Experiment and Modeling of Smoke Ventilation in a Compartment using Coconut Husks as Solid Fuels

Corresponding email: yulianto.nugroho@ui.ac.id

Published at : 25 Mar 2025

Volume : IJtech

Vol 16, No 2 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i2.6278

Alianto, B, Rahim, GP, Santoso, MA, Nasruddin, N & Nugroho, YS 2025, ‘Experiment and modeling of smoke ventilation in a compartment using coconut husks as solid fuels’, International Journal of Technology, vol. 16, no. 2, pp. 411-422

| Beline Alianto | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Depok 16424, Indonesia |

| Gafero Prapila Rahim | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Depok 16424, Indonesia |

| Muhammad Agung Santoso | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Depok 16424, Indonesia |

| Nasruddin Nasruddin | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Depok 16424, Indonesia |

| Yulianto Sulistyo Nugroho | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Depok 16424, Indonesia |

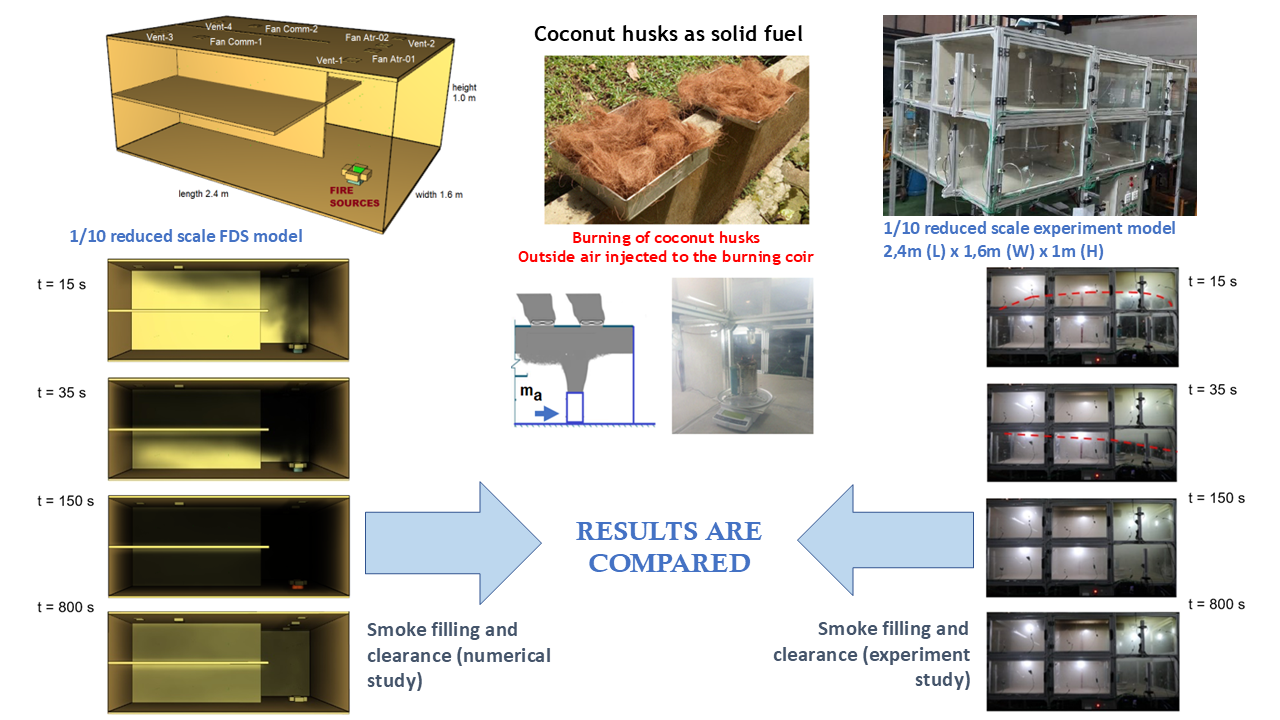

Modern architecture has become increasingly attractive and intriguing, with huge rooms and high ceilings. A 1:10 reduced-scale experimental compartment size 2.4 m x 1.6 m x 1.0 m has two floors with a mezzanine constructed. This study focuses on experimental and numerical using Fire Dynamic Simulator (FDS) studies on the transport of hot smoke produced by burning coconut husks as an actual fire source. A set of thermocouples were installed on the glass wall to measure the compartment temperature rise during the test. Laser beam sensors were utilized to measure the smoke obscuration. The experimental results were then compared with the numerical analysis study using FDS codes on a grid size of The results of tests indicate that the temperature rise in the compartment is mainly influenced by the air supply to the fuel, which varies the heat release rate. When compared, there are differences between the test data and the FDS prediction. FDS overestimates the rise in temperature during the early stages of smoke production compared to the test data. A performance-based design (PBD) can be considered when planning a fire safety system, primarily if solid fuels are used. In addition, coconut husks can be recommended as an alternative fire source for the hot-smoke test when solid fuel is considered. The emergence of white smoke generated by coconut husks provide the repetition of experiments within the same compartment.

Coconut husks; Obscuration; Ventilation; Temperature rise

The design of buildings with high ceilings and large spaces, which can be found in various architectural features, have proved to be significant challenges. Using existing prescriptive codes, applying the requirements for normal-height building space to large spaces with high ceiling height seems impractical. In large-volume spaces, smoke tends to stratify or accumulate at higher levels due to thermal buoyancy. Smoke can spread more extensively and travel longer distances due to the increased volume. Large-volume spaces require larger exhaust systems. To address smoke control in such spaces, fan-forced ventilation systems are commonly utilized (Gutierrez-Montes et al., 2009). Many fire studies use computational fluid dynamics (CFD). For example, (Kerber and Milke, 2007) carried out work to predict the elevation of the smoke layer of the fire incident in an atrium, (Thabari et al., 2023) performed modeling on the stock-pile of coal. Other modeling discussed promoting safety in tall buildings (Nugroho et al., 2022) and underground large-volume spaces (Alianto et al., 2017).

Algebraic analysis which can estimate smoke exhaust rates in small atriums but has limitations. (Klote, et.al., 2002). Various smoke control strategy was investigated. Smoke is vented out by natural exhaust or forced mechanical ventilation systems (Mao and Yang, 2016; Zhang et al., 2014; Li et al., 2010; He, et al., 2002). Natural vents are preferred because less cost required by eliminating the need for fans and ducts. Various improvements combine natural and forced smoke ventilation. (Tong et al., 2018) studied integrating smoke exhaust, natural openings, and make-up fans. (Baalisampang et al., 2018) optimized visibility using smoke detectors and mechanical exhaust. (Fang et al., 2021) investigate the application of a vortex exhaust flow in in atrium fire and (Ayala, et al., 2018) studied the impact of different louvers arrangements in atrium wall.

Many recent fire studies have utilized full scale to analyze smoke behaviour and ventilation effectiveness, for example (Gutierrez-Montes et al., 2010) conducted a full-scale test of 20 m3 atrium. (Bilyaz et al., 2021) investigate the smoke and fire dynamics in 17-storeys buildings while (Al-Waked et al., 2021) investigate the smoke movement in four storeys buildings with natural ventilation. (Ivanov et al., 2021) conducted fire tests in a large room with size of 150 x 40 x 30 m (L x W x H) and (Xu et al., 2021) investigate the smoke and behaviour in a space measuring 16.5 × 2.1 m (L x W) with variable ceiling height of 4, 6, 8, 10 and 12 m.

Experiments on a reduced-scale model are simpler and more cost-effective. Models are smaller in size and less facilities are needed. Many fire experiments have been conducted using reduced-scale model. For example, (Chen et al., 2019) tested a 1/10 reduced-scale model of atrium size of 4,120 x 4,120 x 11,700mm (L x W x H). Additionally, many tests have been performed in real fire and compared with the numerical simulation results. For instance, (Guiterrez-Montes et al., 2009), (Ayala et al, 2013) and (Vigne et al., 2021) conducted the fire test using the real experiment model 19.5 x 19.5 x 17.5 m (L x W x H) with heptane pool fire. Other real building fire tests were conducted in Poly-U / USTC Atrium (22.4 x 11.9 x 27m (L x W x H) by (Shi et al., 2009; Chow et al., 2005; Yi, et al. 2004; Chow et al., 2001). Similar full-scale test and FDS simulation were conducted by (Wang, et.al., 2017; Bystrom et al., 2012; Kerber and Milke, 2007) to predict the height of the smoke layer in an atrium fire and the effect of outside wind speed on the atrium fire (Krol, 2016).

Many studies widely use smoke generated by the burning of liquid fuel. For instance, (Shi et al., 2009) used diesel pool fire, full-scale tests carried out by (Hadjosophocleous et al., 2002) in a full-scale atrium facility. Methanol as fuel sources are modelled in the numerical studies of atrium fire by (Chow et al., 2009). The resulting smoke in the compartment is typically characterized by dark color and higher temperature. This real fire test is a potential hazard when exposed to live buildings and demands careful supervision of the fire source. When liquid fuel is used in experimental models within a laboratory setting, the black smoke rapidly contaminates the surface of the testing compartment model. The primary reason for choosing liquid fuel over solid fuel is its ease of characterization, allowing for better test replication. The presence of black deposits is not desired or can introduce unwanted variables. The emergence of black smoke also complicates the repetition of experiments within the same compartment.

There is limited literature discussing building fires with solid fuel as heat sources. The aim of the current study is to investigate the movement of real smoke released from the smoldering of solid fuels. The paper focuses on and is limited to fire testing using a combination of experimental methods and numerical analysis. The difference between liquid and solid fuels in combustion is discussed by (McCaffrey and Harkleroad 1989). The 1/10 reduced-scale experimental compartment was made of a glass wall and set up in the Laboratory of Thermodynamics and Fire Safety Universitas Indonesia. Scaling down the actual building may still provide valuable insights and data that can be extrapolated to real-size scenarios with appropriate adjustments. Further, scaling down the simulation model generally require fewer computational resources and allows for faster results. Coconut husks as raw material for fibreboards made of milled coconut husks (Araujo Junior et al., 2018; Boger et al., 2017) being agricultural waste, are commonly utilized as building materials and can be found in various applications such as cement composites and wall insulation (Brose et al., 2019). The heat release rate and the smoke flow rate are not determined in this study. Based on the gap analysis, this study provides insights into potential areas of using solid fuels such as coconut husks when conducting tests on a laboratory scale or in a real building. A comparative analysis of the experimental and numerical results is presented in the paper.

2.1. Setup of experimental model

Figure 1 shows an experimental enclosure, which is a 1/10 reduced scale model of a large space with a mezzanine floor. The size of the model is 2.4 × 1.6 × 1 m3, and the height of the mezzanine floor is 0.5 m. Aluminum profiles are used as the structural framework of the compartment. The walls are built of 5 mm thick glass. The roof and floors are constructed using an 8mm thick gypsum-reinforced concrete (GRC) board. Clear tape is employed to seal all fine gaps present in the joints within the compartment. The compartment is located under a hood equipped with an exhaust fan, which serves to extract the smoke. The air velocity in the surrounding is measured to be approximately 2 m/s. Three sets of laser-through beam sensors were installed to measure the obscuration in the compartment during the fire test, as shown in Figure 1.

Figure 1 (a) Experimental model and (b) configuration of laser beam sensors

Bare and sheathed 3mm diameter thermocouples K-type are employed to quantify the temperature rise at the designated zone. The thermocouple is inserted through the holes in the glass wall surface of the compartment. In total, 40 thermocouples are installed on the wall and distributed in 12 zones. In order to observe the movement of smoke, two high-definition cameras were installed near the glass walls of the compartment to record the burning and smoke-spreading processes. The ambient temperature is 28 °C. The data on the accuracy of instruments are shown in Table 1.

Heat is generated by burning coconut husks which are placed inside a cylindrical electric stove. The container measures 12 cm x 8 cm in diameter and is equipped with a 60 W, 12 VDC power source as the heat supply. Figure 2 shows that the cylindrical stove is then placed in the middle of a room with double height. A weight of 60 grams of dried coconut husks is then ignited using a gas igniter lighter pistol. The flame propagates to the surface of the coconut husk, resulting in a smoldering combustion. Smoldering combustion occurs when fuel undergoes slow, incomplete burning with a limited oxygen supply, resulting in lower temperatures. The smoke produced from smoldering combustion has a reduced buoyancy due to the lower temperature of the smoke compared to that generated by flaming combustion in general. Therefore, the air is injected from the outside by a small electric-powered fan into the smoldering coconut husk to expedite the rise and dispersion of smoke. The variation in the injection air quantity aims to obtain an overview of the smoke production generated with different amounts of injected air. The values for the supply of air quantity to the fuel were based on practical considerations by utilizing the features available in the electric stove, which provided three alternative air supply speeds. The measured air quantity is 27, 40, and 54 m3/hr. Four smoke extractor fans with a diameter of 10 cm, each capable of achieving a maximum flow rate of 70 m3/hour, are installed on the top of the enclosure. A voltage regulator is used to adjust the operating speed of the extraction fans.

(a) coconut husks (b) make-up air flow (ma) added to stove (c) burning husks

Figure 2 Coconut husks as fire source burned in a stove

Table 1 Accuracy of the instruments

2.2. Setup for numerical analysis model

The CFD code FDS 6.7.7 has been used to simulate and predict the phenomenon of smoke filling and clearance. The compartment model for Fire Dynamics Simulator (FDS), as shown in Figure 3, is constructed following the same compartment size as that used in the experimental setup. The size of the simulation model is 2.4 m (L) x 1.6 m (W) x 1.0 m (H). The ambient condition is 28 °C and 70% relative humidity. Four smoke exhaust fans are modelled on the roof. The fans operate at two adjustable speeds of 50 m3/hour and 70 m3/hour, respectively. Other FDS parameters are shown in Table 2. The compartment is divided into 12 zones measuring 80 cm x 80 cm, representing a room zoning size of 8 m x 8 m, following the common column spacing in buildings. Generally, the zoning in this study refers to upper and lower floor zones, smoke source zone, zone adjacent to the smoke, and zone located at a somewhat distant location from the fire source at the end of the room. Dividing space into zones helps understand the spread of smoke and focuses on extracting smoke from the affected zone while preventing its migration to other areas. The external wind speed is modelled 2 m/s from the Y+ direction. Different zones within a space may have varying exposure to smoke generation rates or hazards.

Table 2 Input parameter in FDS model

Figure 3 (a) Setup of the numerical analysis model (b) divided into zones

In grid sensitivity tests shown in Figure 5, mesh dimensions are gradually reduced until a good balance in numerical accuracy and computation was reasonable. Figure 4 presents the results of the measurement of obscuration and temperature rise using three numbers of mesh size x = 60 mm, 50 mm, and 30 mm where

x =

y =

z. Comparing the findings for several grids reveals that the relative inaccuracy for the coarsest grids is considerable. The two most refined grids correspond to an almost close agreement between tests and grids of 30x30x30 cm3 and 50x50x50 cm3 cells per side. Therefore the mesh size is selected as

x =

y =

z = 50 mm.

(a) temperature (b) obscuration

Figure 4 (a) Grid sensitivity tests for temperature and (b) obscuration read by sensor A

2.3. Proximate Analysis, Ultimate Analysis, and Thermogravimetric Analysis of Coconut Husks

The composition of fuel is chosen with an empirical formula of the coir from the ultimate analysis is C4.099H6.32N0.0007O2.368S0.003. Before testing, coconut husks were reduced in size by crushing and grinding into fine particles. The husks are later dried in an oven to remove moisture. Table 3 shows the proximate analysis that provides information for moisture contents, volatile matter, ash content, and total sulphur. Ultimate analysis determines the elemental composition of the material. The analysis was conducted using a CHNSO elemental analyzer. The theoretical calorific value is estimated at 4.322 kcal/kg.

Table 3 Proximate and ultimate analysis of coconut-husks.

Figure 5 presents the thermogravimetric analysis (TGA) and DTA (Differential Thermal Analysis) with a steep curve indicating the temperature at which pyrolysis began, whereas a flattening of the curve indicates the temperature at which pyrolysis concluded. A pan containing the sample is placed on a high-precision balance, and thermocouples are used to monitor the temperature accurately while the sample is subjected to a small electrically heated burner. Nitrogen, an inert gas, is added to the system to suppress any potential for oxidation or other undesirable chemical reactions. The sample was heated to a final temperature of 750 °C to identify the optimal pyrolysis of the coconut husks. TGA was carried out using three different heating rates (20°, 25°, and 30°C/min).

Figure 5 TGA analysis of coconut husks with heating rates 20, 25, and 30 °C/min

3.1. Smoke Filling and Extraction

The experimental study of smoke development is compared to that of the FDS simulation. Figure 6 demonstrates that smoke stratification has a distinct interface line. A mass exchange of the hot, smoky layer and the cooler entrained air occurred in the lower layer. It is also noticeable that the height of the smoke layer interface fluctuates at an earlier stage. When the smoke reaches the ceiling, it starts to descend. However, due to buoyancy and driving forces, the smoke is subsequently driven to rise, resulting in higher temperatures in the top zone of each level and a decrease in temperature in the lower zone. Roof vents and smoke extractors play a crucial role in smoke extraction. Vents release a much more uniform flow, avoiding the descent of hot smoke by severing the connection between higher-level hot smoke and lower fresh air.

The calculation of the smoke layer height z (m) per unit time (s) in an atrium with area A (m2) and height H (m) generated by the fire with heat release rate Q (kW) can be expressed by the Eq. 1 by referring to NFPA-92 (NFPA, 2018), SNI-03-6571 (BSN, 2001), SNI-03-7012, (BSN, 2004):

The smoke production rate ms (kg/s) at the smoke layer height at point z is calculated using the equation:

zl is limiting elevation expressed in:

The smoke filling time and estimated obscuration from the experiment are shown in Figure 7. The amount of air 40 m3/hr (a) and 27 m3/hr (b) is added to burn 60 gr of coconut husks. The exhaust air flow rate is set in two scenarios 4 x 50 m3/hr and 4 x 70 m3/hr. The maximum flow rate specified for the fans is 70 m3/hour. The flow rate was appropriately adjusted for the experimental setup to ensure faster smoke extraction time. Additional air enters the compartment through fine gaps originating from connections between aluminum profiles and improperly sealed openings. Full smoke coverage was indicated by the obscuration values. Based on previous experiments, it was observed that it took approximately 600 s for the smoke to fill the entire compartment. The percentage of light blocked recorded by sensor B increased sharply while the values in sensors A and C rose gradually during the early stage of the smoke growth. The values gradually increase until they reached a stable point, indicating that the smoke had completely filled the compartment.

Figure 6 Process of smoke filling and smoke clearance by FDS simulation and real test

The smoke filling time and estimated obscuration from the experiment are shown in Figure 7. The amount of air 40 m3/hr (a) and 27 m3/hr (b) is added to burn 60 gr of coconut husks. The exhaust air flow rate is set in two scenarios 4 x 50 m3/hr and 4 x 70 m3/hr. The maximum flow rate specified for the fans is 70 m3/hour. The flow rate was appropriately adjusted for the experimental setup to ensure faster smoke extraction time. Additional air enters the compartment through fine gaps originating from connections between aluminum profiles and improperly sealed openings. Full smoke coverage was indicated by the obscuration values. Based on previous experiments, it was observed that it took approximately 600 s for the smoke to fill the entire compartment. The percentage of light blocked recorded by sensor B increased sharply while the values in sensors A and C rose gradually during the early stage of the smoke growth. The values gradually increase until they reached a stable point, indicating that the smoke had completely filled the compartment.

Figure 7 Comparison of the smoke obscuration obtained from experimental and FDS studies

In contrast, the FDS prediction exhibited a steep curve, indicating a sudden increase and subsequent drop in smoke obscuration. The rapid filling of smoke in the FDS simulation is primarily caused by the presence of the soot-yield factor. In this simulation, the soot-yield factor is specified as 0.05. A smoke extractor with a higher capacity facilitates faster smoke clearance. The FDS simulation reveals that the atrium space experienced rapid smoke filling within a relatively short duration of 60 - 71 seconds. The smoke is produced continuously until all the fuel is completely burnt out at approximately t = 580 s. Soon after the fans were turned on at t = 600 s, the obscuration was not immediately decreased. The smoke remained trapped for a moment at the upper layer of the compartment. Generally, the smoke filling and clearance timeline in almost all scenarios:

At t = 0 – 30 s: smoke rapidly filled the upper floor.

At t = 30 – 120 s: Upper floor completely covered by smoke. Smoke starts to fill the lower floor.

At t = 120 – 600, secs: Lower floor and upper floor fully contained with smoke. Smoke generation stopped at t = 600 secs, and smoke clearance started.

At t = 600 – 800 secs: Smoke on the upper floor cleared

At t = 800 – 1500 secs: smoke on the lower floor cleared.

3.2. Temperature rise in the compartment

Adding more air to the fuel would increase the buoyancy and HRR (heat release rate). Higher HRR results in greater energy output, leading to a more significant temperature rise. The measured temperature has the highest rise value of T < 40 °C. A summary of recorded temperature rise in every different scenario is presented in Figure 8. The temperature on the lower floor was higher than on the mezzanine floor. The hot air is retained longer on the lower floor because smoke is exhausted only through the top of the compartment. Higher smoke extraction rates also cause higher maximum temperature increases. It is noticeable that the maximum temperature increment is the upper floor is higher than the lower floor.

Figure 8 The experimental rise in the zone temperatures as a function of time

The temperature increase was over-predicted by FDS compared to the experimental results. Zones near the heat source experienced the most significant temperature increase. The FDS predicted a rapid rise in the early development of smoke in t < 100 s. Figure 9 shows the comparison of the temperature rise obtained by FDS simulation and experimental investigation when the fuel is supplied with 54 m3/hr of air in the upper floor (zone 7, 8, 10, and 11) and atrium space (zone 3, 6, 9 and 12). FDS estimated the maximum temperature rise of an average of 9-15 °C on the upper floor and approximately 18 °C in void space, while experimental results measured the rise in temperature of 6 and 9 °C at the same zones. There are several potential reasons for this discrepancy, such as convective heat loss in the experiment due to the smoke vent activation, not providing any possible leakage to the FDS model, which might be occurred on the experimental approach, and different actual fuel property input on the FDS model compared to the experiment.

Figure 9 Comparison of the zone temperature rises obtained from experimental and FDS studies

Both experimental results and numerical analysis results have advantages and limitations. Experimental results obtained through direct measurements in a laboratory setting are generally considered more reliable for validating numerical models due to their direct correlation with physical measurements. However, experimental capabilities are also limited in providing detailed information about flow fields or simulating complex scenarios. Numerical analysis limitations include discretization errors, round-off errors, convergence and stability issues. Experimental data validation is crucial for accurate simulations. This also suggests further research in the field of fire testing using a combined approach of experimental methods and numerical analysis. The combination of experimental methods and numerical analysis provides comprehensive insights in various fields, validating models for materials, fluid dynamics, heat transfer, leading to accurate predictions and deeper understanding of complex phenomena. Designing a fire safety system, it is advisable to take into account a performance-based (PBD) methodology, particularly when employing solid fuel such as coconut husks can also be recommended to be used in the alternative hot and black smoke test in the actual cases. Compared to black smoke, white smoke provides better visibility, allowing researchers to monitor and document the experiment more effectively.

The authors would like to thank Universitas Indonesia for the financial assistance through Hibah Publikasi Terindeks Internasional (PUTI) Q1 2022 with a contract number of NKB-1158/UN2.RST/HKP.05.00/2022 managed by the Directorate for Research and Public Services (DRPM) Universitas Indonesia.

Author Contributions

Beline Alianto: Methodology, data collection, formal analysis, writing—original draft preparation

Gafero Prapila Rahim: Data curation, validation, writing and editing, visualization

Muhammad Agung Santoso: Data analysis, validation, reviewing, visualization

Nasruddin: Conceptualization, methodology, Supervision, reviewing

Yulianto S. Nugroho: Conceptualization, methodology, Supervision, project administration, funding acquisition, reviewing

Conflict of Interest

The authors state that no competing financial interests or personal relationships exist that could have influenced the work reported in this paper.

| Filename | Description |

|---|---|

| R1-ME-6278-20250317132356.docx | --- |

Alianto, B, Astari, N, Nareshwara, D & Nugroho, YS 2017, ‘Modeling of smoke control in underground parking-garage fires’, International Journal of Technology, vol. 8, no. 7, pp. 1296–1305, https://doi.org/10.14716/ijtech.v8i7.779

Al-Waked, R, Nasif, M, Groenhout, N, & Partridge, L 2021. Natural ventilation of residential building atrium under fire scenario. Case Studies in Thermal Engineering, vol. 26, article 101041, https://doi.org/10.1016/j.csite.2021.101041

Araujo Junior, C, Coaquira, , Mattos, A, de Souza Filho, M, Feitosa, J., Morais, J., & de Freitas Rosa, M 2018, 'Binderless fibreboards made of unripe coconut husks. Waste and Biomass Valorization', vol. 9, no. 11, pp. 2245-2254, https://doi.org/10.1007/s12649-017-9979-9

Ayala, P, Cantizano, A, Rein, G, & Gutierrez-Montes, C 2018, 'Factors affecting the make-up air and their influence on the dynamics of atrium fires', Fire Technology, vol. 54, pp. 1067-1091, https://doi.org/10.1007/s10694-018-0725-z

Ayala, P., Cantizano, A, Gutierrez-Montes, C. & Rein, G 2013, ‘Influence of atrium roof geometries on the numerical predictions of fire tests under natural ventilation conditions’. Energy and Buildings, vol. 65, pp. 382-390, https://doi.org/10.1016/j.enbuild.2013.06.010

Baalisampang, T, Saliba, E, Salehi, F, Garaniya, V, Chen, L 2021, 'Optimisation of smoke extraction system in fire scenarios using CFD modelling'. Process Safety and Environemntal Protection, vol. 149, pp. 508-517, https://doi.org/10.1016/j.psep.2020.11.036

Badan Standarisasi Nasional (BSN) 2001, SNI-03-6571 - Fire and Smoke Control Systems in Buildings, Indonesia

Badan Standarisasi Nasional (BSN) 2004. SNI-03-7014 - Smoke Management Systems in Mall, Atrium and Large Volume Spaces, Indonesia

Bilyaz, S, Buffington, T, & Ezekoye, OA 2021. ‘The effect of fire location and the reverse stack on the fire smoke transport in high-rise buildings.’ Fire Safety Journal, vol. 126, article 103446, https://doi.org/10.1016/j.firesaf.2021.103446

Boger, T, Banchi, S, & Frederic, P 2017, 'Binderless boards made of milled coconut husks: an analysis of the technical feasibility and process restraints', International Wood Products Journal, vol. 9, no. 1, pp. 1-6, https://doi.org/10.1080/20426445.2017.1400756

Brose, A, Kongoletos, J & Glicksman, L 2019, ‘Coconut fiber cement panels as wall insulation and structural diaphragm’, Frontiers in Energy Research, vol. 7, p. 9, https://doi.org/10.3389/fenrg.2019.00009

Bystrom, A, Cheng, X, Wickstrom, U & Veljkovic, M 2012, ‘Full-scale experimental and numerical studies on compartment fire under low ambient temperature’. Building and Environment, vol. 51, pp. 255-262, https://doi.org/10.1016/j.buildenv.2011.11.010

Chen, Y, Wang, D, & Chen, J 2019, 'Heat transfer and smoke flow filling progress in a super-high atrium under influence of fire source characteristics', Journal of Fire Sciences, vol. 37, no. 3, pp. 212-235, https://doi.org/10.1177/0734904119848120

Chow, WK, Li, SS, Gao, Y, & Chow, CL 2009, 'Numerical studies on atrium smoke movement and control with validation by field tests. Building and Environment', vol. 44, pp. 1150-1155, https://doi.org/10.1016/j.buildenv.2008.08.008

Chow, WK, Li, YZ, Cui, E & Huo, R 2001, ‘Natural smoke Filling in atrium with liquid pool fires up to 1.6 MW’. Building and Environment, vol. 36, no.1, pp. 212-127, https://doi.org/10.1016/S0360-1323(00)00032-9

Chow, WK, Yi, L, Shi, CL, Li, YZ & Huo, R 2005, ‘Experimental Studies on Mechanical Smoke Exhaust System in an Atrium’. Journal of Fire Sciences, vol. 23, no. 5, pp. 429-444, https://doi.org/10.1177/0734904105051048

Fang, X, Yuen, ACY, Yeoh, GH, Lee, EWM & Cheung, SCP 2021, ,Numerical study on using vortex flow to improve smoke exhaust efficiency in large-scale atrium fires’. Indoor and Built Environment, vol. 32, no.1, pp. 98-115, https://doi.org/10.1177/1420326X211031276

Gutierrez-Montes, C, Sanmiguel-Rojas, E & Viedma, A 2010, ‘Influence of different make-up air configurations on the fire-induced conditions in an atrium’, Building and Environment, vol. 45, no. 11, pp. 2458-2472, https://doi.org/10.1016/j.buildenv.2010.05.006

Gutierrez-Montes, C, Sanmiguel-Rojas, E, Viedma, A & Rein, G 2009, ‘Experimental data and numerical modeling of 1.3 and 2.3 MW fires in a 20 m cubic atrium’, Building and Environment, vol. 44, no. 9, pp. 1827-1839, https://doi.org/10.1016/j.buildenv.2008.12.010

Hadjosophocleous, G, Fu, Z & Lougheed, GD 2002, ‘Experimental study and zone modeling of smoke movement in a model atrium’, ASHRAE Transactions, vol. 108, pp. 868–874

He, Y, Wang, J, Wu, Z, Hu, L, Xiong, Y, Fan W 2002, ‘Smoke venting and fire safety in an industrial warehouse’, Fire Safety Journal, vol. 37, no. 2, pp.191-215, https://doi.org/10.1016/S0379-7112(01)00045-5

Ivanov, ML, Peng, W, Wang, Q & Chow, WK 2021. ‘Sustainable smoke extraction system for atrium: A numerical study’. Sustainability, vol. 13, no. 13, article 7406, https://doi.org/10.3390/su13137406

Kerber, S & Milke, JA 2007, ‘Using FDS to simulate smoke layer interface height in a simple atrium’, Fire Technology, vol. 43, no. 1, pp. 45–75, https://doi.org/10.1007/s10694-007-0007-7

Klote, JH, DiNenno, P J, Drysdale, D, Beyler, CL, Walton, Watts, JM 2002, SFPE handbook of fire protection engineering (Third ed.). Quincy, MA: National Fire Protection Association.

Krol, M 2016, 'Numerical studies on the wind effects on natural smoke venting of atria', International Journal of Ventilation', vol. 15, no. 1, pp. 67-78, http://dx.doi.org/10.1080/14733315.2016.1173293

Li, KY, Huo, R, Ji, J 2010, ‘Experimental investigation on drag effect of sprinkler spray to adjacent horizontal natural smoke venting’, Journal of Hazardous Materials, vol. 174, no. 1-3., pp. 512-521, https://doi.org/10.1016/j.jhazmat.2009.09.082

Mao, S, Yang, D 2016, ‘One-dimensional analysis for optimizing smoke venting in tunnels by combining roof vents and longitudinal ventilation’ Applied Thermal Engineering, vol. 108, pp. 1288-1297, https://doi.org/10.1016/j.applthermaleng.2016.07.193

McCaffrey, BJ & Harkleroad, G 1989, ‘Combustion efficiency, radiation, CO and soot yield from a variety of gaseous, liquid, and solid-fueled buoyant diffusion flames’, Symposium (International) on Combustion, vol. 22, no. 1, pp. 1251–1261, https://doi.org/10.1016/S0082-0784(89)80136-5

National Fire Protection Association (NFPA) 2018, NFPA-92 - The standard for smoke control systems, Quincy, MA, USA

Nugroho, PS, Latief, Y & Wibowo, W 2022, ‘Structural equation modelling for improving fire safety reliability through enhancing fire safety management on a high-rise building’, International Journal of Technology, vol. 13, no. 4, pp. 740–750, https://doi.org/10.14716/ijtech.v13i4.5517

Panyakaew, S & Fotios, S 2011, ‘New thermal insulation boards made from coconut husk and bagasse’, Energy and Buildings, vol. 43, pp. 1732–1739, https://doi.org/10.1016/j.enbuild.2011.03.015

Rodríguez, NJ, Yáñez-Limón, M, Gutiérrez-Miceli, FA, Gomez-Guzma, O, Matadamas-Ortiz, TP, Lagunez-Rivera, L & Vazquez-Feijoo, JA 2011, ‘Assessment of coconut fibre insulation characteristics and its use to modulate temperatures in concrete slabs with the aid of a finite element methodology’, Energy and Buildings, vol. 43, pp. 1234–1272, https://doi.org/10.1016/j.enbuild.2011.01.005

Shi, CL, Zhong, MH, Fu, TR, He, L & Huo, R 2009, ‘An investigation on spill plume temperature of large space building fires’, Journal of Loss Prevention in the Process Industries, vol. 22, pp. 76–85, https://doi.org/10.1016/j.jlp.2008.09.002

Thabari, J, Auzani, AS, Nirbito, W, Muharam, Y & Nugroho, YS 2023, ‘Modeling of coal spontaneous fire in a large-scale stockpile’, International Journal of Technology, vol. 14, no. 2, pp. 257–266, https://doi.org/10.14716/ijtech.v14i2.5367

Tong, Y, Huo, D, Zhu, P, Niu, X 2018. ‘Prediction of natural and hybrid ventilation performance used for fire-induced smoke control in a large single space’. Fire Safety Journal, vol. 10, pp. 20-30, https://doi.org/10.1016/j.firesaf.2018.03.005

Vigne, G, Wegrzynski, W, Cantizano, A, Ayala, P, Rein, G & Guiterrez-Montes, C 2021, ‘Experimental and computational study of smoke dynamics from multiple fire sources inside a large-volume building’. Buildiing Simulation, vol. 14, no. 4, pp. 1147-1167. https://doi.org/10.1007/s12273-020-0715-1

Wang, J, Gui, J, Gao, J & Hu, X 2017. ‘Parametrization of the fire-smoke exhaust system for a large and high-rise atrium in Shanghai through salt-bath experiment’. Indoor and Built Environment, vol. 26, no. 2, pp. 272-291. https://doi.org/10.1177/1420326X16660600

Xu, L, Wang, T & Song, L 2021. ‘Numerical research on the smoke spread process of thin-tall atrium space under various ceiling height’. Case Studies in Thermal Engineering, vol. 25, article 100996, https://doi.org/10.1016/j.csite.2021.100996

Yi, L, Chow, WK, Huo, R, Fong, NK, Li, YZ, Leung, CW, Shi, CL, Hung, YW, & Wang, HB, 2004, Full-scale burning tests of mechanical smoke exhaust in large atrium, ASHRAE Transactions, vol. 110, no. 2, pp. 267 - 273

Zhang, J, Lu, S, Li, C, Yuen, RKK 2014, ‘Vent location impacts on building compartment fire under natural roof ventilation’, APCBEE Procedia, vol. 9, pp. 360-364, https://doi.org/10.1016/j.apcbee.2014.01.063