Machine Learning Approach for Early Assembly Design Cost Estimation: A Case from Make-to-Order Manufacturing Industry

Corresponding email: maruf@itb.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5675

Ma’ruf, A., Nasution, A.A.R., Leuveano, R.A.C., 2024. Machine Learning Approach for Early Assembly Design Cost Estimation: A Case from Make-to-Order Manufacturing Industry. International Journal of Technology. Volume 15(4), pp. 1037-1047

| Anas Ma’ruf | Faculty of Industrial Technology, Bandung Institute of Technology, Jl. Ganesha 10, Bandung, 40132, Indonesia |

| Ali Akbar Ramadani Nasution | Faculty of Industrial Technology, Bandung Institute of Technology, Jl. Ganesha 10, Bandung, 40132, Indonesia |

| Raden Achmad Chairdino Leuveano | Department of Industrial Engineering, Faculty of Industrial Engineering, Universitas Pembangunan Nasional “Veteran” Yogyakarta, Jl. Babarsari 2, Yogyakarta, 55281, Indonesia |

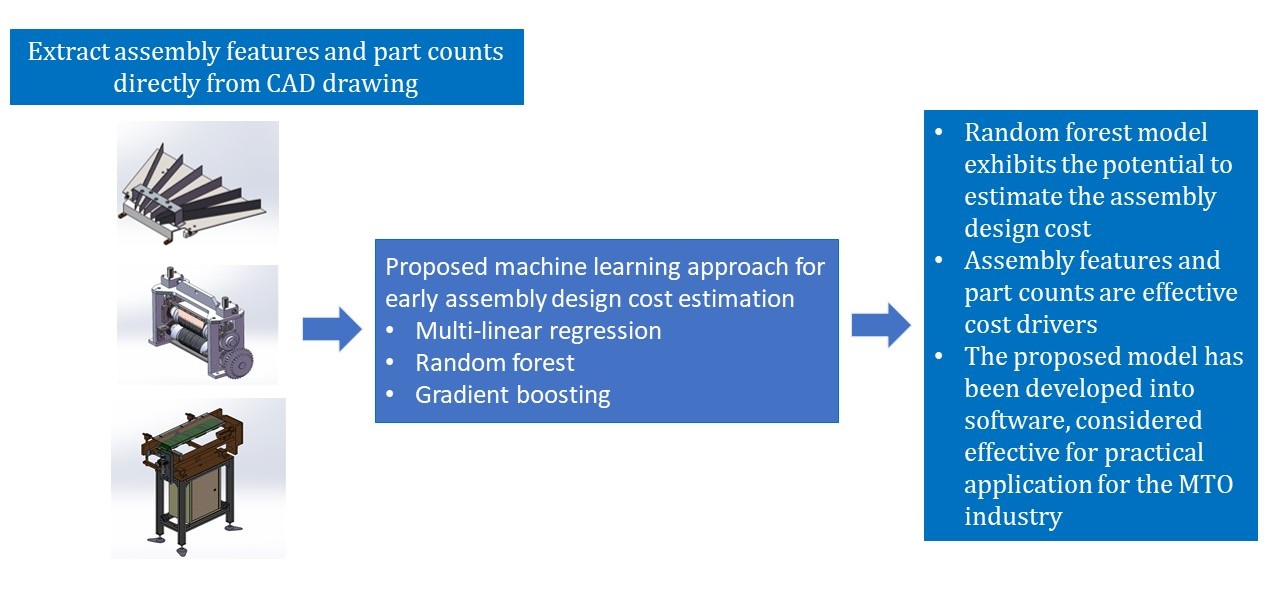

Estimating production costs is a challenging process for the Make-To-Order (MTO) industry because of

the product varieties, which leads to inaccurate cost estimation. The product

engineering process requires accurate assembly cost estimation to take

strategic decisions, specifically during the early design phase. Therefore, an

intelligent machine learning-based approach, namely Multi-linear Regression,

Random Forest, and Gradient Boosting, is proposed to estimate the assembly

design cost. This estimation is done by identifying the assembly features of

the 3D CAD model. The validation results showed that mate and assembly

features, as well as the number of parts, are effective cost drives, while

Random Forest outperformed other models. The proposed methodology is then

implemented in a cost estimation program and applied in the MTO industry. The proposed

estimation method deviated an average of 17.4% from the actual assembly design

cost, considered acceptable during the early design phase. In conclusion, the proposed

model and cost estimation program efficiently help the MTO industry predict

assembly design costs.

3D CAD; Assembly design; Assembly features; Cost estimation; Machine learning

Product

customization is increasingly implemented in the manufacturing industry to

improve competitiveness. Keil

(2024) found that

industries are motivated to meet new standards due to competitive pressures,

complex customer requirements, and stakeholder expectations. This phenomenon

has an impact, particularly on the production of the Make-to-Order (MTO)

industry (Yazdi,

Fini, and Forsythe, 2021). According to Yi et al. (2023), cost estimation

is the quantitative prediction of a product’s cost before completing all

product development stages. This implies that the MTO industry needs to

estimate product costs quickly and accurately. Unlike cost calculation, cost

estimation is based on the assumption that the industry lacks access to

manufacturing process data and with no conventional standard cost model (Latief,

Wibowo, and Isvara, 2013). Koonce

et al. (2003) and Bacharoudis

et al. (2021) stated that a systematic method is used for estimating

material and machining costs by classifying each material and production

operation into individual cost drivers.

Estimating assembly design cost is a more complex process, that includes intangible aspects, such as assembly parts and complexity (Castellani, Otri, and Pham, 2019; Demir et al., 2023). In the final design phase, the method used to estimate assembly design cost for mass production is significantly more developed. H’mida, Martin, and Vernadat (2006) and Niazi et al. (2006) have stated that this approach involves outlining the design activities cost, followed by identifying resources and operations during the design phase. Quintana and Ciurana (2011) have suggested that assembly design cost estimation is often performed by using a knowledge-based system, which is typically used in repetitive production.

With these points, this study proposes

systematic assembly design cost estimation as an alternative to the

conventional MTO approach. Conventional cost estimation is by constructing a

regression model based on complex relationships (Verlinden et al., 2008).

Also, the choice of

method is based on the limited access to manufacturing process data. Hence, the

estimation accuracy significantly affects industry profits. This implies that a

very low price reduces profits, while an extremely high price tends to affect

customer satisfaction negatively (Kalscheuer et al., 2023).

This study examines cost issues related to

initial assembly design in the MTO industry. It has been observed that the

industry produces a small volume of various assembly products, including

precision molding, stamping dies, precision spare parts, and mechanical

devices. The assembly design initiates the product’s engineering process based

on customer orders using specific 3D Computer-Aided Design (CAD) software. At

this phase, accurate cost estimation is essential for making strategic

decisions in the engineering process (Post et al., 2020). However, these detailed product features are typically not available

when using a conventional cost accounting approach. This caused Alfadhlani et al. (2019) to conclude that CAD data is needed when identifying feature

information based on assembly design, saved as historical data of industry

orders. To estimate

accurate assembly design costs, it is necessary to establish a relationship

between the product features and the historical assembly design cost. However,

using the conventional approach, it is challenging for cost engineers to

determine the product's sufficient cost function and behavior based on

experience (Bodendorf, Merkl, and Franke, 2021). Machine Learning (ML) method can be applied to solve

classification and prediction problems (Dawangi and Budiyanto, 2021; Alas and Ali, 2019;

Fagbola, Thakur, and Olugbara, 2019). ML method, as proposed by Durodola

(2022), Hammann (2024), and Ning et

al. (2020), is an efficient and accurate technique for identifying

the relationship between features and historical product cost. The model is

typically employed to overcome this problem as it detects hidden functional

relationships between assembly features and costs (Bodendorf, Merkl, and Franke, 2021). Other approaches to assembly cost estimation are analytical, knowledge-base,

or hybrid approaches (Mencaroni et al., 2023; Hagemann and Stark,

2020; Burggräf et al., 2019).

The main objectives of this study are (1) to

propose the ML method as a model for estimating assembly design costs based on

3D CAD data and (2) to create a program-based Graphical User Interface (GUI)

that engineers can use to quickly predict assembly design costs. In the MTO

industry, it is observed that customers always want to know the product price

ahead of time, and as a result, the preliminary price is expected to be close

to the final price.

2.1.

Data Collection of Assembly Features, Costs, and Pre-Data

Processing

Furthermore, to estimate target costs, actual product

cost data collected based on each 3D CAD file were used. The MTO company

specifically evaluated these models to ensure the cost values were consistent

with their estimates. Data

preprocessing was employed after data collection since it is

impossible to directly use the 3D CAD information as input for the ML method.

This step is crucial when analyzing the mate and assembly features, as well as

the number of parts that affect assembly design costs. Therefore, the

transformation of raw data into datasets began with developing a program to

extract the features in the 3D CAD file. After this extraction, data cleansing,

feature selection, and data transformation were performed.

Subsequently, an Application

Programming Interface (API) was utilized to read the 3D CAD file (Malpass, 2011). A command program was then

created using Python programming language, which generated a loop in data

reading, sequentially stored into data frames, known as the ML model’s input

dataset.

2.2. Develop Early Assembly Design

Cost Estimation Model-based ML methods

The ML method was chosen to

map the complex relationship between assembly design features and costs, based

on the input data, namely assembly features used to estimate the initial

assembly design costs. Therefore, this study proposes three ML methods, including

Multi-linear Regression, Random

Forest, and Gradient Boosting,

which each was developed and programmed with Python code.

2.2.1. Multi-linear regression model

2.2.2. Random forest model

Random Forest (RF) is a supervised ML algorithm that uses a tree-based ensemble learning to predict the output by combining various Decision Trees (DT) (Montesinos López et al., 2022; Rakhra et al., 2021). It is important to note that DTs exhibited distinct observations from the construction of a single DT. The RF algorithm representation using bootstrapping is shown in Figure 3. Bootstrapping uses distinct subsets of the available features to train multiple decision trees concurrently on different subsets of the training data set.

Furthermore, a random feature selection was

chosen based on the aggregation to train several decision trees in parallel (Misra and Li, 2020). Each tree was trained with a unique set of training data and features.

This is carried out to ensure that every decision tree is different from the

others, which can lower the variance of the RF model as a whole. The RF model

integrates the judgments made by each tree in order to achieve superior

generalization outcomes.

To

obtain a good estimation result, the RF model has hyperparameters that need to

be tuned, as shown in Table 1. These include 1)

Table 1 Hyperparameters search

space in GSCV

|

Parameter |

Range |

|

|

{10,50,100} |

|

Max features |

{‘auto’, ‘sqrt’, ‘log’} |

|

Max depth |

{5, 10, 18, None} |

|

Min sample split |

{2, 5, 10, 18, None} |

|

Min sample leaf |

{1, 5, 10, 18, None} |

2.2.3. Gradient boosting model

|

Figure 4 The representation of the GB algorithm for

the case being studied. |

To

expand the model's capability, the GB algorithm creates a number of regression

trees over time. In a forward stepwise manner, the iteration of training

process of the GB model to determine the proximate predicted value and the output

is expressed in Equation (2) (Wang et al., 2020).

Table 2 Hyperparameter of the GB

model

|

Parameter |

Range |

|

|

{10,50,100} |

|

Learning rate |

{0.1, 0.3, 0.5, 1} |

|

Max depth |

{3, 5, 10, 20, None} |

2.2.4. Validating the estimation accuracy of ML models

The ML method produces prediction output  for the

for the  observation where

observation where

= 1, 2,…,

. Each evaluation of the

prediction output requires a model performance measure. The performance metric

was used to validate the accuracy of the model when estimating actual assembly

design cost, as described by Li et al. (2021). To accurately reflect the magnitude of the actual prediction error,

the Mean Absolute Percentage Error (MAPE) and R2 techniques were employed, as expressed

mathematically in Equations (3) and (4).

where  is the predicted value,

is the predicted value,  represents the real target output, and

represents the real target output, and  denotes the observed numbers. After evaluating the

ML model’s accuracy, the final step entails the selection of the best model to

estimate assembly design cost. It was observed that the model with the lowest

MAPE and

denotes the observed numbers. After evaluating the

ML model’s accuracy, the final step entails the selection of the best model to

estimate assembly design cost. It was observed that the model with the lowest

MAPE and  which was closest to one, exhibited the most accurate estimate for early

product assembly design costs.

which was closest to one, exhibited the most accurate estimate for early

product assembly design costs.

2.3. Develop

a Program of Estimated Costs of Product Assembly Design

The

assembly features, and the best model selected in the previous step served as a

reference when developing the application program of the proposed methodology.

Furthermore, the program aims to assist the industry in efficiently predicting

the assembly design cost based on the 3D CAD file.

A total of 104 historical datasets were collected on the

CAD assembly file, which includes the real assembly design of a MTO company.

Upon the completion of the dataset, the cost estimation model was developed,

trained, fine-tuned, and tested using the proposed methodology, as shown in

Figure 1. The three proposed models, namely MLR, RF, and GB, were employed to

estimate the product assembly design cost using training datasets. Table 3 shows the final experimental results of the proposed

model when tested with 20% datasets, while the results of training with 80% of

the datasets are omitted due to its brevity.

As observed in Table 3, the MLR algorithm

has no hyperparameters, and hence no tuning was performed, and the and MAPE results

obtained were 0.21 and 53%, respectively. Furthermore, only the five best

combinations measured by

and MAPE is shown in Table 3. The results

showed that the RF-91 and the GB-43 models, with respective scores of 26.70%

and 32.27% had the least significant MAPE values, while the RF-421 and GB-43

achieved the most significant

score. Consequently, the GB-43 and RF-91 were selected as the best among their

corresponding models, despite the RF scoring the highest

and lowest MAPE. The optimum model was then

determined by comparing the performance of MLR, RF-91, and GB-43 when

predicting the best hyperparameter architecture.

Also, a re-experiment was conducted to fit

each model using all the training data. Every model’s cost was estimated with

the testing data to ensure that the best has the least significant MAPE value

and the most negligible difference in

Figure 5(a) depicts the program-based GUI where the user input a CAD assembly file. The program then uses the CAD's API to automatically identify the number of assembly features and the number of parts, as shown in Figure 5(b). Based on the proposed method, the user is subsequently presented with the estimated assembly design cost.

The results of the cost

estimation model and program development were discussed with the company

engineers, who discovered that two assembly design cases presented a

substantial predictive error value. Further analysis revealed that the product

assembly size was larger than in normal cases. In essence, when the product’s

size increases, the material volume required tends to be more, thereby causing

extra assembly design costs. This simply implies that the prediction model was limited in

estimating the design cost of homogeneous-sized product assembly. Based on

these findings, the proposed prediction model was accepted for use during the

early stage of assembly design.

This study examined the challenges

encountered when estimating the assembly design cost of the MTO industry. Cost

estimation entails early evaluation of various assembly parts, particularly

when information is limited. The proposed ML method for addressing the

challenge was found to be systematic, consistent, fast, and free of

subjectivity. The MLR, GB, and RF models are the ML method utilized to estimate

the assembly design cost. The experimental result showed that the RF model

exhibits the significant potential to efficiently estimate the assembly design

cost with an average deviation of 17.4% from the actual assembly design cost.

Therefore, the proposed model was developed into a practical application

program for MTO industries and considered viable for early assembly design cost

estimation where manufacturing information is incomplete. The model has been

integrated with CAD software to expedite and maintain consistency in assembly design

cost estimation. Nonetheless, the limitation of the proposed model relies on

the consistency of the historical dataset used for training the model. Future

research is directed to explore the impact of dynamic motions such as assembly

motion and kinematic behavior in assembly design cost estimation.

Alas, M., Ali, S.I.A., 2019. Prediction Of The High Temperature Performance Of A Geopolymer Modified Asphalt Binder Using Artificial Neural Networks. International Journal of Technology, Volume 10(2), pp. 417–427

Alfadhlani, Samadhi, T. M. A. A., Ma’ruf, A., Toha, I.S., 2019. Automatic Precedence Constraint Generation For Assembly Sequence Planning Using A Three-Dimensional Solid Model. International Journal of Technology, Volume 10(2), pp. 340–350

Bacharoudis, K., Wilson, H., Goodfellow-Jones, S., Popov, A., Ratchev, S., 2021. An Efficient Cost Estimation Framework For Aerospace Applications Using Matlab/Simulink. Procedia CIRP, Volume 104, pp. 1143–1148

Bodendorf, F., Merkl, P., Franke, J., 2021. Intelligent Cost Estimation By Machine Learning In Supply Management: A Structured Literature Review. Computers & Industrial Engineering, Volume 160, p. 107601

Burggräf, P., Wagner, J., Dannapfel, M., Fluchs, S., Müller, K., Koke, B., 2019. Automation Decisions In Flow-Line Assembly Systems Based On A Cost-Benefit Analysis. Procedia CIRP, Volume 81, pp. 529–534

Castellani, M., Otri, S., Pham, D. T., 2019. Printed Circuit Board Assembly Time Minimisation Using A Novel Bees Algorithm. Computers & Industrial Engineering, Volume 133, pp. 186–194

Dawangi, I. D., Budiyanto, M. A., 2021. Ship Energy Efficiency Management Plan Development Using Machine Learning: Case Study Of CO2 Emissions Of Ship Activities At Container Port. International Journal of Technology, Volume 12(5), pp. 925–934

Demir, O. E., Colledani, M., Paoletti, R., Pippione, G., 2023. Function-Based Selective And Adaptive Cyber-Physical Assembly System For Increased Quality In Optoelectronics Industry. Computers in Industry, Volume 148, pp. 103915

Dogan, A., Birant, D., 2021. Machine Learning And Data Mining In Manufacturing. Expert Systems with Applications, Volume 166(15), pp. 114060

Durodola, J. F., 2022. Machine Learning For Design, Phase Transformation And Mechanical Properties Of Alloys. Progress in Materials Science, Volume 123(August 2020), pp. 100797

Fagbola, T. M., Thakur, C. S., Olugbara, O., 2019. News Article Classification Using Kolmogorov Complexity Distance And Artificial Neural Network. International Journal of Technologies, Volume 10(4), pp. 710–720

H’mida, F., Martin, P., Vernadat, F., 2006. Cost Estimation In Mechanical Production: The Cost Entity Approach Applied To Integrated Product Engineering. International Journal of Production Economics, Volume 103(1), pp. 17–35

Hagemann, S., Stark, R., 2020. An Optimal Algorithm For The Robotic Assembly System Design Problem: An Industrial Case Study. CIRP Journal of Manufacturing Science and Technology, Volume 31, pp. 500–513

Hammann, D., 2024. Big Data And Machine Learning In Cost Estimation: An Automotive Case Study. International Journal of Production Economics, Volume 269, pp. 109137

Kalscheuer, F., Koch, J., Schüppstuhl, T., 2023. Reducing Commissioning Efforts For Hybrid Assembly Systems Using A Data-Driven Approach. Procedia CIRP, Volume 118, pp. 935–939

Keil, S., 2024. Competing For Manufacturing Value Added: How Strong Is Competitive Cost Pressure On Sectoral Level? Structural Change and Economic Dynamics, Volume 69, pp. 197–212

Koonce, D., Judd, R., Sormaz, D., Masel, D. T., 2003. A Hierarchical Cost Estimation Tool. Computers in Industry, Volume 50(3), pp. 293–302

Kurasova, O., Marcinkevicius, V., Medvedev, V., Mikulskiene, B., 2021. Early Cost Rstimation In Customized Furniture Manufacturing Using Machine Learning. International Journal of Machine Learning and Computing, Volume 11(1), pp. 28–33

Latief, Y., Wibowo, A., Isvara, W., 2013. Preliminary Cost Estimation Using Regression Analysis Incorporated With Adaptive Neuro Fuzzy Inference System. International Journal of Technology, Volume 4(1), pp. 63–72

Li, E., Yang, F., Ren, M., Zhang, X., Zhou, J., Khandelwal, M., 2021. Prediction Of Blasting Mean Fragment Size Using Support Vector Regression Combined With Five Optimization Algorithms. Journal of Rock Mechanics and Geotechnical Engineering, Volume 13(6), pp. 1380–1397

Malpass, L., 2011. SolidWorks API Series 1: Programming & Automation. AngelSix

Mencaroni, A., Claeys, D., De Vuyst, S., 2023. A Novel Hybrid Assembly Method To Reduce Operational Costs Of Selective Assembly. International Journal of Production Economics, Volume 264, p. 108966

Misra, S., Li, H., 2020. Noninvasive Fracture Characterization Based On The Classification Of Sonic Wave Travel Times. In Machine Learning for Subsurface Characterization. Elsevier Inc

Molcho, G., Cristal, A., Shpitalni, M., 2014. Part Cost Estimation At Early Design Phase. CIRP Annals - Manufacturing Technology, Volume 63(1), pp. 153–156

Montesinos López, O. A., Montesinos López, A., Crossa, J., 2022. Multivariate Statistical Machine Learning Methods For Genomic Prediction. In Multivariate Statistical Machine Learning Methods for Genomic Prediction

Niazi, A., Dai, J. S., Balabani, S., Seneviratne, L., 2006. Product Cost Estimation: Technique Classification And Methodology Review. Journal of Manufacturing Science and Engineering, Volume 128(2), pp. 563–575

Ning, F., Shi, Y., Cai, M., Xu, W., Zhang, X., 2020. Manufacturing Cost Estimation Based On The Machining Process And Deep-Learning Method. Journal of Manufacturing Systems, Volume 56, pp. 11–22

Ozcan, G., Kocak, B., Gulbandilar, E., Kocak, Y., 2024. Efficient Machine Learning Models For Estimation Of Compressive Strengths Of Zeolite And Diatomite Substituting Concrete In Sodium Chloride Solution. Arabian Journal for Science and Engineering

Post, C., Wentingmann, N., Bramsiepe, C., Schembecker, G., 2020. Using Design Spaces For More Accurate Cost Estimation During Early Engineering Phases. Chemical Engineering Research and Design, Volume 153, pp. 592–602

Quintana, G., Ciurana, J., 2011. Cost Estimation Support Tool For Vertical High Speed Machines Based On Product Characteristics And Productivity Requirements. International Journal of Production Economics, Volume 134(1), pp. 188–195

Rakhra, M., Soniya, P., Tanwar, D., Singh, P., Bordoloi, D., Agarwal, P., Takkar, S., Jairath, K., Verma, N., 2021. Crop Price Prediction Using Random Forest And Decision Tree Regression:-A Review. Materials Today: Proceedings

Verlinden, B., Duflou, J.R., Collin, P., Cattrysse, D., 2008. Cost Estimation For Sheet Metal Parts Using Multiple Regression And Artificial Neural Networks: A Case Study. International Journal of Production Economics, Volume 111(2), pp. 484–492

Wang, M. X., Huang, D., Wang, G., Li, D.-Q., 2020. SS-XGBoost: A Machine Learning Framework For Predicting Newmark Sliding Displacements Of Slopes. Journal of Geotechnical and Geoenvironmental Engineering, Volume 146(9), pp. 1–17

Yazdi, A. J., Fini, A. A. F., Forsythe, P., 2021. Mass-Customisation Of Cross-Laminated Timber Wall Systems At Early Design Stages. Automation in Construction, Volume 132, pp. 103938

Yi, L., Werrel, M., Ehmsen, S., Glatt, M., Aurich, J.C., 2023. A Specific Manufacturing Cost Model For Fast Cost Estimation In Additive Manufacturing. Procedia CIRP, Volume 120, pp. 21–26