Influence of Temperature on the Thermal Properties of the Core Material - the Coefficient of Temperature Conductivity, Specific Heat Capacity, Thermal Conductivity

Corresponding email: os_kharitonova@mail.ru

Published at : 04 Apr 2023

Volume : IJtech

Vol 14, No 2 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i2.6009

Burlutsky, E., Balzamov, D., Bronskaya, V., Kharitonova, O., Khairullina, L., Solovyeva, O., 2023. Influence of Temperature on the Thermal Properties of the Core Material - the Coefficient of Temperature Conductivity, Specific Heat Capacity, and Thermal Conductivity. International Journal of Technology. Volume 14(2), pp. 443-454

| Efim Burlutsky | 1. Kazan State Power Engineering University, 51 Krasnoselskaya St., Kazan 420066, Russia, 2. Almetyevsk State Oil Institute, 2 Lenina St., Almetyevsk, 423450, Russia |

| Denis Balzamov | Kazan State Power Engineering University, 51 Krasnoselskaya St., Kazan 420066, Russia |

| Veronika Bronskaya | 1. Kazan National Research Technological University, 68 Karl Marx St., Kazan 420015, Russia, 2. Kazan Federal University, 18 Kremlyovskaya St., Kazan, 420008, Russia |

| Olga Kharitonova | Kazan National Research Technological University, 68 Karl Marx St., Kazan 420015, Russia |

| Liliya Khairullina | Kazan Federal University, 18 Kremlyovskaya St., Kazan, 420008, Russia |

| Olga Solovyeva | Kazan State Power Engineering University, 51 Krasnoselskaya St., Kazan 420066, Russia |

The absorption of heat by rocks is accompanied by an

increase in the kinetic energy of molecules and atoms and is recorded by a

change in rock temperature. The thermal properties of rocks characterize the

ability to transfer and absorb heat and change their size when the temperature

rises. The main thermal properties of rocks are thermal conductivity, heat

capacity, linear thermal expansion, and thermal volumetric expansion. In this

paper, the influence of temperature effects on the thermal properties of reservoirs

– the coefficient of temperature conductivity, specific heat capacity, and

thermal conductivity is studied using the samples of oil-saturated reservoirs

from the good number 19Bp of the Upper Uplift of Sotnikovsky deposit. The

dependence of the thermal properties of the core material on temperature was

revealed using a number of laboratory experiments. The results of these studies

contribute to improving the reliability of data on the relationship of thermal

properties with other physical properties of oil-saturated reservoirs and can

be used to improve the efficiency of the development of fields of super-viscous

oil.

Core material; Core material temperature; Thermal conductivity; Thermal conductivity coefficient; Specific heat capacity

The degree of study of the thermal field of the Earth

and the Earth's crust is still low, and it is incomparable with the modern

results of studies of seismic, magnetic, gravitational and other physical

fields of our planet. This is largely due to the insufficient level of

development of thermal petrophysics (thermal physics of rocks) underlying the

study of natural and artificial thermal fields in the subsurface. To solve such

problems as modeling of sedimentary basins and oil and gas bearing systems,

search and exploration of hydrocarbon deposits, design of thermal methods of

production of high-viscosity oils, interpretation of results of thermometry in

wells, determination of heat flux density from the bowels, etc. requires reliable

database on thermal conductivity, thermal conductivity, the specific heat

capacity of rocks (Abed and Yakhlef,

2020; Adam, 2009).

The situation is complicated by the fact that rocks, as an object of

thermophysical research, have characteristic features, consideration of which

is necessary when creating methods and equipment for determining their thermal

properties. First, this is their essential heterogeneity, multiphase

(saturation of solid rock skeleton by various pore fluids, such as formation

water, gas, oil and their various combinations), dependence on thermodynamic

conditions of occurrence (rock, formation pressure, temperature).

It should be noted that a significant part of the core from shallow

deposits of extra-viscous oils is weakly consolidated and loose samples, which

requires a special research methodology (which, until recently, was practically

absent).

The variety of problems solved in mining thermal physics also determines

the difference in the methods used for experimental determination of the

thermal characteristics of rocks (Alas and

Ali, 2019).

The choice of methods is influenced by many factors, including the purpose

of the study, the range of changes in the thermal properties of rocks,

different degrees of consolidation (from unconsolidated sedimentary reservoirs

of ultra-viscous oils to hard low-porous rocks of the crystalline basement),

the degree of sample saturation, etc. The depth of sampling determines the

values of pressures at which it is necessary to study the rocks. The nature of

the thermal influence determines the temperature range of research (Balzamov et al., 2020b).

The depletion of easily recoverable oil reserves leads to the need to

involve in the development of increasingly complex facilities containing

hard-to-recover oil reserves (HTR reserves). At the moment, the trends are that

due to a decrease in the number of reserves, the lifting of traditional fossil

fuels will be supplemented by the development of unconventional sources of raw

materials (shale oil and gas, high-viscosity oils, bitumen, bituminous sand

oil, coal methane, gas hydrates, etc.).

The world reserves of natural bitumen are estimated at more than 800

billion tons. At the same time, Russia is one of the leaders in reserves, a

third of which is located on the territory of the Republic of Tatarstan.

The extraction of bituminous oil requires an unconventional, unique

approach. There are various ways to develop deposits of heavy oils and natural

bitumen, which differ in technological and economic characteristics.

The research aims to determine the temperature dependence of the specific heat capacity and thermal conductivity of weakly cemented, bituminous-saturated sandstone samples. Data on the thermophysical properties of rocks are a key parameter for numerical models of reservoir systems. In addition, they are needed to determine the rate of advance of the coolant front, assessment of thermal resources of deposits and design development systems.

The efficiency of the

lifting of SVO and natural bitumen using thermal methods largely depends on the

methodological base, based on laboratory studies to determine data on the

thermophysical properties of rocks (Ibragimova et

al., 2017; Ismagilova et al., 2016; Valeeva

et al., 2013). In addition, they are necessary for work

to determine the speed of advance of the heat transfer agent front, the

assessment of thermal resources of deposits and the design of development

systems. All of the above determines the relevance of the topic of this work.

The LFA 467 laser

burst device was used to determine the temperature conductivity. An infrared detector is used to measure

the temperature increase from the back of the sample as a function of time. The

measurement of temperature conductivity, specific heat capacity allows (with a

known or additionally measured volumetric density) to calculate the thermal

conductivity of the sample under study (Balzamov et al., 2020a; Petrov et al., 2019;

Ganeeva et al., 2014).

To determine the specific heat capacity of the

rock, a differential scanning calorimeter DS 204 HP was used in work. The essence of the method consists in measuring the heat of processes

and the specific heat capacity of substances through the heat flux - the

derivative of heat over time (differential). Heat flows are measured

simultaneously by the temperature difference at two points of the measuring

system (Balzamov et al., 2020c; Mirgorodskaya et al., 2018; Gabdrakhmanov et al.,

2015). The determination of

specific heat is carried out by a special program NETZSCH TA4_5.

The

results of this study will optimize the methods of lifting SVO. In this paper,

the influence of temperature on the thermal properties of the core material is

studied – the coefficient of temperature conductivity, specific heat capacity,

and thermal conductivity, the purpose of which is to analyze the influence of

temperature on the thermophysical properties of the core material. The

temperature conductivity is measured on the LFA-467 device, and the specific

heat capacity - on the DSC-204 HP device, the thermal conductivity is

determined by mathematical calculation. The dependence of the thermal

properties of the core material on temperature was revealed using a number of

laboratory experiments. The results of these studies can be used to improve the

efficiency of developing super-viscous oil fields.

The LFA

467 incorporates sophisticated equipment and simple software to provide fast,

accurate and safe measurements. The LFA 467 is based on the laser flash method

according to international standards ASTM E-1461, DIM EN 821 and DIN 30905.

An

infrared detector measures the temperature increase on the sample's backside as

a time function. The measurement of thermal diffusivity and specific heat

capacity allows (with known or additionally measured bulk density) to calculate

the thermal conductivity of the sample under study.

Mathematical

analysis of the measured temperature dependence on time allows us to determine

the thermal diffusivity ?. The analysis is performed by a special program using

a set of differential mathematical models for various applications.

Figure 1 Holder

for thermal conductivity measurements

When the

sample is loaded, the measuring cell LFA 467 is opened, and the samples (round

or square) are placed in the corresponding sample holder. The upper flap of the

furnace is put back in place with the extraction device, and the measuring cell

is closed.

Start the

measurement. Start the measurement by using the NETZSCH software. Determine the

basic settings for the measurement. Set the gas parameters. Set the holder to

be used. Mark the desired sample position in the left window (the sample will

be marked green) and define the parameters of the respective sample:

- Sample

properties

- Stain,

layer properties

-

Template for measurements

-

Thermophysical properties

Temperature

program. Select the start and end temperature of the measurement and determine

the temperature step value (in our work, this corresponds to 50°C).

Set the

required interval for analysis. The calculation interval should be

approximately 10-12 half-periods.

To

ensure correct estimation of the calculation interval, both curves (the

original signal curve and its smoothing) should be combined (Figure 2 see on

supplementary).

Figure 3 Scheme of measurements by DSC 204 HP

method

(F -

furnace (heater), S - sample, R - standard, TF, TmS, TmR - temperatures of

furnace and junction of differential thermocouple of sample and standard, FFS,

FFR - heat fluxes)

The

essence of the method consists in measuring the heat of processes and the

specific heat capacity of substances through the heat flow - the derivative of

heat over time (differential). Heat fluxes are measured by the temperature

difference in two points of the measuring system at one point in time.

Measurements are carried out both in isothermal conditions and in dynamic mode

with a programmable change in the shell's temperature (heater).

Figure 4 Dynamics of changes in the coefficient of specific heat capacity at a depth of 195.9 m

Figure 5 Dynamics of

changes in the coefficient of specific heat capacity at a depth of 196 m

Figure 6 Dynamics of changes in the coefficient of

specific heat capacity at a depth of 196.1 m

Figure 7

Dependence of specific heat capacity on temperature

Where · - 195.9

m; · - 196.0 m; · - 196.1 m

Figure 8 Dynamics of changes in

the temperature conductivity coefficient at a depth of 195.9 m

Figure 9 Dynamics of changes in the

temperature conductivity coefficient at a depth of 196 m

Figure 10 Dynamics of changes in the

temperature conductivity coefficient at a depth of 196.1 m

Figure 11 Results of the temperature conductivity study temperature conductivity mm2/s

Where · - 195.9 m; · - 196.0 m; · - 196.1

m.

The analytical study of thermal

conductivity is reduced to the study of spatio-temporal changes in temperature

and specific heat capacity, i.e., to find equation 2.

When calculating the

thermal conductivity according to the formula using the data of temperature

conductivity and specific heat capacity, the following results were obtained

(Table 1).

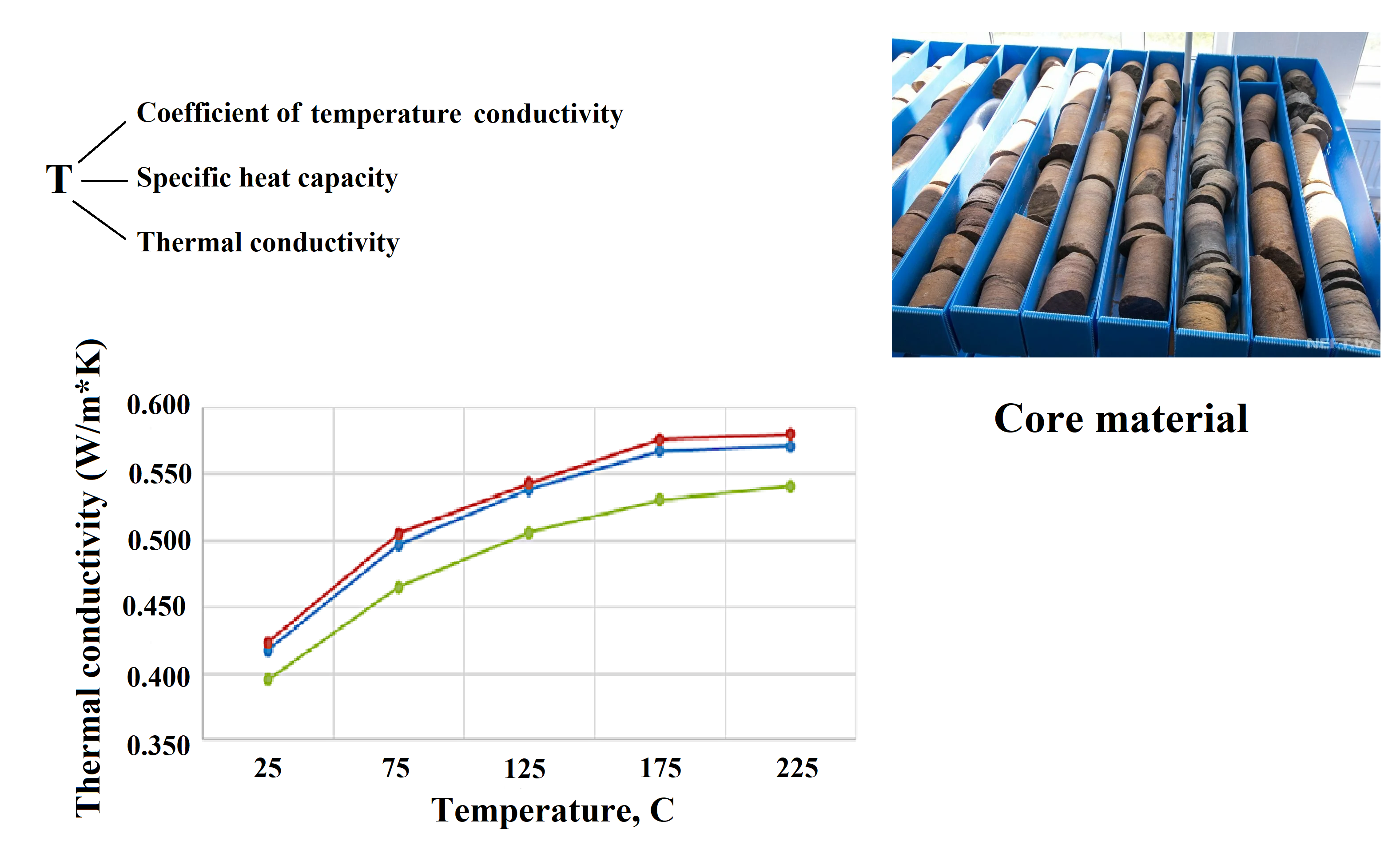

Table 1 Defined

values of thermal conductivity of core material samples temperature

|

Name of

indicators |

T, oC |

Intervals

of sampling of core material | ||

|

195.9 m |

196.0 m |

196.1 m | ||

|

Thermal

conductivity, W/m*K |

25 |

0.417 |

0.423 |

0.395 |

|

75 |

0.497 |

0.505 |

0.465 | |

|

125 |

0.538 |

0.543 |

0.506 | |

|

175 |

0.567 |

0.576 |

0.531 | |

|

225 |

0.571 |

0.580 |

0.541 | |

Figures 6-8 show the direct relationship

between the coefficient of thermal conductivity and

Figure 12 Dynamics of changes in the thermal

conductivity coefficient at a depth of 196.1 m

Figure 13 Dynamics of changes in

the thermal conductivity coefficient at a depth of 196.1 m

Figure 14 Dynamics of changes in the thermal

conductivity coefficient at a depth of 196.1 m

Figure 15

Dependence of thermal conductivity on temperature

Where · - 195.9 m; · - 196.0

m; · - 196.1 m

According to the results of the research, it was found that the

coefficient of thermal conductivity decreases with an increase in the

temperature of the core material, and the coefficient of specific heat capacity

increases with an increase in the temperature of the unconsolidated core. The

highest values of specific heat are observed at a temperature of 225°C. The

coefficient of thermal conductivity also increases with an increase in the

temperature of the core material. The highest thermal conductivity values are

observed at a temperature of 225°C. The increase of the thermal conductivity of

the core material with the temperature change can be explained by the fact that

with increasing temperature, the thermal conductivity of the medium that fills

the gaps between the grains increases (the core material can be attributed to

granular materials), and the heat transfer by radiation inside the granular massif

also increases. The thermophysical properties of the core material obtained

during laboratory studies can be applied in designing and optimizing methods

for lifting viscous oil with thermal effects on the productive reservoir.

The study was carried out

within the framework of a scientific project of the Russian Science Foundation

(RSF) No 21-79-10406 (https://www.rscf.ru/project/21-79-10406/).

| Filename | Description |

|---|---|

| R2-CE-6009-20230330083727.docx | --- |

Abed, A., Yakhlef, M., 2020. Brownfield regeneration

as a strategy for sustainable development: Amman case study. International

Journal of Technology, Volume 11(4), pp. 732–742

Adam, R.B. 2009. Converting oil shale to liquid fuels

with the Alberta Taciuk Processor: energy inputs and Greenhouse Gas Emissions. Energy

& Fuels, Volume 23(12), pp. 6253– 6258

Alas, M., Ali, S.I.A., 2019. Prediction of the high-temperature

performance of a geopolymer modified asphalt binder using artificial neural

networks. International Journal of Technology, Volume 10(2), pp.

417– 427

Balzamov, D., Akhmetova, I., Bronskaya, V., Kharitonova,

O., Balzamova, E., 2020a. optimization of thermal conditions of heat recovery

boilers with regenerative heating in the high-temperature section of Isoamylene

Dehydrogenation. International Journal of Technology, Volume 11(8), pp. 1598–1607

Balzamov, D.S., Balzamova, E.Yu., Bronskaya, V.V., Oykina

G.I., Rybkina E.A., Shaikhetdinova,

R.S., Kharitonova, O.S., 2020b. The beneficial using the heat of the exhaust gases of

the furnaces of the technological unit for the ethylene oxide production. In: IOP Conference Series:

Materials Science and Engineering, Volume 862(6), 062044

Balzamov, D.S., Balzamova, E.Y., Bronskaya, V.V.,

Rybkina, E.A., Kharitonova, O.S., 2020c. Beneficial use of thermal secondary energy resources

in the rectification cycle at ethylene glycol production unit. In: IOP Conference Series:

Materials Science and Engineering, Volume 919(6), 062027

Balzamov, D.S., Balzamova, E. Yu., Bronskaya, V.V.,

Valitov, N.V., 2020d. Possibility of using associated petroleum gas as a

fuel for a production boiler house. In: IOP Conference Series: Materials Science and

Engineering, Volume 791(1), 012006

Chekalyuk, E.B., 1955. The temperature field of the formation when

the coolant is injected into the well. Oil economy, Volume 4, pp. 39–42

Gabdrakhmanov, D.R., Valeeva, F.G., Syakaev, V.V.,

Lukashenko, S.S., Lakharov, S.V., Kuryashov, D.A., Bashkirtseva, N.Y.,

Zakharova, L.Y., Latypov, S.K., Sinyashin, O.G., 2015. Novel supramolecular

system based on a cationic amphiphile bearing glucamine fragment: structural

behavior and hydrophobic probe binding. Mendeleev Communications, Volume

25(3), pp. 174–176

Ganeeva, Y.M., Yusupova, T.N., Romanov, G.V.,

Bashkirtseva, N.Y., 2014. Phase composition of asphaltenes. Journal of

Thermal Analysis and Calorimetry, Volume 115(2), pp. 1593–1600

Ibragimova, D.A., Ivanova, I.A., Sharafieva, Z.F.,

Kharitonova, O.S., 2017. Evaluation of

paraffin and asphaltenes phase equilibrium in petroleum systems. International

Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology

Management, SGEM, Volume 17(15), pp. 147–154

Ismagilov, I.F., Kuryashov, D.A., Idrisov, A.R., Alieva,

M.R, Kashapova, N.E., 2016. Supramolecular system based on cylindrical micelles

of anionic surfactant and silica nanoparticles. Colloids and Surfaces A:

Physicochemical and Engineering Aspects, Volume 507, pp. 255–260

Jamilatun, S., Budhijanto, Rochmadi, Yuliestyan, A.,

Aziz, M., Hayashi, J., Budiman, A., 2020. Catalytic Pyrolysis of Spirulina

platensis Residue (SPR): Thermochemical behavior and kinetics. International Journal of Technology,

Volume 11(3), pp. 522–531

Khisamov R.S., Zakirov I.S., Zakharova E.F.,

Bazarevskaya V.G., Abusalimova R.R., Timirov D.A., 2018. Experience of study

and development of domanik deposits by example of Bavlinskoye field of Republic

of Tatarstan. Petroleum Economy, Volume 11, pp. 78–83

Mirgorodskaya, A.B., Valeeva, F.G., Zakharov, S.V., Kuryashov, D.A., Bashkirtseva, N.Yu., Zakharova, L.Ya., 2018. Aggregation

behavior of morpholinium surfactants in the presence of organic electrolytes. Russian

Chemical Bulletin, Volume 67(2), pp. 291–296

Petrov, S., Nosova, A., Bashkirtseva, N.,

Fakhrutdinov, R., 2019. Features of heavy oil spraying with single evaporation.

In: IOP Conference Series:

Earth and Environmental Science, Volume 282(1), p. 012004

Rubinstein, L.I., 1958. About the temperature field of the

formation when a hot coolant is injected into the formation: (about the

articles by E.B. Chekalyuk). In: Proceedings of the Ufa Petroleum Institute,

Issue 2, pp. 149–173

Sheinman, A.B., Malofeev, G.E., Sergeev, A.I., 1969. The impact of

heat on the reservoir during oil production. M. Nedra

Tugov A.N., Ots A., Siirde A., Sidorkin V.T., Ryabov

G.A. 2016. Development of measures to improve technologies of energy recovery

from gaseous wastes of oil shale processing. Thermal Engineering, Volume

63(6), pp. 430–438

Valeeva, F.G., Kuryashov, D.A., Zakharov, S.V. Vagapova,

G.I., Vasilieva, E.A., Bashkirtseva, N.Yu., Zakharova, L.Ya., Konovalov, A.I., 2013. Supramolecular

system 4-aza-1-hexadecyl-1-azoniabicyclo[2.2.2]octane bromide - Sodium

salicylate. Aggregation and rheological properties. Russian Chemical

Bulletin, Volume 62(4), pp. 989–993