Baby Incubator with Overshoot Reduction System using PID Control Equipped with Heart Rate Monitoring Based on Internet of Things

Corresponding email: anitamiftah@poltekkesdepkes-sby.ac.id

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.5678

Irianto, B.G, Maghfiroh, A.M., Sofie, M., Kholiq, A., 2023. Baby Incubator with Overshoot Reduction System using PID Control Equipped with Heart Rate Monitoring Based on Internet of Things. International Journal of Technology. Volume 14(4), pp. 811-822

| Bambang Guruh Irianto | Departement of Electromedical Enginering, Politeknik Kesehatan Kemenkes Surabaya, Jalan Pucang Jajar Tengah No.56, Surabaya 60282, Indonesia |

| Anita Miftahul Maghfiroh | Departement of Electromedical Enginering, Politeknik Kesehatan Kemenkes Surabaya, Jalan Pucang Jajar Tengah No.56, Surabaya 60282, Indonesia |

| Moh Sofie | STIKES Semarang, Jalan kolonel warsito sugiarto km 2,5 Sadeng GunungPati, Semarang 50222, Indonesia |

| Abd Kholiq | Departement of Electromedical Enginering, Politeknik Kesehatan Kemenkes Surabaya, Jalan Pucang Jajar Tengah No.56, Surabaya 60282, Indonesia |

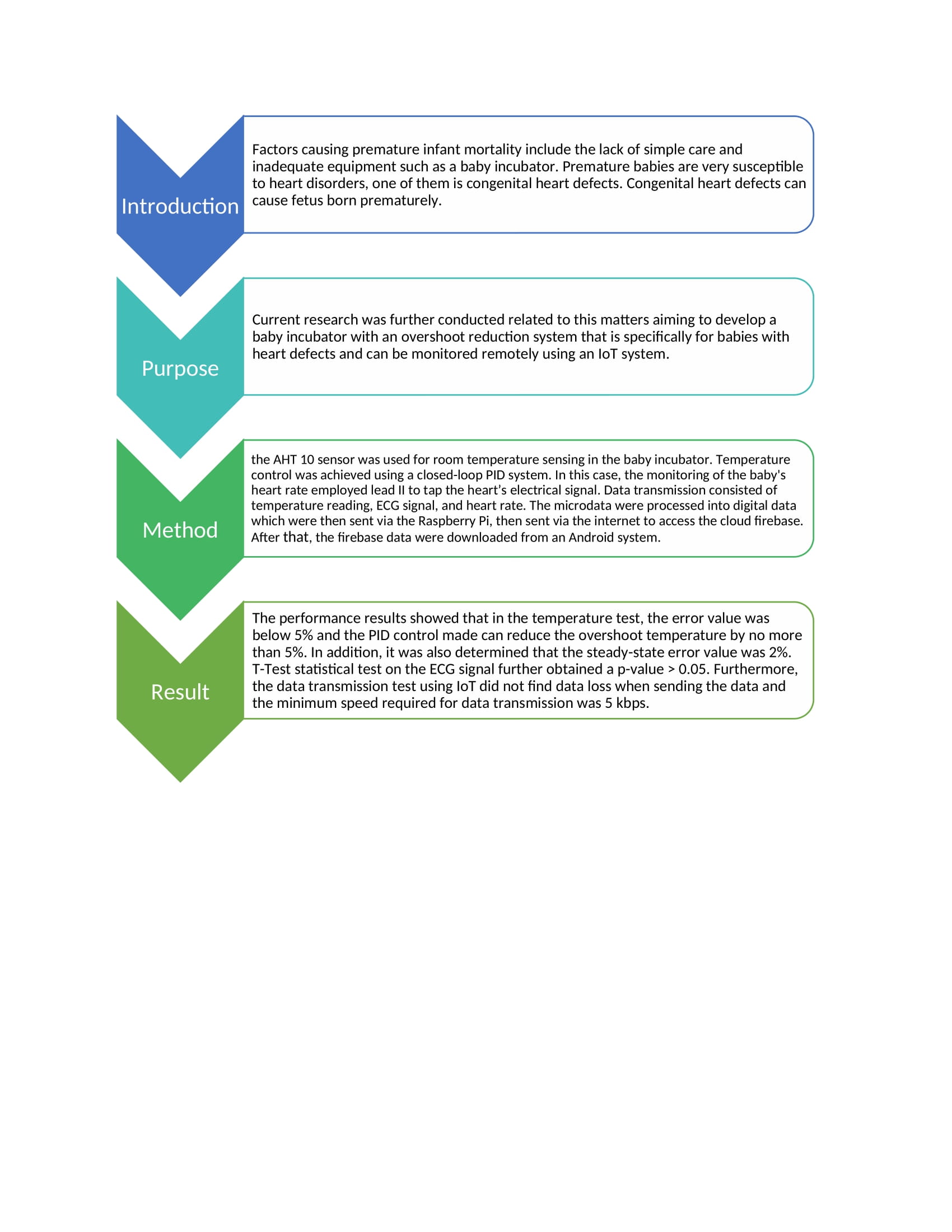

Factors causing premature infant mortality include

the lack of simple care and inadequate equipment such as a baby incubator.

Premature babies are very susceptible to heart disorders, including congenital

heart defects. Congenital heart defects can cause a fetus to be born

prematurely. The current research related to this matter was further conducted,

aiming to develop a baby incubator with an overshoot reduction system

specifically for babies with heart defects that can be monitored remotely using

an IoT system. In this study, the AHT 10 sensor was used for room temperature

sensing in the baby incubator. Temperature control was achieved using a

closed-loop PID system. In this case, the monitoring of the baby's heart rate

employed leads II to tap the heart's electrical signal. Data transmission

consisted of temperature readings, ECG signals, and heart rate. The microdata

was processed into digital data, which were then sent via the Raspberry Pi,

then sent via the internet to access the cloud firebase. After that, the

firebase data were downloaded from an Android system. The performance results

showed that in the temperature test, the error value was below 5%, and the PID

control made can reduce the overshoot temperature by no more than 5%. In addition,

it was also determined that the steady-state error value was 2%. T-Test

statistical test on the ECG signal further obtained a p-value > 0.05.

Furthermore, the data transmission test using IoT did not find data loss when

sending the data, and the minimum speed required for data transmission was 5

kbps. This research further implied that the user or the patient's family could

easily monitor the baby's development anywhere and anytime.

Baby incubator; ECG signal; Heart rate; IoT; Temperature

In addition, the room temperature in the baby incubator must be controlled according to the specified standard so that the baby still gets warmth, moisture, and oxygen as what they get in the womb. Several researchers have made a temperature control system for baby incubators using PID control (Maghfiroh et al., 2022; Kirana et al, 2021; Theopaga, Rizal, and Susanto, 2014). This system is considered to control the temperature well and suppress excessive temperature overshoot levels so that premature babies get warm according to standards. Widhiada et al. (2019a) made a baby incubator using a fuzzy logic control system with two measurement conditions. The first measurement is without load, and the second measurement uses a baby simulation with a load of 2 kg. The resulting overshoot value was less than 5% (Widhiada et al., 2019a). However, in using this fuzzy system, the variables entered were only based on the researcher's experience, so further system testing is necessary. (Sinuraya and Pamungkas, 2019) further used the DHT11 sensor for sensing elements using a fuzzy-PI adaptive control system, resulting in its ability to suppress overshoot according to the setpoint within 200 seconds with an error of 5% (Sinuraya and Pamungkas, 2019). However, the computation of this system was quite heavy. A closed-loop control system was further designed and implemented by Mathew and Gupta et al. to regulate temperature, humidity, light level, and oxygen in infant incubators (Mathew and Gupta, 2015). This system was quite effective in maintaining the temperature from the threshold value limit. However, the threshold value was still set manually using the potentiometer.

2.1. System Design and System Control

Figure 1 The design of baby incubator. The input ECG

signal is amplified by an instrument amplifier circuit so that it can be read

by the microcontroller, the instrument output is filtered with HPF and LPF

filters with a bandwidth frequency of 0.05 Hz-100Hz. The signal output will be

displayed on the LCD display and sent via android

The

block diagram of the PID control is described in Figure 2. In this case,

monitoring the baby's heart rate used lead II as the heart's electrical signal

tapping (Utomo, Nuryani, and Darmanto, 2017). The electrode output

from lead II was amplified with an instrument amplifier with a gain of 100

times to eliminate noise interference or other artifacts. A filter was made

according to the heart signal frequency, namely 0.05Hz-100Hz. The

microcontroller output in the form of an electrocardiogram signal and the room

temperature of the baby incubator sent via Resbery Pi from Resbery Pi will be

received by the web server using a firebase. Furthermore, the data were sent to

the Android phone. In this case, the Android display used the MIT App

application, which must be installed first on a cellphone with an android

system.

Figure 2 The

design of PID control, setting the temperature as an input to

the microcontroller then a closed loop system is used in this method to control

the room temperature on the baby incubator by using the AHT10 sensor to sense

the room

The PID control is based on Equation 1 and Equation

2 (Ang, Chong, and Li, 2005):

Where CD(s)

is the response to disturbance, D(s) is the interference effect test.

Where the selection of Kp, Ki, and Kd was applied to the proper control for closed-loop performance.

2.2. Data Acquisition ECG Signal

The ECG signal was obtained from the heart's electrical leads on Lead II. In this study, an ECG instrument was designed with a filter that was adjusted to the frequency of the heart signal, namely 0.05 Hz - 100 Hz. The designed ECG instrument is described in Figure 3. The amplitude of the ECG signal at the electrode output was still very small, namely 0.1 mV – 0.3 mV, so an instrument amplifier was needed. In this study, ICAD620 was used with 100 times the gain based on Equation 7 (Maghfiroh, Arifin, and Sardjono, 2019).

As for getting the ECG signal in this study, a filter was designed with an HPF cut-off frequency of 0.05Hz and an LPF cut-off frequency of 100Hz. As for getting the cut-off frequency bandwidth value for HPF was based on Equation 8 (Maghfiroh, Arifin, and Sardjono, 2019).

The Sullen-Key topology method was used for order 2 LPF circuits. Value a1 = 1.8478; b1 = 1.0000; a2 = 0.7654; and b2 = 1.0000 were Butterworth coefficients for order 2. The first-order low pass filter can be calculated by Equations 9 and 10 with a value of C1 = 47 nF.

2.3. Data Collection

Figure

4 Temperature test using the Incu Analyzer type INCU 2 Brand Fluke, with

five temperature parameters namely T1, T2, T3, T4 and T5 which are placed as

shown in the picture

Figure 5 Electrocardiograph

signal simulation with Phantom ECG using lead II displayed on the oscilloscope

2.4. Data

Transfer

In

this study, data transmission consisted of temperature readings, ECG signals,

and heart rate. The microdata was processed into digital data, which were then

sent via resbery pi. Resbery data were sent via the internet to access the

cloud firebase, then from the firebase data was downloaded from the android

system as described in Figure 6. In order to test the IoT system, the

researcher set the speed of bps WiFi to determine the speed of data transmitted

to android, with each speed measured 6 times.

In

order to find out the performance of the baby incubator according to the

standard, a calibration test was carried out. The parameters tested were the

setting temperature of 35oC, 36oC, and 37oC

using the INCU Analyzer, as described in Figure 4. Measurements were carried

out 6 times, and then the average calculation was carried out, which later

found the error from the temperature deviation of the baby incubator. The

average calculation was obtained based on Equation 11 (Duvernoy, 2015).

Where x is the data retrieval to, and n is

the number of data retrieval. While the temperature reading error value was

based on Equation 12.

Error

= Mean – standard tool reading (12)

3.1. Temperature

Testing and PID Control

The results of the comparison of

temperature readings on the baby incubator with the INCU analyzer are described

in Figure 7. Based on the description

in Figure 7, it is explained that the average error of reading the temperature

of the baby incubator was compared with the INCU analyzer at temperature

settings of 35oC, 36oC, and 37oC with 5

measurement sensor points with the maximum error value on the reading of the

temperature point T2 which is 36oC ± 0.7oC, namely T1,

T2, T3, T4 and T5 which are described in Figure 4 that is still within the

threshold for use, namely the error value is still below 5% (Widhiada et al., 2019b).

Meanwhile, the PID control overshoot

reduction test with disturbance was carried out at a temperature setting of 37oC,

described in Figure 8.

3.2. Electrocardiograph (ECG) testing

This test was carried out using a Fluke Phantom ECG brand with BPM settings of 30, 60, 120, 180, and 240. Measurements were carried out for each BPM setting on the Phantom ECG, as described in Table 1. The heart rate value in this study using the adaptive threshold system (Kohler, Hennig, and Orglmeister, 2002). Meanwhile, to get the number of heartbeats was based on Equation 13.

Formulae should be numbered consecutively throughout the manuscript as Equation 1 and equation 2. In cases where the derivation of formulae has been abbreviated, it is of great help to the reviewers if the full derivation can be presented on a separate sheet (not to be published).

Where HR is the heart

rate (BPM), while tn+1 is the period time for the peak of R-peak (n+1), and tn

is the period time for the peak of R tn. The results of the ECG heart rate test

(BPM) with Phantom ECG are described in Table 1.

|

BPM |

MEAN (%) |

SD (%) |

|

30 |

30.16 |

0.37 |

|

60 |

60 |

0 |

|

120 |

120 |

0 |

|

180 |

180.16 |

0.40 |

|

240 |

239.66 |

1.36 |

Based on the calculation of the standard deviation in Table 1, the mean value and standard deviation of each BPM setting were obtained. At the BPM 30 setting, the standard deviation value was 0.3727%, while at BPM 60 and 120 settings, the standard deviation was 0%. Furthermore, the BPM 180 setting obtained a standard deviation of 0.4082%, while the BPM 240 setting obtained a standard deviation of 1.3662%. From the average values that have been explained, it is known that the highest average error value is produced by the BPM 240 value with an average value of 239.66 BPM ± 1.36 BPM. It can be concluded that the higher the BPM value, the higher the error value obtained. However, the value generated in this assessment is that this tool is suitable for use according to medical standards [32]. Meanwhile, to find out whether there is a significant difference in the heart rate (BPM) ECG calculation with the BPM setting on the Phantom ECG, a statistical test was carried out using a T-Test with a p-Value > 0.05 indicator as described in Table 2.

Table 2 Testing the difference using the T-Test statistic|

Alpha |

0.05 | ||||

|

std err |

t-stat |

df |

p-value |

t-crit | |

|

One Tail |

54.73431 |

0.000761 |

6 |

0.499708708 |

1.94318 |

|

Two Tail |

54.73431 |

0.000761 |

6 |

0.999417415 |

2.446912 |

The results of the

T-Test statistical test in Table 2 showed that there was a one-tail T-Test

result with p-Value = 0.499708708, while in two tails, the p-value was

0.999417415, which means that there was no significant difference because the

p-Value > 0.05 and the error rate was still within the appropriate level for

medical purposes.

3.3. Data Transfer Test

Data transfer testing was carried

out to test whether the sending data was missing data or there was a delay at

the time of delivery. This system uses an IoT system by utilizing an API base

to store data which later be downloaded via android. Therefore, this system was

not affected by the distance that can be accessed from the feed and anywhere as

long as the cellphone was in a WiFi network connection. In this test, the bps

speed setting was conducted to find out the right bps speed for sending data

via android based on IoT. The data transfer test is described in Figure 9.

Figure 9 above shows that the output of LCD display and Android display is the same. In addition, the testing of the EKG signal was carried out using the oscilloscope. From the three displays, there was no difference in SCG signal presentation.

Data transmitted via android were temperature data, humidity monitoring, ECG signal, and BPM heart rate. The comparison of readings between the LCD on the baby incubator and the display on the android system is described in Figure 10.

Meanwhile, for the data transmission test, 6 measurements were made at a temperature setting of 36oC, and a setting of 80 BPM on the Phantom ECG with internet speed settings ranging from 5 kbps, 10 kbps, 20 kbps, 30 kbps, 40 kbps, and 50 kbps was used. Based on this internet speed setting, it was known that there was no difference in data reading on the LCD display on the baby incubator with the data sent to the android. However, there was a delay in the data transmission process. The test results are described in Table 3.

Based on the results of the table above, there was no data loss during the data transmission process, starting from the speed setting of 5 kbps to 50 kbps, because the researcher utilized the firebase web server function, which could accommodate data according to the data sent. In addition, the data were downloaded by the android system, so no data was lost. However, the weakness of this system is that there was a delay with an average time of 3.67 seconds, and it can be concluded that the minimum bps speed required for data transmission is 5 kbps. The advantage of this system is that data can be accessed anywhere and anytime without any minimum distance.

Table 3 Testing data transmission with Internet speed settings

|

BPS Speed (kbps) |

Mean Temperature Reading (°C) |

Mean Heartbeat Reading (BPM) |

Transmission Data Delay (Second) |

|

5 |

36.2 |

80 |

3.65 |

|

10 |

36.2 |

80 |

3.53 |

|

20 |

36.2 |

80 |

3.79 |

|

30 |

36.2 |

80 |

3.65 |

|

40 |

36.2 |

80 |

3.74 |

|

50 |

36.2 |

80 |

3.71 |

The

research aims to reduce overshoot in baby incubators using the PID method,

specifically for babies with heart defects, which can be monitored remotely

using the IoT system. After investigating the performance of the PID method for

an infant incubator temperature control system, it was found that the

steady-state error value was 2%. While the results of measurements using the

INCU Analyzer obtained the highest overshoot value at T4 with temperatures

reaching 380C ± 1.30C. It can be concluded that the performance

of the PID control system is very good for reducing temperature overshoot in

baby incubators and is suitable for medical purposes. Then testing was also

carried out on the ECG for heart rate (BPM) on the ECG signal using the T-Test

statistical test, and the results obtained were p-Value > 0.05. From this

value, it shows that this system is feasible to be used for medical purposes

because there is no significant difference in value. Data transmission using

IoT is also tested by changing several bps speeds with a speed setting of 5

kbps – 50 kbps. The results obtained are that there is no data loss when

sending data, and the minimum speed required for data transmission is 5 kbps.

However, there is a delay with an average time of 3.67 seconds in the data

transmission process. From the overall results of measurements and tests

carried out, it can be concluded that the method used is suitable for use

according to medical standards. For further research development, researchers

want to develop central monitoring of baby incubators so that nurses or users

can easily monitor several baby incubators in the NICU room.

Appreciation

is given to the Department of Electromedical Engineering and Research

Management & Innovation Centre, Poltekkes Kemenkes Surabaya, for supporting

this research work.

Abdurrakhman,

A., Soehartanto, T., Hadi, H.S., Toriki, M.B., Widjiantoro, B.L., Sampurno, B.,

2020. Design of Output Power Control Systems Based on Mass Flow Rate Comparison

of Air-Fuel Ratio (AFR) on Dual Fuel Generator Set by Using the PID Control

Method. International Journal of Technology, Volume 11(3), pp. 574–586

Ang, K.H., Chong, G., Li, Y., 2005. PID Control System

Analysis, Design, and Technology. IEEE Transactions on Control Systems

Technology, Volume 13(4), pp. 559–576

Agresara,

M.N., Vyas, D.D., Bhensdadiya, B.S., 2017. System for

Remote Monitoring and Control of Baby Incubator and Warmer. International

Journal of Futuristic Trends in Engineering and Technology, Volume 3(6),

pp.1–6

Ashish, B. 2017. Temperature Monitored IoT Based Smart Incubator. Proceedings

of the International Conference on IoT in Social, Mobile, Analytics and Cloud,

I-SMAC 2017, pp. 497–501

Duvernoy, J., 2015. World Meteorological

Organization (WMO). Guidance on the Computation of Calibration Uncertainties

Fadilla, R., Idhil, A.N.I.I., Anggraini, M.A.P., Dewi, A.K.,

Sanjaya, M.R., Nurrohman, M.Y., 2020. A Multifunction Infant Incubator

Monitoring System with Phototherapy and ESP-32 Based Mechanical Swing. International

Journal of Science, Technology & Management, Volume 1(4), pp. 371–381

Hubsher, J.A., 1961. The Electrocardiogram of the Premature Infant.

American Heart Journal 61(4), pp. 467–475

Janney, B.J., Krishnakumar, S., Anushree,

P.B., Rayshma, V., Suresh, S., 2018. Deisgn of Mobile Infant Incubator with

Comforting Pillow. International Journal of Engineering and Technology(UAE),

Volume 7(2), pp. 6–9

Kanalikova, K., 1990. Diagnosis of Congenital Heart Defects in

Childhood. Bratislavské lekárske listy, Volume 91(12), pp. 868–873

Kirana, V.C., Andayani, D.H., Pudji, A., 2021.

“Effect of Closed and Opened the Door to Temperature on PID-Based Baby

Incubator with Kangaroo Mode. Indonesian Journal of Electronics,

Electromedical Engineering, And Medical Informatics, Volume 3(3), pp. 121–127

Kohler,

B.U., Hennig, C., Orglmeister, R., 2002. The Principles of Software QRS

Detection. IEEE Engineering in Medicine and biology Magazine, Volume

21, pp. 42–57

Koli, M., Ladge, P., Prasad, B., Boria, R., Balur, N.J., 2018.

Intelligent Baby Incubator. Proceedings of the 2nd International Conference

on Electronics, Communication and Aerospace Technology, ICECA 2018, pp.

1036–1042

Kvalvik, L.G., Wilcox, A.J., Skjærven, R., Ostbye, T., Harmon,

Q.E., 2020. Term Complications and Subsequent Risk of Preterm Birth: Registry Based

Study. The BMJ, Volume 369

Lawn, J.E., Davidge, R., Paul, V., Von Xylander, S., De Graft

Johnson, J., Costello, A., Kinney, M., Segre, J., Molyneux, E., 2013.

Preterm Baby Survival and Care Round the World Born Too Soon: Care for the

Preterm Baby. Reproductive Health, Volume 10(10), p. 5

Luthfiyah, S., Kristya, F., Wisana, I.D.G.H., Thaseen, M., 2021. Baby Incubator

Monitoring Center for Temperature and Humidity Using WiFi Network. Journal

of Electronics, Electromedical Engineering, and Medical Informatics, Volume

3(1), pp. 8–13

Maghfiroh, A.M., Amrinsani, F., Setiawan,

S.Y., Firmansyah, R.M., Misra, S., 2022. Infant Warmer with Digital Scales for

Auto Adjustment PID Control Parameters. Jurnal Teknokes, Volume 15(2),

pp. 117–123

Maghfiroh, A.M., Arifin, A., Sardjono, T.A., 2019. Wavelet-Based

Respiratory Rate Estimation Using Electrocardiogram. Proceedings - 2019

International Seminar on Intelligent Technology and Its Application, pp.

354–359

Mathew, H.B.D.L., Gupta, A., 2015. Controlling of Temperature

and Humidity for an Infant Incubator Using Microcontroller. International

Journal of Advanced Research in Electrical, Electronics and Instrumentation

Engineering, Volume 4(6), pp. 4975–4982

Muosa, A.H., 2017. Wireless Controland

Monitoring Systemfor Premature Infant IncubatorEnvironment. Journal of College of Education For Pure

Sciences (ICEPS), Volume 7(4), pp. 28–39

Nachabe, L., Girod-Genet, M., ElHassan, B., Jammas, J., 2015.

M-Health Application for Neonatal Incubator Signals Monitoring through a

CoAP-Based Multi-Agent System. 2015 International Conference on Advances in

Biomedical Engineering, pp. 170–173

Nayak, A., Singh, M., 2015. Study of Tuning of PID Controller By

Using Particle Swarm Optimization. International Journal of Advanced

Engineering Research and Studies IV(Jan.-March), Volume 346, p. 350

Ogata, K., 2005. Mathematical Modelling of Control Systems. Modern

control Engineering, pp. 13–62

Rahman, A., Hassan, N., Ihsan, S.I., 2022. Fuzzy

Logic Controlled Two Speed Electromagnetic Gearbox for Electric Vehicle. International

Journal of Technology 13(2), pp. 297–309

Sattar, Y., Chhabra, L., 2021. Electrocardiogram. StatPearls

Publishing

Shaib, M., Rashid, M., Hamawy, L., Arnout, M., El Majzoub, I.,

Zaylaa, A.J., 2017. Advanced Portable Preterm Baby Incubator. In 2017

Fourth International Conference on Advances in Biomedical Engineering (ICABME), pp.

1–4

Sinuraya, E.W., Pamungkas, 2019. Design of Temperature Control

System for Infant Incubator Using Auto Tuning Fuzzy-PI Controller. International

Journal of Engineering and Information Systems (IJEAIS), Volume 3(1), pp.

33–41

Utomo, S.B., Irawan, J.F., Mujibtamala, A., Nari, M.I., Amalia, R.,

2021. Automatic Baby Incubator System with Fuzzy-PID Controller. IOP

Conference Series: Materials Science and Engineering, Volume 1034(1), p.

012023

Utomo, T.P., Nuryani, N., Darmanto, 2017. QRS Peak Detection for

Heart Rate Monitoring on Android Smartphone. Journal of Physics: Conference

Series, Volume 909(1), p. 012006

Widhiada, W., Nindhia, T.G.T., Gantara, I.N., Budarsa, I.N.,

Suarndwipa, I.N., 2019a. Temperature Stability and Humidity on Infant Incubator

Based on Fuzzy Logic Control. ACM International Conference Proceeding Series,

pp. 155–159

Widhiada, W., Antara, I.N.G., Budiarsa, I.N. and Karohika, I.M.G.,

2019b. The Robust PID Control System of Temperature Stability and Humidity on

Infant Incubator Based on Arduino at Mega 2560. IOP Conference Series: Earth

and Environmental Science, Volume 248(1), p. 012046

Zaelani, A.V., Koestoer, R.A., Roihan, I.,

Harinaldi, 2019. Analysis of Temperature Stabilization in Grashof Incubator

with Environment Variations Based on Indonesian National Standard (SNI). AIP

Conference Proceedings, Volume 2062(1), p. 020003