Effect of Reducing Agents on The Performance of AgNPs and PANI Flexible Conductive Fabrics

Published at : 03 Nov 2022

Volume : IJtech

Vol 13, No 6 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i6.5853

Nurlis, A.G., Adhika, D.R., Suprijanto, 2022. Effect of Reducing Agents on The Performance of AgNPs and PANI Flexible Conductive Fabrics. International Journal of Technology. Volume 13(6), pp. 1163-1172

| Aulia Ghifari Nurlis | 1. Engineering Physics, Faculty of Industrial Technology, Institut Teknologi Bandung, Jl. Ganesa 10, Bandung 40132, Indonesia 2. National Research Center for Nanotechnology, Institut Teknologi Bandu |

| Damar Rastri Adhika | 1. Engineering Physics, Faculty of Industrial Technology, Institut Teknologi Bandung, Jl. Ganesa 10, Bandung 40132, Indonesia 2. National Research Center for Nanotechnology, Institut Teknologi Bandu |

| Suprijanto | Engineering Physics, Faculty of Industrial Technology, Institut Teknologi Bandung, Jl. Ganesa 10, Bandung 40132, Indonesia |

Cotton

fabric with the addition of silver nanoparticles (AgNPs) and polyaniline (PANI)

was developed as a flexible electrode to measure muscle biopotential signals

using Electromyography (EMG) in

this study. AgNPs are synthesized using two reducing agents, Gum Acacia and

Hydrazine Hydrate. The effect of the two different reducing agents will be

studied by measuring the electrical conductivity of each sample and also by

comparing flexible electrode performance during EMG measurements. The results

obtained from this study are that the AgNP electrodes synthesized using the Gum

Acacia have very high SNR and conductivity. The absence of an electrolyte gel

during EMG measurement using the developed flexible electrode can provide

comfort to the user without any risk of skin irritation due to electrolyte gel

when the measurement process is carried out for a long duration. The AgNP

fabric electrode with Gum Acacia as the reducing agent is expected to be used

to replace commercial electrodes in the

future.

Conductivity; Flexible electrodes; Gum acacia; Hydrazine hydrate; Reducing agents

The flexible

electrode has a good conductivity value and high flexibility. The problem that

is taken as the basis for developing this flexible electrode is that the

electrodes commonly used to carry out biopotential measurements have their

respective drawbacks. The dry electrode is fairly rigid and does not require an

electrolyte gel during the measurement process, but the measures will produce a

high noise signal

Functionalization of fabrics with the

addition of conductive materials could be performed to achieve a fabric-based

dry flexible electrode. Conductive materials added to the fabrics should have

good conductivity and maintain the fabrics' flexibility. The choice of

conductive polymer material is because most polymers already have a high degree

of flexibility and are elastic

AgNP with high purity and small size is

necessary for medical applications (Khumaeni et al., 2019). The

addition of AgNP to the fabric electrode increases the electrode conductivity.

The small diameter size AgNP can get into crevices and stick to the surface of

the fabric substrate. If the measurement conductivity increases, the noise

reduction in the EMG will increase. Adding AgNP and polyaniline to cotton

fabrics will produce a flexible electrode with good flexibility and

conductivity that can be used for biopotential signal measurements such as Electroencephalography

(EEG), Electrocardiography (ECG), and Electromyography (EMG) signals. The main

advantage of this fabric-based flexible electrode is that the fabric electrode

can follow the shape of the user's body curve when measuring the signals. Therefore,

the skin-to-electrode contact could be improved, and the measurement results

can be more accurate. In addition, the absence of an electrolyte gel can

provide comfort to the user without giving symptoms of skin irritation when the

measurement process is carried out for a long duration. Comfort in measurement

is also very important because the biopotential signal can possibly change due

to fatigue (Puspasari et al., 2017).

Plain white cotton fabric and aqua-dm were

obtained from a local market in Indonesia. Aniline, Ammonium Persulfate (APS),

NaOH, and HCl were purchased from Merck, Germany. Gum Acacia and Hydrazine

Hydrate were obtained from a local chemical store in Indonesia. Silver nitrate

(AgNO3) was purchased from PT. Antam Indonesia.

2.1. Preparation of Fabric-Based Flexible Electrode with Addition of

AgNP with Different Reducing Agents and PANI

At this stage, AgNP will be synthesized

using two different reducing agents to compare the performance of the

electrodes with each other. In this research, the dimensions of the white

cotton fabric used are 4 cm x 2 cm. After the cotton fabric was prepared, the

AgNP solution was designed using different reducing agents. AgNP reducing

agents used were gum acacia and hydrazine hydrate. To increase the

conductivity, the electrodes coated with

AgNP are varied with an additional layer, namely PANI. Electrode performance

will be seen based on the results of the SEM EDS characterization,

conductivity, and EMG signal of each sample. Based on the characterization,

variations of reducing agents that produce better performance will be selected

for the next optimization stage. The procedure for preparing AgNP and PANI

solutions is described in the following subsections.

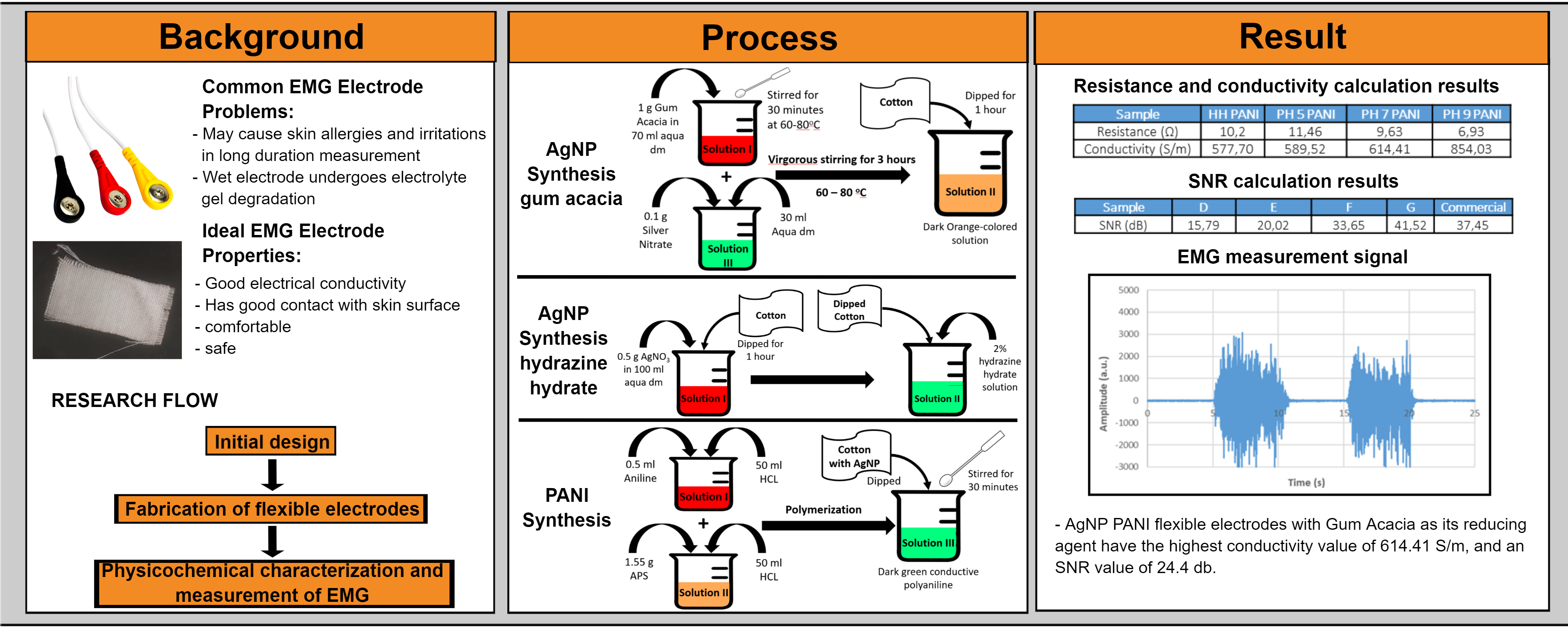

2.1.1. Green

synthesis of AgNPs with Gum Acacia

Gum Acacia is commonly used as a green synthesis-reducing agent to produce AgNP. Besides gum acacia, Rosman et al. (2021) has synthesized AgNP with another green synthesis-reducing agent, namely polychaete (Marphysa moribidii) (Rosman et al., 2021). However, gum Acacia has a low, reducing property; therefore, the AgNP synthesis process with Gum Acacia also requires a longer time. A total of 1%-wt (1 g) of Gum Acacia was added to 70 mL of distilled water in a flask. The solution is then stirred with a magnetic stirrer at the desired temperature (60-80oC) for about half an hour to obtain a homogeneous solution. At the same time, 0.1% by weight (0.1 g) of silver nitrate was dissolved in 30 mL of distilled water at room temperature and then rapidly injected into the above Gum Acacia solution with vigorous stirring (Dong et al., 2014). The solution was maintained at the desired temperature and allowed to react for 3 hours until a dark-colored solution was obtained. Then, the cotton fabric was dipped in the AgNP solution for 1 hour so that the solution was well absorbed into the cotton fabric. After soaking in AgNP solution, the sample will be dried in an oven at 60oC for 2 hours.

Figure 1 AgNP coating procedure on fabric

with gum acacia (Dong et al., 2014)

2.1.2. Green synthesis of AgNPs with Hydrazine Hydrate

Figure 2 AgNP

coating procedure on fabric with hydrazine hydrate

Hydrazine

hydrate is one of the reducing agents which is quite strong in reducing Ag

solution. However, hydrazine hydrate solution is a very toxic solution and can

trigger cancer cells when in contact with body surfaces. The AgNP fabrication

process using a reducing agent is carried out in a fumehood so that the gas

from hydrazine hydrate is not inhaled. The fabrication begins with dissolving

silver nitrate powder into aqua dm to produce a solution of AgNO3

with a solubility of 5 g/l for 1 hour. Then, the cotton fabric is rapidly

dipped in the 2% hydrazine hydrate solution. The sample was soaked until there

were no bubbles resulting from reducing AgNO3 to Ag on the fabric.

After the sample is saturated, the sample will be dried in an oven at a

temperature of 60oC for 2 hours. Fabric samples coated with AgNP

with hydrazine hydrate will have a gray cotton fabric; the gray color indicates

AgNP has adhered to the cotton fabric.

2.1.3. Synthesis of PANI

The synthesis procedure was started by

preparing cotton fabric as a substrate, 0.5 mL of aniline monomer in 50 mL 1 M

HCl (solution I), and 1.55 grams of APS in 50 mL HCl 1 M (solution II) (Abu-Thabit, 2016). The solutions I and II were

mixed while stirring using a magnetic stirrer to keep the stirring rate constant

so that the polymerization that occurred was evenly distributed. Next, the

AgNP-treated fabric substrate was immersed in the solution during the

polymerization process for approximately 30 minutes to obtain an average

polymerization conversion of 90%. The success of the polymerization is

indicated by a change in color to dark green, like the color of emerald salt.

After the cotton fabric substrate is dark green, the cotton fabric is dried in an oven at 60oC to dry.

Figure 3 PANI coating procedure on fabric

Based on the synthesis procedure

described previously, the electrode samples will be varied into four models the

nomenclature of the samples obtained from the synthesis process can be seen in Table

1.

Table 1 Nomenclature of the

sample

|

Sample |

Composition |

||

|

A |

Cotton |

AgNP Gum Acacia |

|

|

B |

Cotton |

AgNP Hydrazine Hydrate |

|

|

C |

Cotton |

AgNP Gum Acacia |

PANI |

|

D |

Cotton |

AgNP Hydrazine Hydrate |

PANI |

The fabric-based flexible electrodes

from each sample have different colors due to other treatments. The color

change of white cotton fabric after being coated by AgNP solutions from other

reducing agents and PANI can be seen in Figure 1.

|

|

Figure 4 Fabric substrate in (a) after being coated with AgNP acacia gum (b) after being coated with AgNP hydrazine hydrate (c) after PANI coating

2.2. Characterization of Fabric-Based Flexible Electrode

SEM (Hitachi SU3500) was used to analyze PANI-coated fabrics' morphology and composition. In addition, electrical conductivity characterization was carried out using a digital multimeter (Keithley DMM7510) and a DC source generator using the four-point probe (FPP) method (Figure 5). FPP is suitable for measuring the resistance of thin films or substrates in ohms per square by forcing a current through the two outer probes and reading the voltage across the two inner probes (Chlaihawi, et al., 2018). Using this FPP configuration can avoid errors in measurement due to contact resistance between the probe and sample. In this method, the value of the voltage generated by the electrode is measured, which is given an electric current with a constant value

Figure 5 (a) Keithley DMM7510 digital multimeter and (b) four-point probe

After the tool has been prepared, the DC source generator is turned on.

The value of the input current source used is 0.5 mA, which is estimated

because the source meter used has a maximum value limit of the measured

voltage, which is 22 Volts. Measurements were repeated until 100 data were

obtained for each electrode. The data obtained are then tabulated into a table

in the form of the average voltage value, standard deviation, maximum voltage

value, minimum voltage value, and peak-to-peak value of all electrode samples.

2.3. Biopotential EMG Measurement

Testing of the electrodes that have been

generated in the EMG signal measurement instrument was carried out using the

FlexComp Infiniti – 10 Channel System device, which was produced and displayed

on the Infiniti BioGraph software.

Figure 6 (a) Set-up of EMG signal measurement with FlexComp Infiniti – 10

Channel System device (b) the placement of the EMG measurement probe for the

detection electrodes is placed on A and B while the reference electrode is

placed on C

The

placement of the EMG measurement probe can be observed in Figure 3 where two

electrodes were attached to the biceps muscle, and one electrode was attached

to the elbow, which served as a reference electrode. The three electrodes

installed on the arm are then connected to the EMG test equipment, and the

obtained measurement signals are displayed on a computer. The measurement

signals were received by clenching the hands to get muscle signals when

contracting and releasing fists to get muscle signals when relaxing for 5 seconds

each. This process was repeated twice so that the total measurement was carried

out for about 20 seconds. When the hand is relaxed, the biopotential signal

shows a value close to zero, but when the hand contracts, the signal moves to a

peak.

3.1. SEM EDS Observation

SEM-EDS is a tool for

characterizing the morphology of the sample surface and calculating the

composition of the material making up the sample. The design of each sample (A,

B, C, and D) follows the composition in Table 1. Samples A and C were coated

with silver nanoparticles synthesized using acacia gum, while samples B and D

were synthesized with hydrazine hydrate. In addition, samples C and D were

given an additional PANI layer. From the obtained SEM images in Figure 7, it

can be seen that the variation of the electrode without the addition of PANI

has flashes due to the charging effect. The charging product seen in the SEM

image is due to the low conductivity of the observed sample. Qualitatively, the

results of SEM A did not show a charging effect as large as the SEM results of

sample B, so it can be concluded that the conductivity in sample A is higher

than B. In addition, SEM samples C and D have better SEM results because no

charging effect occurred. Absence of the charging effect indicates a higher

conductivity on samples C and D than that of A and B due to the addition of

PANI. Silver particles could be identified as small particles on the surface of

the fabric on the SEM image.

Figure 7 SEM characterizations of

(a) sample A (b) sample B (c) sample C (d) sample D

The

SEM results that have been obtained are then analyzed using EDS. Based on the

results of the EDS analysis in Table 2, it was found that there was a decrease

in silver content during the PANI coating process on AgNP electrodes. Samples A

and C, which use gum acacia as the reducing agents, decreased about 0.8% silver

particles during the PANI coating process. Otherwise, samples B and D decreased

silver content by 0.7%. The silver content decreased due to the addition of C,

O, N, S, and other PANI atoms and the possibility of silver particles being

released during the PANI coating process. Samples A and B do not have N and S

atomic compositions because samples A and B are only composed of AgNP and

cotton fabric without PANI addition. According to Monier's research, cotton is

only composed of C, H, and O atoms (Monier

et al., 2014).

Table 2 EDS characterization

of AgNP electrode with a variation of reducing agents and PANI addition

|

Sample |

Atomic Composition (%) |

||||

|

C |

N |

O |

S |

Ag |

|

|

A |

47.2 |

- |

51.7 |

- |

1.1 |

|

B |

46.9 |

- |

52.1 |

- |

1 |

|

C |

46 |

3.9 |

42.7 |

7.1 |

0.3 |

|

D |

41.5 |

8.5 |

39.2 |

10.5 |

0.3 |

3.2. Electrical Conductivity

Measurements

The measured voltage data

for the four samples amounted to 100, then averaged. The following is the

result of the voltage data obtained from the measurement results, as listed in Table

3.

Table 3 Voltage measurement of flexible electrode sample

(units in Volts)

|

Sample |

A |

B |

C |

D |

|

n Data |

100 |

100 |

100 |

100 |

|

Average |

0.01036 |

0.00723 |

0.00143 |

0.00153 |

|

Standard

Deviation |

0.00147 |

0.00324 |

0.00007 |

0.00026 |

The dimensions of each

tested sample were measured using a ruler to measure length and width and using

the CHY-CA thickness measurement instrument to measure the thickness of the

sample. The dimensions of the electrode samples can be seen in Table 4.

Table 4 Fabric electrode

sample size dimension (units in meters)

|

Sample |

A |

B |

C |

D |

|

Thickness |

0.00018 |

0.00017 |

0.00017 |

0.00017 |

|

Length |

0.04 |

0.04 |

0.04 |

0.041 |

|

Width |

0.02 |

0.02 |

0.02 |

0.02 |

The electrode resistance could be

calculated using the formula 1 below:

(1)

R is the sample resistance (?), V is the

read voltage (Volt), and I is the electric current (0.5 mA). CF1, CF2, and CF3

were the correction factor values due to the influence of sample size, sample

thickness, and temperature, respectively, when FPP measurement was performed.

So that each has a value of CF1 = 3.2246; CF2 = 1,000; and CF3 = 1.0410. The

sample's electrical conductivity value is obtained using equation 2 below.

(2)

Where ? is the electrical

conductivity of the electrode, p is the resistivity of the electrode, Rs is the

resistance of the electrode, and t is the thickness of the electrode. Each

sample was tested for conductivity. The result is tabulated in Table 5.

Table 5 The flexible

electrode's electricalconductivity (?) and resistivity (?) table

|

Sample |

A |

B |

C |

D |

|

Resistance

(?) |

48.5 |

69.6 |

9.6 |

10.2 |

|

Conductivity

(S/m) |

119.2 |

113.2 |

614.4 |

577.7 |

Based on the test results,

sample C showed the highest conductivity value compared to other variations,

which was 614.41 S/m. The number and

uniform distribution of conductive molecules across the electrodes, such as

polyaniline and silver nanoparticles, increased.

3.3. EMG Measurement of

Flexible Electrode

Signal-to-Noise Ratio

(SNR) can be calculated using formula 3:

(3)

Where SNR is the signal-to-ratio, S is the RMS voltage of the measured

EMG signal, and N is the RMS voltage of the measured noise signal. EMG

measurements were carried out only on the electrode samples with the best

conductivity. In this case, the electrodes added with PANI, samples C and D,

gave the highest conductivity values. The EMG measurement of samples C and D

are tabulated in Table 6.

Table 6 EMG measurement

table of AgNP PANI electrode

|

Sample |

C |

D |

|

SNR (dB) |

24.4 |

15.8 |

The results of the EMG measurements show a correlation between the conductivity values of the electrodes and the obtained SNR values. The SNR value indicates that the noise signal does not interfere with the EMG measurement process. The higher the SNR value, the smaller the effect of the noise signal. Based on the results that have been processed, sample C shows the highest SNR value compared to the other sample. The SNR value obtained from sample C is 24.4 dB, while sample D shows 15.8 dB. The biopotential signal is shown in Figure 8.

Figure 8 EMG

measurement signal of (a) sample C [AgNP Gum Acacia + PANI] (b) sample D [AgNP

Hydrazine Hydrate + PANI]

After getting the SNR results from fabric-based flexible electrode

samples C and D, a comparative study of electrode performance was carried out

to compare the performance of the electrodes produced by this research with the

results of other researchers. The results of the comparative study can be seen

in Table 7 below.

Based on the comparative study above, fabric-based flexible electrodes made of AgNP PANI with acacia gum as a reducing agent have a higher SNR value than commercial electrodes, which is 24.4 dB. While commercial electrodes have an SNR value of 21.2 dB Therefore, the performance of AgNP PANI is better than the common electrodes.

Table 7 Comparative electrode performance study for body biopotential signals

measurement

|

No |

Material |

Substrate |

Type |

SNR (dB) |

References |

|

1 |

MWCNTs/PDMS composites on Ag |

TPU on fabric |

Dry |

23.1 |

|

|

2 |

Laser Induced Graphene |

PDMS |

Dry |

32 |

|

|

3 |

Ag/AgCl |

Parylene C |

Dry |

23.8 |

|

|

4 |

Ag/AgCl |

Commercial |

Wet |

21.2 |

(Masihi, et al.,

2021) |

|

5 |

AgNP PANI with Gum Acacia |

Cotton fabric |

Dry |

24.4 |

This Study |

|

6 |

AgNP PANI with Hydrazine

Hydrate |

Cotton fabric |

Dry |

15.8 |

This Study |

The

conclusion that can be drawn from this research is that the combination of AgNP

and PANI in cotton flexible electrodes can perform quite well for measuring

biopotential muscle signals. The flexible electrode has the advantage of good

electrode flexibility and conductivity; therefore, it does not need to use an

electrolyte gel to provide good skin-to-electrode contact. These advantages can

solve problems that often occur when using common Ag/AgCl commercial

electrodes, such, as high noise signals, uncomfortable usage, and skin

allergies. AgNP PANI flexible electrode with Gum Acacia as a reducing agent has

the highest conductivity and SNR value among other variations, which is 614.41

S/m, and an SNR value of 24.4 dB. Future work is focused on improving the

attachment of AgNP and PANI to the cotton fabric and the sustainability of

flexible electrodes.

Authors

express their gratitude to PPMI Engineering Physics ITB 2020 Project for

financial support.

Abu-Thabit, N.Y., 2016. Chemical Oxidative Polymerization of

Polyaniline: A Practical Approach for Preparation of Smart Conductive Textiles.

Journal of Chemical Education, Volume 93(9), pp. 1606–1611

Ahn, S., Han, T-H., Maleski, K., Song, J., Kim, Y-H., Park, M-H., Zhou, H., Yoo, S., Gogotsi, Y., Lee, T-W., 2020. A 2D Titanium Carbide MXene Flexible

Electrode for High?Efficiency Light-Emitting Diodes. Advanced Materials, Volume 32(23), p. 2000919

Chlaihawi, A. A. et al., 2018. Development of Printed and Flexible Dry ECG

Electrodes. Sensing and Bio-Sensing Research, Volume 20, pp. 9–15

Dong, C., Zhang, X., Cai, H., Cao, C., 2014. Facile and One-Step Synthesis of Monodisperse Silver Nanoparticles Using Gum Acacia in Aqueous Solution. Journal of

Molecular Liquids, Volume 196, pp. 135–141

Fu, X., Li, T., Qi, F., Zhang, S.,

Wen, J., Shu, W., Luo, P., Zhang, R., Hu, S., Liu Q., 2020. Designing High Electrochemical Surface

Area Between Polyaniline and Hydrogel Polymer Electrolyte for Flexible

Supercapacitors. Applied Surface Science, Volume 507, p. 145135

Gicevicius, M., Celiesiute, R., Kucinski, J., Ramanaviciene, A., Bagdziunas, G., Ramanavicius, A., 2018. Analytical Evaluation of

Optical Ph-Sensitivity of Polyaniline Layer Electrochemically Deposited on ITO

Electrode. Journal of The Electrochemical Society, Volume 165(14), pp. H903–H907

Khumaeni, A., Sutanto, H., Budi, W.S., 2019. The

Role of Laser Irradiance, Pulse Repetition Rate, And Liquid Media in The

Synthesis of Gold Nanoparticles by The Laser Ablation Method Using an Nd: YAG

Laser 1064 Nm at Low Energy. International Journal of Technology, Volume 10(5), pp. 961–969

Masihi, S., Panahi, M., Maddipatla, D., Hanson, A.J., Fenech, S., Bonek, L., Sapoznik, N., 2021. Development of a Flexible Wireless ECG

Monitoring Device with Dry Fabric Electrodes for Wearable Applications. IEEE

Sensors Journal, Volume 22(12), pp. 11223–11232

Monier, M., Akl, M. A., Ali, W.M., 2014. Modification and Characterization of Cellulose Cotton Fibers for Fast Extraction

of Some Precious Metal Ions. International Journal of Biological

Macromolecules, Volume 66, pp. 125–134

Peng, H.L., Liu, J.Q., Dong, Y.Z., Yang, B., Chen, X., Yang, C.S.,

2016. Parylene-Based Flexible Dry Electrode for Bioptential Recording. Sensors

and Actuators B: Chemical, Volume 231, pp. 1–11

Penhaker, M., Polomik, J., Kubicek, J. Kasik, V., 2017.

Biopotential Conducting Polymer Electrodes Design and Realization for ECG Measurement. In: 10th International

Conference on Biomedical Electronics and Devices

Puspasari, M.A., Iridiastadi, H., Sutalaksana, I.Z., Sjafruddin,

A., 2017. Effect of Driving

Duration on EEG Fluctuations. International Journal of Technology, Volume 8(6), pp. 1089–1096

Rosman, N.S.R., Masimen, M.A.A., Harun, N.A., Idris, I., Ismail,

W.I.W., 2021. Biogenic Silver Nanoparticles (AgNPs) from Marphysa Moribidii

Extract: Optimization of Synthesis Parameters. International Journal of

Technology, Volume 12(3), pp. 635–648

Saude, M.A. Morshed, B.I., 2016. Polypyrrole (PPy) Conductive

Polymer Coating of Dry Patterned Vertical CNT (pvCNT) Electrode to Improve

Mechanical Stability. In: 2016 IEEE Topical Conference on Biomedical

Wireless Technologies, Networks, and Sensing Systems (BioWireleSS)

Tseghai, G.B., Melengier, B., Fante, K.A. Langenhove, L.V., 2020.

The Status of Textile-Based Dry EEG Electrodes. AUTEX Research Journal, Volume 21(1), pp. 63–70

Wang, C., Yang, Y., Li, R., Wu, D., Qin, Y., Kong, Y., 2020. Polyaniline Functionalized Reduced

Graphene Oxide/Carbon Nanotube Ternary Nanocomposite as a Supercapacitor Electrode. Chemical

Communications, Volume 56(28), pp. 4003–4006

Yang, J., Zhang, K., Yu, J., Zhang, S., He, L., Wu, S., Deng, Y.,

2021. Facile Fabrication of Robust and Reusable Pdms Supported Graphene Dry

Electrodes for Wearable Electrocardiogram Monitoring. Advanced Materials

Technologies, Volume 6(9), p. 2100262

Yokus, M.A. Jur, J.S., 2016. Fabric-Based Wearable Dry Electrodes

for Body Surface Biopotential Recording. IEEE Transactions on Biomedical

Engineering, pp. Volume 63(2), pp. 423–430