Performance Analysis of Combined Gas-Electric Steam Turbine System as Main Propulsion for Small-scale LNG Carrier Ships

Corresponding email: ma.budiyanto@ui.ac.id

Published at : 28 Jul 2023

Volume : IJtech

Vol 14, No 5 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i5.6149

Budiyanto, M.A., Zidane, S.A., Putra, G.L., Riadi, A., Andika, R., Theotokatos, G., 2023. Performance Analysis of Combined Gas-Electric Steam Turbine System as Main Propulsion for Small-scale LNG Carrier Ships. International Journal of Technology. Volume 14(5), pp. 1093-1102

| Muhammad Arif Budiyanto | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Sultan Alif Zidane | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Gerry Liston Putra | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Achmad Riadi | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Riezqa Andika | Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Gerasimos Theotokatos | Department of Naval Architecture, Ocean and Marine Engineering, University of Strathclyde, G4 0LZ, UK |

The

development of liquefied natural gas (LNG) carrier ships is increasing rapidly

along with the demand for alternative energy sources. This study aims to

analyze the performance of an LNG-fueled propulsion system for a small-scale

LNG carrier ship with a combination gas-electric steam turbine system (COGES).

The performance of the propulsion system is analyzed based on the power output

generation and the environmental effect of the system. The total power output

was evaluated using thermodynamic analysis and the environmental impact was

measured by carbon emissions using the life-cycle assessment approach. The analysis

results show the COGES propulsion system potentially generates total power of

7600 kW at peak load. The desired ship operational speed of 12 knots can be

achieved at 24% load of the total power output. The COGES propulsion system

also indicates a low emission than other systems with a carbon emission is

0.149 kgCO2/kWh.

COGES; Propulsion system; Small-scale LNG carrier

In the transportation

industry, natural gas is a promising alternative fuel source that offers benefits

such as improved combustion efficiency and a decrease in greenhouse gas

emissions

LNG carriers are ships equipped with tanks

designed to transport liquefied natural gas with temperatures below -162°C (Bai and Jin, 2015). LNG carriers vary in

cargo capacity, ranging from small capacities starting at 1000 m3 to

the largest cargo capacity currently reaching 266,000 m3.

A Small-scale LNG carrier

is an LNG carrier that has a carrying capacity of up to 40,000 m3 (Guerrero, 2019). The

small-scale LNG carrier is used for

remote areas with shallow water draught. In its development, the use of small-scale LNG

carriers needs to be reviewed in terms of economic value and transportation

costs (Budiyanto et al., 2020).

In transporting LNG using sea transportation,

it is necessary to pay attention to the use of the propulsion system to obtain

efficiency and economic feasibility considerations. International Maritime

Organization (IMO) has formulated an energy efficiency design index policy for

the ships. According to research based on data from registered ship engines,

tankers and gas carriers are among the ship types that produce the most carbon

emissions (Budiyanto, Adha and Prayoga, 2022). The

small-scale LNG carrier thus is designed to feature a propulsion system that

uses natural gas or LNG as fuel to facilitate more affordable and

environmentally friendly gas transportation

In terms of energy efficiency, numerous

alternative propulsion systems with higher efficiency values have been proposed

including the dual fuel diesel engine and the combined cycle. The ship

propulsion system mainly consists of three main parts, i.e.: the prime mover,

the transmission system, and the ship propulsion device. The design of the

ship's propulsion system will depend on the type of ship, the main size, the

ship’s speed, the stern model, and the hull model (Lin et al., 2020). The propulsion system of the main part of the

ship is closely related to the thermal power generation cycle

Combined gas turbine electricity and steam

(COGES) is a propulsion system that uses a gas turbine to generate electric

power, which is then utilized to drive an electric motor that is connected to a

shaft propeller

The purpose of this study is to analyze the

proposed COGES propulsion system for a small-scale LNG carrier. The

contribution of this study is twofold, which is providing a comparison of the

power output of COGES with conventional systems and understanding the

environmental impact of the proposed system.

2.1.

Case study of LNG carriers

The

case study used in this research is a small-scale LNG carrier with a capacity

of 7500 m3. The size of small LNG carriers has capacities varying

from 1000 - 40,000 m3 (TGE-Marine, 2022; Wärtsilä, 2022; Bai and Jin, 2015). No classification regulates the dimensions of small LNG

carriers. The use of small LNG carriers is attractive for short-distance

shipping inter islands with limited draft depths and small amounts of cargo

Table 1 Ship dimensions of the case study

Figure 1 The required power at the desired speed of the case study

2.2.

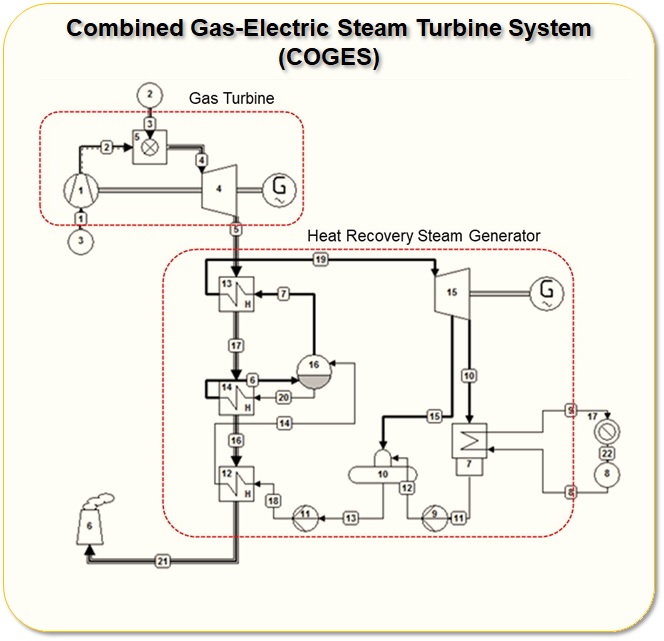

Proposed design of COGES propulsion system

The

design of the small-scale LNG carrier propulsion system proposed in this study

is COGES which consists of two power generators each sourced from a gas turbine

and a heat recovery steam generator. The system diagram of the proposed COGES

design is shown in Figure 2. The design of the COGES propulsion system consists

of several main components, namely gas turbines, heat recovery steam

generators, condensers, deaerators, pumps, and generators. The thermodynamic

system analysis of the proposed COGES design was carried out using the

Cycle-Tempo application to obtain the output power generation and total

efficiency of the design system. Cycle-Tempo is commercial software to analyze

and optimize the thermodynamics of the energy system hambient is

environment enthalpy/ambient

s is entropy environment

sambient is environment entropy/ambient

m is mass flow

Tambient is

environment temperature/ambient (K), Q in is the calorie

input of system (kW), W is performance output of the system (kW), and E(x,n)

is exergy rate (kW).

Figure 2 Proposed design of COGES propulsion system

An

analysis of the effect of boiled gas (BOG) produced from the LNG carrier cargo

tank was carried out to investigate the effect of BOG as turbine fuel on the

performance of the system. The power

output generated by the design system will also be influenced by the amount of

fuel obtained from the BOG of the ship's cargo. It is necessary to take into

account the amount of BOG produced by the ship. The ship's BOG is also

influenced by the boil-off rate (BOR) of the number of shiploads, therefore

several variations will be made based on the BOR of cargo starting from the

range 0.1%-0.3% per day. Equation 5 shows the calculation of BOG, where V is

LNG cargo volume (m3), is LNG density (kg/m3), and t is

shipping time (hours).

2.3. Estimation of carbon emission

In this

study, carbon emissions are estimated based on the power output (kWh) for each

propulsion system. The estimation was carried out using the life cycle

assessment software application, namely SimaPro

Performance

analysis of the COGES was conducted by thermodynamic analysis to determine the

amount of power output that can be generated by the designed system. The power

output of the COGES propulsion system is shown in Figure 3. According to the

thermodynamic analysis results, the proposed COGES potentially generate up to

7600 kW of power at full load. To attain the ship's operating speed of 12

knots, which requires 1832 kW, the COGES system only needs to load around 24%

of the entire design load. These results are consistent with the power output

trendline of other similar studies, which in this study also stated that the

load needed to meet the ship's propulsion power requirements was 33% (Nirbito, Budiyanto

and Muliadi, 2020). This shows that the use of the COGES design

system makes the work of the main components lighter so that the use of the

system will be more durable because it does not always work at maximum load

conditions. In actual operation, the power output produced by COGES is used to

power all systems on board the ship in addition to the propulsion system.

Figure

3 The power output of the COGES

propulsion system

The

condition of the system's performance is strongly influenced by the

availability of fuels. The proposed COGES propulsion system is assumed to use

boil-off gas. On LNG ships, the amount of boil-off gas naturally depends on the

rate of evaporation that occurs in the cargo tanks and is a function of the

length of the ship's journey. The relationship between the boil-off gas and

sailing time is shown in Figure 4. With the use of the proposed COGES

propulsion system, ships can take advantage of boil-off gas evaporation from

the cargo tanks. The availability of boil-off gas is strongly influenced by the

boil-off rate and the sailing time which is related to the ship's speed. To

meet the fuel needs of ships with a ship speed of 12 knots, assuming a boil-off

rate of 0.3% per day (Pamitran, Budiyanto

and Maynardi, 2019), it takes about 3 days of sailing. The longer the

sailing time, the greater the result of boil-off gas so that it can be more

profitable from an operational point of view.

Figure

4 Variation of boil-off of gas results

during sailing time

Figure

5 Comparison of the power output from

the 3 different propulsion systems

Figure

5 shows a comparison of the power output generated by COGES and other power

generation systems that are commonly used as power generators, namely diesel

and dual fuel diesel electric (DFDE). To determine the output power of each

system in kWh units, the output power calculation is carried out using the

equivalent heat input. According to the findings, COGES has a higher output

power than diesel or DFDE.

In

addition to comparing the output power produced by each system, this research

also estimates the carbon emissions produced by each system. Figure 6 shows a

comparison of the carbon emissions produced by the COGES system, the diesel

system, and the DFDE system. Compared to the diesel system and the DFDE system,

the COGES system produces fewer emissions. Each system produces 0.149 kgCO2/kWh,

0.314 kgCO2/kWh, and 0.155 kgCO2/kWh of carbon emissions,

respectively, with the same heat input. The emission estimation in this study

is lower than other studies which state that the COGES propulsion system

produces carbon emissions of 0.48 kg/kWh (Wiggins, 2011).

Figure

6 Comparison Graph of Propulsion System Emissions

Apart

from the results of CO2 emissions, the comparison of environmental

impacts is obtained using the eco-indicator 99 (H) method. Where the

environmental impact will affect health, ecosystem quality, and resources for a

power output of 1 kWh. Referring to the input and output of each component in

the COGES system, then each component will have an influence on the environment

that can be transmitted as an eco-indicator through the life cycle assessment

method. Figure 7 shows the environmental impact assessment of the COGES

propulsion system. The environmental impact assessment results show four major

components that produce high environmental effects, i.e. combustion chamber,

gas turbine, heat recovery steam generator, and compressor. The combustion

chamber produces an environmental impact of 3.78 mPts/s, this result is

consistent with previous research where the environmental impact on the

combustion chamber in a gas turbine is 3.92 mPts/s (Budiyanto,

Nasruddin and Nawara, 2020).

Figure 7 Environmental impact assessment of

COGES propulsion system

Performance

analysis of the COGES propulsion system has been carried out using the method

of thermodynamic analysis and environmental impact assessment. The design of a small-scale

LNG carrier with a capacity of 7500 m3 has been used as a case study

to determine the desired power requirements. A comparison of the COGES

propulsion system with the diesel system and the DFDE propulsion system was

also carried out to determine the advantages of the proposed system. The

findings of the thermodynamic study indicate that the suggested COGES

potentially produce up to 7600 kW of electricity when fully loaded. Only around

24% of the total design load is required for the COGES system to operate at the

ship's operational speed of 12 knots, which consumes 1832 kW. The COGES

propulsion system has the advantage of higher output power with lower emissions

compared to the diesel and DFDE systems. The contribution of carbon emissions

to the COGES system, the diesel system, and the DFDE system is 0.149 kgCO2/kWh,

0.314 kgCO2/kWh, and 0.155 kgCO2/kWh, respectively.

According to the advantages of the COGES propulsion system, this system is

feasible to be proposed as a small-scale LNG carrier propulsion system. It is

necessary to carry out further research related to techno-economic studies to

assess whether this system is feasible in terms of investment costs.

The

author would like to thank the Ministry of Research and Technology of the

Republic of Indonesia for providing basic research funding through the PDUPT

scheme program based on Decree Number 036/E5/PG.02.00/2022 and Contract

Agreement Number NKB-837/UN2.RSTIHKP.05.00/2022. The authors also thank the

World Class Professor (WCP) 2022 program of the Directorate General of Higher

Education for fine-tuning and writing assistance of the manuscript.

Ahmadi, G., Akbari, O.A., Zarringhalam, M.,

2017. Energy and Exergy Analyses of Partial Repowering of a Natural Gas-Fired

Steam Power Plant. International Journal of Exergy, Volume 23(2), pp.

149–168

Asimptote, 2023. Cycle-Tempo. Available

online at: https://asimptote.com/cycle-tempo/. Accessed on January 31, 2023

Aspelund, A., Gundersen, T., 2009. A

Liquefied Energy Chain for Transport and Utilization Of Natural Gas For Power

Production With CO2 Capture And Storage – Part 4: Sensitivity

Analysis of Transport Pressures and Benchmarking With Conventional Technology

for Gas Transport. Applied Energy, Volume 86, pp. 815–825

Bai, Y., Jin, W., 2015. Marine Structural

Design. 2nd Edition. UK: Elsevier

Birk, L., 2019. Holtrop and Mennen’s Method.

In: Fundamentals of Ship Hydrodynamics, pp. 611–627

Budiyanto,

M.A., Adha, A., Prayoga, P.H.N., 2022. Distribution of Energy Efficiency Design Index for

Tankers in Indonesia. Energy Reports, Volume 8, pp. 170–176

Budiyanto,

M.A., Nasruddin, Nawara, R., 2020. The Optimization of Exergoenvironmental Factors in The

Combined Gas Turbine Cycle and Carbon Dioxide Cascade to Generate Power in LNG

Tanker Ship. Energy Conversion and Management, Volume 205, p. 112468

Budiyanto, M.A., Riadi, A., Buana, I.G.N.S.,

Kurnia, G., 2020. Study on the LNG Distribution to Mobile Power Plants

Utilizing Small-Scale LNG Carriers. Heliyon, Volume 6(7), p. 04538

Cheenkachorn, K., Poompipatpong,

C., Ho, C.G., 2013. Performance and Emissions of a Heavy-Duty Diesel Engine

Fuelled with Diesel and LNG (Liquid Natural Gas). Energy, Volume

53, pp. 52–57

Dawangi, I.D., Budiyanto, M.A., 2021. Ship

Energy Efficiency Management Plan Development Using Machine Learning: Case

Study of CO2 Emissions of Ship Activities at Container Port. International

Journal of Technology, Volume 12(5), 1048–1057

Djermouni, M., Ouadha, A., 2017. Comparative

Assessment of LNG and LPG in HCCI Engines. Energy Procedia, Volume 139,

pp. 254-259

Dotto, A., Campora, U., Satta, F., 2021.

Feasibility Study of An Integrated COGES-DF Engine Power Plant in LNG

Propulsion for A Cruise-Ferry. Energy Convers Management, Volume 245, p. 114602

Gaber, M., El-Banna, S.H., Hamad, M.S.,

Eldabah, M., 2020. Studying the Effect of Using Multi-Phases Switched

Reluctance Motor to Reduce the Torque Ripple for Ship Propulsion System. In:

2020 IEEE PES/IAS PowerAfrica

Glomski, P., Michalski, R., 2011. Problems

with Determination of Evaporation Rate and Properties of Boil-Off Gas on Board

LNG carriers. Journal of Polish CIMAC, Volume 6(1). pp. 133–140

Goedkoop, M., Oele, M., Leijting, J., Ponsioen,

T., Meijer, E., 2016. Introduction to LCA with SimaPro. USA: SimaPro

Guerrero, C., 2019. Assessment of Innovative

Small Scale LNG Carrier Concepts. In: 19th International

Conference and Exhibition on Liquefied Natural Gas, pp. 1–14

Lin, J.F., Zhao, D.G., Guo, C.Y., Su, Y.M.,

Zhong, S.H., 2020. Comprehensive Test System for Ship-Model Resistance and

Propulsion Performance in Actual Seas. Ocean Engineering, Volume 197, p.

106915

Muslim, M., Alhamid, M.I., Nasruddin, N.,

Yulianto, M., Marzuki, E., 2019. Cycle Tempo Power Simulation of the Variations

in Heat Source Temperatures for an Organic Rankine Cycle Power Plant using

R-134A Working Fluid. International Journal of Technology, Volume 10(5),

pp. 979–987

Nirbito, W., Budiyanto, M.A., Muliadi, R.,

2020. Performance Analysis of Combined Cycle with Air Breathing Derivative Gas

Turbine, Heat Recovery Steam Generator, and Steam Turbine as LNG Tanker Main

Engine Propulsion System. Journal of Marine Science and Engineering,

Volume 8, p. 726

Pamik, M., Bayraktar, M., Konur, O., Nuran,

M., 2022. A Revelatory Case Study for the Emergence of Powerships: The Floating

Power Plant Innovation for Rural Electrification. Transactions on Maritime

Science, Volume 11(1), pp. 54–66

Pamitran, A.S., Budiyanto, M.A., Maynardi,

R., 2019. Analysis of ISO-tank Wall Physical Exergy Characteristic – Case Study

of LNG Boil-Off Rate from Retrofitted Dual Fuel Engine Conversion. Evergreen,

Volume 6, pp. 134–142

TGE-Marine, 2022. Small-scale LNG.

TGE-Marine. Available online at: https://www.tge-marine.com/products-references/small-scale-lng/,

Accessed on 20 October 2022

Wärtsilä, 2022. LNG Small Scale and Bunker

Vessels. Wärtsilä. Available online at:

https://www.wartsila.com/marine/products/gas-solutions/lng-small-scale-and-bunker-vessels,

Accessed on 20 October 2022

Wibisana, L.P., Budiyanto, M.A., 2021. Design

and Cost Multi-Objective Optimization of Small-Scale LNG Carriers using the

Value Engineering Approach. International Journal of Technology, Volume

12(6), pp. 1288–1301

Wiggins, E.G., 2011. COGAS Propulsion for LNG

Ships. Journal of Marine Science and Application, Volume 10, pp. 175–183

Ziolkowski, P., Kowalczyk, T., Lemanski, M.,

Badur, J., 2019. On Energy, Exergy, and Environmental Aspects of a Combined

Gas-Steam Cycle for Heat and Power Generation Undergoing a Process of

Retrofitting by Steam Injection. Energy Conversion and Management,

Volume 192, pp. 374–384