Properties Enhancement of Brewer Rice Flour Biodegradable Films via Ultrasonication and Acetylation Treatments

Corresponding email: moh.djaeni@live.undip.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6130

Utari, F.D., Siqhny, Z.D., Purbasari, A., Kusworo, T.D., Utomo, D.P., Djaeni, M., 2024. Properties Enhancement of Brewer Rice Flour Biodegradable Films via Ultrasonication and Acetylation Treatments. International Journal of Technology. Volume 15(4), pp. 976-986

| Febiani Dwi Utari | Department of Chemical Engineering, Faculty of Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Zulhaq Dahri Siqhny | Faculty of Agriculture Technology, Semarang University, Jl. Soekarno Hatta, Semarang 50196, Indonesia |

| Aprilina Purbasari | Department of Chemical Engineering, Faculty of Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Tutuk Djoko Kusworo | Department of Chemical Engineering, Faculty of Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Dani Puji Utomo | Department of Chemical Engineering, Faculty of Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Mohamad Djaeni | Department of Chemical Engineering, Faculty of Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

Increasing the use of conventional plastics causes

environmental problems. Producing biodegradable films from biodegradable

sources might help overcome these problems. Brewer rice, a by-product in rice

processing, can be potentially converted into rice flour for biodegradable film

production. Ultrasonic and chemical modification can enhance the mechanical

properties of the rice flour biodegradable film. This study aims to produce a

biodegradable film using rice flour with different levels of amylose through

conventional and ultrasonic acetylation. The rice flour was mixed and diluted

with distilled water and placed in an ultrasonic bath for 15 minutes at 40 kHz

agitation. The mixture was then acetylated using acetic acid. The modified rice

flour was then mixed with glycerol and dried to form a biodegradable film. The

produced biodegradable films were then characterized for their morphological

structure, chemical composition, and crystallinity properties. Results show

that ultrasonication and acetylation enhanced the elongation at the break until

2.5 times higher than the conventional process (without modification) and

improved hydrophobicity. These results suggest that ultrasonication and

acetylation improved biodegradable film properties, making it a potential for

biodegradable packaging materials and coatings.

Acetylation; Amylose; Biodegradable film; Rice flour; Ultrasonication

Plastics

are widely used in various human products. However, conventional plastics

produced from petroleum are difficult to degrade (Marichelvam, Jawaid, and Asim, 2019). Plastic waste harms the

environment and human health, among other issues (Judawisastra et al., 2018). Producing biodegradable film from starch can

potentially overcome the problem of non-degradable plastics (Chinaglia et al., 2018; Haider et al., 2019;

Hasan et al., 2020; Jiang et al., 2020; Tanjung et al., 2023) . However, using starch leads to new problems, such

as the competition between its use as a food product and higher preparation

costs (Wellenreuther, Wolf, and

Zander, 2022). Therefore, it is important to find the raw materials

for the biodegradable film that do not compete with the application as the food

materials with the low preparation cost.

Rice flour contains ~78% starch, non-starch

polysaccharides, sugar, protein, fat, and inorganic materials (Majzoobi et al., 2015).

Previous studies show that using rice starch as a biodegradable film has

disadvantages in low water resistance due to its hydrophilic nature and low elasticity (Alcázar-alay, Angela, and Meireles,

2015; Wang and Shi, 2013). Most studies reported that starch as the main

ingredient could increase interest in flour as a raw material for film

production (Pelissari et al., 2013). On the other hand, flour is a cheap material because

it comes from brewer’s rice. It is easier to find than pure materials, such as

starch or proteins (Majzoobi et al., 2015). The application of rice flour as the raw material of

the biodegradable film can be an option to overcome the problem of competition

materials for food and reduce the production cost since the cheaper materials.

Several

studies have investigated rice starch modification to enhance its physical

properties using physical and chemical methods (Imani et al., 2022; Marichelvam,

Jawaid, and Asim, 2019). Heat, a physical method, can reduce the size of the

starch granules. However, there is no further study regarding the quantity of

heat energy consumption in this process (Alcázar-alay, Angela, and Meireles,

2015). Other physical modifications

include vacuum, ultrasonic, and microwave processes (Zia-ud-Din, Xiong, and

Fei, 2017). The frequency, temperature, and time are usually

varied in the modification using ultrasonic exposure. The modification makes

the granule surface porous (Zhu, 2015; Zuo et al., 2012).

Chemical

modification methods such as acetylation can improve the lack of native rice

starch by converting the hydrophilic hydroxyl groups into hydrophobic acetyl

groups (Chi et al., 2008; Yang et al., 2018). The hydroxyl moieties react with the acetyl group

through an esterification pathway to form acetates in the presence of a free

proton (H+) (Liu et al., 2022).

Additionally, acetylation in cassava starch successfully enhances the

elongation at break up to 1.5 times more than native cassava starch film (Schmidt et al., 2019). However, the reaction time can be longer in

acetylation. The reaction was carried out at 50°C for 3 hours (Chi et al., 2008) to produce a 0.8 DS. The DS can

be increased by increasing reaction time, reaction temperature, reactant

concentration, presence of a catalyst, and pH (Ackar et al., 2015; Kumoro and Amalia, 2015; Chi et

al., 2008). However, the increasing reaction temperature increases running

production costs for energy. So, the innovation research on accelerating the

reaction time is crucial.

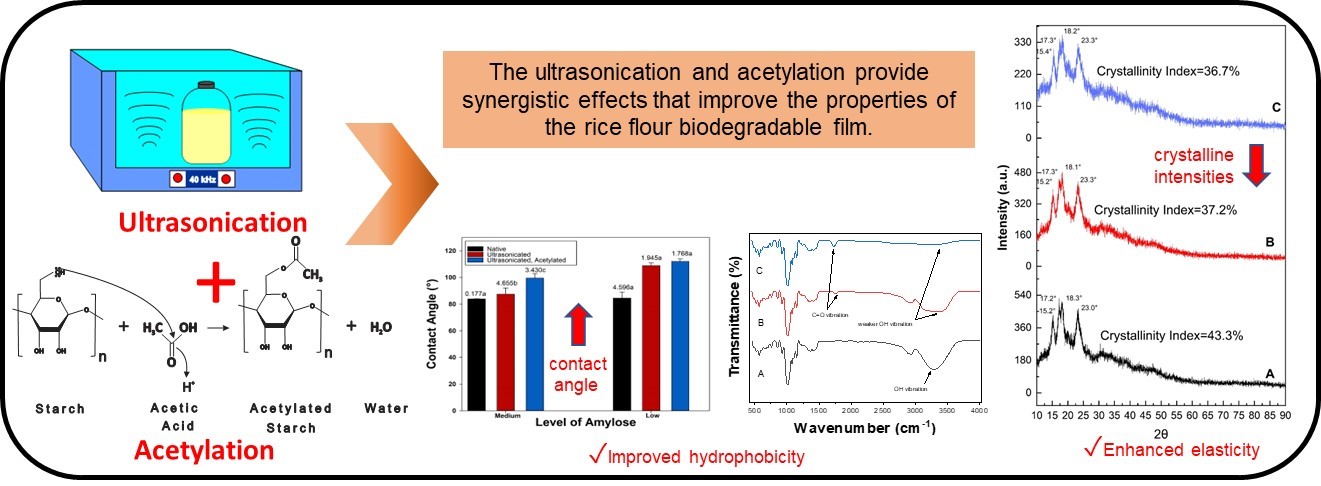

The

combination of ultrasonication and acetylation in Dioscorea zingiberensis

starch increased the starch particle’s surface area to enhance the reaction

efficiency (Zhang et al., 2012). However, based on the literature study, it is hard

to find the application of these combination methods in biodegradable film

production. The ultrasonication and acetylation can provide synergistic effects

that improve the properties of the biodegradable film. This research aimed to

produce a biodegradable film using different amylose levels of rice flour

through physical and chemical modifications, ultrasonication, and acetylation.

The different amylose levels of rice flour will result in the different

properties of the biodegradable film produced in this study. Amylose is a

linear molecule of glucose units linked with a-(1 à 4) bonds (Luo et al., 2021; Tao et al., 2019). Pure

amylose has shown strong cohesive energy density due to intermolecular hydrogen

bonding along polymer chains that form brittle properties of the film (Muscat et al., 2012). In other words, the properties of the biodegradable

film can be controlled by maintaining the amylose composition in the raw

materials. The mechanical properties, microstructure, and hydrophobicity of the

modified biodegradable film were evaluated and compared with native rice flour

to determine the effectiveness of the modification process.

2.1. Materials

This study used the two kinds

of commercial rice flour produced by Budi Starch & Sweetener Ltd. (Subang,

Indonesia). The products, rice flour, and glutinous rice flour, contained

amylose of about 22.68% ± 0.03 and 8.84% ± 0.04, respectively. All chemicals used

in experiments were of analytical grade. Glacial acetic acid and acetic

anhydride were purchased from Merck (Darmstadt, Germany). Glycerol was used as

the plasticizer and was purchased from Brataco Ltd. (Surabaya, Indonesia).

2.2. Methods

In this study, biodegradable film production

consists of three main steps: (1) physical modification

using ultrasonication, (2) chemical modification using acetylation, and (3)

biodegradable film casting. Figure 1

depicts the schematic process flow of biodegradable film production.

Figure 1 The scheme of biofilm production

2.2.1.

Physical modification using ultrasonic

Rice flour (30 wt%) was

mixed with distilled water and agitated for 10 min. The slurry was then placed

in an ultrasonic chamber (BUC 65L, B-One Ultrasonic Cleaner, China). The

ultrasonic frequency was 40 kHz (15 min). Table 1 lists the experimental

ultrasonication and acetylation time. At the end of the sonication process, the

suspension was cooled to room temperature. After that, it was filtered by a

vacuum filtration process using a Buchner funnel connected to a filtering flask

with a side tube connected to a vacuum pump. Upon completing the filtration

process, the filtrates were dried in an electric oven at 40°C for 48 h. The dry

powder was then sieved using an 80-mesh sieve and stored in an air-tight

container.

Table 1 Process variables values

|

Level of amylose |

Ultrasonication time (minutes) |

Acetylation time (minutes) |

Coded |

|

Medium |

0 |

0 |

NM |

|

0 |

90 |

MA | |

|

15 |

90 |

MU15A | |

|

Low |

0 |

0 |

NL |

|

0 |

90 |

LA | |

|

15 |

90 |

LU15A |

2.2.2.

Chemical modification using acetylation

The

acetylation treatment referred to the previous method by Zhang

et al. (2012). After the ultrasonic treatment, 10 g of the dried ultrasonicated flour

was mixed with glacial acetic acid (10 mL). The suspension was placed in a

three-neck flask under agitation for 2 minutes. Subsequently, the acetic

anhydride (30.0 mL) was added. The reaction was performed at 50°C for 90 min

(Table 1). The mixture was then neutralized using distilled water. The

filtering and drying processes were the same as the described process in the

ultrasonic treatment section.

2.2.3.

Biodegradable film casting

The glycerol was used in this study as

the plasticizer. The concentration of glycerol was 3 wt% of the total solution.

10 g of rice flour (after ultrasonication and acetylation treatment), glycerol,

and 100 ml of distilled water were mixed and stirred for 10 min. Then the

mixture was heated at 60°C with continuous stirring for 10 min. The product was

uniformly cast on a Petri dish. This cast film was then dried in the dehydrator

(ARD-PM99, Maksindo, Indonesia) at 50°C for 8 h, resulting in the final biodegradable

film product. For comparison, the biodegradable films produced from the native

form of medium amylose and low amylose were coded as NM and NL, respectively

(Table 1).

2.3. Characterization of biodegradable film

2.3.1.

Morphology

The

morphological structures of the produced biodegradable films were observed

using a scanning electron microscope (SEM) (JEOL JSM-6510LA). The biodegradable

films were scanned at 1500× magnifications.

2.3.2.

Fourier transform infrared (FTIR)

The chemical functional groups of the

biodegradable films were evaluated using FTIR spectra recorded by Frontier

spectrometer (PerkinElmer, America). The wavenumber ranged from 4000 to 450 cm-1.

2.3.3.

X-ray diffraction (XRD)

XRD

patterns of the biodegradable film were recorded using an X-Ray Diffraction

device (Shimadzu XRD-700, Japan). The diffraction signals were observed at 2 from 10° to 90°. The instrument was operated with nickel-filtered Cu and K

radiation at a voltage of 30 kV and a current of 30 mA.

2.3.4.

Mechanical properties

A

texture analyzer (UTS H001, China) measured the biodegradable film’s mechanical

properties (tensile strength and elongation at break). The biodegradable film

was prepared in the standard dimension (4 cm × 2 cm) for the analysis. The

analysis was conducted at a crosshead speed of 20 mm/min, and each sample

measured the rice.

2.3.5.

Water contact angle measurement

The contact angle, the angle between the biodegradable film surface and liquid drop, determine the nature of the surface and hydrophilicity of the biodegradable film. The contact angle was examined using an anglemeter (RACE anglemeter, Japan).

3. Results and Discussion

3.1. Rice flour biodegradable film morphology

The morphological changes in the native and modified biodegradable film are shown in Figure 2A-F. In Figure 2A, the NM biodegradable film showed a crack because of internal stress. During the drying process of NM biodegradable film, the internal stress enhanced significantly, exceeding the material’s strength and cracking the biodegradable film surface (Jin et al., 2013). The cracked surface in NM biodegradable film indicated the lack of mechanical properties. In Figure 2D, the NL biodegradable film only showed some nodules, indicating the mechanical properties were better than the NM biodegradable film.

The MA and LA biodegradable films showed a better surface than the native biodegradable film; however, they comprise some nodules (Figure 2B and 2E). The insoluble materials were found in the SEM image of biodegradable film (Prasetyaningrum et al., 2021). After the acetylation process, the acetyl group was linked to starch molecules, which increased the hydrophobicity and decreased water solubility (Colussi et al., 2015). Because of the lower solubility, some materials could not be dissolved, and they appear as nodules in the biodegradable film surface. Additionally, more nodules appeared in the low amylose biodegradable film than in the medium amylose biodegradable film. The low-amylose biodegradable film contains higher amylopectin. The amylopectin had lower solubility and resulted in the nodules in the SEM image (Cuevas, Gilbert, and Fitzgerald, 2010).

Figure 2 Surface scanning electron microscope (SEM) photograph of biofilm at 1500× magnifications (A) NM, (B) MA, (C) MU15A, (D) NL, (E) LA, (F) LU15A

In Figure 2B, 2C, 2E, and 2F, the surface of MA, MU15A, LA, and LU15A biodegradable films consisted of multiple layers, which may be attributed to the lower bound moisture. Acetylation converted the hydroxyl groups in starch molecules into acetyl groups (Ackar et al., 2015). After the acetylation process, the drying process was the next step in biodegradable film production. In lower hydroxyl groups or the lower bound water, the surface moisture evaporation becomes dominant, resulting in the multilayer surface. Additionally, the ultrasonication on starch formed new pores that increased the surface area of the reaction and enhanced the acetylation reaction efficiency (Zhu, 2015; Zuo et al., 2012). If the degree of acetylation increases, the covalent bonding between starch molecules and the acetyl group strengthens. Therefore, the prepared biodegradable film (MU15A and LU15A) showed the best surface morphology, with higher smoothness and fewer nodules, with less cracking, indicating the enhancement of mechanical properties (see Figures 2C and 2F).

3.2. Fourier transform infrared (FTIR) of biodegradable film

Figure 3A-F shows the FTIR spectra of native and acetylated rice flour biodegradable film. Both NM and NL displayed the O-H peak at 3200 cm-1, indicating the hydrophilicity of the biodegradable film. This O-H peak decreased after the ultrasonication and acetylation process (MU15A and LU15A biodegradable film), resulting in the lowest O-H peak (Figure 3C and Figure 3F). The acetylation process was categorized as an addition/elimination reaction (Wojeicchowski et al., 2018). The hydroxyl groups in starch molecules were converted into an acetyl group in acetylation (Figure 4). Therefore, the O-H peak decreased, resulting in a new peak at 1750 cm-1 corresponding to the acetylated starch. From Figure 3, the low amylose biodegradable film displayed higher peak changes than medium amylose, attributed to the conversion of a hydroxyl group to the acetyl group. The low amylose biodegradable film promotes a spacious surface area for acetylation.

Figure 3 FTIR spectra of (A) NM, (B) MA, (C) MU15A, (D) NL, (E) LA, (F) LU15A at a frequency of 450–4000 cm-1

Figure 4 Reaction of starch acetylation forming starch acetate

3.3. X-ray diffraction (XRD) of biodegradable film

XRD analysis was conducted to observe the crystallinity of native and modified rice flour biodegradable film at 2 range of 10°-90°. Based on the XRD analysis displayed in Figure 5A-F, the results indicated the typical A-type crystalline peaks at 2

of 15°, 17°, 18°, and 23° (Dome et al., 2020). The value of the crystallinity index ranged from 43.3% to 35.3%. After the acetylation process, the crystallinity index was lower. Acetylation reduced the intermolecular hydrogen bonding in starch molecules responsible for the crystalline structure of starch (Zhang et al., 2012), indicating that the film became more amorphous. The lowest crystallinity index was observed in the ultrasonicated and acetylated biodegradable film, which is attributed to the reduced hydrogen bonding. These findings are comparable with several biodegradable film production studies from Dioscorea zingiberensis (Zhang et al., 2012) and barley (Halal et al., 2015).

Figure 5 The X-ray diffraction (XRD) pattern of (A) NM, (B) MA, (C) MU15A, (D) NL, (E) LA, (F) LU15A

3.4. Biodegradable film mechanical properties evaluation

The tensile strength analysis evaluates biodegradable film’s performance as a packaging material. Tensile strength is the maximum stress of biodegradable film before breaking (Marichelvam, Jawaid, and Asim, 2019). In this study, the biodegradable film was produced using two types of rice flour, low and medium amylose. The effect of ultrasonication and acetylation on the tensile strength of rice flour biodegradable film was evaluated, as depicted in Figure 6A. This result showed that the tensile strength value in native rice flour biodegradable film was 7.65 MPa for medium amylose and 6.35 MPa for low amylose. The tensile strength of medium amylose film is higher than that of low amylose film could be due to the linear structure of amylose to promotes more extensive hydrogen bonds between their polymer chains (Muscat et al., 2012). After the ultrasonication and acetylation process, the tensile strength decreased up to 1.3-1.6 times. This phenomenon was in line with XRD analysis, which showed that the crystallinity index decreased after the modification, implying that the crystalline phase converted into an amorphous phase. The tensile strength was linear with the crystalline phase (Ebnesajjad, 2000). As a result, the tensile strength was decreased after the ultrasonication and acetylation process.

Figure 6B showed that elongation values at the break in native rice flour biodegradable film were 18.5% for medium amylose and 29.5% for low amylose. Films with lower amylose content exhibited better flexibility and underwent fracture at a slower pace. This might be due to the fact that amylose (in medium amylose rice flour) forms stiff strands network that makes fracture mechanism of rapid brittle fracture. While amylopectin is a branched molecule of glucose polymer (Muscat et al., 2012).

Additionally, the values of elongation at break of both native rice flour biodegradable films were lower than that of modified rice flour biodegradable film. The low elongation value means the lack of biodegradable film performance (Xu et al., 2021). Further, these results were confirmed with SEM characterization, where the NM displayed cracking in the biodegradable film surface. The brittle characteristic improves with acetylation. In this study, the ultrasonication and acetylation process can enhance the elongation at break up to 2.5 times. The increased elongation at the break after the acetylation process was supported by the XRD analysis, which showed decreased crystalline intensity. It implied that the crystalline phase was converted into an amorphous phase. The crystalline phase is linear with stiffness, whereas the amorphous phase is linear with elongation at break (Ebnesajjad, 2000).

Figure 6 Mechanical properties of native and modified rice flour biofilm (A) tensile strength, (B) elongation at break

3.5. Biodegradable film hydrophilicity through contact angle value

The starch-based biodegradable films are hydrophilic polymers with several hydrophilic hydroxyl groups. Thus, hydrophilic polymers were easily dissolved in water (Zuo et al., 2019). The hydrophilicity of biodegradable film can be determined using contact angle analysis. The contact angle in NL and NM biodegradable film was <90°, which is hydrophilic (Figure 7). In this study, the ultrasonication and acetylation decreased the hydrophilicity of the native rice flour biodegradable film.

Figure 7 Contact angle of native and modified rice flour biofilm

After ultrasonication and acetylation, the contact angle was 1.3 times higher than native rice flour biodegradable film. Moreover, after those modifications, the contact angle was higher than 90° and resulted in the hydrophobic film. The ultrasonication and acetylation converted the hydrophilic hydroxyl groups into hydrophobic ester groups (Chi et al., 2008). Furthermore, compared to the level of amylose, the modified low-amylose rice flour biodegradable film had the highest contact angle value and was the most hydrophobic biodegradable film. In the modified low-amylose rice flour biodegradable film, the acetylation reaction was more effective because of a higher surface reaction. The ultrasonication forms new starch granule pores that enhance the reaction efficiency (Zhu, 2015; Zuo et al., 2012).

3.6. Comparison with other rice flour or starch-based biodegradable film production

The biodegradable film obtained from this study has recently been characterized. The modified low amylose rice flour biodegradable film (LU15A) resulted in the biodegradable film with higher tensile strength and elongation at break than that of the other biodegradable films preparation such as by a combination of rice starch and corn starch (Marichelvam, Jawaid, Asim, 2019) and heat moisture treatment of rice flour (Majzoobi et al., 2015). The combination of ultrasonication and acetylation performed in this study can enhance the mechanical properties of the biodegradable film.

The medium and low amylose rice flour

biodegradable film was produced in this study. The ultrasonication and

acetylation decreased the biodegradable film’s tensile strength. However, it

improved the mechanical properties of biodegradable films, such as higher

elongation at break and higher contact angle value. The higher elongation at

break was also proven by XRD analysis. The increasing value of the contact

angle indicated that the hydrophobicity of the modified biodegradable film

increased, which was revealed by the acetyl peak. The low-amylose rice flour

had better mechanical properties due to the efficiency of the acetylation

reaction. The effect of ultrasonication was dominant in enhancing the

acetylation reaction by forming new pores and a larger surface area. Thus, the combined

ultrasonication and acetylation process on native rice flour resulted in a

mechanically improved biodegradable film for packaging materials and coatings.

This research was funded by Diponegoro University, grant number 521-05/UN7.6.1/PP/2022.

Ackar, D., Babic, J., Jozinovic, A., Milicevic, B., Jokic, S., Milicevic, R., Rajic, M., Šubaric, D, 2015. Starch Modification by Organic Acids and Their Derivatives: A Review.

Molecules, Volume 20(10), pp. 19554–19570

Alcázar-alay, S.C., Angela, M., Meireles,

A., 2015. Physicochemical Properties, Modifications and Applications of

Starches From Different Botanical Sources. Food Science and Technology,

Volume 35(2), pp. 215–236

Chi, H., Xu, K., Wu, X., Chen, Q., Xue,

D., Song, C., Zhang, W., Wang, P., 2008. Effect of Acetylation on The

Properties of Corn Starch. Food Chemistry, Volume 106(3), pp. 923–928

Chinaglia, S., Tosin, M., & Degli-Innocenti, F. 2018. Biodegradation

Rate of Biodegradable Plastics at Molecular Level. Polymer Degradation and

Stability, Volume 147, pp. 237–244

Colussi, R., El Halal, S. L. M., Pinto,

V. Z., Bartz, J., Gutkoski, L. C., Zavareze, E. da R., Dias, A. R. G. 2015.

Acetylation of Rice Starch in an Aqueous Medium for use in Food. LWT - Food

Science and Technology, Volume 62(2), pp. 1076–1082

Cuevas, R.P., Gilbert, R.G., Fitzgerald,

M.A., 2010. Structural Differences Between Hot-Water-Soluble and

Hot-Water-Insoluble Fractions of Starch in Waxy Rice (Oryza Sativa L.). Carbohydrate

Polymers, Volume 81(3), pp. 524–532

Dome, K., Podgorbunskikh, E., Bychkov,

A., Lomovsky, O., 2020. Changes in the Crystallinity Degree of Starch Having

Different Types of Crystal Structure After Mechanical Pretreatment. Polymers,

Volume 12(3), pp. 1–12

Ebnesajjad, S., 2000. Processing of

Polychlorotrifluoroethylene. In Non-Melt Processible Fluoroplastics.

Elsevier, pp. 199–204

Haider, T.P., Völker, C., Kramm, J., Landfester, K., Wurm,

F.R. 2019. Plastics of the Future? The Impact of Biodegradable Polymers on the

Environment and on Society. Angewandte Chemie - International Edition,

Volume 58(1), pp. 50–62

Halal, S.L.M.El, Colussi, R., Pinto,

V.Z., Bartz, J., Radunz, M., Carreño, N.L.V., Dias, A.R.G., Zavareze, E.D.R.,

2015. Structure, Morphology and Functionality of Acetylated and Oxidised Barley

Starches. Food Chemistry, Volume 168, pp. 247–256

Hasan, M., Gopakumar, D.A., Olaiya, N.G., Zarlaida, F.,

Alfian, A., Aprinasari, C., Alfatah, T., Rizal, S., Khalil, H.P.S.A. 2020.

Evaluation of the Thermomechanical Properties and Biodegradation of Brown Rice

Starch-Based Chitosan Biodegradable Composite Films. International Journal

of Biological Macromolecules, Volume 156, pp. 896–905

Imani, N.A.C., Kusumastuti, Y., Petrus,

H.T.B.M., Timotius, D., Putri, N.R.E., Kobayashi, M. 2022. Preparation,

Characterization, and Release Study of Nanosilica/Chitosan Composite Films. International

Journal of Technology, Volume 13(2), pp. 444–453

Jiang, T., Duan, Q., Zhu, J., Liu, H., Yu, L. 2020.

Starch-based Biodegradable Materials: Challenges And Opportunities. Advanced

Industrial and Engineering Polymer Research, Volume 3(1), pp. 8–18

Jin, Q., Tan, P., Schofield, A.B., Xu,

L., 2013. Eliminating Cracking During Drying. European Physical Journal E,

Volume 36(3), pp. 1–5

Judawisastra, H., Sitohang, R.D.R.,

Taufiq, D.I., Mardiyati, M., 2018. The Fabrication of Yam Bean (Pachyrizous

Erosus) Starch Based Bioplastics. International Journal of Technology,

Volume 9(2), pp. 345–352

Kumoro, A.C., Amalia, R., 2015. Mass

Transfer and Chemical Reaction Approach of the Kinetics of the Acetylation of

Gadung Flour Using Glacial Acetic Acid. Bulletin of Chemical Reaction

Engineering Catalysis, Volume 10(1), pp. 30–37

Liu, C., Yan, H., Liu, S., Chang, X. 2022. Influence of

Phosphorylation and Acetylation on Structural, Physicochemical and Functional

Properties of Chestnut Starch. Polymers, Volume 14(1)

Luo, X., Cheng, B., Zhang, W., Shu, Z., Wang, P., Zeng, X.

2021. Structural And Functional Characteristics of Japonica Rice Starches with

Different Amylose Contents. CyTA - Journal of Food, Volume 19(1), pp. 532–540

Majzoobi, M., Pesaran, Y., Mesbahi, G.,

Golmakani, M.T., Farahnaky, A., 2015. Physical Properties of Biodegradable

Films from Heat-Moisture-Treated Rice Flour and Rice Starch. Starch/Staerke,

Volume 67(11–12), pp. 1053–1060

Marichelvam, M.K., Jawaid, M., Asim, M.,

2019. Corn and Rice Starch-Based Bio-Plastics As Alternative Packaging

Materials. Fibers, Volume 7(4), pp. 1–14

Muscat, D., Adhikari, B., Adhikari, R.,

Chaudhary, D.S., 2012. Comparative Study of Film Forming Behaviour of Low and

High Amylose Starches Using Glycerol and Xylitol as Plasticizers. Journal of

Food Engineering, Volume 109(2), pp. 189–201

Pelissari, F.M., Andrade-Mahecha, M.M.,

Sobral, P.J.d.A., Menegalli, F.C., 2013. Comparative Study on The Properties of

Flour and Starch Films of Plantain Bananas (Musa Paradisiaca). Food

Hydrocolloids, Volume 30(2), pp. 681–690

Prasetyaningrum, A., Utomo, D.P.,

Raemas, A.F.A., Kusworo, T.D., Jos, B., Djaeni, M., 2021.

Alginate/?-Carrageenan-Based Edible Films Incorporated with Clove Essential

Oil: Physico-Chemical Characterization and Antioxidant-Antimicrobial Activity. Polymers,

Volume 13(3), pp. 1–16

Schmidt, V.C.R., Blanco-Pascual, N.,

Tribuzi, G., Laurindo, J.B., 2019. Effect of the Degree of Acetylation,

Plasticizer Concentration and Relative Humidity on Cassava Starch Films

Properties. Food Science and Technology, Volume 39(2), pp. 491–499

Tanjung, D.A., Jamarun, N., Arief, S.,

Aziz, H., Isfa, B., Ritonga, A.H., Sisca, V., 2023. Effects of LLDPE on

Mechanical Properties, Degradation Performance, and Water Absorption of

Thermoplastic Sago Starch Blends. International Journal of Technology,

Volume 14(1), pp. 173–184

Tao, K., Li, C., Yu, W., Gilbert, R. G., Li, E. 2019. How Amylose

Molecular Fine Structure of Rice Starch Affects Functional Properties. Carbohydrate

Polymers, Volume 204, pp. 24–31.

Wang, J.H., Shi, B., 2013. Converting

Polysaccharides into High-Value Thermoplastic Materials. ACS Symposium Series,

Volume 1144, pp. 407–421

Wellenreuther, C., Wolf, A., Zander, N.,

2022. Cost Competitiveness of Sustainable Bioplastic Feedstocks – A Monte Carlo

Analysis for Polylactic Acid. Cleaner Engineering and Technology, Volume

6, p. 100411

Wojeicchowski, J.P., de Siqueira, G.L.

de A., Lacerda, L.G., Schnitzler, E., Demiate, I.M., 2018. Physicochemical,

Structural and Thermal Properties of Oxidized, Acetylated and Dual-Modified

Common Bean (Phaseolus Vulgaris L.) Starch. Food Science and Technology,

Volume 38(2), pp. 318–327

Xu, J., Sagnelli, D., Faisal, M.,

Perzon, A., Taresco, V., Mais, M., Giosafatto, C. V. L., Hebelstrup, K.H.,

Ulvskov, P., Jørgensen, B., Chen, L., Howdle, S.M., Blennow, A., 2021.

Amylose/Cellulose Nanofiber Composites for All-Natural, Fully Biodegradable and

Flexible Bioplastics. Carbohydrate Polymers, Volume 253(20), p. 117277

Yang, S., Xie, Q., Liu, X., Wu, M., Wang, S., Song, X., 2018.

Acetylation Improves Thermal Stability and Transmittance In FOLED Substrates

Based on Nanocellulose Films. RSC Advances, Volume 8(7),pp. 3619–3625

Zhang, L., Zuo, B., Wu, P., Wang, Y.,

Gao, W., 2012. Ultrasound Effects on The Acetylation of Dioscorea Starch

Isolated from Dioscorea Zingiberensis C.H. Wright. Chemical Engineering and

Processing: Process Intensification, Volume 54, pp. 29–36

Zhu, F., 2015. Impact of Ultrasound on

Structure, Physicochemical Properties, Modifications, and Applications of

Starch. Trends in Food Science and Technology, Volume 43(1), pp. 1–17

Zia-ud-Din, Xiong, H., Fei, P., 2017.

Physical and Chemical Modification of Starches: a Review. Critical Reviews

in Food Science and Nutrition, Volume 57(12), pp. 2691–2705

Zuo, Y., He, X., Li, P., Li, W., Wu, Y.,

2019. Preparation and Characterization of Hydrophobically Grafted Starches by

in Situ Solid Phase Polymerization. Polymers, Volume 11(1), p. 72

Zuo, Y.Y.J., Hébraud, P., Hemar, Y.,

Ashokkumar, M., 2012. Quantification of High-Power Ultrasound Induced Damage on

Potato Starch Granules Using Light Microscopy. Ultrasonics Sonochemistry,

Volume 19(3), pp. 421–426