and maintained at 4°C for 24 hours.

2.4. Biodiesel Synthesis and Quantification

2.5. Model mechanism and assumptions

Biodiesel synthesis was carried out in 3 sequential elementary reaction stages. The transesterification follows Ping-Pong Bi-Bi mechanism that involves the formation of diglyceride and monoglyceride, and each reaction is reversible (Bornadel et al., 2013; Gog et al., 2012; Fjerbaek, Christensen and Norddahl., 2009). This process was carried out involving T, A, D, B, M, and G, denoting triglyceride, alcohol, diglyceride, biodiesel, monoglyceride, and glycerol respectively. Assuming there was no water-induced hydrolysis process, the only reaction in the system is transesterification.

2.6. Mathematical Model Derivation

2.7. Model Validation

The compatibility between secondary and estimation data from the developed kinetics model is shown by fitting it with transesterification data from other studies. There are 3 data sets used for model fitting, namely experimental data from this study, data from Shibasaki-Kitakawa et al. (2007), and data from Vicente (2006). Table 1 shows the experimental data and it was used to perform fittings with Models 2 and 3. Triglyceride and alcohol concentration in Table 1 were calculated from FAME concentration based on stoichiometric equilibrium. The data in Table S1 was obtained from Shibasaki-Kitakawa et al. (2007) and will be used for fitting with Model 3. The data shown in Table S2 was obtained from Vicente (2006) and will be used for fitting with Model 1. The fitting quality will be assessed using the relative error sum in Equation 38.

Using the Microsoft Excel software, differential equations were simulated through 4th-order Runge-Kutta numerical calculations, and the Solver program within Excel was used for data fitting. The alignment between experimental data and fitting results showcases the model's accuracy in estimating experimental data. Each model iteratively adjusts its kinetics parameters to minimize the sum of relative errors, aiming to achieve a value close to 0.

3.1.

Modelling result

In Figures 3-4, Model 3 presents concentration profiles with

the assumption of excess alcohol. The data fitting from Table 1 and S1 to Model

3 is shown in Figure 3a and 3b, respectively. While Model 3 is capable of

estimating the formation of both biodiesel and triglycerides, it tends to overestimate

the concentration of biodiesel. According to molar balance principles, it is

expected that additional products arise from the transformation of

triglycerides. Assuming only transesterification occurs, diglycerides and

monoglycerides are expected as secondary products. However, due to Model 3

assumption of the absence of intermediate product formation, it simulates a

thorough conversion of diglycerides and monoglycerides into biodiesel and

glycerol.

It is crucial to take into account alcohol concentration,

especially when making incremental additions, as alcohol plays the role of a

limiting reactant. Model 2 incorporates alcohol concentration into its

equations and assumes a pseudo-steady state for intermediates (D and M) to

simplify the model. The visual representation of the fitting results obtained

from the data in Table 1 can be observed in Figure 3c. Model 2 can replicate

the concentration profiles of each component by assuming a pseudo-steady state

for diglycerides and monoglycerides. The fitting results of Model 2 do not

significantly differ from those of Model 3. This shows that Model 2 is capable of simulating the data

while considering limited concentrations of methanol.

Figure 3 Fitting of a) data from this study

using Model 3, b) data from Shibasaki-Kitakawa et al. (2007) using Model 3, and c) data from this

study using Model 2

Figure 4 shows the data fitting from Table S2 into Model 1,

which considers the concentration profiles of A, D, and M. The Model examines

the formation of D and M as intermediates, recognizing their potential impact

on biodiesel yield. Diglycerides and monoglycerides can form due to the

transesterification reaction occurring in three elementary steps(Kadi et

al., 2019). When enzymes catalyze the

formation of biodiesel, one of the three fatty acid chains on triglycerides is

detached, resulting in the formation of diglycerides. Monoglycerides are

generated when one of the two fatty acids in a diglyceride reacts to form

biodiesel, leaving a single fatty acid chain on the glycerol molecule.

Model 1 shows a strong

agreement with the data. After reaching the peak, both D and M decrease and

reach very low concentrations. The reduction in the concentration of D and M is

attributed to a gradual reaction with a consumption rate higher than the formation

rate. The negligible amount of D and M at the higher reaction time has been

observed in most reports (Chen et al., 2020; Tran, Chen and Chang, 2016; Haigh et

al., 2014). Model 1 can replicate this phenomenon while

also simulating biodiesel formation. The model overestimates biodiesel and

underestimates alcohol concentration. However, the prediction of triglyceride

concentration yields accurate results. Despite triglycerides being completely

consumed, the data shows a lower concentration of biodiesel than in the

simulation. A few possibilities might explain this, including the potential

formation of other side products such as inactive enzyme-fatty acid complexes

or even the adsorption of triglycerides onto the enzyme's support matrix.

Figure 4 Fitting to Model 1 using data from Vicente et al. (2006)

Table 2 presents a

comparison of kinetics parameters, showing the highest reaction constant

derived from an experiment conducted by Vicente et

al. (2006). The experiment used 1 wt% catalyst (based on oil) for

transesterification. According to the investigation, the reactant was 240 g of B.

carinata oil (± 800 mol/m3), and for simplicity, it was assumed

to be equivalent to 300 mL (assuming a density of 800 g/L). This led to the

calculation of the concentration of catalyst used, which is 8 kg/m3.

Shibasaki-Kitakawa et al. (2007) synthesized biodiesel using 2 g of PA306s resin and

10g of reactants consisting of oil and 10 - 20 molar equivalents of methanol

(based on oil). Assuming this 10g was equal to 20 ml of reactant, the

concentration of the catalyst is estimated to be 100 kg/m3. Although

the kinetics constant for each catalyst might appear low, the overall reaction

rate can be substantial with the assistance of a significant quantity of

catalysts.

Table

2 Comparison of kinetics parameter

|

Kinetics constant |

Model 1 |

Model 3 |

Model 2 | |

|

Data from: | ||||

|

Vicente et al. (2006) |

Shibasaki-Kitakawa et al.

(2007) |

This study |

This study | |

|

K1 |

1.59 |

9.95×10-2 |

1.70×10-1 |

4.58×10-2 |

|

K2 |

6.55 |

- |

- |

- |

|

K3 |

6.27 |

- |

- |

- |

|

K4 |

0 |

2.77×10-6 |

8.00×10-5 |

6.66×10-3 |

|

K5 |

6.09 |

2.60×10-6 |

8.28×10-3 |

4.55×10-3 |

|

K6 |

8.40 |

2.70×10-6 |

8.28×10-3 |

5.47×10-2 |

|

CE,tot |

8 |

100 |

1.77 |

1.77 |

|

sum relative error |

1.64 |

3.49×10-2 |

4.13×10-2 |

5.05×10-2 |

In the

context of the stepwise transesterification

reaction, K1 signifies the

inclination to yield diglycerides. K2 represents the tendency to

generate monoglycerides from diglycerides, and K3 shows the propensity to release glycerol from

monoglycerides. These constants show

forward reactions. In Models 2 and 1, where diglycerides and monoglycerides are

assumed to react rapidly, K2 and K3 are excluded.

Conversely, K4, K5, and K6 denote hindrances

to biodiesel formation. K4-K6 are associated with k2,

k4, and k6, reflecting the rate constants of diglyceride,

monoglyceride, and glycerol release. K4 represents the dissociation

of triglyceride, leading to the enzyme complex producing biodiesel from the

fatty acid of triglyceride. The same meaning also applies to K5 and

K6, with the only difference in the source of fatty acid (such as

diglyceride for K5, and monoglyceride for K6).

In

Model 3, a total of 6 parameters need to be estimated, while Models 1 and 2

require 4. The resulting parameter data shows that ion exchange resin exhibits the highest K1 reaction

rate. Model 2, assuming a controlled alcohol

reaction, shows

significant changes in the constant K6 when compared to Model 1. The experiment carried out by Vicente

et al. (2006) had the highest value of kinetics constants compared to other

studies.

In

conclusion, 3 mechanistic models based on the Ping-Pong Bi-Bi mechanism were

developed to predict how each part of triglyceride transesterification behaves.

Each model could provide a better understanding of how both the reactants and

products change over time. Model key parameter helps to explain how operational

conditions affect the transesterification process. Data fitting of this

experiment data into Model 3 resulted in 4.13×10-2, which shows good

alignment. However, Model 1 had a high sum relative error, due to many

substrates and product concentrations that the model need to adjust, therefore

the sum relative error calculates all the misalignments, producing the highest

sum of error. This model could become a go-to reference for understanding

transesterification kinetics and further studies on the inhibition of substrate

and product are needed to improve the model.

The

study was supported by supported by the Ministry of

Education, Culture, Research, and Technology of Indonesia through the Penelitian

Dasar Unggulan Perguruan Tinggi (PDUPT) scheme, with grant numbers 021/E5/PG.02.00.PL/2023

and NKB-905/UN2.RST/HKP.05.00/2023 in the year 2023.

| Filename | Description |

|---|---|

| R3-CE-6612-20231217145727.docx | --- |

Aisyah, A.N., Ni’maturrohmah, D., Putra, R.,

Ichsan, S., Kadja, G.T.M, Lestari, W.W., 2023. Nickel Supported on MIL-96(Al)

as an Efficient Catalyst for Biodiesel and Green Diesel Production from Crude

Palm Oil. International Journal of Technology, Volume 14(2), pp. 276–289

Aliyah, A.N., Edelweiss,

E.D., Sahlan, M., Wijanarko, A., Hermansyah, H., 2016. Solid State Fermentation

Using Agroindustrial Wastes To. International Journal of Technology,

Volume 8, p.1392–1403

Al-Zuhair, S., 2005.

Production of Biodiesel By Lipase-Catalyzed Transesterification of Vegetable

Oils: A Kinetics Study. Biotechnology Progress, Volume 21(5), pp.

1442–1448

Al-Zuhair, S., Ling, F.W., Jun,

L.S., 2007. Proposed Kinetic Mechanism Of The Production Of Biodiesel From Palm

Oil Using Lipase. Process Biochemistry, Volume 42(6), pp. 951–960

Ani,

F.N., Said, N.H., Said, M.F.M., 2018. Optimization of Biodiesel Production

using a Stirred Packed-bed Reactor. International Journal of Technology,

Volume 9(2), pp. 219–228

Bornadel,

A., Åkerman, C.O., Adlercreutz, P., Hatti-Kaul, R., Borg, N., 2013. Kinetic

Modeling of Lipase-Catalyzed Esterification Reaction Between Oleic Acid and

Trimethylolpropane: A Simplified Model for Multi-Substrate Multi-Product

Ping–Pong Mechanisms. Biotechnology Progress, Volume 29(6), pp. 1422–1429

Budžaki, S. Milji?.,

G., Sundaram, S., Tišma, M., Hessel, V., 2018. Cost Analysis of Enzymatic

Biodiesel Production in Small-Scaled Packed-Bed Reactors. Applied Energy,

Volume 210(6), pp. 268–278

Calabrò,

V., Ricca, E., De Paola, M.G., Curcio, S., Iorio, G., 2010. Kinetics of

Enzymatic Trans-Esterification of Glycerides For Biodiesel Production. Bioprocess

and Biosystems Engineering, Volume 33(6), pp. 701–710

Chen,

X., Li, Z., Chun, Y., Yang, F., Xu, H., Wu, X., 2020. Effect of the Formation

of Diglyceride/Monoglycerides on the Kinetic Curve in Oil Transesterification

with Methanol Catalyzed by Calcium Oxide. ACS Omega, Volume 5(9), pp.

4646-4656

Demirbas,

A., 2008. Biodiesel: A Realistic Fuel Alternative For Diesel Engines. In: Biodiesel:

A Realistic Fuel Alternative for Diesel Engines. London: Springer

Ezzati,

R., Ranjbar, S., Soltanabadi, A., 2021. Kinetics Models Of Transesterification

Reaction For Biodiesel Production: A Theoretical Analysis. Renewable Energy,

Volume 168, pp. 280–296

Fedosov, S.N., Brask, J.,

Pedersen, A.K., Nordblad, M., Woodley, J.M., Xu, X., 2013. Kinetic Model Of

Biodiesel Production Using Immobilized Lipase Candida Antarctica Lipase B. Journal

of Molecular Catalysis B: Enzymatic, Volume 85, pp. 156–168

Feng, Y., He, B., Cao, Y.,

Li, J., Liu, M., Yan, F., Liang, X., 2010. Biodiesel Production Using

Cation-Exchange Resin as Heterogeneous Catalyst. Bioresource Technology,

Volume 101(5), pp. 1518–1521

Fjerbaek, L., Christensen,

K., Norddahl, B., 2009. A Review of The Current State of Biodiesel Production Using

Enzymatic Transesterification. Biotechnology and Bioengineering, Volume

102(5), pp. 1298–1315

Gog, A., Roman, M., To?a,

M., Paizs, C., Irimie, F., 2012. Biodiesel Production using Enzymatic

Transesterification – Current State and Perspectives. Renewable Energy, Volume

39(1), pp. 10–16

Haigh, K., Vladisavljevi?, G.T., Reynolds, J.C., Nagy, Z.,

Saha, B., 2014. Kinetics of the Pre-treatment of Used Cooking Oil using

Novozyme 435 for Biodiesel Production. Chemical Engineering Research and

Design, Volume 92(4), pp. 713–719

Hermansyah,

H., Ibnu-Maulana, H., Frederick, S., Pingkan-Vanessa, S., Patrick, C., 2023.

Ion Exchange Resin and Entrapped Candida rugosa Lipase for Biodiesel

Synthesis in the Recirculating Packed-Bed Reactor?: A Performance Comparison of

Heterogeneous Catalysts. Energies, Volume 16(12), p. 4765

Hermansyah,

H., Kubo, M., Shibasaki-Kitakawa, N., Yonemoto, T., 2006. The Mathematical

Model For Stepwise Hydrolysis Of Triolein Using Candida Rugosa Lipase In

A Biphasic Oil-Water System. Biochemical Engineering Journal, Volume

31(2), pp. 125–132

Hidayatullah,

I.M., Arbianti, R., Utami, T.S., Suci, M., Sahlan, M., Wijanarko, A., Gozan,

M., Hermansyah, H., 2018. Techno-Economic Analysis Of Lipase Enzyme Production

From Agro-Industry Waste With Solid State Fermentation Method. IOP

Conference Series: Materials Science and Engineering, Volume 316(1), p.

012064

Hidayatullah,

I.M., Makertihartha, I.G.B.N., Setiadi, T., Kresnowati, M.T.A.P., 2021.

Modeling-Based Analysis And Optimization Of Simultaneous Saccharification and Fermentation

For The Production Of Lignocellulosic-Based Xylitol. Bulletin of Chemical

Reaction Engineering & Catalysis, Volume 16(4), pp. 857–868

Iuliano, M., Sarno, M., De Pasquale, S., Ponticorvo, E.,

2020. Candida rugosa lipase for the biodiesel production from renewable

sources. Renewable Energy, Volume 162, pp. 124-133

Kadi, M., Akkouche, N., Awad, S., Loubar, K., Tazerout,

M., 2019. Kinetic Study of Transesterification Using Particle Swarm

Optimization Method. Heliyon, Volume 5(8), p. 101016

Kalita,

P., Basumatary, B., Saikia, P., Das, B., Basumatary, S., 2022. Biodiesel As Renewable Biofuel Produced Via Enzyme-Based

Catalyzed Transesterification. Energy Nexus, Voume 6, p. 100087

Kareem,

S.O., Falokun, E.I., Balogun, S.A., Akinloye, O. A., Omeike, S.O., 2020. Improved

Biodiesel From Palm Oil Using Lipase Immobilized Calcium Alginate And Irvingia Gabonensis

Matrices. Beni-Suef University Journal of Basic and Applied

Sciences, Volume 9(1), p. 101186

Monika,

Banga, S., Pathak, V.V., 2023. Biodiesel production from waste cooking oil: A

comprehensive review on the application of heterogenous catalysts. Energy

Nexus, Volume 10(5), p. 100209.

Muharam, Y., Soedarsono, J.A. 2020.

Hydrodeoxygenation of Vegetable Oil in a Trickle Bed Reactor for Renewable

Diesel Production. International Journal of Technology, Volume 11(7),

pp. 1292–1299

Ng,

W.Z., Obon, A.A., Lee, C.L., Ong, Y.H., Gourich, W., Maran, K., Tang, D.B.Y.,

Song, C.P., Chan, E.S., 2022. Techno-Economic Analysis

Of Enzymatic Biodiesel Co-Produced In Palm Oil Mills From Sludge Palm Oil For

Improving Renewable Energy Access In Rural Areas. Energy, Volume 243, p.

122745

Pessoa,

F.L.P., Magalhães, S.P., Falcão, P.W.C., 2009. Kinetic Study of Biodiesel

Production by Enzymatic Transesterification of Vegetable Oils. Computer

Aided Chemical Engineering, Volume 27, pp. 1809-1814

Rahma, F.N., Hidayat, A., 2023. Biodiesel

Production from Free Fatty Acid using ZrO2/Bagasse Fly Ash Catalyst. International

Journal of Technology, Volume 14(1), pp. 206–218

Ren, Y., He, B., Yan, F., Wang, H., Cheng,

Y., Lin, L., Feng, Y., Li, J., 2012. Continuous Biodiesel Production in a Fixed

Bed Reactor Packed with Anion-Exchange Resin as Heterogeneous Catalyst. Bioresource

Technology, Volume 113, pp. 19–22

Shibasaki-kitakawa,

N., Honda, H., Kuribayashi, H., Toda, T., 2007. Biodiesel Production Using

Anionic Ion-Exchange Resin As A Heterogeneous Catalyst. Bioresource

Technology, Volume 98(2), pp. 416–421

Tran,

D.T., Chen, C.L., Chang, J.S., 2016. Continuous Biodiesel Conversion via

Enzymatic Transesterification Catalyzed By Immobilized Burkholderia Lipase in a

Packed-Bed Bioreactor. Applied Energy, Volume 168, pp.340-350

Vicente,

G., Martínez, M., Aracil, J., 2006. Kinetics Of Brassica Carinata Oil

Methanolysis. Energy and Fuels, Volume 20(4), pp. 1722–1726

Wancura, J.H., Fantinel,

A.L., Ugalde, G.A., Donato, F.F., De Oliveira, J.V., Tres, M.V., Jahn, S.L., 2021.

Semi-Continuous Production of Biodiesel on Pilot Scale via Enzymatic

Hydroesterification of Waste Material: Process and Economics Considerations. Journal

of Cleaner Production, Volume 285, p. 124838

Xu,

Y., Du, W., Liu, D., 2005. Study On The Kinetics of Enzymatic

Interesterification Of Triglycerides For Biodiesel Production With Methyl

Acetate As The Acyl Acceptor. Journal of Molecular Catalysis B: Enzymatic,

Volume 32(5–6), pp. 241–245

Yücel,

S., Terzio?lu, P., Özçimen, D., 2012. Lipase Applications in Biodiesel

Production. In Biodiesel: Feedstocks, Production and Applications.

IntechOpen