Adhesives Type on the Burning Rate and Emission Properties of Honeycomb Sandwich Composite

Corresponding email: arsubmt@unud.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5728

Adhi, I.G.A.K.C., Atmika, K.A., Dwidiani, N.M., Subagia, I.D.G.A., 2024. Adhesives Type on the Burning Rate and Emission Properties of Honeycomb Sandwich Composite. International Journal of Technology. Volume 15(4), pp. 999-1011

| I Gusti Agung Ketut Catur Adhi | Department of Mechanical Engineering, Mataram University, Nusa Tenggara Barat, 83121, Indonesia |

| Ketut Adi Atmika | 1. Mechanical Engineering Study Program, Udayana University, Bukit Jimbaran 80361, Badung-Bali, Indonesia 2. Technology and Material Research Centre, the Institution of Research and Community Servic |

| Ni Made Dwidiani | Mechanical Engineering Study Program, Udayana University, Bukit Jimbaran 80361, Badung-Bali, |

| I Dewa Gede Ary Subagia | 1. Mechanical Engineering Study Program, Udayana University, Bukit Jimbaran 80361, Badung-Bali, Indonesia 2. Materials Engineering Laboratory, Engineering Faculty, Udayana University, Bukit Jimbaran |

Sandwich composite is an important part of engineering products capable

of replacing metallic composite. It consists of two types of material, namely

polypropylene honeycomb core and skin made from jute fiber-reinforced epoxy

composite (JFRP), which are joined with glue. This study presented a unique

discussion about adhesives that focused on the burning rate and emission

performance of SA-A and SD-E. The burning rate performance was

assessed with the UL-94 HB test in accordance with the ASTM D 635 standard.

Emission value of both adhesives was also examined in line with the ASTM D 2863

standard using a Gasboard-3100P Syngas analyzer. In addition, FTIR and SEM

analyses were used to determine the characteristics of the SA-A and

SD-E adhesives. The results showed a significant difference in

adhesives rates, with SA-A burning 0.5% faster than SD-E

in addition to a 0.58% reduced weight loss. Emission test confirmed that both

adhesives have similar LOI values of 22.6% and 22.8%, respectively. SA-A

adhesives contained LSD, which is dangerous to human health. In conclusion, SD-E

adhesives should be used on sandwich composite due to its epoxy-based potential

as a flame retardant because SA-A adhesives has more potential to

trigger firing due to the fuel content.

Adhesives; Burning rate; Emission; Fire; Sandwich composite

Sandwich composite structures are widely used in manufacturing

engineering products, and it consist of three components, namely skin, core and

adhesives (Jeevi, Nayak, and Abdul-Kader, 2019;

Novotný, Doubrava, and Ružicka, 2017). The thick

core is covered by a pair of thin skins (Wei et al., 2020). Sandwich

composite structures are characterized by the lightweight nature, production

ease, strong mechanical properties and are highly used in manufacturing

airplanes, automobiles, ships, and packaging, including electrical insulators,

energy absorption, and other industrial purposes (Rupani, Acharya, and Jani,

2017).

Failure caused by fire has become increasingly relevant in recent years (Suwondo et al., 2021), despite the numerous benefits of composite materials, one significant disadvantage is the highly inflammable nature (Zhu et al., 2020). Fire performance was determined based on factors such as ignition, self-extinguishing ability, flame spread, burn through, heat release, smoke obscuration, toxicity, and related scenarios. Therefore, the process of assessing the resistance of composite materials is needed to examine the ability to perform the intended load-bearing functions when exposed to fire. Several studies have extensively examined fire performance of composite materials (Ortega et al., 2020; Hörold et al., 2017; Suoware, Ezema, and Edelugo, 2017; Salmeia et al. 2016; Bar, Alagirusamy, and Das, 2015; Szolnoki et al., 2015). However, the most widely accepted study focused on an experiment conducted by incorporating fire retardant into the polymer matrix. The aim was to suppress heat release, increased temperature, and gas emission, perceived as toxic sources, through the solid and gaseous phase mechanism (Ogabi et al., 2021; Kim, Dutta, and Bhattacharyya, 2018).

These properties need to be considered

when studying the combustibility of honeycomb-based composite materials. According

to Kim, Dutta, and Bhattacharyya (2018), several

factors such as the chemical composition, physical features, load-bearing

capacity of adhesives, surface condition of the joints, and the use of

materials that do not adhere to health standards significantly affect the

toxicity of emitted smoke (Jeevi, Nayak, and Abdul-Kader, 2019; Ledesma et al., 2018). Preliminary

studies stated that synthetic adhesives, such as structural silicone, or

stiffer substances namely acrylic or epoxy are commonly used for assembling

composite materials (Shang et

al., 2020; Valente et al., 2019; Ledesma et al., 2018;

Machalická and Eliášová, 2017). However,

thermosetting types such as phenol-formaldehyde (PF), urea-formaldehyde (UF),

and polyurethane (PU) are currently been used due to the water-resistant

properties (Chanda, Kim, and Bhattacharyya, 2022; Shavandi and Ali, 2018). The

application of adhesives in non-metallic structural materials has numerous

benefits, including uniform stress distribution, eliminating the need for

drilling, and enabling the bonding of substances with varying mechanical and

thermal properties. Sugiman and Sulardjaka (2016), stated that

adhesives play a critical role in the bonding of materials. Arenas, Narbón, and Alía (2010), stated that joint strength

is inversely proportional to the thickness of adhesives, meaning the shear

strength increases as the thickness of adhesives decreases. Davies et al. (2009), examined the physical,

chemical, and mechanical properties of Aluminium substrates bonded with epoxy

adhesives of varying thicknesses ranging from 0.2 to 1.3 mm. However, there is

no proof that varying thickness can weaken composite materials (Kostin, Nasonov, and Zinin, 2021;

Momber, Fröck, and Marquardt, 2021; Shang et al. 2020; Jeevi, Nayak, and

Abdul-Kader, 2019; Shavandi and Ali, 2018).

Adhesives are an essential aspect of

sandwich composite structures that bond the core and skin. Generally, the

liquid types such as SA-A and SD-E are commonly used due

to ease of application. Aica-Aibon (SA-A), a kind of poly-chloroprene-based

glue with toluene characteristics (C7H8) (Tualeka et al., 2019; Djurendic-Brenesel, Stojiljkovic,

and Pilija, 2016), contains lysergic acid

diethylamide (LSD) with the chemical formula C20H25N3O.

LSD is a synthetic narcotic drug that causes mental disorders when consumed

excessively. Liao et al. (2020) stated that when SA-A

is burned, it tends to have minimal impact on the surrounding environment.

Meanwhile, Dextone-Epoxy (SD-E) is an

epoxy-based adhesive dependent on epoxy resin and one of the most essential

polymer classes due to the multiple binding capacities provided by the oxirane

ring. Due to the significant differences in the source materials, studying the

flame and emission of these adhesives becomes interesting. This study mainly focused on examining the impact of flammability and emission on

adhesives used in sandwich composite. Furthermore, both adhesives were tested

concerning the application process in honeycomb composite to evaluate burning

rate and emission. The aim is to investigate the potential roles as triggers

for fuel fire and the resulting emission. The tests were carried out based on

ASTM D 635 and 2863 standards to determine both adhesives burning rate and

emission.

2.1.

Materials

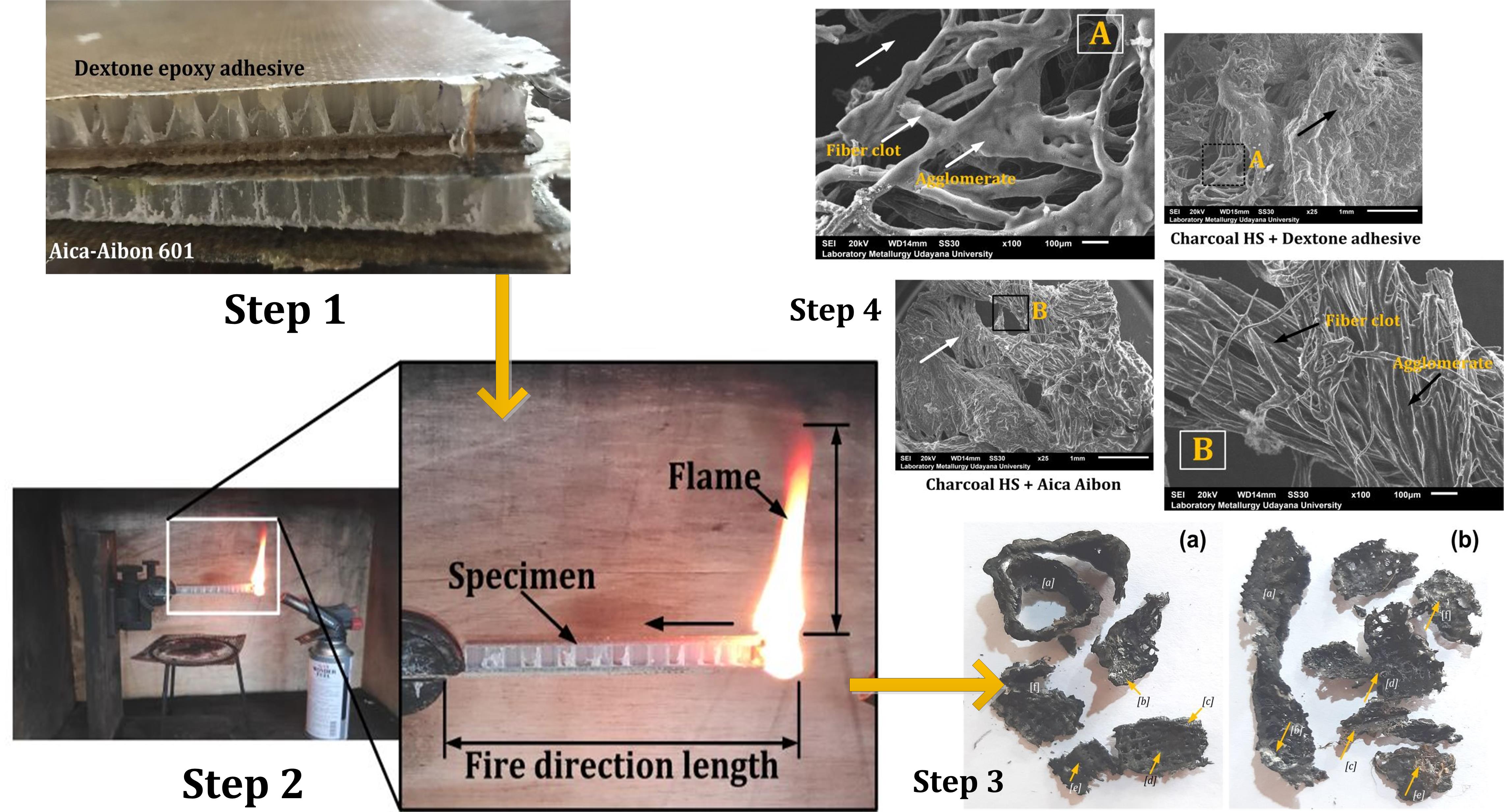

Sandwich composite panel comprised three

main parts, namely skins, adhesives, and honeycomb core. A typical example is

the natural jute fiber, produced by Casthanal Textile CIA in Brazil, shown in

Figure 1 (Gupta, Srivastava, and Bisaria, 2015).

The fiber has relatively low conductivity, ranging from 0.29 to 0.32/mK, as

well as composite matrix materials, namely Bakelite Korea epoxy resin

Bakelite-EPR-174 and Justus Kimia-Raya cycloaliphatic amine curing agent

Bakelite-EPH-555, shown in Tables 1 and 2.

Polypropylene honeycomb (PPH),

particularly a Nomex 8 mm mesh, was used as the core of composite sandwich.

This material has a low density and good performance function as a shear

load-carrying core in sandwich composite construction. PPH is a hexagonal

structure with equal sides and six interior angles of the same dimension

measuring 1200, as shown in Figure 2.

Figure 2 Geometry and

cross-section of honeycomb

After

SD-E is an epoxy-based adhesive containing epichlorohydrin

bisphenol-A (DGEBA) in the formulation. Epoxy resin is characterized by

low-molecular-weight comprised of oxirane or epoxide rings as functional

groups, imparting thermosetting properties. This makes epoxy resin a commonly and widely used material in various applications,

including adhesives, coatings, semiconductor packaging, and composite matrices.

The specific SD-E adhesive characteristics

are shown in both Tables 2 and 3.

2.2.

Sandwich composite structures

Sandwich composite panel used in the experiment was 350 mm x 350 mm in

size. A panel with three layers of 2 mm thick jute fiber reinforcement was used

as the skin of composite. In addition, the panel was manufactured using the

vacuum injection process (VaRTM), with the core bonded to both skins using two

different types of synthetic adhesives. Figure 3 and Table 4 show sandwich

composite and specimen structures using both SA-A and SD-E

adhesives, respectively.

Figure

4 shows the geometry of the sample and burning test schema following the ASTM D

635 standards. The specimen used was composed of three segments measuring 125

mm in length. The first segment, positioned 25 mm from the free end, was the

initial burning area. The subsequent and final ones, which served as burning

test and clamping areas, were 75 mm and 25 mm long, respectively.

2.3. Analytical

Method

where LOI is the limiting oxygen index (%) (Parmar et al. 2014), O2 and N2 are

denoted as oxygen and nitrogen. L is the distance between two marking lines (75 mm), t is fire

spreading time (minutes), FP is the flame propagation (mm/second), Dp

is the propagation distance (mm), Pt is fire propagation time

(second), and Lt is burning time (second).

where W is the total weight loss after burning (gram/sec), w

is the weight loss of the specimen during the burning process, w0

is the initial weight (gram), w1 is the final weight (gram),

and t is the burning time (second).

2.4. FT-IR spectroscopic analysis

The characteristics of adhesives in

sandwich composite were measured using Fourier transform infrared spectroscopy

(FTIR) spectra obtained with a Shimadzu spectrometer. The signal resolution of

the FTIR was 1 cm-1, and a minimum of 16 scans were obtained

and averaged within the range of 500 to 4000 cm-1.

2.5. Scanning

electron microscopy (SEM)

The residue

from the horizontal burning test on sandwich composite was subjected to SEM

analysis using a JSM-6510 from Japan. In addition, the residue surface was

coated with gold before being tested.

3.1. FTIR analysis

Figure 5 FT-IR spectra pattern adhesives of SA-A

and SD-E

Analysis of the

FTIR spectra comparing the SA-A (red line) and SD-E adhesives

(blue line) shows significant differences. The O-H stretching region in the

absorbance range of 2500 cm-1 to 3000 cm-1 showed there

was a peak shift of 2936 cm-1 and 2924 cm-1 for SD

–E and SA-A. However, within an absorbance range of 2000 cm-1

to 2500 cm-1, SD-E had increased energy compared to SA-A,

depicting a greater tendency for bond breaking, thereby contributing to

enhanced stability and reduced flammability. The characteristic peaks for C-O-C

ether and aromatic C-C stretching were observed at 1036 cm-1 and

1509 cm-1, respectively. The stretching C=C in the aromatic ring was

observed at 1608 cm-1, while C-H bending bands occurred within the

absorbance range of 500 cm-1 to 1000 cm-1.

3.1. Burning

Rate

The

recent focus on building fire has proven the importance of understanding the

material types used (Suwondo et

al., 2021). Building materials and equipment types have

been identified as the main factors contributing to the frequency of these fire

(Nugroho, Latief, and Wibowo, 2022). The

combustibility of a material depends on various factors related to the

constituents, which impact characteristics such as heat release, flame spread,

and ignitability (Pausas, Keeley, and Schwilk, 2017). In addition, the presence of adhesives used to bond the skin and core

of sandwich composite was considered fire reaction properties, as shown in

Table 5.

Figure 6 Comparison of adhesives

on burn test and weight loss of honeycomb composite

Figure 6 shows a bar graph of burning

rate and weight-loss combination of sandwich composite using SA-A

and SD-E adhesives. The use of dark colour shows there is a

significant difference in burning rate between sandwich composite using SA-A

and SD-E. This was caused by the different chemical compound

properties of both adhesives, as shown in Figure 5. SA-A is an

elastomer-based adhesive that can function as thermoplastic and thermosetting

types, depending on the required cross-linked structure. It is also

characterized by rapid

adhesion and belongs to a group of elastomers with rubber-based adhesives,

including butyl, butadiene, styrene-butadiene, and nitrile rubber, as well as

silicone, and neoprene (Wang et al., 2022). However, adhesiveness and cohesion levels are

limited at temperatures greater than 70°C, and a stabilizer is needed to

withstand environmental effects such as UV and ozone. Adhesives can be dried at

normal temperatures and has good heat, water, and chemical resistance,

depending on the contents of the hardening compounds. SA-A adhesives

characterized based on FTIR analysis, showed features of a rubber-based

composition,

for example, C=C aromatic

bonds observed at a wavenumber of 1656.92 cm-1. Meanwhile, the

aliphatic C-H or C-C hydrocarbon groups that trigger the flame were observed in

the wavenumber range of 2000 cm-1 to 2500 cm-1 with a

prominent peak at 2358.08 cm-1 and an intensity of 79.64 mm. SD-E adhesives are epoxy-based, mainly

synthesized from active hydrogen reactions in phenols, alcohols, amines, and

acids with epichlorohydrin under well-controlled conditions. Generally, SD-E

adhesives were prepared by packing epoxy and curing agent composition

separately before use, with curing occurring briefly after mixing in accordance

with the mixing ratio. Epoxy adhesives such as SD-E often have a higher

glass transition temperature, making it suitable for applications requiring

high-temperature resistance. In FTIR analysis, the epoxy tends to react with amines and amides

(NH) at frequencies ranging from 3140 to 3320 cm-1. The deformation

band of C-O occurred at 828.46 cm-1 within the wavenumber range of 750 cm-1

to 1000 cm-1. In the spectrum range, characteristics of the aromatic

ring were observed, double chain, benzene and C-C aromatics, C-O-C chain from

the ether, C-O chain of oxirane group, and CH2 chain were formed at

wavenumbers of 1606 cm-1, 1506 cm-1, 1031 cm-1,

913 cm-1, 862 cm-1 and 769 cm,-1 respectively.

The stretching of hydroxyl groups of O-H was depicted by broadband at 3500 cm-1,

suggesting the presence of species and dimers of high molecular weight. In

addition, a band corresponding to the ether linkage was observed within the

1000 to 1100 cm-1 spectrum range.

The average combustion

length of the SA-A and SD-E adhesives was 75 mm and 72

mm, respectively. The results showed the carbon composition of the SA-A adhesives

possessed higher fuel propagation capacity compared to the SD-E,

which had greater fire resistance. This result is in line with the study conducted by Chanda, Kim, and

Bhattacharyya (2022), focusing on the significant influence of adhesive

formulation materials on fuel value. The burning rate of each sandwich

composite sample using the SA-A adhesives was 0.5% faster than the SD-E.

The difference was caused by certain thermos-physical properties, such as the

reaction rate depending on the temperature threshold or higher amount of oxygen

(O2) during the combustion process, leading to increased heat energy

(Ogabi et al., 2021). Table 5 shows the burning time of the two

adhesives used.

In Figure 6, the result of

the weight loss measures in the bar graph is shown in grey. The result is

similar to the burning rate, and the weight loss of SA-A adhesive

samples has a higher value than SD-E, with a significant difference

of 0.58%. This difference directly correlates with the degradation of the

samples caused by increased heat and smoke production. The higher weight loss

and low percentages of mass residues observed in the SA-A samples

were attributed to the pyrolysis and burning phases, depicting a prolonged

exposure to heat flux. These results are in line with previous studies (Vinod et al., 2022).

3.2. Burning Emission

Table 6 shows emission from burning

sandwich composite, which were tested to determine the environmental effects of

burning adhesives. When burned, adhesives in composite emits carbon dioxide (CO2)

and carbon monoxide (CO) as combustion products, which is proven by the results

of the FTIR test shown in Figure 5. However, both SA-A and SD-E

adhesives generated the same quantity of oxygen, measured at 20.9 mg/m3.

The NO2 produced by the SA-A adhesives is slightly

greater than SD-E by 0.01%, the two materials have similar LOI

values of approximately 22.6% and 22.8%, respectively. The difference in

burning behavior was caused by the higher carbon content in SD-E,

which formed a denser carbon layer, preventing heat transfer during the burning

process. There is a definite relationship between burning rate and oxygen

content, with a threshold of 21%. Materials with an LOI less than this

threshold are typically regarded as flammable or combustible and would burn

readily in an open-air setting, while a higher index showed lower flammability (Raajeshkrishna and Chandramohan, 2020). When the oxygen content drops below the critical LOI values, the

material ceases to burn because the available oxygen is insufficient for

combustion. However, a high LOI value, minimizes burning potential and oxygen

concentration, in order to sustain combustion (Misnon et al., 2018). LOI is a distinguishing characteristic of materials, often used to rank

the relative flammability of polymer composite materials (Raajeshkrishna and Chandramohan, 2020;

Chukwunwike et al., 2019; Bhattacharyya and Kim, 2017).

3.3.

Burning residue

Figures 7a and b show the charcoal from sandwich composite with SA-A

and SD-E adhesives, respectively. The characteristics of the

charcoals depend on the quantity of lignin and cellulose content in the jute

fiber and properties of the polypropylene in the core. Furthermore, Charcoal

produced from poly-propylene is more reflective and contains the following

compounds CO, CO2, HC2, NO2, and CxHx.

The elements produced from combustion are also described in the spectral range

of the FTIR test for each adhesive applied in the bonding of sandwich

composite. This implied that the chemical breakdown of each adhesive sample

contributed to the formation of oxides and other degradation products, forming

the crosslinking network that produced the coal. Meanwhile, the LSD element

contained in the SA-A adhesives was in the form of CxHx,

which is harmful when inhaled.

Figure 8 Photography SEM adhesive residue after the burning process. a) SEM SD-E

adhesives, b) SEM SA-A adhesives

In

conclusion, adhesives were critical in sandwich composite structures, directly

impacting the burning rate. To address the flammability of composite, it was

necessary to incorporate materials or substances capable of inhibiting the

burning rate. Synthetic adhesives such as SA-A and SD-E were

used to bond the skin to the core of sandwich composite. The results showed

that sandwich composite's burning rate using SA-A adhesives was 0.5%

faster, with a weight loss of 0.58% greater than SD-E. Emission test

results for both samples had a comparatively similar LOI value of 22.6% and

22.8%, respectively. Therefore, adhesives significantly impacted burning rate

and composite emission, depending on the presence of flammable substances

contained in the constituents. The

SA-A adhesives posed a significant risk when burned due to its

aromatic nature and the presence of LSD elements, which could be harmful when

inhaled. However, SD-E adhesives only showed the aromatic properties

when burned. The use of SA-A adhesives on sandwich composite

materials posed a greater risk compared to SD-E. This was due to the

potential of SA-A adhesives to ignite more intense fire attributed

to the contained benzene. So, it was suggested that using SA-A

adhesives in materials subjected to high temperatures and susceptible to

flammability be avoided.

The authors are grateful to the Institution of Research and

Community Service for their financial support. The authors are also grateful to

the Udayana University and the Indonesian Ministry of Education, Culture, and

Research for the grant under contract number B/136-8/UN14.4.A/PT.01.05/2021.

| Filename | Description |

|---|---|

| R3-MME-5728-20230817232633.jpg | Replace Figure 5 |

Arenas, J.M., Narbón, J.J., Alía, C., 2010.

Optimum Adhesive Thickness in Structural Adhesive Joints Using Statistical

Techniques Based on Weibull Distribution. International Journal of Adhesion

and Adhesives, Volume 30(3), pp. 160–165.

Bar, M., Alagirusamy, R., Das, A., 2015.

Flame Retardant Polymer Composites. Fibers and Polymers, Volume 16(4),

pp. 705–717

Bhattacharyya, D., Kim, N.K., 2017.

Flammability of Natural Fiber-Reinforced Polymeric Composites. In: ICCM

International Conferences on Composite Materials, Volume 2017, pp. 1–9

Chanda, A., Kim, N.K., Bhattacharyya, D.,

2022. Effects of Adhesive Systems On The Mechanical and Fire-Reaction

Properties of Wood Veneer Laminates. Composites Science and Technology,

Volume 230, p. 109331

Chukwunwike, S.A., Ike-Eze, I.E., Aigbodion,

V.S., Okafor, K.J., 2019. Flammability

Properties of Flame Retarded Natural Fiber Reinforced Polymer Composites: An

Overview. Journal of Materials and Environmental Sciences, Volume 10(7),

pp. 647–656

Davies, P., Sohier, L., Cognard, J.Y.,

Bourmaud, A., Choqueuse, D., Rinnert, E., Créac’hcadec, R., 2009. Influence of

Adhesive Bond Line Thickness on Joint Strength. International Journal of

Adhesion and Adhesives, Volume 29(7), pp. 724–736

Djurendic-Brenesel, M., Stojiljkovic, G.,

Pilija, V., 2016. Fatal Intoxication with Toluene Due to Inhalation of Glue. Journal

of Forensic Sciences, Volume 61, pp. 875–878

Gupta, M.K., Srivastava,

R.K., Bisaria, H., 2015. Potential of Jute Fibre

Reinforced Polymer Composites?: A Review. International Journal of Fiber and

Textile and Research, Volume 5(3), pp. 30–38

Hörold, A., Schartel, B., Trappe, V., Korzen,

M., Bünker, J., 2017. Fire Stability Of Glass-Fibre Sandwich Panels: The

Influence of Core Materials And Flame Retardants. Composite Structures,

Volume 160, pp. 1310–1318

Jeevi, G., Nayak, S.K., Abdul-Kader, M.,

2019. Review on Adhesive Joints and Their Application In Hybrid Composite

Structures. Journal of Adhesion Science and Technology, Volume 33(14),

pp. 1497–1520

Kim, N.K., Dutta, S., Bhattacharyya, D.,

2018. A review of Flammability of Natural Fibre Reinforced Polymeric

Composites. Composites Science and Technology, Volume 162, pp. 64–78

Kostin, V., Nasonov, F., Zinin, A., 2021.

Influence of Adhesive Bond Line Thickness on Joint Strength of Composite

Aircraft Structures. Journal of Physics: Conference Series, Volume

1925(1), pp. 724–736.

Ledesma, R., Yost, W., Palmieri, F., Cataldo,

D., Connell, J., 2018. Correlation of Optically Stimulated Electron Emission

with Failure Mode of Adhesively Bonded Epoxy Composites. International

Journal of Adhesion and Adhesives, Volume 84, pp. 257–264

Lee, C. H., Salit, M.S., Hassan, M.R., 2014.

A Review of The Flammability Factors of Kenaf and Allied Fibre Reinforced

Polymer Composites. Advances in Materials Science and Engineering,

Volume 2014, p. 514036

Liao, B., Yang, L., Ju, X., Peng, Y., Gao,

Y., 2020. Experimental Study on Burning and Toxicity Hazards of a PET Laminated

Photovoltaic Panel. Solar Energy Materials and Solar Cells, Volume 206,

p. 110295

Machalická, K., Eliášová, M., 2017. Adhesive

Joints in Glass Structures: Effects of Various Materials in The Connection,

Thickness of The Adhesive Layer, and Aging. International Journal of

Adhesion and Adhesives, Volume 72, pp. 10–22

Misnon, M.I., Islam, M.M., Epaarachchi, J.A.,

Chen, H., Goda, K., Khan, M.T.I., 2018. Flammability Characteristics of

Chemical Treated Woven Hemp Fabric Reinforced Vinyl Ester Composites. Science

and Technology of Materials, Volume 30(3), pp. 174–188

Momber, A.W., Fröck, L., Marquardt, T., 2021.

Effects of Adhesive Type on The Mechanical Properties of Adhesive Joints

Between Polyurethane Top Coats and Polyurethane-Based Adhesives After

Accelerated Atmospheric Aging. Marine Structures, Volume 79, p. 103022

Novotný, C., Doubrava, K., Ružicka, M., 2017.

Testing Of Adhesive Joints In Sandwich Structures. Materials Today:

Proceedings, Volume 4(5), pp. 5898–5903

Nugroho, P.S., Latief, Y., Wibowo, W., 2022.

Structural Equation Modelling For Improving Fire Safety Reliability through

Enhancing Fire Safety Management on High-Rise Building. International

Journal of Technology, Volume 13(4), pp. 740–750

Ogabi, R., Manescau, B., Chetehouna, K.,

Gascoin, N., 2021. Composites and Their Gaseous Emission Assessment. Energy,

Volume 14, pp. 1–32

Ortega, R., Monzón, M.D., Ortega, Z.C.,

Cunningham, E., 2020. Study and Fire Test of Banana Fibre Reinforced Composites

with Flame Retardance Properties. Open Chemistry, Volume 18(1), pp.

275–286

Parmar, M.S., Singh, M., Tiwari,

R.K., Saran, S., 2014. Study on Flame Retardant Properties Of

Poly(Lactic Acid) Fiber Fabrics. Indian Journal of Fibre and Textile

Research, Volume 39(3), pp. 268–273

Pausas, J.G., Keeley, J.E., Schwilk, D.W.,

2017. Flammability as an Ecological and Evolutionary Driver. Journal of

Ecology, Volume 105(2), pp. 289–297

Raajeshkrishna, C.R., Chandramohan, P., 2020.

Effect of Reinforcements and Processing Method on Mechanical Properties of

Glass and Basalt Epoxy Composites. SN Applied Sciences, Volume 2 (5), p.

959

Rupani, S.V., Acharya, G., Jani,

S.S., 2017. Design, Modelling and Manufacturing aspects of Honeycomb

Sandwich Structures: A Review. International Journal of Scientific

Development and Research, Volume 2(4), pp. 526–532

Salmeia, K.A., Jovic, M., Ragaisiene,

A., Rukuiziene, Z., Milasius, R., Mikucioniene, D., Gaan, S., 2016. Flammability of Cellulose-Based Fibers and The Effect of Structure of

Phosphorus Compounds On Their Flame Retardancy. Polymers, Volume 8 (8),

p. 293

Shang, X., Marques, E.A.S., Carbas, R.J.C.,

Barbosa, A.Q., Jiang, D., da Silva, L.F.M., Chen, D., Ju, S., 2020. Fracture

Mechanism of Adhesive Single-Lap Joints with Composite Adherends Under

Quasi-Static Tension. Composite Structures, Volume 251, p. 112639

Shavandi, A., Ali, A., 2018. A New Adhesive

From Waste Wool Protein Hydrolysate. Journal of Environmental Chemical

Engineering, Volume 6(5), pp. 6700–6706

Sugiman, Sulardjaka, 2016. Water Absorption

and Desorption Behavior and Their Effect on The Tensile Properties of FM 73M

Adhesive Film. International Journal of Technology, Volume 7(3), pp.

438–446

Suoware, T.O., Ezema, I.C., Edelugo, S.O.,

2017. Flammability of Flame Retarded Natural Fibre Composites and Application

in Automobile Interior: A Review. Imperial Journal of Interdisciplinary

Research, Volume 3(8), pp. 2454–1362

Suwondo, R., Cunningham, L., Gillie, M.,

Suangga, M., Hidayat, I., 2021. Model Parameter Sensitivity for Structural

Analysis of Composite Slab Structures in Fire. International Journal of

Technology, Volume 12(2), pp. 339–348

Szolnoki, B., Bocz, K., Soti, P.L., Bodzay,

B., Zimonyi, E., Toldy, A., Morlin, B., Bujnowicz, K., Marosi, G., 2015.

Development of Natural Fibre Reinforced Flame Retarded Epoxy Resin Composites. Polymer

Degradation and Stability, Volume 119, pp. 68–76

Tualeka, A.R., Wibrata, D.A., Ilmi,

B., Ahsan, A., Rahmawati, P., 2019. Association Between

Toluene Inhalation Exposure and Demography Towards Risk of Neurotoxic: A

Cross-Sectional Study at Plastic Sack Industry Workers in Indonesia. Global

Journal of Health Science, Volume 11(2), p. 20

Valente, J.P.A., Campilho, R.D.S.G., Marques,

E.A.S., Machado, J.J.M., Da Silva, L.F.M., 2019. Adhesive Joint Analysis Under

Tensile Impact Loads By Cohesive Zone Modelling. Composite Structures,

Volume 222, p. 110894

Vinod, A., Tengsuthiwat, J., Gowda, Y.,

Vijay, R., Sanjay, M.R., Siengchin, S., Dhakal, H.N., 2022. Jute/Hemp Bio-Epoxy

Hybrid Bio-Composites: Influence of Stacking Sequence on Adhesion of

Fiber-Matrix. International Journal of Adhesion and Adhesives, Volume

113, p. 103050

Wang, W., Wang, D., Xia, B., Li, T., Wang,

Y., Zhang, X., Bai, H.,Chen, M., Dong, W., 2022. Rigid Polyurethane Foams Based

on Dextrin and Glycerol. Industrial Crops and Products, Volume 177, p.

114479

Wei, X., Xiong, J., Wang, J., Xu, W., 2020.

New Advances in Fiber-Reinforced Composite Honeycomb Materials. Science

China Technological Sciences, Volume 63(8), pp. 1348–1370

Zhu, C., Li, S., Li, J., Clement, M., Rudd,

C., Yi, X., Liu, X., 2020. Fie Performance of Sandwich Composites with

Intumescent Mat Protection: Evolving Thermal Insulation, Post-Fire Performance

and Rail Industry Testing. Fire Safety Journal, Volume 116, p. 103205