Machine Learning Algorithms for Failure Prediction Model and Operational Reliability of Onshore Gas Transmission Pipelines

Corresponding email: andy.noorsaman@ui.ac.id

Published at : 09 May 2023

Volume : IJtech

Vol 14, No 3 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i3.6287

Noorsaman, A., Amrializzia, D., Zulfikri, H., Revitasari, R., Isambert, A., 2023. Machine Learning Algorithms for Failure Prediction Model and Operational Reliability of Onshore Gas Transmission Pipelines. International Journal of Technology. Volume 14(3), pp. 680-689

| Andy Noorsaman | Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Dea Amrializzia | Department of Process Engineering, PT. Rekayasa Engineering, Jl. Kalibata Timur II No.36, South Jakarta, Jakarat 12740, Indonesia |

| Habiburrahman Zulfikri | Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Reviana Revitasari | Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Arsene Isambert | Laboratoire de Genie de Procedes et Materiaux, Ecole Centrale Paris, F 92295 Chatenay Malabry Cedex, France |

A

transmission pipeline is the safest and most effective way of transporting

large volumes of natural gas over long distances. However, if not maintained

efficiently, failures of gas transmission pipelines can occur and cause

catastrophic events. Therefore, an accurate prediction of pipe failures and

operational reliability is required to determine the optimal pipe replacement timing

such that the incidence of pipe failures can be prevented. Nowadays,

computer-assisted technology helps businesses make better decisions, and

machine learning is among the excellent techniques that can be utilized in

predicting failures. In this study, two machine learning algorithms, i.e.,

random forest and binary logistic regression, are developed, and their

prediction abilities are compared. The model is developed based on a decade of

unstructured and complex historical failure data of the onshore gas

transmission pipelines released by the United States Department of

Transportation. The modeling process begins with data pre-processing followed

by model training, model testing, performance measuring, and failure

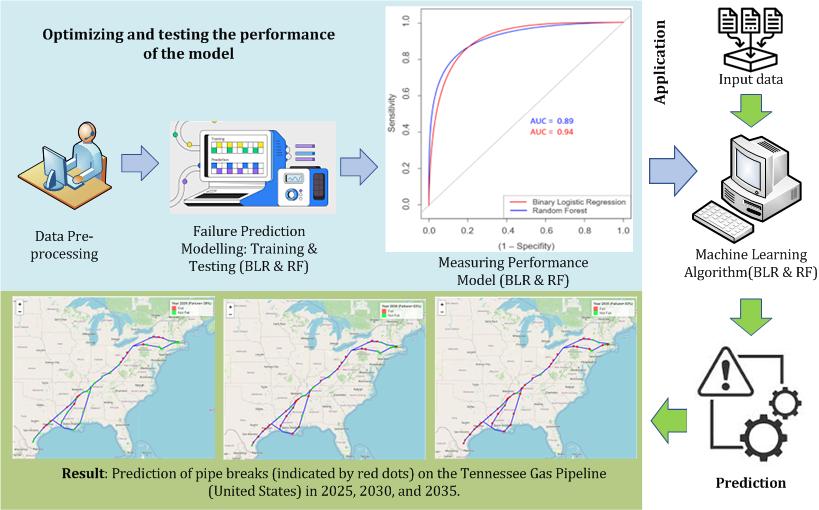

predicting. Both algorithms have demonstrated excellent

results. The random forest model achieved an AUC of 0.89 and a predictive

accuracy of 0.913, while the binary logistic regression model outperformed with

an AUC of 0.94 and a prediction accuracy of 0.949. The trained model is further

employed to predict future failures on a 11900-mile natural gas pipeline

spanning from Louisiana to the northeast section of the United States. We show

the location of the pipes that will be broken in the interval of five years and

estimate that 29%/63%/83% of the pipes will break by 2025/2030/2035.

Binary logistic regression; Failure prediction; Machine learning; Random forest; Transmission pipeline

Natural gas as a petroleum substitute offers many economic, technological, and environmental benefits and increases efficiency because it is quickly developed (Lee et al., 2012) as cited in Bawono and Kusrini, 2017). It is a versatile energy source because it can be stored and transported in trucks or tankers as liquified natural gas, medium-conditioned liquified gas, or compressed natural gas (Ríos-Mercado and Borraz-Sánchez, 2015) as cited in (Farizal, Dachyar, and Prasetya, 2021). However, Mikolajková-Alifov et al. (2019) study conveys that transporting large amounts of natural gas via pipelines, one of which is through onshore gas transmission pipelines, is more cost-effective (Farizal, Dachyar, and Prasetya, 2021). A submarine pipeline in a submerged floating tunnel (SFT) is proposed as an alternative solution to pipeline-related ecological issues (Budiman, Raka, and Wahyuni, 2017). However, SFT is not covered by the scope of this study, which is concerned with a natural gas pipeline that runs from Louisiana to the northeast United States.

Although

more efficient than trucks or tankers, onshore gas transmission pipelines face

serious challenges. Its failures are disastrous, causing financial losses,

environmental damage, and even death. Gas pipeline failures are caused by

several factors, including pipe/weld material failure, excavation damage,

corrosion, equipment failure, soil movement, and incorrect operation (Dai et al., 2017). Between January 2010 and November

2017, approximately 17.55 billion cubic feet of methane gas was lost through

the transmission pipeline in the United States. This amount of gas is enough to

heat around 233 thousand houses for a year. Unfortunately, during this period,

pipeline failures caused nearly 100 fatalities, and around 500 injuries, and

incurred a cost of approximately 1.1 billion US dollars

In the

context of industrial internet of things (IIoT)– increased interconnectedness

and opportunities to collect data, process and analyze information – predictive

maintenance can be a good strategy to face the problem. Predictive maintenance

utilizes a wealth of process data and advanced analytical methods to predict

failures well before urgent action has to be taken.

The current

era of the fourth industrial revolution has enabled computer-assisted

technology to help businesses, including the oil and gas industries, make

better decisions (Hanga and

Kovalchuk, 2019).

In particular, machine learning techniques, which allow for automation of the

process of analytical model building, offer great potential in predicting

failures accurately. Machine learning tools are built to learn from data by

establishing data structures and mapping complex relationships between input

parameters and targets such that they can adapt to future input data (Shalev-Shawrtz and Ben-David, 2014). For instance, recently, the

machine-learning created model for predicting pipe failures in water supply

networks in Seville, Spain, shows detailed estimation and suggest specific and

realistic suggestion to prevent approximately 30% of failures by replacing only

3% of the network's pipes annually (Robles-Velasco et al., 2020). Eastvedt, Naterer, and Duan

(2022) have

presented a method of monitoring a subsea oil pipeline for fault detection

using a regression-supervised machine learning (ML) algorithm. ML algorithms

were developed by using flow velocity data derived from ANSYS Fluent

simulations, pressure, and temperature. It shows that the ML algorithm could

97% accurately predict the outputs (Eastvedt, Naterer,

and Duan, 2022). A study has also been carried out by

analyzing the performance of the Bayesian network in predicting pipe failure

using a large and highly variable dataset from the water distribution system in

the United Kingdom. Method one involved a supervised learning method to build a

Bayesian network by understanding common failure types (joint, pinhole,

circumferential, and longitudinal), while method two involved an automated

learning method. The Bayesian network built using the automated method was able

to achieve an overall accuracy of 84.4% compare to the 81.2% for the Bayesian

network supervised learning method (Tang, Parsons,

and Jude, 2019). Therefore, machine learning, if trained properly, can predict

failures quickly and accurately. In this study, two ML algorithms, i.e., random

forest and binary logistic regression, are developed, and their performances

are compared in predicting a decade of historical data on gas transmission

pipeline failures in the US.

2.1. Raw Dataset

Figure 1 Map of status of pipes for onshore natural gas transmission in the United

States from 2010 to 2020

2.2. Methods

Pre-processing,

learning, testing, performance measuring, and mapping of the datasets were

performed using R, a language and software environment for statistical

computing, version 4.0.2. R studio version 1.2.5042 was used as an integrated

development environment for R. The ‘caret’ R package was used to perform the

models (Kuhn, 2008), and Leaflet, an

open-source JavaScript library, is employed to create an interactive map of the

pipes network with the attached state of failure.

2.2.1. Data Pre-Processing

Raw datasets

are usually not used directly in machine learning because of several reasons,

including missing values and noises. Therefore, data pre-processing is

necessary to perform easy operations in later steps. Firstly, the attributes

deemed irrelevant to the prediction system, such as gas flow, and the

attributes with more than 50% missing values, are eliminated. Secondly, to

improve the predictors’ predictive performance and to simplify the model for

easy interpretation, several most influential attributes in the prediction

problems are selected based on the importance value (Guyon

and

Elisseeff, 2003). Here, calculations of filter-based variable importance were

carried out to select attributes for the model. Thirdly, we divided the dataset

into 90% of the dataset for the training set and the remaining 10% for the

testing set. We note that the percentage of failed and not-failed pipes in both

training and testing data sets is the same.

It is well

known that the problem of learning from imbalanced data (He and

Gracia, 2009) emerged from underrepresented data, and severe class distribution

skews can cause the standard classification models to perform improperly (Wang et al., 2013). In the

present study, the dataset is imbalanced as 84% of the data are correlated to

the “fail” status, and hence the model will tend to predict a “fail” status.

One method that can be applied to solve the imbalance problem, which is

employed in the present study, is the Randomly Over Sampling Example (ROSE)

technique. One method that can be applied to solve the imbalance problem, which

is employed in the present study, is the Randomly Over Sampling Example (ROSE)

technique (Lunardon, Menardi, and Torelli, 2014). After

incorporating the imbalanced treatment is incorporated in the pre-processing

step, the user data is ready to be used for the machine learning algorithms.

2.2.2. Failure Prediction

Modeling: Training and Testing

The random forest algorithm is a classification

model that consists of a structured collection of trees. Unlike a decision

tree, which only consists of one tree in the classification and prediction

process, a random forest creates a voting mechanism for the class, which

significantly affects the accuracy of the model (Chen, Liaw, and Breiman, 2004). Decision trees are generated using the

attribute selection indicators such as information acquisition, acquisition

ratio, and the Gini index for each attribute. The Gini index is used to measure

the probability of a particular variable being misclassified when randomly

selected.

where

f(x) is the predicted output. n is the number of decision trees in the

forest.

fi(x) is the predicted output of the ith decision tree.

Each decision tree is trained on a different subset of the training data

and a random subset of the features. The final prediction is made by taking the

average of the predictions of all the decision trees.

Random forest depends on

a random vector value with the same distribution in all trees. Each decision

tree has the maximum depth. The random forest is a classifier consisting of a

tree classifier is a random vector distributed independently,

and each tree with the most votes and the most popular class is selected as a

result. RF is arguably simpler and more powerful than other non-linear

classification algorithms (Breiman, 2001).

2.2.3. Measuring Performance

In building

the prediction system, we need a numerical indicator to tell whether the system

performs well or not. The performance is measured by the confusion matrix, the

receiver operating characteristic (ROC) curve, and the estimation of the

accuracy. The confusion matrix contains the real values against those predicted

for the validation set (Table II). There are four possible results for each

sample: true-positive (TP), true-negative (TN), false-positive (FP), and false-negative

(FN). Each box would include the value of observations of each type (Han, Kamber and Pei, 2000).

Table 1 Confusion matrix for

evaluating the performance of a classification model

|

|

|

Predicted |

| |

|

|

|

Negative |

Positive | |

|

Actual |

Negative |

TN |

FP | |

|

Positive |

FN |

TP | ||

The Receiver

Operating Characteristics curve depicts the TP rate (or recall) against the FN

rate (or 1?specificity) for the different values of a risk threshold. The

accuracy is calculated as the fraction of the correct predictions to the total

predictions. Furthermore, it is common to calculate the Area Under the Curve

(AUC) as a metric, representing a classifier’s ability to avoid false

classifications. The AUC is between 0 and 1

After

optimizing and testing the performance of the model, we applied it to predict

the failure on a 11900-mile natural gas pipeline that spans from Louisiana to

the northeast section of the United States. The pipeline is operated by the

Tennessee Gas Pipeline Company. The reconstructed dataset consists of

approximately 50 documented properties, including diameter, material, and

length.

We considered thirteen attributes, the importance value of which are

calculated and shown in Table II. The correlation value between pipe failures

(dependent variable) and other selected attributes (independent variable) from

the training datasets is listed in the column of Table II. Attributes, the

importance value of which is below 0.5, are considered to have no relevance to

pipe failures (Wang et al., 2016).

Therefore, the attributes "Explode Indication," "Ignite

Indication," and "Case" are excluded in the modeling stage, and

further computation will only consider the remaining ten attributes.

Table 2 Attributes of the

dataset with the type of data, description, and the important values between

each attribute and the “Failure” attribute.

|

Name

of Attributes |

Type |

Description |

Value |

|

Explode

Indication |

Categorical |

Indication

of possible pipe explosion |

0.206 |

|

Ignite

Indication |

Categorical |

Indication

of possible pipe ignition |

0.212 |

|

Cause |

Categorical |

Cause

of pipe failure |

0.215 |

|

MAOP |

Numerical |

Maximum Allowable Operating Pressure in

psig |

0.630 |

|

Thickness |

Numerical |

The

pipe’s wall thickness is in inch |

0.634 |

|

Depth |

Numerical |

The

depth of cover in inch |

0.637 |

|

Age |

Numerical |

The

pipe’s age in a year |

0.647 |

|

Area |

Categorical |

The

area of the laid pipe |

0.651 |

|

Coat |

Categorical |

The

pipe coating type |

0.655 |

|

Diameter |

Numerical |

The

nominal pipe size in inch |

0.689 |

|

Length |

Numerical |

The

length of isolation segment in ft |

0.741 |

|

Class |

Categorical |

The

pipe class (class 1, class 2, and class 3) |

0.842 |

|

Failure |

Categorical |

The

status of the pipe (fail or not fail) |

1 |

Table

3 displays how each algorithm performed on the testing data by creating the

confusion matrix for each algorithm. The rows in a confusion matrix correspond

to what the machine learning algorithm predicted, and the columns correspond to

the historical data. Both algorithms perform very well in predicting at least

93.5% of the failed pipes and 80% of the not-failed pipes. BLR algorithm

performs slightly better than the RF algorithm as BLR identifies 4 more failed

pipes correctly, bringing the percentage of correctly identified failed pipes

to 97.2%.

Table 3 Confusion matrix

obtained from the BLR and RF algorithms

|

Algorithm: BLR |

Predicted | ||

|

Not Fail |

Fail | ||

|

Actual |

Not Fail |

16 (80.0%) |

3 (2.8%) |

|

Fail |

4 (20.0%) |

104 (97.2%) | |

|

Algorithm: RF |

Predicted | ||

|

Not Fail |

Fail | ||

|

Actual |

Not Fail |

16 (80.0%) |

7 (6.5%) |

|

Fail |

4 (20.0%) |

100 (93.5%) | |

Table 4 presents a summary of the accuracy, sensitivity, precision, and F1 score of both studied algorithms. Based on the results, logistic regression is preferred over the random forest model due to its superior performance in terms of accuracy, precision, recall, and F1 score. The higher F1 score of the logistic regression model suggests that it is more effective in predicting outcomes and is more stable than the random forest model.

Table 4 The performance of machine learning algorithms

|

Performance |

Binary Logistic Regression |

Random Forest |

|

Accuracy |

0.945 |

0.913 |

|

Specificity |

0.842 |

0.696 |

|

Precision |

0.972 |

0.935 |

|

Recall |

0.963 |

0.962 |

|

F1

Score |

0.967 |

0.948 |

Figure 2 ROC curve for pipe failures obtained from the application of binary

logistic regression and random forest algorithms. The values of AUC are also

indicated.

ROC curves, which plot the true positive rate (sensitivity/recall) in the

y-axis as a function of the false positive rate (1?specificity) in the x-axis,

from the computations using each algorithm are shown in Figure 2. The ROC

curves for both methods can be categorized as excellent since the area under

the curve (AUC) value is higher than 0.9. (Hosmer and Lemeshow, 2000). Again, the BLR algorithm demonstrates a

slightly better performance as the resulting AUC is larger than that of RF

(0.89 vs 0.94).

As the binary logistic regression

algorithm shows better performance, we employ it to predict the failures of the

pipeline operated by the Tennessee Gas Pipeline. This pipeline is chosen

because the available data match the input attribute requirements of the

trained model. The results are mapped into the geographical location of the

pipeline shown in Figure 3. Our analysis

predicts that 29% of the pipes are expected to break by 2025, 63% by 2030, and 83%

by 2035. Interestingly, the percentage of predicted pipe breaks does not

increase monotonically as a function of time, with the highest number of pipe

breaks anticipated to occur between 2025 and 2030.

Figure 3 Prediction of pipe breaks (indicated by red dots) on the Tennessee Gas

Pipeline in 2025, 2030, and 2035

A study on the failure prediction and operational

reliability of gas transmission pipelines using random forest and binary

logistic regression algorithms has been carried out. Both algorithms showed

excellent results. Random forest has an AUC of 0.89 and a prediction accuracy

of 0.913, while the binary logistic regression shows better performance, namely

an AUC of 0.94 and a prediction accuracy of 0.949. The created model is

expected to help companies assess and predict failures of transmission gas

pipelines such that better inspections and maintenance schedules can be

conducted. The trained model predicts that 29%/63%/83% of the pipes on a

11900-mile natural gas pipeline spanning from Louisiana to the northeast

section of the United States will break by 2025/2030/2035. Several aspects can

be explored to further improve the present study. Firstly, we note that some

important attributes, e.g., temperature and natural gas flow, which we

estimate, can improve prediction performance, were not available in the raw

dataset. Secondly, this study has not considered the costs incurred due to pipe failures and the costs required

to maintain the pipes. Such economic analysis will be beneficial for the

industry to plan their annual budget accordingly. This study can help gas

transmission pipeline industry optimize their preventive maintenance schedule

in advance. This allows for estimating the remaining runtime of pipelines with

high accuracy. It also can estimate time to failure and identify which sections

of pipelines need to be fixed. By predicting failures before they happen,

companies can minimize the possibility of catasthrophic incidents, and the cost

due to unplanned downtimes or maintenance.

The authors would like to

thank the Process Systems Engineering Laboratory, Chemical Engineering

Department, Engineering Faculty, Universitas Indonesia for the computing

facilities provided.

Bawono, A. A., Kusrini, E., 2017. The Impacts

of Financing Investment

Scenarios On Piped-Natural Gas Prices (GPs) for Households in Indonesia. International

Journal of Technology, Volume 8(8), pp. 1402–1413

Breiman, L., 2001. Random Forest. Machine

Learning, Volume 45, pp. 5–32

Budiman, E., Raka, I., Wahyuni, E., 2017. Concept

Application for Pipelines Using A

Submerged Floating Tunnel for Use In The Oil and Gas Industry. International

Journal of Technology, Volume 8(4), pp. 719–727

Chen, C., Liaw, A., Breiman, L., 2004. Using Random

Forest to

Learn Imbalanced Data. Berkeley: Department of Statistics

Dai, L., Wang, D., Wang, T., Feng, Q., Yang, X., 2017. Analysis and

Comparison of Long-Distance

Pipeline Failures. Journal of Petroleum Engineering, p. 3174636

Eastvedt, D., Naterer, G., Duan, X., 2022. Detection of Faults

in Subsea Pipelines By

Flow Monitoring With Regression Supervised Machine Learning. Process Safety

and Environmental Protection, Volume 161(30), pp. 409–420

Farizal, Dachyar, M., Prasetya, Y., 2021. City Gas

Pipeline Routing Optimization Considering Cultural Heritage and Catastrophic Risk. International

Journal of Technology, Volume 12(5), pp. 1009–1018

Fawcett, T., 2006. An Introduction to ROC Analysis. Pattern

Recognition Letter, 27(8), pp. 861–874

Guyon, I., Elisseeff, A., 2003. An Introduction To Variable and Feature Selection. Journal

of Machine Learning Research, Volume 3, pp. 1157–1182

Han, J., Kamber, M., Pei, J., 2000. Classification:

Basic Concepts. Data mining: Concepts and Techniques. 3rd Edition. Burnaby: Morgan

Kaufmann Publishers

Hanga, K. M., Kovalchuk, Y., 2019. Machine Learning and Multi-Agent Systems in Oil and Gas Industry

Application : A Survey. Compter Science Review, Volume 34, p. 100191

Harrell, F. E., 2005. Binary Logistic Regression.

Regression Modeling Strategies. 2nd Edition. New York: Springer

He, H., Gracia, E. A., 2009. Learning from Imbalanced Data. Transactions

on Knowledge and Data Engineering, Volume 21(9), pp. 1263–1284

Hosmer, D. W., Lemeshow, S., 2000. Assessing

the Fit of The Model. In: Applied Logistic

Regression. 2nd Edition. New York City: John

Wiley & Sons

Kuhn, M., 2008. Building Predictive Models in R Using The Caret

Package. Journal of Statistical Software, Volume 28(5), pp. 1–26

Lee, A., Zinaman, O., Logan, J., Bazilian, M.,

Arent, D., Newmark, R. L., 2012. Interactions, Complementarities and Tensions at The Nexus of Natural Gas and Renewable Energy. The

Electricity Journal, Volume 25(10), pp. 38–48

Lunardon, N., Menardi, G. & Torelli, N., 2014.

ROSE: A Package For Binary Imbalanced Learning. R Journal, Volume 6(1), pp. 82–92

Mikolajková-Alifov, M., Petterson, F.,

Björklund-Sänkiaho, M., Saxén, H., 2019. Model Of Optimal Gas Supply To A

Set Of Distributed Consumers. Energies, Volume 12(3), pp. 1–27

Robles-Velasco, A., Cortes, P., Mun?uzuri, J., Onieva, L., 2020. Prediction of Pipe

Failures In Water Supply Networks Using Logistic Regression and Support Vector

Classification. Reliability Engineering & System Safety, Volume

196, p. 106754

Ríos-Mercado, R.Z., Borraz-Sánchez, C., 2015.

Optimization Problems In Natural Gas Transportation Systems: A State-Of-The-Art

Review. Applied Energy, Volume 147, pp. 536–555

Shalev-Shawrtz, Ben-David, S., 2014. Understanding Machine

Learning: From Theory To

Algorithms. New York: Cambridge University Press

Tang, K., Parsons, D. J., Jude, S., 2019. Comparison of Automatic

and Guided Learning For

Bayesian Networks to

Analyse Pipe Failures in The Water Distribution System. Reliability

Engineering & System Safety, Volume 186, pp. 24–36

Thompson, J., 2017. High Country News. Available Online at:https://www.hcn.org/issues/49.22/infographic-a-map-of-leaking-natural-gas-pipelines-across-the-nation, Accessed on June 10, 2020

Wang, G., Gunasekaran, A., Ngai, E.W.T., Papadopoulos, T., 2016.

Big Data Analytics In Logistics and Supply Chain Management: Certain investigations

for research and applications. International Journal of Production Economics,

Volume 176, pp. 98–110

Wang, R., Dong, W., Wang, Y., Tang, K., Yao, X., 2013. Pipe Failure Prediction: A Data Mining Method. In: IEEE 29th International Conference on Data Engineering (ICDE), pp. 1208–1218