Uninterrupted Electricity Supply using Off-Grid Solar PV Systems for Remote Areas

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.6089

Ajiwiguna, T.A., Kirom, M.R., 2024. Uninterrupted Electricity Supply using Off-Grid Solar PV Systems for Remote Areas. International Journal of Technology. Volume 15(5), pp. 1561-1572

| Tri Ayodha Ajiwiguna | 1. Engineering Physics Study Program, Telkom University, Jalan Telekomunikasi, Bandung, 40527, Indonesia. 2. Center of Excellence of Sustainable Energy and Climate Change, Telkom University, Jalan Tel |

| Mukhammad Ramdlan Kirom | Engineering Physics Study Program, Telkom University, Jalan Telekomunikasi, Bandung, 40527, Indonesia |

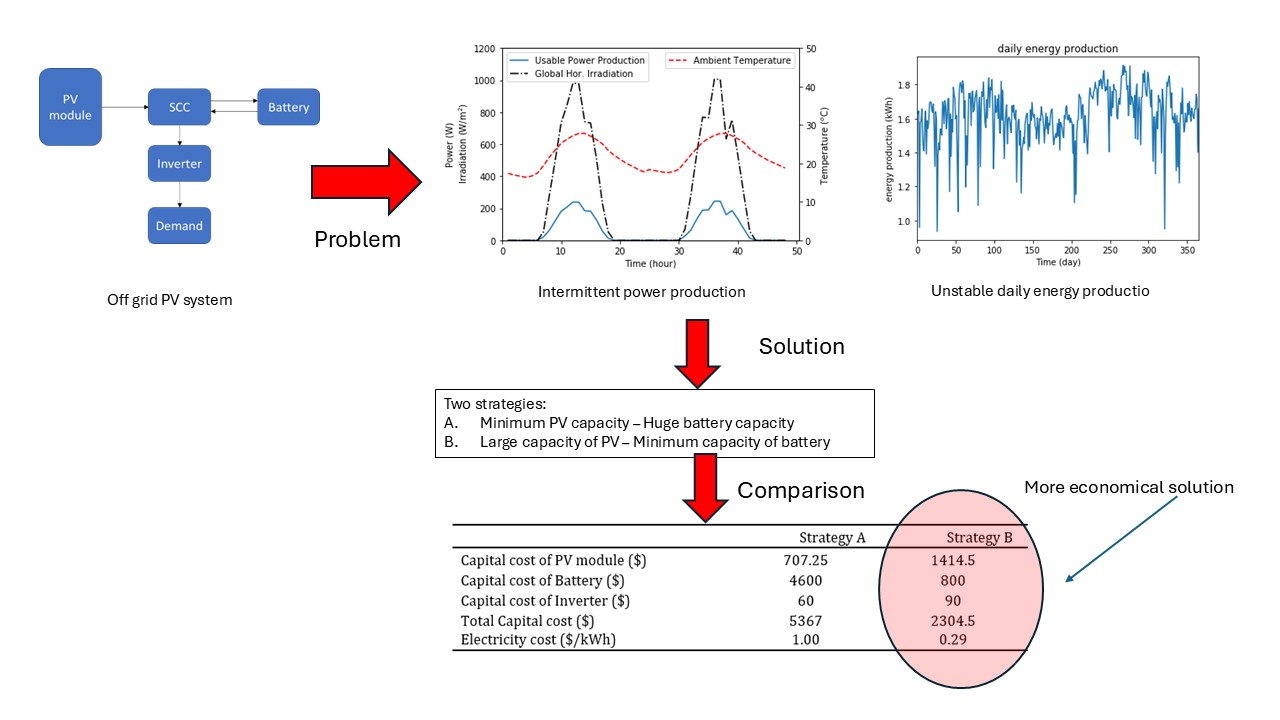

Due to the intermittent electricity production, the

battery takes an important role in the off-grid PV systems by storing excess

electricity production. The stored electricity is then used when the PV system

generates less electricity than what is demanded. However, the current price

and lifetime of the battery make the electricity cost of the off-grid PV system

expensive. Therefore, the capacity of components must be designed to fulfill

the demand at the lowest electricity cost. In this study, two strategies in the

design of off-grid PV systems to fulfill the same demand are compared. The

first strategy is to employ the PV module with proper capacity, which means the

annual energy production equals the annual energy demand, but it needs a huge

capacity battery to store the accumulation of the excess energy. The second

strategy is to use the large capacity of the PV module, which considers the

lowest energy production day, but it requires the small capacity of the

battery. The results show that the electricity cost of the second strategy is

only 29.0 % of the first strategy. However, it dumps 50.1 % of the annual

produced electricity.

Electricity cost; Off-grid system; Sizing strategy; Solar photovoltaic

1. Introduction

The economic analysis of the off-grid PV system for the

remote area has been presented by various studies (Cuesta, Castillo-Calzadilla,

and Borges, 2020; Jamshidi and Askarzadeh, 2019; Mandal, Das, and Hoque, 2018).

Taufiqurrohman designed and evaluated the off-grid PV system to fulfill the

electricity demand at 1.61 kWh/d for small houses in Indonesia (Taufiqurrohman, 2018). The resulting electricity cost

was 0.30 $/kWh. Awapone presented the feasibility of the off-grid system

consisting of PV, battery, and diesel generators in Ghana (Awopone, 2021). The system was designed for 80

houses with an electricity demand of 224.06 kWh/d. The electricity cost

resulted at 0.4 $/kWh. Sinaga et al., (2019) presented

the off-grid PV system in the area of Kupang, Indonesia

This study presents a novel strategy to minimize the capacity of the battery without interrupting the electricity supply simultaneously. The proposed strategy is to consider the lowest energy production day to determine the PV capacity. By using this strategy, the battery capacity can be minimized to only one autonomous day because the daily electric energy production is always equal to or higher than the daily electric energy demand. However, it also implies that dumping energy is not avoidable. The electricity cost is then estimated as the final parameter of system performance. The proposed design system is also compared technically and economically with the design without dumping energy that was presented by (Ajiwiguna et al. 2022).

2. System

and Case Study Description

The

schematic diagram of an off-grid PV system is shown in Figure 1 (Awasthi et al., 2020; Ghafoor and Munir, 2015).

PV module converts solar irradiation into direct current (DC) electricity.

Solar charge controller (SCC) manages the electricity by sending it to the

demand, storing it in the battery, or both. If the electricity produced by the

PV system is higher than the demand, the excess energy is stored in the battery

(the battery is charged). If the electricity produced by the PV system is lower

than the demand, the deficit energy is supplied from energy stored in the

battery (the battery is discharged). The specification of the PV module and

battery used in this study is shown in Table 1 and Table 2, respectively.

Although the lifetime of PV modules was 25 years, the

off-grid PV system was designed only for 20 years, considering the lifetime of

other components, especially the battery. The lifetime of the components must

be considered because if it is shorter than the system lifetime, the

replacement cost is required. Operational and maintenance cost is mostly for

the PV module for cleaning and checking the connection. For battery, its

O&M cost is negligible since the battery used in this study is

maintenance-free.

Figure 1 Configuration

of off-grid PV system

Table 1

Specifications of the PV module

|

Maximum Power (STC), PSTC |

375 W |

|

Open Circuit Voltage, VOC |

47.6 V |

|

Short Circuit Current, ISC |

9.93 A |

|

Nominal Operating Cell Temperature, NOCT |

41 ± 3oC |

|

Temperature coefficient of power, |

-0.37%3oC |

|

Lifetime |

25 years |

Table 2 Specification of battery per unit

|

Capacity |

1.2 kWh (100 Ah) |

|

Voltage |

12 V |

|

Battery efficiency |

85% |

|

Depth of discharge |

80 % |

|

Lifetime |

7 years |

The

case study was conducted in Cisoka Village, Indonesia, which was selected due

to its potential in the tourism industry, but with limited access to

electricity. The solar PV system was designed to cater to small residential

buildings, with a daily electricity consumption assumption as presented in

Table 3. The total daily energy consumption of 3.23 kWh is reasonable, as it

falls within the range of energy consumption reported by Palaloi for small

buildings in Indonesia (Palaloi, 2014). The

required capacity of system components was estimated based on Typical

Meteorological Year (TMY) weather data obtained from the Repository of Free

Climate Data in 2019.

Table 3 Appliances and estimation of daily energy consumption

|

No |

Appliance |

Quantity |

Effective operation hour (h/d) |

Wattage (W) |

Energy consumption (kWh) |

|

1 |

Lamp 1 (outdoor) |

3 |

12 |

18 |

0.65 |

|

2 |

Lamp 2 (indoor) |

5 |

10 |

12 |

0.60 |

|

3 |

Refrigerator |

1 |

8 |

110 |

0.88 |

|

4 |

Rice cooker |

1 |

2 |

300 |

0.60 |

|

5 |

Pump |

1 |

2 |

100 |

0.20 |

|

6 |

Washing Machine |

1 |

1 |

300 |

0.31 |

|

|

Total daily energy consumption |

|

|

|

3.23 |

where

where is battery

efficiency, and L is the overall losses of the system. By using the procedure

above, the hourly data for a year are obtained because the weather data used in

this study is also hourly data.

In

this study, the comparison of two different design strategies to fulfill the

same electricity demand was conducted. The strategies

presented in this study aim to supply electricity to the demand without

interruption while the weather and season are not constant. To obtain this

purpose, two different strategies can be applied. The first strategy is to

minimize the PV capacity thus, the annual electricity production is as same as

the annual electricity demand. This option needs the huge capacity battery to

store the excess electricity production on the consecutive sunny days and to

use it on cloudy or rainy days. The second strategy, our proposed strategy,

is to use the worst weather day of electricity production as the basis for

determining the capacity of the PV system. By using this option, the PV

capacity must be huge because it must produce the electricity as much as demand

on the worst production day. However, the battery capacity can

be reduced to only one day's worth of autonomy, as the system does not need to

store excess electricity production for consecutive days. This allows the

system to efficiently supply electricity to meet demand without encountering

any problems on the following day. The differences between the two design

strategies are summarized in Table 4.

In the first

strategy (Strategy A), the PV module capacity was determined so that the annual

electrical energy production was as same as the annual demand. The flow chart

for determining the PV capacity is shown in Figure 2. Since the weather is not

constant, the battery capacity was determined by considering the accumulation

of storing excess electricity production. Generally, Indonesia has two seasons:

Dry and Rainy. In the dry season, solar irradiation is very high; thus, the

electricity production from the PV system is also high. Most of the excess

electricity production is in this period. To accommodate the accumulation of

stored energy from consecutive days, a huge capacity battery is needed. The methods used to calculate the

capacity of PV modules and batteries were based on the study presented by Ajiwiguna et al.

(2022).

Table 4

Design characteristics of the two strategies

|

|

Strategy

A |

Strategy

B |

|

PV

module capacity |

Determined

by calculating the annual electrical energy production as same as athe nnual

demand |

Determined

by using the worst daily weather in a year to produce electrical energy |

|

Battery

capacity |

Considering

the accumulation of energy storage and/or energy deficit in a year |

One

autonomous day |

|

Dumping

energy |

No

(or minimum) |

Yes |

Figure 2 Flowchart to determine the capacity of PV module for strategy A

where is daily energy produced by a PV system using

a single module, and

is a time interval of data. Next, the minimum

daily energy production,

is chosen

as the basis for determining the capacity of the PV module. The required number

of PV modules was calculated by using Equation (5).

where is daily energy demand. Then the PV capacity

for strategy B is calculated by using Equation (6).

By using

that capacity, the electricity demand on the other days was fulfilled because

the weathers were better than that worst day. Since the daily energy production

was always equal to or higher than daily demand, the battery didn’t need to

store the excess energy for consecutive days. It also meant the required

capacity of the battery was only one autonomous day. However, dumping energy in

this strategy was unavoidable. One of the functions of a solar charge

controller is to stop the charging process when the battery is already full.

Therefore, the overcharging of the battery can be avoided.

3.2. Electricity cost estimation method

Electricity

cost was calculated as the ultimate parameter for comparison between the two

strategies. It considered capital cost, operational and maintenance cost, and

replacement cost. The total capital cost PV module

capital cost

Inverter capital cost

Solar charge controller capital cost

and battery capital cost were calculated

by using Equations (7) to (11).

where are the total price of the PV module,

inverter, solar charge controller, and battery, respectively. For the PV

module, it considered 15% of the installation cost (Mohamed

and Papadakis, 2004). This installation cost is

included in the installation of other components. Therefore, the other

components' capital costs were only the total price of components.

Annual

operational and maintenance cost (OnM) was assumed to be (Fu, Feldman, and

Margolis, 2018). Since the PV system was designed

for 20 years of operation, the replacement cost must be considered for the

components, which have a lifetime of less than 20 years. The components

replacement cost is the frequency of replacement multiplied by the component

capital cost. In this case, the battery was replaced two times since its

lifetime was only 7 years. Operational and maintenance cost and total

replacement cost

was

calculated by using Equations (12) and (13).

where is the total capacity of PV modules,

is the replacement cost of the inverter,

is the replacement of the solar charge

controller, and

is the replacement of the battery.

The

annualized capital and replacement cost, called annual fixed charge (AFC),

was then calculated by considering the amortization factor This factor

considers the inflation rate and lifetime of the PV system. Equations (10) and

(11) were used to calculate the amortization factor and annual fixed charge,

respectively. In these equations, i is the inflation rate, and n

is the lifetime of the PV system.

The electricity cost was then calculated by using Equation (12):

where is annual electricity demand.

Table 5 shows the assumptions of the prices of each component. The price information was obtained by surveying the market, and their reasonability was checked by comparing it with the report from NREL (Cole and Frazier, 2019; Fu, Feldman, and Margolis, 2018). The specific price is needed to check the reasonability of the price used in this study because most of the statistical report shows specific prices.

Table 5 Price list of main components

|

No |

Component |

Capacity/unit |

Price

($) |

specific

price |

|

1 |

PV

module |

375

W |

307.5

$ |

0.82

$/W |

|

2 |

Battery |

1.2

kWh |

200

$ |

166.67

$/kWh |

|

3 |

Inverter

|

500

W |

30

$ |

0.06

$/W |

|

No |

Parameter |

Strategy A |

Strategy B |

|

1 |

PV module Capacity |

0.75 kW |

1.5 kW |

|

2 |

Battery capacity |

27.2 kWh |

4.0 kWh |

|

3 |

Annual energy demand |

1180 kWh |

1180 kWh |

|

4 |

Annual energy production |

1181.8 kWh |

2363.8 kWh |

|

5 |

Annual dumped energy |

1.8 kWh |

1183.7 kWh |

Strategy A required 0.75 kW of PV module capacity and 26.8 kWh of

battery capacity. The PV module capacity was determined by estimating the

annual energy production so that it was as same as the annual energy demand.

Therefore, the mismatch between daily energy production and demand was

unavoidable. This strategy required a huge capacity of battery to accommodate

the accumulation of excess energy production in the dry season and deficit

energy production in the rainy season. Without considering the recommended DoD,

the required capacity of the battery is 6.6 autonomous days. It meant that the

battery was enough to supply electricity to the demand for 6.6 days without

interruption, even if the production from the PV system was zero. The dumped

energy was very low, which is 1.8 kWh, because almost all the excess daily

energy production is stored in the battery. The PV capacity of the PV module is

slightly oversized because the number of PV modules must be an integer.

In strategy B, the PV module and battery capacities were 1.5 kW and 4.0

kWh, respectively. The PV capacity is determined by choosing the lowest energy

production day as the basis calculation. Therefore, it required a relatively

huge capacity of PV modules. By using this strategy, the daily energy

production was always equal to or higher than the energy demand. This strategy

allowed the system not to store the accumulation of consecutive excess daily

energy production. It implied that the required battery capacity could be

minimized to only one autonomous day. However, dumping energy was not

unavoidable due to the limitation of battery capacity. The annual dumped energy

was 50.1 % of annual energy production. It was reasonable since the energy must

be dumped almost every day (except the lowest energy production day).

Those two strategies discussed above were the only options if the demand

must be fulfilled without interruption for a whole year. Reducing the capacity

of the PV module or battery caused energy shortage conditions for some hours.

From the energy point of view, strategy A is the most optimum strategy because,

theoretically, the dumped energy can be avoided. In other words, all the energy

produced by the PV module is used to supply energy demand.

Table 7

shows the economic comparison between the two strategies. The capital costs of

the components were proportional to their capacity. It is worth noting that the

capital cost is the initial cost for the system to work properly during the

first operation. Therefore, the replacement cost is not included in the capital

cost. It also meant that the capital cost of the battery was only for the first

seven years of operation. For the whole designed operation time (20 years), the

battery must be replaced twice. The replacement costs were considered for

calculating the electricity cost as expressed in Eq. 16. The most expensive

capital cost for strategy A was for the battery, which takes 80.9 % of the

total capital cost. Contrarily, 67.2 % of the total capital cost was for the PV

module in strategy B which made it the highest capital cost of the component.

The total capital cost of strategy B was only 52.5% of the total capital cost

of strategy A. In the case of the electricity cost, strategy B also resulted in

much lower costs which only 29 % of the cost resulting from strategy A. Based

on this economic analysis, it implies that strategy B was more feasible than

Strategy A to fulfill the same electricity demand.

Table 7 Economic aspect comparison

|

|

Strategy A |

Strategy B |

|

Capital

cost of PV module ($) |

707.25 |

1414.5 |

|

Capital

cost of Battery ($) |

4600 |

800 |

|

Capital

cost of Inverter ($) |

60 |

90 |

|

Total

Capital cost ($) |

5367 |

2304.5 |

|

Electricity

cost ($/kWh) |

1.00 |

0.29 |

The

problem of off-grid PV system are the expensiveness of battery and the

interruption electricity supply. To overcome those two problems, certain design

strategy is needed. In this study, two different strategies for designing the

off-grid PV system to fulfill the same demand were compared. The first strategy

uses the optimum number of the PV system, so the dumped energy can be

minimized. However, it needs a large capacity battery to accommodate the

difference between electricity production and demand. The second strategy uses

a minimum capacity of the battery. The capacity of the PV module is determined

by considering the lowest energy production day. Therefore, this strategy dumps

a lot of energy produced by the PV system. Strategy B uses a larger capacity PV

system but a smaller capacity battery than Strategy A. Even though the capacity

of the PV system is larger, strategy B is more feasible than strategy A since

the total capital cost and electricity cost are only 42.9 % and 29.0 % of

strategy B, respectively. However, strategy B dumped 50.2% of the energy

produced by the PV system because the capacity of the battery is small. In the

future, the design concept for harnessing the dumped energy should be

investigated thus the system may have additional economic value.

Agarwal, N., Kumar, A., Varun, 2013. Optimization of Grid

Independent Hybrid PV–Diesel–Battery System for Power Generation in Remote

Villages Of Uttar Pradesh, India, Energy for Sustainable Development,

Volume 17(3), pp. 210–219

Ajiwiguna, T.A., Lee, G., Lim, B., Choi, S., Park, C.,

2022. Design Strategy and Economic Analysis on Various Configurations of

Stand-Alone PV-RO Systems. Desalination, Volume 526, p. 115547

Albadi, M.H., 2019. Solar PV Power Intermittency and Its

Impacts on Power Systems – An Overview. The Journal of Engineering Research (TJER), Volume 16(2), pp. 142–150

Aneke, M., Wang, M., 2016. Energy Storage Technologies

and Real Life Applications–A State of the Art Review. Appl Energy, Volume

179, pp. 350–377

Awasthi, A., Kumar, S.A., Manohar, M.S.R., Dondariya, C.,

Shukla, K.N., Porwal, D., Geetam, R. G., 2020. Review on Sun Tracking

Technology in Solar PV system. Energy Reports, Volume 6, pp. 392–405

Awopone, A.K., 2021. Feasibility Analysis of Off-Grid

Hybrid Energy System for Rural Electrification in Northern Ghana. Cogent

Engineering, Volume 8(1), p. 1981523

Benda, V, Cerná, L., 2020. PV Cells and Modules – State

of The Art, Limits and Trends. Heliyon, Volume 6(12), p. e05666

Benda, V., 2017. Photovoltaic Cells and Modules Towards

Terawatt Era. Journal of Electronic Science and Technology, Volume 15(4),

pp. 351–357

Bhayo, B.A., Al Kayiem H., Gilani S., Ismail F., 2020.

Power Management Optimization Of Hybrid Solar Photovoltaic- Battery Integrated

With Pumped-Hydro-Storage System For Standalone Electricity Generation. Energy

Convers Management, Volume 215, p. 112942

Blakers, A., 2019. Development of the PERC Solar Cell. IEEE

Journal of Photovoltaics, Volume 9(3), pp. 629–635

Branker, K., Pathak, M.J.M., Pearce, J.M., 2011. A Review

of Solar Photovoltaic Levelized Cost of Electricity. Renewable and

Sustainable Energy Reviews, Volume 15, pp. 4470–4482

Brazovskaia, V., Gutman, S., 2021. Classification of

Regions by Climatic Characteristics for the Use of Renewable Energy Sources.

International Journal of Technology, Volume 12(7), pp. 1537–1545

Cole, W., Frazier, A.W., 2019. Cost Projections for

Utility-Scale Battery Storage. Technical Report: Cost Projections for

Utility-Scale Battery Storage, National Renewable Energy Laboratory (NREL), US

Cuesta, M., Castillo-Calzadilla, T., Borges, C., 2020. A

Critical Analysis on Hybrid Renewable Energy Modeling Tools: An Emerging

Opportunity to Include Social Indicators to Optimise Systems in Small

Communities. Renewable and Sustainable Energy Reviews, Volume 122, p.

109691

Ekren, O., Ekren, B.Y., 2010. Size Optimization of a PV/Wind Hybrid Energy Conversion

System with Battery Storage Using Simulated Annealing. Applied Energy, Volume

87(2), pp. 592–598

El-Hadad, R., Tan, Y.-F, Tan, W.-N, 2022. Anomaly

Prediction in Electricity Consumption Using a Combination of Machine Learning

Techniques. International Journal of Technology, Volume 13(6), pp.

1317–1325

Fu, R., Feldman, D., Margolis, R., 2018. U.S. Solar

Photovoltaic System Cost Benchmark: Q1 2018. Technical Report National

Renewable Energy Laboratory (NREL), US

Ghafoor, A., Munir, A., 2015. Design and Economics

Analysis of an Off Grid PV System for Household Electrification. Renewable

and Sustainable Energy Reviews, Volume 42, pp. 496–502

Gowrisankaran, G., Reynolds, S.S.,

Samano, M., 2011. Intermittency and the Value of

Renewable Energy. Journal of Political Economy, Volume 124(4), pp.

1187–1234

Hove, T., Tazvinga, H., 2012. A Techno-Economic Model for

Optimising Component Sizing And Energy Dispatch Strategy for PV-Diesel-Battery

Hybrid Power Systems. Journal of Energy in Southern Africa, Volume 23(4), pp. 18–28

Jager-Waldau, A., 2020. Snapshot of

photovoltaics—February 2020, Energies, Volume 13(4), p. 930

Jamshidi, M., Askarzadeh, A., 2019. Techno-Economic

Analysis and Size Optimization of An Off-Grid Hybrid Photovoltaic, Fuel Cell

and Diesel Generator System. Sustainable Cities and Society, Volume 44,

pp. 310–320

Ma, T., Javed, M.S., 2019. Integrated Sizing of Hybrid

PV-Wind-Battery System for Remote Island Considering the Saturation of Each

Renewable Energy Resource. Energy Convers Manage, Volume 182, pp.

178–190

Maleki, A., Askarzadeh, A., 2014. Optimal Sizing of a

PV/Wind/Diesel System with Battery Storage for Electrification to an Off-Grid

Remote Region: A Case Study of Rafsanjan, Iran. Sustainable Energy

Technologies and Assessments, Volume 7, pp. 147–153

Malik, K., Rahman, S.M., Khondaker, A.N., Abubakar, I.R.,

Aina, Y.A., Hasan, M.A., 2019. Renewable Energy Utilization to Promote

Sustainability in GCC Countries: Policies, Drivers, and Barriers. Environmental

Science and Pollution Research, Volume 26, pp. 20798–20814

Mandal, S., Das, B.K., Hoque, N., 2018. Optimum Sizing of

A Stand-Alone Hybrid Energy System For Rural Electrification In Bangladesh. Journal

of Cleaner Production, Volume 200, pp. 12–27

Merei, G., Berger, C., Sauer, D.U., 2013. Optimization of

an off-Grid Hybrid PV–Wind– Diesel System with Different Battery Technologies

Using Genetic Algorithm. Solar Energy, Volume 97, pp. 460–473

Mohamed, E.S., Papadakis, G., 2004. Design, Simulation

and Economic Analysis of a Stand-Alone Reverse Osmosis Desalination Unit

Powered by Wind Turbines and Photovoltaics. Desalination, Volume 164(1),

pp. 87–97

Palaloi, S., 2014. Analisis Pengunaan Energi Listrik Pada

Pelanggan Rumah Tangga Kapasitas Kontrak Daya 450 VA (Analysis of Energy

Consumption on Residential Building with Power Contract 450 AV). In: Prosiding

Seminar Nasional Aplikasi Sains & Teknologi (SNAST), pp. 211–216

Poddar, S., Kay, M., Prasad, A.,

Evans, J.P., Bremner, S., 2023. Changes in Solar Resource Intermittency and

Reliability Under Australia’s Future Warmer Climate. Solar Energy,

Volume 266, p. 112039

Qadir, S.A., Tahir, F., Al-Fagih, L., 2020. Impact of

Fossil Fuel Subsidies on Renew- Able Energy Sector. In: 12th

International Exergy, Energy and Environment Symposium. IEEES-12. Doha, Qatar.

Riffonneau, Y., Bacha, S., Barruel, F., Ploix, S., 2011.

Optimal Power Flow Management for Grid Connected PV Systems with Batteries. IEEE

Transactions on Sustainable Energy, Volume 2(3), pp. 309–320

Saroji, G., Berawi, M.A., Sari, M., Madyaningarum, N.,

Socaningrum, J.F., Susantono, B., Woodhead, R., 2022. Optimizing the

Development of Power Generation to Increase the Utilization of Renewable Energy

Sources. International Journal of Technology, Volume 13(7), pp.

1422–1431

Sen, R., Bhattacharyya, S.C., 2014. Off-Grid Electricity

Generation with Renewable Energy Technologies in India: An Application of

HOMER. Renew. Energy, Volume 62, pp. 388– 398

Sinaga, R., Tuati, N.F., Beily, M.D.E., Sampeallo, A.S.,

2019. Modeling and Analysis of The Solar Photovoltaic Levelized Cost of

Electricity (LCoE)-Case Study in Kupang. Journal of Physics: Conference

Series, Volume 1364(1), p. 012066

Taufiqurrohman, I., 2018. The Assessment of Off-Grid

Photovoltaic (PV) Systems for Rural Electrification in Indonesia. In: 3rd

International Conference of Integrated Intellectual Community (ICONIC), Volume

2018, p. 3201095