The Study of Methylene Blue Loading into Chitosan-graft-Maleic Sponges

Corresponding email: yuni_kusumastuti@ugm.ac.id

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6133

Timotius, D., Kusumastuti, Y., Omar, R., Kamal, S.M.M., Jenie, S.N.A., Petrus, H.T.B.M., 2022. The Study of Methylene Blue Loading into Chitosan-graft-Maleic Sponges. International Journal of Technology. Volume 13(8), pp. 1796-1805

| Daniel Timotius | Department of Chemical Engineering, Faculty of Industrial Engineering, Universitas Pembangunan Nasional “Veteran” Yogyakarta, Jl. SWK 104, Yogyakarta 55283, Indonesia |

| Yuni Kusumastuti | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jalan Grafika 2, Yogyakarta 55281, Indonesia |

| Rozita Omar | Department of Chemical and Environmental Engineering, Faculty of Engineering, Universiti Putra Malaysia, Serdang 43400, Selangor, Malaysia |

| Razif Harun | Department of Chemical and Environmental Engineering, Faculty of Engineering, Universiti Putra Malaysia, Serdang 43400, Selangor, Malaysia |

| Siti Mazlina Mustapa Kamal | Department of Food and Process Engineering, Faculty of Engineering, Universiti Putra Malaysia, Serdang 43400, Selangor, Malaysia |

| Siti Nurul Aisyiyah Jenie | Research Centre for Chemistry, National Research and Innovation Agency (BRIN), Kawasan Puspiptek Building 452, Serpong, Tangerang Selatan 15314, Indonesia |

| Himawan Tri Bayu Murti Petrus | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jalan Grafika 2, Yogyakarta 55281, Indonesia |

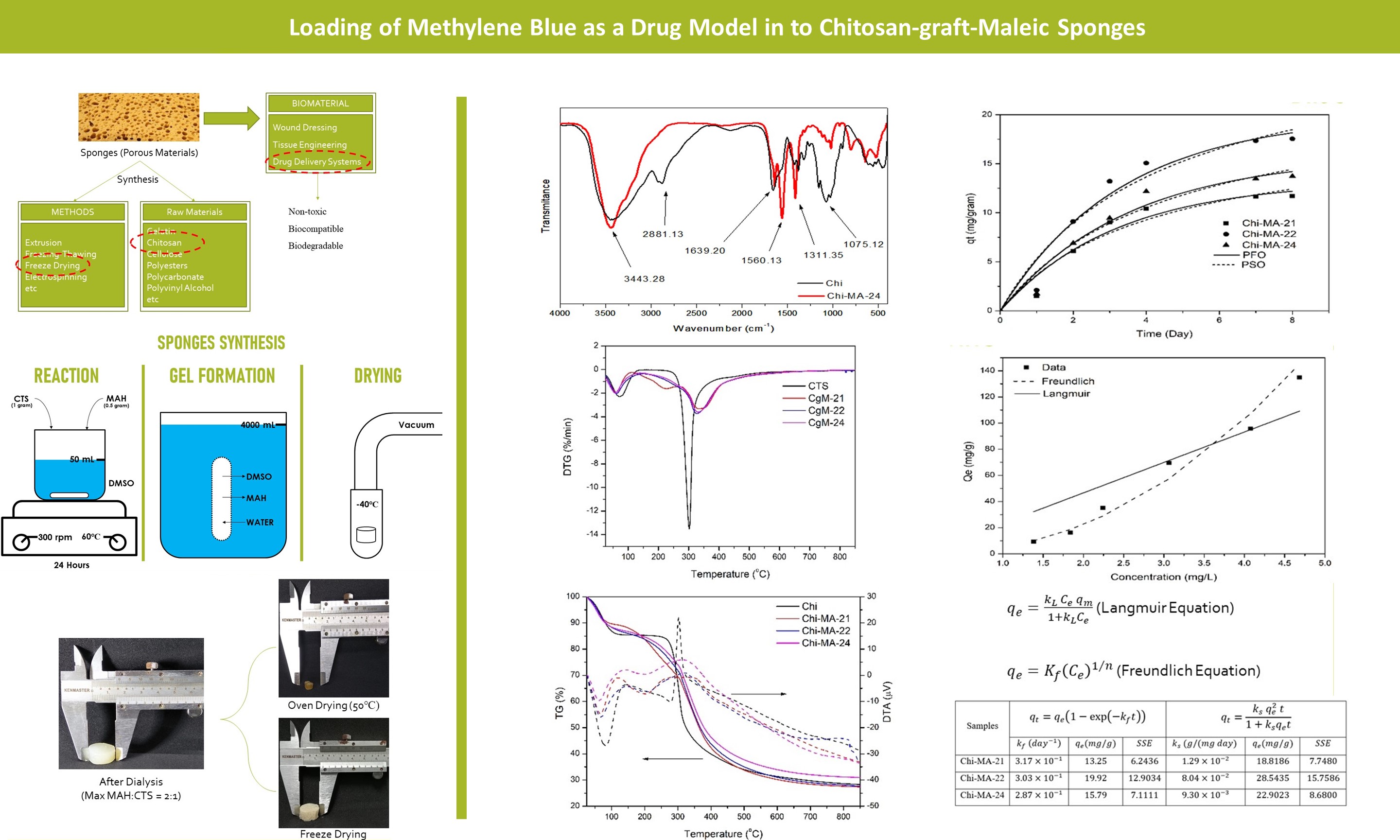

This work succeeded in synthesizing sponges

from chitosan-graft-maleic anhydride. Chitosan and maleic anhydride at a

certain mass ratio (1:2, 1:1; and 2:1) were reacted in dimethyl sulfoxide

(DMSO) at 60? for 24 hours. While the gel formation was carried out in distilled

water using a dialysis tube. The removal of DMSO from the gel was carried out

by soaking the gel in distilled water for two days. After that, the obtained

gel was frozen at -25oC overnight before being lyophilized under a

vacuum at -40oC for 24 hours. The dry sponge weight obtained after lyophilization is

about 5.61% – 6.77% (dry sponge/wet gel). FTIR and TG/DTA then characterized

the sponges. The intensity of the new strong FTIR band appeared in the

chitosan-graft-maleic sponge at 1560.13 cm-1, which corresponds to

the C=C strain. The results of TG/DTA showed that pure chitosan and sponge

chitosan-maleate underwent two stages of degradation, namely evaporation of

water and pyrolysis of organic compounds. The shift in the peak rate of

degradation in the second stage occurred at 300? for pure chitosan and at 340? for a

graft-chitosan-maleate sponge. Both results indicate that the reaction was

successful. The drug loading capability was investigated using methylene blue

as the drug model. The drug loading kinetics corresponded to a

pseudo-first-order model with kf ranging from 0.287 to 0.317 day-1.

According to the Freundlich model, the adsorption equilibrium with Kf

and 1/n values was 4.923 mg/gram and 2.192, respectively.

Chitosan; Drug delivery system; Maleic anhydride; Methylene blue; Sponges

Sponges are porous materials

synthesized from various materials and methods (Deb

et al, 2018). It has many advantages in the field of biomaterials, such

as wound dressings (Horio et al., 2010),

tissue engineering (Nikolova & Chavali, 2019),

and drug delivery systems (Cai et al., 2018).

A large surface area is required to attach the active molecule or drug in drug delivery systems.

Not only surface area but also materials for drug delivery systems require

several properties, such as non-toxicity, biocompatibility, and

biodegradability (Patel et al., 2018). These

properties are found in many natural polymers, one of which is chitosan (Peers et al., 2020).

Chitosan

(1-4)-2-amino-2-deoxy-?-D-glucan is the second most abundant polysaccharide (Ali & Ahmed, 2018). And it is usually

synthesized from the deacetylation of chitin (Sinha

et al., 2004) which extracted from the exoskeleton of crustaceans (Liu et al., 2016). Chitosan and chitin can be

distinguished by deacetylation (DD) degree. If the DD greater than 50%, it will

consider as chitosan (Knidri et al.,

2018). Chitosan

has been extensively used as a drug delivery system due to its properties,

namely non-toxic, biodegradable, and mucoadhesive (Krisanti

et al., 2020). Chitosan has two active functional groups, amine and hydroxyl,

and is usually further modified by other chemicals. Sponges from chitosan are

made by lyophilization of gel or chitosan solution. Lyophilization or

freeze-drying is a process in which water is frozen and removed through

sublimation (primary drying) and desorption (secondary drying). In sponges,

pore size is an important parameter (Deb et al.,

2018). The pore size of the sponge can be controlled by varying several

parameters, such as the geometry of the thermal gradient during freezing, ice

crystal size, freezing temperature, and freezing rate (Pottathara

et al., 2021).

Chitosan is

usually reacted with a crosslinking agent to form a gel. There are many

crosslinking agents with different interactions, namely chemical and physical

crosslinkers (Hamedi et al., 2018). Chemical

crosslinks are formed by irreversible covalent bonds between polymers and

crosslinkers (Liu et al., 2014), whereas

physical crosslinks are reversible interactions between polymers and

crosslinkers (Croisier & Jérôme, 2013).

In physical crosslinking, crosslinking can be found in the form of ions or

ionic molecules. Chitosan is polycationic with a protonated amine group.

Therefore, to physically crosslink chitosan, anions or anionic molecules are

needed (Kono et al., 2013). Maleic anhydride becomes an

attractive anionic molecule to use if it is to be further modified. Chitosan

reacts with maleic anhydride through the amidation and esterification

processes. After the reaction, chitosan has a cationic functional group from

the protonated amine group and anionic functional group from the deprotonated

carboxyl group, therefore it becomes a polyampholyte (Timotius

et al., 2022).

The drug model used in this study is methylene blue. Methylene blue has a long journey as a drug that is applied on malaria diseases (Ashley & Phyo, 2018). Now, this cationic drug has been widely used, not only on malaria, but also on other diseases, namely methemoglobinemia, ifosfamide-induced neurotoxicity, paraplegic adrenaline-resistant shock, and Alzheimer's (Schirmer et al., 2011). Another study uses methylene blue to enhance the apoptosis of cells in lung cancer by photodynamic therapy (Lim et al, 2013). Another study reviews its potency as anti-aging drug (Xue et al., 2021).

This study is aiming the potency of chitosan-graft-maleic sponges as a drug carrier. In this study, the lyophilization method successfully synthesized a novel chitosan base sponge from chitosan and maleic anhydride. The modified chitosan solution is prepared by reacting low molecular weight chitosan with maleic anhydride in dimethyl sulfoxide (DMSO). Furthermore, the gel formation is carried out by dialysis of the modified chitosan solution under aquadest. Then before lyophilization, the gels were frozen at –25?. The obtained sponges are then further characterized.

2.1. Materials

Low molecular weight chitosan (50

– 190 kDa, 75 – 85% DD) was obtained from Sigma Aldrich, USA. Acetic acid

(100%) was supplied from Merck, Germany. Maleic anhydride (>99% purity) was

purchased from Nacalai Tesque Inc., Japan. Methylene blue was obtained from

Merck, India. Merck, Japan, supplied dimethyl sulfoxide (DMSO). All reagents

were used without further purification or treatment.

2.2. Methods

2.1.1. Synthesis

of Chitosan-graft-Maleic Sponges

The chitosan-graft-maleic (Chi-MA) synthesis followed previous studies with slight modifications (Zhou et al., 2017). The scheme of sponges synthesis is provided in Figure 1. About 1 gram of chitosan is dissolved in 50 mL of dimethyl sulfoxide. After the chitosan was dissolved entirely, maleic anhydride was added to the solution, followed by stirring at 300 rpm, 60oC for 24 hours. Gel formation was carried out using a dialysis tube. After the reaction, the solution is placed in cellulose dialysis tubing (MWCO 15 kDa) and dialyzed under deionized water to form a gel. The removal of DMSO from the gel was carried out by soaking the gel in distilled water for two days. Afterward, the obtained gel was frozen at -25oC overnight before being lyophilized under a vacuum at -40oC for 24 hours. This method was performed for several MA masses (0.5 grams, 1 gram, and 2 grams) labeled Chi-MA-21, Chi-MA-22, and Chi-MA-24.

Figure 1 Preparation of Chitosan-graft-Maleic

Sponges

2.1.2. Characterization

FTIR and

thermogravimetric analysis were carried out for the characterization of

chitosan sponges. The FTIR study was performed by SHIMADZU IR Pestige-21. The sponges

were scanned with wavenumber ranging from 400 – 4000 cm-1. The

thermogravimetric analysis (TGA) study was conducted by NEXTA STA (Hitachi

STA200RV) with actual view sample observations, and 15 mg of the sample was

heated to a temperature of 900oC with a heating rate of 10oC /min.

2.1.3. Drug

Loading

Drug loading

was carried out using the Chi-MA gel state. Methylene blue was dissolved in

deionized water and analyzed using a Vis Spectrophotometer (Genesys 20) as the

initial concentration (). Chi-MA gel was weighed and immersed in methylene blue solution.

A decrease in concentration (

) was observed for several increments. Observations are completed

when equilibrium has been reached. The adsorbed methylene blue (

) was calculated using Equation 1, where the V and

Kinetic

studies were evaluated using two simple models, namely pseudo-first-order (PFO,

Equation 2) and pseudo-second-order (PSO, Equation 3) (Syafiuddin

et al., 2018). Where and

The

adsorption model evaluation was conducted by two different models: Langmuir

adsorption isotherm and Freundlich adsorption isotherm. The Langmuir model was

presented using Equation 5, while the Freundlich model was shown in Equation 6 (Ayawei et al., 2017). The

adsorption isotherm was conducted by measuring the equilibrium state of drug

loading.

3.1. Gel Preparation

The gel synthesis is successfully obtained up to 2:1 of MA to chitosan mass ratio. According to previous work (Zhou et al., 2017), the MA to chitosan ratio of about 3.5:1 makes the modified chitosan dissolve in the water instead of gel formation. It might happen because most of the amine groups are grafted by MA. Therefore, carboxyl groups instead of amine groups will dominate the chitosan. In the present work, 2:1 is being a maximum MA to chitosan ratio. The appearance of the gel is presented in Figure 1.

Figure 2 Gel State

of Chitosan-graft-Maleic

The drying process of the gel is performed

with two different methods, namely oven and freeze-drying. The oven-drying process shows an extreme shrinkage in the gel volume, as shown in

Figure 2a. This might have happened because the polymers cannot hold their

structure. Unlike the oven-drying

process, the freeze-drying or lyophilization process creates a sponge with low

shrinkage, and the polymer can maintain its structure, as presented in Figure

2b. The shrinkage on oven drying is about 92.97% in volume, while freeze-dried

sponge only shrank about 12.11%. This is occurred due to the sublimation

process when the ice crystal is directly converted into a gas state (Kassem et al., 2015). The sponge's sample varies

from 5.61 – 6.77%, while the rest is water.

|

|

Figure 3 Result of Oven Drying (a) and

Freeze Drying (b) of Chi-MA Gels

3.2. Component Analysis

FTIR study on chitosan and

Chi-MA-24 is conducted to observe each sample's functional group. Both results

are shown in Figure 3. The FTIR spectrum of pure chitosan shows a broad peak at

around 3443.28

|

|

|

Figure 4 FTIR Spectra of Pure

Chitosan (a) and Chitosan-graft-Maleic (b)

3.3. Thermogravimetric

Analysis

The study is

conducted to analyze the thermal stability of the Chi-MA samples. The result of

TG/DTA from Chi and Chi-MA samples is presented in Figure 5. The result shows

that the first endothermic peak in DTA result at 82.56? for pure chitosan

and around 63-67? for Chi-MA are due to the evaporation of

water and volatile organic compound (Kusumastuti et

al., 2020), which in line with the TG

result. At the same time, the second endothermic flow corresponds to the glass

transition temperature. The rate of degradation of chitosan and Chi-MA samples

consists of 2 steps, as shown in Figure 5b. The first step is due to the

samples' drying process, water evaporation, and volatile organic matter. In

contrast, the second step occurs due to the degradation of organic compounds to

form char. In the first step of pure chitosan, water evaporation occurs up to

100? with a weight loss of about 15%. Meanwhile, the primary degradation

occurs from about 250 to 450?, with a minimal degradation

rate. It is consistent with another study (Kumar

& Koh, 2012). The degradation pattern of Chi-MA samples is similar

to pure chitosan. However, there is a slight shift in the degradation rate

between chitosan and Chi-MA samples, as shown in Figure 5a. The chitosan has a

steeper degradation rate, while the Chi-MA samples are thermally more stable.

Figure 5 TG/DTA of Chi and

Chi-MA Samples at 10?/min Heating Rate

3.4. Drug Loading

The result of

methylene blue adsorption into the hydrogel’s matrices is presented in Figure

6. The result shows that the equilibrium state appeared after eight days of

adsorption for all samples. The optimum drug loading appears in Chi-MA-22

samples with the highest methylene blue loading. Kinetic adsorption of

methylene blue onto Chi-MA samples is determined using pseudo-first order and

pseudo-second order kinetics (Aljeboree et al,

2017). The plot for both models is shown in Figure 6, while the

parameter values are shown in Table 1. From the results, it can be concluded

that pseudo-first

order best fits all samples. Where ).

The pseudo-first-order rate model primarily models the physical adsorption

phenomenon, while the pseudo-second-order model primarily models the chemical

adsorption phenomenon. According to the result, the kinetic has the best fit on

the pseudo-first order model with higher compared to pseudo-second-order model. The

physical adsorption occurred due to the interaction between positive charges of

the methylene blue with the COO- functional groups in the Chi-MA

samples (Wirawan et al, 2022).

The equilibrium study

is carried out by measuring the equilibrium concentration of methylene blue.

The measurements are conducted at room temperature and several Chi-MA-22 doses

involving two equilibrium models: Langmuir (Equation 5) and Freundlich

(Equation 6), which are presented in Table 2. The Langmuir model consists of 2

parameters: full monolayer coverage()

and Langmuir constant (

).

While in the Freundlich model,

and

Table 1 Kinetic Parameter Values of Each

Model

Figure 6 Methylene Blue Loading into Chi-MA Samples

Table 2 Adsorption Equilibrium Parameter

Values of Each Model

Figure 7 Adsorption Isotherm of

Methylene Blue in Chi-MA-22

The

chitosan-graft-maleic sponge was synthesized using the lyophilization method.

The maximum ratio of maleic anhydride to chitosan mass ratio is 2:1. According

to the result, the reaction and lyophilization were successfully conducted,

which showed by the appearance of a peak at 1560.13cm-1,

corresponding to the C=C bond. The shift in the peak rate of degradation in the

second stage occurred at 300oC for pure chitosan and at 340oC for a graft-chitosan-maleate sponge. The methylene blue loading followed a pseudo-first-order

kinetics model with Kf values varying from 0.287 – 0.317day-1.

While the adsorption isotherm was best fitted with the Freundlich isotherm

model with Kf and 1/n values are 4.92 and 2.19,

respectively. Hence it can be concluded that a chitosan-graft-maleic sponge can

be used as a methylene blue carrier.

The authors would like to acknowledge Ministry of Education and

Culture of Indonesia for the financial support through PDUPT scheme (No.

2573/UN1-DITLIT/DIT-LIT/LT/2019) and partial support from SEAMEO for providing

financial support under the University Consortium Seed Fund for Collaborative

Research Grant. The authors also would like to extend their gratitude to the

Universitas Gadjah Mada and Universiti Putra Malaysia for the research

facilities and raw materials for completing this study.

Ali, A., Ahmed, S., 2018. A Review on Chitosan

and Its Nanocomposites in Drug Delivery. International Journal of Biological Macromolecules, Volume 109, pp. 273–286

Aljeboree,

A.M., Alshirifi, A.N., Alkaim, A.F., 2017. Kinetics and Equilibrium Study for

the Adsorption of Textile Dyes on Coconut Shell Activated Carbon. Arabian Journal of Chemistry, Volume 10, pp. S3381–S3393

Ayawei, N.,

Ebelegi, A.N., Wankasi, D., 2017. Modeling and Interpretation of Adsorption Isotherms.

Journal Chemistry, Volume 2017, p. 3039817

Ashley, E.A., Phyo. A.P., 2018.

Drugs in Development for Malaria. Drugs, Volume 78(9), pp 861-879

Barleany, D.R.,

Ananta, C.V., Maulina, F., Rochmat, A., Alwan, H., Erizal, 2020. Controlled

Release of Metformin Hydrogen Chloride from Stimuli-Responsive Hydrogel Based

on Poly(N-Isoprpylacrylamide)/Chitosan/Polyvinyl Alcohol Composite. International Journal of Technology, Volume 11(3), pp. 511–521

Cai, B., Zhong,

T., Chen, P., Fu, J., Jin, Y., Liu, Y., Huang, R., Tan, L., 2018. Preparation, Characterization

and In Vitro

Release Study of Drug-Loaded

Sodium Carboxymethyl Cellulose/Chitosan Composite Sponge. PLoS ONE, Volume 13(10), pp. e0206275

Croisier, F.,

Jérôme, C., 2013. Chitosan-Based Biomaterials for Tissue Engineering. European Polymer Journal, Volume 49, pp. 780–792

Deb, P.,

Deoghare, A.B., Borah, A., Barua, E., Lala, S.D., 2018. Scaffold Development

Using Biomaterials: A Review. Materials

Today: Proceedings, Volume 5(5),

pp. 12909–12919

Haerudin, H.,

Pramono, A.W., Kusuma, D.S., Jenie, A., Voelcker, N.H., Gibson, C., 2010.

Preparation and Characterization of Chitosan/Montmorillonite (MMT)

Nanocomposite Systems. International

Journal of Technology, Volume 1(1), pp. 65–73

Hamedi, H.,

Moradi, S., Hudson, S.M., Tonelli, A.E., 2018. Chitosan Based Hydrogels and

Their Application for Drug Delivery in Wound Dressing: A Review. Carbohydrate Polymers, Volume 199, pp. 445–460

Horio, T.,

Isihara, M., Fujita, M., Kishimoto, S., Kanatani, Y., Ishizuka, T., Nogami, Y.,

Nakamura, S., Tanaka, Y., Morimoto, Y., Maehara, T., 2010. Effect of

Photocrosslinkable Chitosan Hydrogel and Its Sponges to Stop Bleeding in a Rat

Liver Injury Model, Artificial

Organs, Volume 34(4), pp. 342–347

Kassem, M.A.A.,

Elmeshad, A.N., Fares, A.R., 2015. Lyophilized Sustained Release Mucoadhesive

Chitosan Sponges for Buccal Buspirone Hydrochloride Delivery: Formulation and In Vitro Evaluation. AAPS

PharmSciTech, Volume 16(3), pp. 537–547

Knidri, H.E.,

Belaabed, R., Addaou, A., Laajeb, A., Lahsini, A., 2018. Extraction, Chemical

Modification, and Characterization of Chitin and Chitosan. International Journal of Biological

Macromolecules, Volume 120, pp. 1181–1189

Kono, H., Oeda,

I., Nakamura, T., 2013. The Preparation, Swelling Characteristics, and Albumin

Adsorption and Release Behaviors of a Novel Chitosan-Based Polyampholyte

Hydrogel. Reactive &

Functional Polymers, Volume 73,

pp. 97–107

Krisanti, E.A.,

Lazuardi, D., Kiresya, K.K., Mulia, K., 2020. Tablet Formulation Containing

Chitosan-Alginate Microparticles: Characterization and Release Profile of

Xanthones. International Journal

of Technology, Volume 11(5), pp. 900–909

Kumar, S., Koh,

J., 2012. Physiochemical, Optical and Biological Activity of Chitosan-Chromone

Derivative for Biomedical Applications. International Journal of Molecular Sciences, Volume 13, pp. 6102–6116

Kusumastuti, Y., Shibasaki, Y., Hirohara, S.,

Kobayashi, M., Terada, K., Ando, T., Tanihara, M., 2017. Encapsulation of Rat

Bone Marrow Stromal Cells using a Poly-Ion Complex Gel of Chitosan and

Succinylated Poly (Pro-Hyp-Gly). Journal

of Tissue Engineering and Regenerative Medicine, Volume 11(3), pp. 869–876

Kusumastuti,

Y., Timotius, D., Putri, N.R.E., Syabani, M.W., Rochmadi, 2020. Rheological and

Kinetic Studies of Low-Density Polyethylene (LDPE)-Chitosan Biocomposite Film. IOP Conference Series: Materials Science

and Engineering, Volume 722, p. 012054

Lavanya, R.,

Gomathi, T., Vijayalakshmi, K., Saranya, M., Sudha, P.N., 2017. Adsorptive

Removal of Copper (II) and Lead (II) Using Chitosan-g-Maleic

Anhydride-g-Methacrylic Acid Copolymer. International Journal of Biological Macromolecules, Volume 104, pp. 1495–1508

Liu, R., Xu,

X., Zhuang, X., Cheng, B., 2014. Solution Blowing of Chitosan/PVA Hydrogels

Nanofiber Mats. Carbohydrate Polymers, Volume 101, pp. 1116–1121

Liu, Y., Shen,

X., Zhou, H., Wang, Y., Deng, L., 2016. Chemical Modification of Chitosan Film

Via Surface Grafting of Citric Acid Molecular to Promote Biomineralization. Applied Surface Science, Volume 370, pp. 270–278

Nadtoka, O.,

Virych, P., Kutsevol, N., 2020. Hydrogels Loaded with Methylene Blue:

Sorption-Desorption and Antimicrobial Photoactivation Study. International Journal of Polymer Science, Volume 2020, p. 9875290

Nikolova, M.P.,

Chavali, M.S., 2019. Recent Advances in Biomaterials for 3D Scaffolds: A

Review. Bioactive Materials, Volume 4, pp.

271–292

Patel, S.,

Srivastava, S., Singh, M.R., Singh, D., 2018. Preparation and Optimization of

Chitosan-Gelatin Films for Sustained Delivery of Lupeol for Wound Healing. International journal of Biological Macromolecules, Volume 107(Part B), pp. 1888–1897

Peers, S.,

Montembault, A., Ladavière, C., 2020. Chitosan Hydrogels for Sustained Drug

Delivery. Journal of Controlled

Release, Volume 326, pp. 150–163

Pottathara,

Y.B., Vuhere, T., Maver, U., Kokol, V., 2021. Morphological, Mechanical, and In-Vitro Bioactivity of Gelatine/Collagen/Hydroxyapatite Based Scaffolds Prepared by Unidirectional Freeze-Casting. Polymer Testing. Volume 102, p. 107308

Schirmer, R.H., Adler, H., Pickhardt., Mandelkow,

E., 2011. Lest We Forget You – Methylene Blue. Neurobiology of Aging, Volume

32(12), pp. e7–e16

Sinha, V.R.,

Singla, S.K., Wardhawan, S., Kaushik, R., Kumria, R., Bansal, K., Dhawan, S.,

2004. Chitosan Microspheres as a Potential Carrier for Drugs. International Journal of Pharmaceutics, Volume 274, pp. 1–33

Syafiuddin, A.,

Salmiati, S., Jonbi, J., Fulazzaky, M.A., 2018. Application of the Kinetic and

Isotherm Models for Better for Better Understanding of the Behaviors of Silver

Nanoparticles Adsorption onto Different Adsorbents. Journal of Environmental Management, Volume 218, pp. 59–70

Timotius, D.,

Kusumastuti, Y., Rochmadi., 2022. Characterization and Equilibrium Study of

Drug Release of pH-Responsive Chitosan-graft-Maleic Film. International Journal of Technology, Volume 13(2), pp. 398–409

Wirawan, S.K.,

Timotius, D., Nugraha, I.M., Restana, A., Anggara, A.L., Hidayatullah, S.,

2022. Kinetics and Adsorption Equilibrium Study of Free Fatty Acid (FFA) from

Crude Palm Oil (CPO) on Anionic Resin. ASEAN Journal of Chemical Engineering, Volume 22(1), pp. 33–41

Xue, H.,

Thaivalappil, A., Cao, K., 2021. The Potentials of Methylene Blue as an

Anti-Aging Drug. Cells. Volume 10(12), p. 3379

Zhou, Y., Dong,

Q., Yang, H., Liu, X., Yin, X., Tao Y., Bai, Z., Xu, W., 2017. Photocrosslinked

Maleilated Chitosan/Methacrylated Poly (Vinyl Alcohol) Bicomponent Nanofibrous Scaffolds

for Use as Potential Wound Dressings. Carbohydrate Polymers, Volume 168,

pp. 220–226