Inactivation of Avian Influenza Virus of Subtype H5N1 and H9N1 in The Vaccine Industrial Wastewater Treatment with an Advanced Oxidation Process Base on Ozone

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.5814

Enjarlis, E., Wijaya, K., Karomah, E.F., Huda, S., 2022. Inactivation of Avian Influenza Virus of Subtype H5N1 and H9N1 in The Vaccine Industrial Wastewater Treatment with an Advanced Oxidation Process Base on Ozone. International Journal of Technology. Volume 15(6), pp. 1898-1910

| E. Enjarlis | Department of Chemical Engineering, Institut Teknologi Indonesia, Jl. Raya Puspiptek Serpong, South Tangerang, Banten, 15314 Indonesia |

| Karna Wijaya | Department of Chemical Engineering, Institut Teknologi Indonesia, Jl. Raya Puspiptek Serpong, South Tangerang, Banten, 15314 Indonesia |

| Eva Fathul Karomah | Department of Chemical Engineering, Universitas Indonesia, Kampus Baru UI Depok, Depok, West Java, 16424 Indonesia |

| Shabri Huda | Department of Chemical Engineering, Institut Teknologi Indonesia, Jl. Raya Puspiptek Serpong, South Tangerang, Banten, 15314 Indonesia |

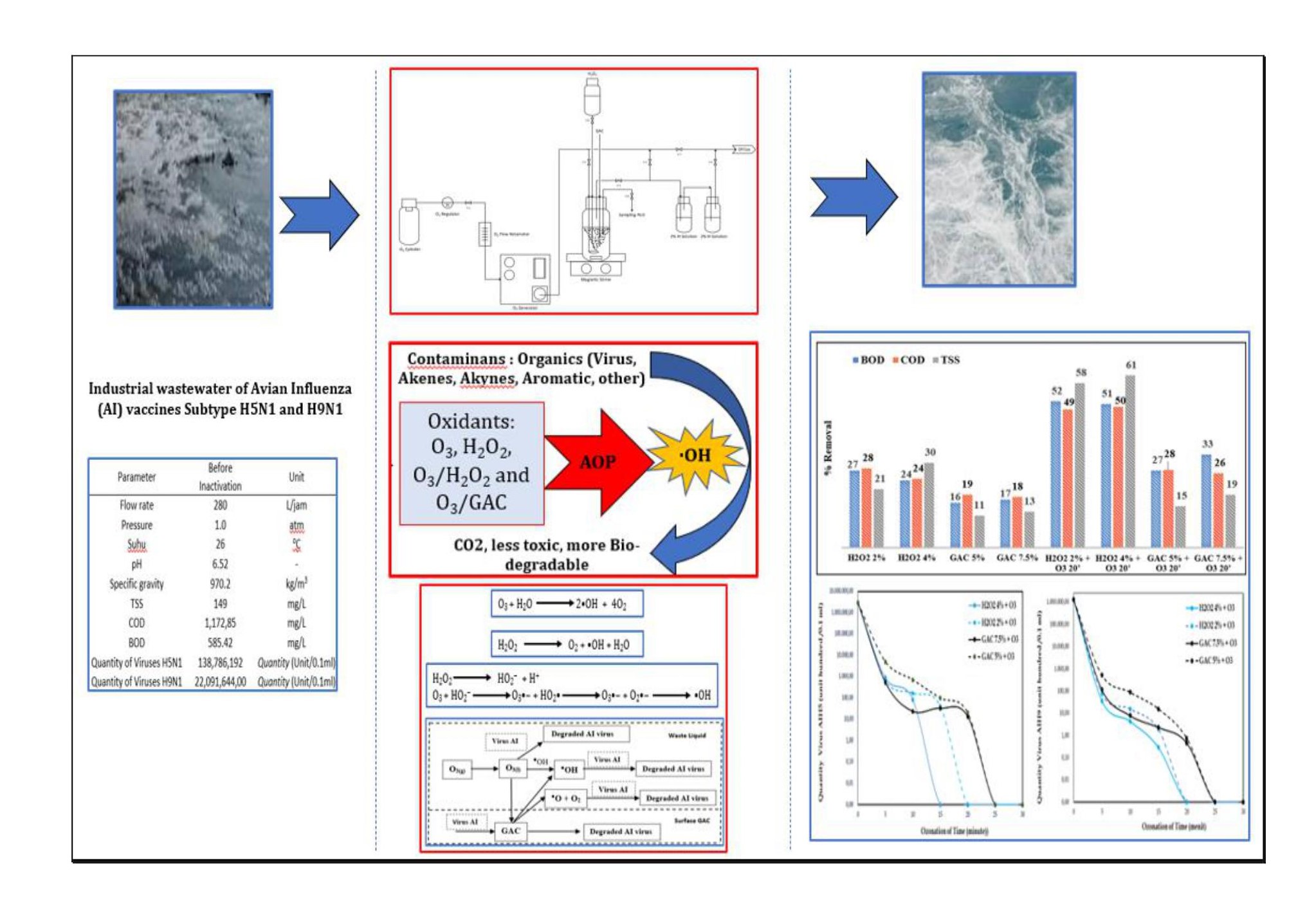

This study

aims to compare the effectiveness of oxidation and adsorption technology in the

inactivation of Avian Influenza (AI) virus subtypes H5N1 as well as H9N1 and

remove the content of COD, BOD, and TSS in industrial wastewater of Avian

Influenza (AI) vaccines production. The experiment variables are the number and

type of oxidizers (O3 and H2O2), the number of

adsorbents granular activated carbon (GAC), and the type of Advanced Oxidation

Process (AOP) based on O3 (O3/H2O2

and O3/GAC). The measured parameters include virus inactivation test

(CT Value) and the number of AI virus subtypes H5N1 and H9N2 as well as TSS,

COD, and BOD of wastewater from the vaccine industry. The results showed that

the AOP with O3/H2O2 at a dose of 0.00013 g O3/ml

of wastewater is the most effective technology in the inactivation of AI virus

of subtypes H5N1 and H9N1 and the decrease in the content of COD, BOD, and TSS.

Furthermore, approximately 2% of H2O2 and ozonation for

20 minutes with CT Value equal to No CT, virus quantity was 0.0 thousand

units/0.1 mL and pH 7.16, while percentage removal of TSS, COD, and BOD were

58% (86.42 mg/L), 49% (575 mg/L), 52% (304.42 mg/L. For the COD and BOD values

to meet the quality standards, it is recommended to apply the O3/H2O2

technology in series with an additional processing time of approximately 10

minutes, or as alternative processing can be continued at the Wastewater

Treatment Plant (WWTP) which is already owned by the Vaccine Industry.

Advanced Oxidation Process; Inactivation of Avian Influenza Virus (H5N1 and H9N1); Ozonation; Wastewater of vaccine industry

The COVID-19 virus epidemic had a significant impact on human life and the economy of countries around the world (Nur et al., 2022). This showed that outbreaks of other deadly viruses, such as Avian Influenza (AI) are expected to be transmitted to animals and humans. In Indonesia, the AI virus vaccine industry in West Java, in the production process, generates wastewater from live egg allantois, tank washing, and sterilization. The wastewater is processed by the disinfection method at a steam temperature of 850C for 45 minutes. However, the products obtained usually contain AI virus strains H5N1 and H9N1 activity with COD, BOD, and TSS values that exceed quality standards. AI virus is a single-stranded RNA virus of the family Orthomyxoviridae, which is deadly zoonotic and contagious to humans (Everest et al., 2021; Mostafa et al., 2018). Therefore, to prevent environmental pollution and the spread of avian influenza Virus subtypes H5N1 and H9N1 from liquid waste from the Avian Influenza virus vaccine industry, the waste must be treated with the right technology. The 2 categories of these viruses are Low Pathogenic Avian Influenza (LPAI), including H9N1, which has 9 subtypes and High Pathogenic Avian Influenza (HPAI), which includes H5N1 with 5 subtypes. Furthermore, the viruses are divided into subtypes based on 2 surface proteins, namely hemagglutinin (HA) and neuraminidase (NA) (CDCP, 2022; Everest et al., 2021; Huang et al., 2021; Koutsakos, Kedzierska, and Subbarao, 2019). The HA is a type of glycogen and a class 1 fusion protein that has a multifunctional activity for attaching viruses to cells, while NA is an enzyme that releases viruses for complete infection (Kosik and Yewdell, 2019; Naguib et al., 2019).

The oxidation process using ozone and Advance

Oxidation Procces (AOP) base on Granular Activated Carbon (GAC) and Ozone are

more environmentally friendly, efficient and effectively in treating industrial

wastewater containing AI viruses. This method is also superior to the use of

other chemicals such as alcohol, formalin, surfactants, sodium dichloro in the

inactivation of microorganisms on the surface of solid objects. Ozone of

oxidizers are strong and unstable, have a broad spectrum of antimicrobials and are

reactive to proteins and lipids (Tizaoui,

2020; Megahed, Aldridge, and Lowe, 2018). In water, ozone is decomposed into free

radicals such as HO•, HO2•, O3•-

and O2 (Fu et al.,

2019). The

inactivation of the AI virus by this compound is influenced by dose, time,

temperature, and relative humidity (Dubuis

et al., 2021; Kong et al., 2021). Hydrogen peroxide (H2O2)

is also a strong oxidizer, with an oxidation potential of 1.77 Volts, which

reacts and damages the structure of microorganisms by disrupting their

metabolic stability. The same study also showed that H2O2

was an extremely effective inactivating for both RNA and DNA viruses in less

than 2 h after exposure to a 3% aqueous solution of H2O2 (Elveborg, Monteil, and Mirazimi, 2022). The advantages of

activated carbon include its high absorption capacity, with a surface area of

500 to 1500 m2, and its good absorb inorganic and organic pollutants such as

phenol and heavy metal ions in the water and wastewater (Huang et al., 2022; Desmiarti et al., 2019), as well as during

ozonation (O3/GAC) has been reported to improve oxidation

performance through acts as an initiator and increased transformation of O3

to OH radicals (Rekhate and

Srivastava, 2020).

Advanced Oxidation Process

(AOP) is higher oxidation with •OH as an oxidating potential of 2.8

volts and is non-selective, the most reactive free radical formed in vivo (Martemucci et al., 2022). The •OH

formation systems are homogeneous such as O3/H2O2

(Fan, Sokorai, and Gurtler, 2020) and heterogeneous, namely O3/GAC (Chen et al., 2021; Wang et al.,

2020). In O3/H2O2

systems, •OH and oxidants (O2•- and O2)

are produced through a reaction between H2O2 and water to

generate HO2-, which further reacts with O3 (Kim et al., 2021). Meanwhile, the mechanism

of O3/GAC in wastewater treatment is such that organic

micropollutants whose low reactivity to ozone can be removed by either (i)•OH,

especially micro-hydrophilic pollutants and/or (ii) adsorption on the surface

of activated carbon for hydrophobic micropollutants (Lisovskayaa et al., 2021; Wang et al., 2018; Vega and Valdes, 2018). Ozone has a low solubility

at room temperature, and the solubility of ozone can be increased by using an

aerator pump so that it can reduce the size of the ozone bubble by up to 90%

and increase the effective ozone solubility to 0.47 ppm (Verinda et al., 2022).

Inactivation of AI Viruses

subtypes H5N1 and H9N1 has been carried out in drinking water treatment (Lenes et al., 2010). However, research on AI

virus inactivation in wastewater containing COD, TSS, and BOD exceeding the

standard has not been carried out using oxidation processes (O3 and

H2O2) and Advanced oxidation (O3/H2O2

and O3/GAC). The purpose of this study was to compare the processes

of oxidation (O3 and H2O2), adsorption (GAC),

and Advanced oxidation of the vaccine Industrial wastewater treatment: inactivation

of AI Viruses subtypes H5N1 and H9N1 and their impact on decreasing COD, BOD,

and TSS values.

2.1. Equipment and Materials

Oxidation reactor from glass

material size ID 4.0 cm and H 60 cm, equipped with incoming and outgoing ozone

gas ports, Plate Magnetic Stirrer 500 – 1500 rpm (Thermo Scientific, USA),

Biosafety Cabinet model BSC-1500IIB2-X (MEDFUTURE, China), Analytical Balance

Sheet model ABJ320-4NM, max 220 grams (KERN, Germany), Realtime PCR

Quantstudio5 (Thermo Scientific, USA),

Ozone Generator with capacity 3 grams O3/h (Quanju, China), Egg

Candler 2,000 mAh (Magicfly, China), Egg Incubator model T-JZ1056 (Tengao,

China), Laminar Air Flow (LAF) for PCR model 321 PCR Workstation (Captair Bio,

Malaysia), and pH Meter work on ATC (Mettler Toledo, Indonesia, Sulfuric acid

(Merck, Indonesia), Hydrogen Peroxide (H2O2) (Sindopex

Perotama Indonesia), GAC (Granular Activated Carbon) (Bumi Agung Chemistry,

Indonesia), Viral Nucleic Acid Extraction Kit (Geneaid, Taiwan), Quantitect, RT-PCR

Kit (Qiagen, USA), Primer & Probe (Macrogen, Korea Selatan), Egg Specific

Pathogen Free (SPF) (SPF Egg Plant,

Indonesia), Iodine (I2)

(Merck, Indonesia), Potassium Iodide (KI) (Merck, Indonesia), Sulfuric

Acid (H2SO4) (Meck, Indonesia), Sodium Thiosulfate

(Merck, Indonesia) and Kanji Solution (C6H10O5)n (Merck, Indonesia).

2.2. Preparation and

Characteristics of Liquid Waste of AI Virus Vaccine Industry

Liquid waste of H5N1 and

H9N1 virus vaccine industry from PT. Vaksindo Satwa Nusantara (Ungas vaccine

industry) Gunung Putri, Bogor Regency. The collecting tank at the sampling

point was used to collect 500 mL in a tightly closed glass bottle and stored at

4oC. The characteristics of liquid waste from the vaccine industry

before treatment are stated in Table 1.

2.2. Qualitative and Quantitative Analysis of AI

Viruses in liquid waste (OIE,

2014)

2.3.1. Inoculation of Wastewater Samples on

Eggs

A total of 0.1 mL of wastewater was inoculated onto 11-day-old SPF

(Specific Pathogen Free) eggs, which were then incubated at a temperature of

37°C during 5 days. The eggs were observed (candled) using an egg candler tool

to determine the growth of embryos at dead or live eggs. RNA extraction was

performed after incubation.

2.3.2. Ribonucleic

Acid (RNA) Extraction

Allantois sample was obtained from inoculation on eggs, and RNA

(Ribonucleic Acid) was extracted using a Viral Nucleic Acid Extraction Kit from

Genaid with the appropriate procedure on the www.Geneaid.com website.

2.3.3. Mixing

RNA (RT-PCR)

RT-PCR (Quantstudio5) was used to detect AI viruses of subtypes H5N1 and

H9N1 qualitatively and quantitatively. The RNA in samples was amplified with

Quantitect Probe RT-PCR Kit reagents with procedures according to using

specific primers (www.macrogen.com) for each strain of the virus. Meanwhile, the cut-offs for each of the

H5N1 and H9N1 methods are presented in Table 2. CT is a measure of disinfectant

concentration (C) multiplied by the time (T) required to achieve a given

inactivation level of a microorganism.

2.3.4. Chemical Oxygen Demand (COD), Biological

Oxygen Demand (BOD), dan TSS Analysis

Measurement of COD, BOD and TSS of wastewater Industry vaccine AI virus

subtype AIH5 dan AIH9 before and after treatment from the Indonesian National

Standard (SNI) (BSN, 2019), for COD

with SNI6989.2: 2019, BOD with SNI 06-6989.14-2004 and TSS with SNI 06-6989.3-

2004.

2.4. Wastewater Treatment of Vaccine Industry and

AI Virus Inactivation

Figure

1 Process flow diagram Wastewater

Treatment of Vaccine Industry and AI Virus Inactivation with Ozonation and AOP

base on Ozone (O3/H2O2 and O3/GAC)

3.1. Inactivate of AI Virus in

wastewater of vaccine Industry with H2O2.

Table 3 shows the inactivation data of H5N1 and H9N1 viruses by H2O2 at 2.0, 4.0, and 6.0%. The optimum inactivation was obtained at H2O2 of 6% with each No CT and quantity value of approximately 0.0 units/0.1 mL, and the egg is still alive. This indicates that the virus is inactive (dead) and is incapable of damaging the egg. At a concentration of 4%, the egg was still alive, showing that the virus was inactive, where the H5N1 and H9N1 quantity values had approximately 0.0 Units/0.1 mL and 17.60 units/0.1 mL with No CT and a value of 35.51, respectively the eggs also die in H2O2 of 2% which indicated that the virus is still active and can infect eggs in both subtypes, with quantity values of 4,261.81 units/0.1 mL and 10,404.53 units/0.1mL with CT values of 35.31 and 27.41, respectively. Previous reports stated that the effectiveness of H2O2 in the inactivation of the AI virus occurs at concentrations of H2O2 > 5 % micro aerosol (Neighbor et al., 1994), and the inactivated virus by H2O2 still has the ability to induce an immune response in the same level as live viruses (Dembinski et al., 2014). When compared to the maximum removal of Paracetamol in Pharmacy wastewater, it reaches 80% with the use of O3: H2O2 (1: 0.25 or 25% H2O2). Therefore, to minimize costs, the use of H2O2 needs to be combined with ozone gas. Ozone is a selective oxidant, but the addition of H2O2 is generated in situ.

Table 3 Data of AI Virus of subtypes H5NI and H9N1 in wastewater of vaccine industry before and after inactivation with H2O2

Hydrogen peroxide is a strong, broad-spectrum inactivating agent that

can decompose into water, oxygen, and highly reactive hydroxyl free radicals

(•OH). These radicals can cleave or crosslink a wide range of biomolecules,

including proteins, nucleic acids, and lipids (Lisovskaya

et al., 2021). The H2O2

reaction in AI virus inactivation in the wastewater of the vaccine industry is

as follows: H2O2 acts as an oxidant by producing hydroxyl free radicals (•OH),

which attack the essential cell components, including lipids, proteins, and DNA

as well as RNA (Ofoedu et al., 2021; Elveborg, Monteil, and Mirazimi, 2022).

3.1. Inactivate of AI Virus in

wastewater of vaccine Industry with H2O2.

Table 3 shows the inactivation data of

H5N1 and H9N1 viruses by H2O2 at 2.0, 4.0, and

6.0%. The optimum inactivation was obtained at H2O2 of 6% with each No CT

and quantity

value of

approximately 0.0 units/0.1 mL, and the egg is still alive. This indicates that

the virus is inactive (dead) and is incapable of damaging the egg.

3.2. Inactivation of AI Virus in

the wastewater of Vaccine Industry with O3

The inactivation of AI viruses of

subtypes H5N1 and H9N1 by ozone in the wastewater of the vaccine Industry in

Table 4 shows a very significant effect. At 50 minutes of ozonation (0.0325 mg

O3/mL) for H5N1 viruses, the decrease in CT and the quantity of

viruses reaches 100%, namely No CT and a quantity of 0.0 units/mL or complete

inactivation. This is very important to restrict any possibility of DNA/RNA

mutations (Hossain,

2022). Meanwhile, AIH9 has a CT value of approximately

34.27, a virus quantity of 407.4 units/mL, and more glycogen than H5N1. Since

the viruses are in organic wastewater, H9N1 inactivation needs greater ozone (Kong et al., 2021).

AI virus is a single-stranded RNA virus that

can be decomposed by ozone (Martemucci et al., 2022; Blanco et al., 2021; Mostafa et al., 2018; Megahed, Aldridge, and Lowe, 2018) and radical OH from ozone decomposition.

3.3. Inactivation of AI Virus in

wastewater of Vaccine Industry with GAC

The inactivation of AI viruses of

subtypes H5N1 and H9N1 by GAC in Table 5 seems less effective, where at 10%

GAC, a quantity of 1,577.9 units/0.1 mL and 6,618.28 units/0.1 mL was detected

in the liquid waste. This indicated that it takes a GAC > 10% to achieve a

CT value and quantity of viruses of approximately 0. The removal of viruses

with GAC through the adsorption process depends on the dose of activated carbon

or adsorption capacity, the contact time between activated carbon and

adsorbate/virus (Zhang

et al., 2021; Dotto and McKay, 2020; Wang et al., 2020;

Matsushita et al., 2013).

3.4. Inactivate of AI Virus in

wastewater of vaccine Industry with O3/H2O2

and O3/GAC

Figure 2 The

quantity of AI viruses of the subtypes H5N1 and H9N1 in wastewater of the

vaccine industry after inactivation with O3/H2O2

and O3/GAC

Figure 3 Mechanism of AI Virus Degradation and Inactivation

with O3/GAC in wastewater of Industry of vaccine

3.5. Effect of O3/H2O2

and O3/GAC on the removal of COD, BOD, and TSS in liquid waste from

the vaccine industry

Figure 4 The effect inactivation of AI Virus of Subtype H5N1 and H9N1 with O3/H2O2 and O3/GAC on Removal TSS, COD and BOD in wastewater of Vaccines industrial of AI viruses

In O3/H2O2,

ozone decomposition in OH radicals becomes faster with the presence of H2O2

(Cuerda-Correa et

al., 2019; Wang et al., 2018), and it's a significant impact on the removal

of TSS, COD, and BOD

However,

COD and BOD still did not meet the quality standards of 300 mg/L and BOD 100

mg/L, respectively. The use of O3/GAC for the inactivation of viruses H5N1 and

H9N1 was less effective, as the percent removal of TSS, COD, and BOD was only

14.77% and 18.79%, 27.60%, and 26.32%, and 27.44% and 33.01%, respectively. Compared

to the Tofu Industrial wastewater, the COD reduction reached 46.26% and TSS

12.38% through a combination of ozonation (155 mg O3/hour) and GAC

(50 gr) (Karamah, Adripratiwi, and Anindita, 2018). Visual observations

also show that the results of wastewater treatment of the AI virus with O3/H2O2

are clearer than the use of O3/GAC, H2O2, and

GAC alone.

Advanced Oxidation Process (AOP) based on Ozone and

Hydrogen Peroxide (O3/H2O2) is proven to be

effective and economical in inactivating AI viruses (H5N1 and H9N1) in AI

vaccine industry wastewater. The use of ozone as much as 0.00013 g O3/ml

for 20 minutes and as much as 2% H2O2 can cause the AI virus to die with a CT of 0.0 unit/0.1 mL. Researchers suggest that

stakeholders from the Ministry of Environment have a policy so that liquid and

solid waste from the vaccine industry is treated using O3/H2O2

technology at least at the final processing stage before being discharged into

the environment. In addition, the use of AOP technology (O3/H2O2)

in vaccine wastewater treatment can simultaneously reduce TSS, COD, and BOD

values; 58% (86.42 mg/L), 49% (575 mg/L) and 52 % (304.42 mg/L). If the COD and

BOD values ??of vaccine industrial wastewater are large enough, then in

processing the amount of ozone can be increased by extending the processing

time or as alternative processing can be continued at the Wastewater Treatment

Plant (WWTP) which is already owned by the Vaccine Industry, so that the impact

on humans can be prevented, considering that the AI virus shows symptoms of

resistance to all types of drugs on the market. Whereas in drinking water

treatment, it is recommended that at the disinfection process stage it is

enough to use O3/GAC or Ozonation only if a pandemic situation

occurs. There are two problems encountered in this study, namely optimizing the

contact of ozone gas, H2O2 with the sample, so that the

removal of COD and BOD is maximized. In addition, researchers must ensure that

they have received the vaccine because the AI virus is zoonotic. The future

research, it is hoped that the AOP method will be tested against other virus

variants found in the wastewater, for example hospital wastewater.

Blanco, A., Ojembarrena, F.D.B., Clavo, B., Negro, C., 2021. Ozone Potential to Fight Against SAR-COV-2 Pandemic: Facts and Research Needs. journal Environmental Science and Pollution Research, Volume 28, pp. 16517–1653. DOI: 10.1007/s11356-020-12036-9

Beltrán, F.J., Rey, A., Gimeno, O. 2021. The Role of Catalytic Ozonation Processes on the Elimination of DBPs and Their Precursors in Drinking Water Treatment. Catalysts, Volume 11(4), pp. 521–584. DOI: 10.3390/catal11040521

Center for Disease Control and Prevention (CDCP), 2022. Influenza (Flu). https://www.cdc.gov (December, 27, 2023)

Chen, Y., Duan, X., Zhou, X., Wang, R., Wang, S., Ren, N.Q., Ho, S.H., 2021. Advanced Oxidation Processes for Water Disinfection: Features, Mechanisms and Prospects. Chemical Engineering Journal, Volume 409, p. 128207. DOI: 10.1016/j.cej.2020.128207

Chasanah, U., Yulianto, E., Zain, A.Z., Sasmita, E., Restiwijaya, M., Kinandana, A.W., Arianto, F., Nur, M., 2019. Evaluation of Titration Method on Determination of Ozone Concentration Produced by Dielectric Barrier Discharge Plasma (DBDP) Technology. Journal of Physics: Conference Series, Volume 1153, p. 012086. DOI: 10.1088/1742-6596/1153/1/012086

Cuerda-Correa, E.M., Alexandre-Franco, M.F., Fernández-González, C., 2020. Advanced Oxidation Processes for the Removal of Antibiotics from Water. An Overview., Journals Water, Volume 12 (1), pp 102–153. DOI:10.3390/w12010102

Dembinski, J.L., Hungnes, O., Hauge, A.G., Kristoffersen, A.-C., Haneberg, B., Mjaaland, S., 2014. Hydrogen Peroxide Inactivation of Influenza Virus Preserves Antigenic Structure and Immunogenicity. Journal of Virological Methods, Volume 207, pp. 232–237 DOI: 10.1016/j.jviromet.2014.07.003

Desmiarti, R., Martynis, M., Trianda, Y., Li, F., Viqri, A., Yamada, T., 2019. Phenol Adsorption in Water by Granular Activated Carbon from Coconut Shell. International Journal of Technology, Volume 10(8), pp. 1488–1497. DOI:10.14716/ijtech.v10i8.3463

Dotto, G.L., Mc Kay, G., 2020. Current Scenario and Challenges in Adsorption for Water Treatment. Journal of Environmental Chemical Engineering, Volume 8(4), pp. 103988–103994. DOI: 10.1016/j.jece.2020.103988

Dubuis, M.E., Racine, E., Vyskocil, J.M., Turgeon, N., Tremblay, C., Mukawera, E., 2021. Ozone Inactivation of Airborne Influenza and Lack of Resistance of Respiratory Syncytial Virus to Aerosolization and Sampling Processes. PLoS ONE, Volume 16(7), p. e0253022 DOI:: 10.1371/journal.pone.0253022

Elveborg, S., Monteil, V.M., Mirazimi, A., 2022. Methods of Inactivation of Highly Pathogenic Viruses for Molecular, Serology or Vaccine Development Purposes. Pathogens, Volume 11, p. 271. DOI: 10.3390/pathogens11020271

Everest, H., Billington, E., Daines, R., Burman, A., Iqbal, M., 2021. The Emergence and Zoonotic Transmission of H10Nx Avian Influenza Virus Infections. mBio, Volume 12(5), p. 1128. DOI: 10.1128/mBio.01785-21

Fan, X., Sokorai, K.J.B., Gurtler, J.B., 2020. Advanced Oxidation Process for The Inactivation of Salmonella Typhimurium on Tomatoes by Combination of Gaseous Ozone and Aerosolized Hydrogen Peroxide. International Journal of Food Microbiology, Volume 312, pp. 108387–108393. DOI: 10.1016/j.ijfoodmicro.2019.108387

Fu, L.Y., Wu, C.Y., Zhou, Y.X., Zuo, J., Song, G.Q., Tan, Y., 2019. Ozonation Reactivity Characteristics of Dissolved Organic Matter in Secondary Petrochemical Wastewater by Single Ozone, Ozone/H2O2, and Ozone/Catalyst. Chemosphere, Volume 233, pp. 34–43. DOI: 10.1016/j.chemosphere.2019.05.207

Huang, J., Wu, S., Wu, W., Liang, Y., Zhuang, H., Ye, Z., Qu, X., Liao, M., Jiao, P., 2021. The Biological Characteristics of Novel H5N6 Highly Pathogenic Avian Influenza Virus and its Pathogenesis in Ducks. Frontiers in Microbiol, Volume 12, pp. 628545-628551. DOI: 10.3389/fmicb.2021.628545

Hossain, F., 2022. Sources, Enumerations and Inactivation Mechanisms of Four Emerging Viruses in Aqueous Phase. Journal of Water and Health, Volume 20(2), pp. 396–440. DOI:10.2166/wh.2022.263

Jasim, B.A., Al-Furaiji, M.H., Sakran, A.I., Abdullah, W.I., 2021. A Competitive Study Using UV and Ozone with H2O2 in Treatment of Oily Wastewater. Baghdad Science Journal, Volume 17(4), pp. 1177–1182. DOI: 10.21123/bsj.2020.17.4.1177

Karamah, E.F., Adripratiwi, I.P., Anindita, L., 2018. Combination of Ozonation and Adsorption Using Granular Activated Carbon (GAC) for Tofu Industry Wastewater Treatment. Indonesia Journal of Chemistry, Volume 18 (4), pp. 600–606. DOI: 10.22146/ijc.26724

Kosik, I., Yewdell, J.W., 2019. Influenza Hemagglutinin and Neuraminidase: Yin–Yang Proteins Coevolving to Thwart Immunity. Viruses, Volume 11(4), pp. 346–364. DOI: 10.3390/v11040346

Kim, T.-K., Kim, T., Lee, I., Cjoi, K., Zoh, K.D., 2021. Removal of Tetramethylammonium Hydroxide (TMAH) in Semiconductor Wastewater Using the Nano-Ozone H2O2 Process. Journal Hazard Materials, Volume 409, p. 123759. DOI: 10.1016/j.jhazmat.2020.123759

Kong, J., Lu Y., Ren, Y., Chen, Z., Chen, M., 2021. The Virus Removal in UV Irradiation, Ozonation and Chlorination. Journal Water Cycle, Volume 2, pp. 23–31. DOI: 10.1016/j.watcyc.2021.05.001

Koutsakos, M., Kedzierska, K., Subbarao, K., 2019. Immune Responses to Avian Influenza Viruses. The Journal of Immunology, Volume 202 (2), pp. 382–391. DOI:10.4049/jimmunol.1801070

Lénès, D., Deboosere, N., Ménard-Szczebara, F., Jossent, J., Alexandre, V., Machinal, C., Vialette, M., 2010. Assessment of the Removal and Inactivation of Influenza Viruses H5N1 and H1N1 by Drinking Water Treatment. Water Research, Volume 44(8), pp. 2473–2486. DOI: 10.1016/j.watres.2010.01.013

Lisovskaya, A., Shadyro, O., Schiemann, O., Carmichael, I., 2021. OH-Radical Reactions with The Hydrophilic Component of Sphingolipids. Physical Chemistry Chemical Physics, Volume 23 (2), pp. 1639–1648. DOI: 10.1039/d0cp05972b

Li, D., Baert, L., De Jonghe, M., Van Coillie, E., Ryckeboer, J., Devlieghere, F., Uyttendaele, M., 2011. Inactivation of Murine Norovirus 1, Coliphage ?X174, and Bacillus fragilis Phage B40-8 on Surfaces and Fresh-Cut Iceberg Lettuce by Hydrogen Peroxide and UV Light. Applied and Environmental Microbiology, Volume 77(4), pp. 1399–1404. DOI: 10.1128/AEM.02131-10

Matsushita, T., Suzuki, H., Shirasaki, N., Matsui, Y., Ohno, K., 2013. Adsorptive Virus Removal with Super-Powdered Activated Carbon. Separation And Purification Technology, Volume 107, pp. 79–84. DOI: 10.1016/j.seppur.2013.01.017

Mostafa, A., Abdelwhab, E., Mettenleiter, T., Pleschka, S., 2018. Zoonotic Potential of Influenza A Viruses: A Comprehensive Overview. Viruses, Volume 10(9), pp. 497. DOI: 10.3390/v10090497

Megahed, A., Aldridge, B., Lowe, J., 2018. The Microbial Killing Capacity of Aqueous and Gaseous Ozone on Different Surfaces Contaminated with Dairy Cattle Manure. PloS one, Volume 13(5), p. e0196555. DOI: 10.1371/journal.pone.0196555.

Martemucci, G., Costagliola, C., Mariano, M., D’andrea, L., Napolitano, P., D’Alessandro, A.G., 2022. Free Radical Properties, Source and Targets, Antioxidant Consumption and Health. Oxygen, Volume 2(2), pp. 48–78. DOI:10.3390/oxygen2020006

Moersidik, S.S., Annasari, L., Nugroho, R., 2021. Application of Cavitation Ozonation Process on Recalcitrant Organic Matter Degradation from Stabilized Landfill Leachate. International Journal of Technology, Volume 12(1), pp. 78–89. DOI:10.14716/ijtech. v12i1.4284

Naguib, M.M., Verhagen, J.H., Samy, A., Eriksson, P., Fife, M., Lundkvist, Å., Ellstrom, P., Järhult, J.D., 2019. Avian Influenza Viruses at The Wild–Domestic Bird Interface in Egypt. Infection Ecology & Epidemiology, Volume 9(1), p. 1575687. DOI: 10.1080/20008686.2019.1575687.

Neighbor, N.K., Newberry, L.A., Bayyari, G.R., Skeeles, J.K., Beasley, J.N., Mc New, R.W., 1994. The Effect of Microaerosolized Hydrogen Peroxide on Bacterial and Viral. Poultry Science, Volume 73, pp. 1511–1516. DOI:10.3382/ps.0731511

Nur, M., Nidom, C.A., Indrasari, S., Ansori, A.N.M., Alamudi, M.Y., Nidom, A.N., Sumariyah, S., Sasmita, E., Yulianto, E., Kinandana, A.W., Usman, A., Kusala, M.K.J., Normalina, I., Nidom, R.V., 2022. A Successful Elimination of Indonesian SARS-CoV-2 Variants and Airborne Transmission Prevention by Cold Plasma in Fighting COVID-19 Pandemic: A Preliminary Study. Karbala International Journal of Modern Science, Volume 8 (3), pp. 446–454. DOI:10.53730/ijhs. v6nS5.11265

OIE, 2014. Avian Influenza Virus. Office International des Epizooties. https://www.woah.org (October, 03, 2020)

Ofoedu, C.E., You, L., Osuji, C.M., Iwouno, J.O., Kabuo, N.O., Ojukwu, M., Korzeniowska, M. 2021. Hydrogen Peroxide Effects on Natural-Sourced Polysacchrides: Free Radical Formation/Production, Degradation Process, and Reaction Mechanism—A Critical Synopsis. Foods, Volume 10(4), pp. 699–732. DOI: 10.3390/foods10040699

Rekhate, C.V., Srivastava, J.K., 2020. Recent Advances in Ozone-Based Advanced Oxidation Processes for Treatment of Wastewater-A Review. Chemical Engineering Journal Advances, Volume 3, pp. 100031–100049. DOI: 10.1016/j.ceja.2020.100031

Shimabuku, Q.L., Ueda-Nakamura, T., Bergamasco, R., Fagundes-Klen, M.R., 2018. Chick-Watson Kinetics of Virus Inactivation with Granular Activated Carbon Modified with Silver Nanoparticles and/or Copper Oxide. Process Safety and Environmental Protection, Volume 117, pp. 33–42. DOI: 10.1016/j.psep.2018.04.005

Suryawan, I.W.K., Septiariva, I.Y., Helmy, Q., Notodarmojo, S., Wulandari, M., Sari, N.K., Sarwono, A., Pratiwi, R., Lim, J., 2021. Comparison of Ozone Pre-Treatment and Post-Treatment Hybrid with Moving Bed Biofilm Reactor in Removal of Remazol Black 5. International Journal of Technology, Volume 12(4), pp. 728–738. DOI:10.14716/ijtech. v12i4.4206

Badan Standardidasi Nasional (BSN), 2019. SNI 6989.2:2019: Air dan Air Limbah – Bagian 2: Cara Uji Kebutuhan Oksigen Kimiawi (Chemical Oxygen Demand/COD) dengan Refluks Tertutup Secara Spektrofotometri (SNI 6989.2:2019: Water and Wastewater – Part 2: Method of Testing Chemical Oxygen Demand (COD) with Closed Reflux Spectrophotometrically). Badan Standardidasi Nasional

Tizaoui, C., 2020. Ozone: A Potential Oxidant for COVID-19 Virus (SARS-CoV-2). Ozone: Science & Engineering, Volume 42(5), pp. 1–8. DOI:10.1080/01919512.2020.1795614

Uppal, T., Khazaieli, A., Snijders, A.M., Verma, S.C., 2021. Inactivation of Human Coronavirus by FATHHOME’s Dry Sanitizer Device: Rapid and Eco-Friendly Ozone-Based Disinfection of SARS-CoV-2. Pathogen, Volume 10, pp. 339–356. DOI: 10.3390/pathogens10030339

Vatankhah, H., Riley, S.M., Murray, C., Quiñones, O., Steirer, K.X., Dickenson, E.R.V., Bellona, C., 2019. Simultaneous Ozone and Granular Activated Carbon for Advanced Treatment of Micropollutants in Municipal Wastewater Effluent. Chemosphere, Volume 234, pp. 845–854. DOI: 10.1016/j.chemosphere.2019.06.082

Vega, E., Valdés, H., 2018. New Evidence of The Effect of The Chemical Structure of Activated Carbon on The Activity to Promote Radical Generation in An Advanced Oxidation Process Using Hydrogen Peroxide. Microporous and Mesoporous Materials, Volume 259, pp. 1–8. DOI:10.1016/j.micromeso.2017.09.018

Verinda, S.B., Muniroh, M., Yulianto, E., Maharani, N., Gunawan, G., Amalia, N.F., Hobley, J., Usman, A., Nur., M., 2022. Degradation of Ciprofloxacin in Aqueous Solution Using Ozone Microbubbles: Spectroscopic, Kinetics, and Antibacterial Analysis. Heliyon, Volume 8, pp. 10137–10147. DOI: 10.1016/j. heliyon. 2022. e10137.

Vimbert, M.R., Loyo, A.M., Sánchez, C.D., Raurich, G.J., Asensio, M.P., 2020. Evidence of OH·Radicals Disinfecting Indoor Air and Surfaces in A Harmless for Humans Method. International Journal of Engineering Research & Science (IJOER), Volume 6(4), pp. 26–38. DOI:10.5281/zenodo.3767883

Wang, H., Zhan, J., Yao, W., Wang, B., Deng, S., Huang, J., Wang, Y., 2018. Comparison Of Pharmaceutical Abatement in Various Water Matrices by Conventional Ozonation, Peroxone (O3/H2O2), and An Electro-Peroxone Process. Water Research, Volume 130, pp. 127–138. DOI: 10.1016/j.watres.2017.11.054

Wang, T., Song, Y., Ding, H., Liu, Z., Baldwin, A., Wong, I., Zhao, C., 2020. Insight Into Synergies Between Ozone and In-Situ Regenerated Granular Activated Carbon Particle Electrodes in A Three-Dimensional Electrochemical Reactor for Highly Efficient Nitrobenzene Degradation. Chemical Engineering Journal, Volume 349, pp. 124852–124862. DOI: 10.1016/j.cej.2020.124852

Zhang, Y., Wang, R., Qiu, G., Jia, W., Guo, Y., Guo, F., and Wu, J., 2021. Synthesis of Porous Material from Coal Gasification Fine Slag Residual Carbon and Its Application in Removal of Methylene Blue. Molecules, Volume 26(20), pp. 6116–6131. DOI: 10.3390/molecules26206116