Pyrolysis of Reclaimed Asphalt Aggregates in Mortar

Corresponding email: bhsetiadji@ft.undip.ac.id

Published at : 07 Oct 2022

Volume : IJtech

Vol 13, No 4 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i4.5621

Setiadji, B.H., Wibowo, M.A., Jonkers, H.M., Ottele, M., Widayat, Qomaruddin, M., Sugianto, F.H., Purwanto, Lie, H.A., 2022. Pyrolysis of Reclaimed Asphalt Aggregates in Mortar. International Journal of Technology. Volume 13(4), pp. 751-763

| Bagus Hario Setiadji | Department of Civil Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| M Agung Wibowo | Department of Civil Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Henk M Jonkers | Department of Materials, Mechanics, Management & Design, Building 23, Stevinweg 1, 2628 CN Delf, The Netherlands |

| Marc Ottele | Department of Materials, Mechanics, Management & Design, Building 23, Stevinweg 1, 2628 CN Delf, The Netherlands |

| Widayat | Department of Chemical Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Mochammad Qomaruddin | 1. Department of Civil Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia 2. Department of Civil Engineering, University Islamic of Nahdlatul Ulama, J |

| Felix Hariyanto Sugianto | Department of Civil Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Purwanto | Department of Civil Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

| Han Ay Lie | Department of Civil Engineering, Diponegoro University, Jl. Prof. Soedarto, S.H., Tembalang, Semarang, 50275, Indonesia |

Asphalt pavement consists of

aggregates resulting in a waste material at end of its life. The aggregates can

be reused as basic material for asphalt or cementitious binding agents. In both

scenarios, the recycled aggregates should provide a good bond with the binder

to achieve strength. This study focuses on reusing recycled asphalt aggregates

(RAA) in mortar. The major weakness of RAA is the thin oily film originating

from the asphalt residue, weakening the bond with cement. The pyrolysis method

is accessed in an attempt to overcome this weakness. Three scenarios were

investigated; the use of virgin aggregates (VA), RAA, and pyrolysis recycled

asphalt aggregate (PRAA) as constituent in mortar. All

variables were set a constant except for the aggregate type, the VA mortar

function as controlling element. This research is methodologically based on

experimental data conducted in the laboratory, while aggregate samples were

taken from the field. To analyze the influence of pyrolysis to the

aggregate-to-cement bond behaviour, qualitative and quantitative data were

collected. The quantitative data were the mechanical properties, the mortar

tensile, and compression strength. The qualitative data were obtained from

scanning electron microscope readings to visually observe the aggregate surface

roughness and voids, including the aggregates cross-section and pre-existing

micro-cracks in the aggregate-to-cement interface. Supporting data were the

aggregates‘ abrasion rate

and absorption. The RAA resulted in a significant mortar strength decrease.

This conclusion was supported by the findings of pre-existing cracks in the

interfacial transition zone. The pyrolysis method improved the compression strength

but negligibly affected the tensile behavior. The compression and tensile

strength increased as a function of time for both RAA and PRAA, and a strength

convergence was reached at 28 days. The PRAA is considered an option for reuse

in mortar, supporting nature conservation.

Mechanical properties; Mortar constituent; Pyrolysis recycled asphalt aggregates

The aggregates in cementitious composites originate

from quarries or through stone crushing, which is basically recyclable (Ashadi et al., 2015; Turu’allo,

2015; Purnomo et al., 2021). Two most commonly used

recycle aggregate, i.e., recycled concrete or paving-originated aggregates,

supports the sustainability of the aggregate’s lifecycle. The main

issue when dealing with recycled aggregates is the quality: the physical

and mechanical properties that are highly influenced by the original binding

agent residue. The quality and origin of cement highly influence the alteration

of the aggregate properties when dealing with concrete and mortar. For asphalt

pavements, the asphalt is the main affecting material. The untraceable origin

and the wide range of cement and asphalts make the aggregates a very unreliable

material for recycling purposes.

The use of recycled asphalt aggregate

(RAA) in mortar has been widely studied (Abraham & Ransinchung,

2018; Sola & Ozyazgan, 2019; Debbarma et al., 2020; Shi et

al., 2020). In general, RAA from road scarifying is used directly

as a constituent in mortar. The studies concluded that the use of RAA in mortar

decreases the mechanical properties as a function of asphalt content in the

RAA. The main source of this depreciation is the poor bond. Debbarma et al. (2020) recommend

applying surface treatments (mechanically or chemically) to remove the residue

from the surface to stabilize the aggregate. The following is an overview of

methods nowadays used.

The use of microwaves for concrete

aggregate recycling started as early as 2011 and is still being investigated to

date (Akbarnezhad

et al., 2011; Choi et al., 2014; Mousa et al., 2020; Wei et al., 2021a; 2021b;

2021c). Microwave heating is also used in asphalt road

maintenance work, such as hot in-place recycling. This method does not

completely remove asphalt from the aggregate surface but only softens the

asphalt to facilitate mixing of the recycled asphalt pavement with additional

asphalt or new aggregate (Benedetto & Calvi, 2013; Sun & Sheng, 2020; Gulisano & Gallego, 2021).

Mechanically removing the thin layer of the bonding agent using acid and lime

immersion and mechanical rubbing (Kazmi et al., 2019) was also

attempted. Improving the contaminated surface was conducted by accelerated

carbonation techniques and slurry wrapping (Wang et al., 2020). The two

basic approaches differed in their method: the first was by film removal, and

the second was by treatment of the coated surface. Most recent is the

introduction of nano-silica technology through a combination of pre-spraying,

air-drying, and particle size evaluation (Gao et al., 2020; Li et al., 2021), and the

self-healing concept. The latter evolves around re-hydrating, bacterial

self-healing, and micro-encapsulation (Li et al., 2021). An

overview of methods, their advantages, and disadvantages, are outlined in the

following works (Wang

et al., 2020; Tam et al., 2021).

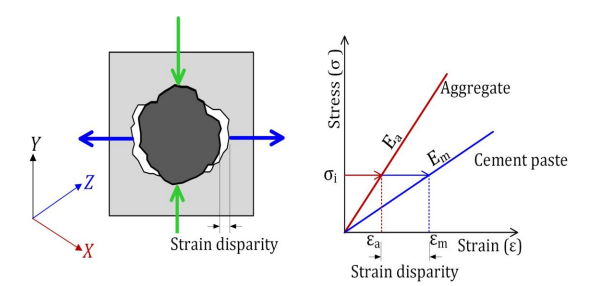

This work is focused on the reuse of RAA in mortar. The focus

is directed on mortar, since the behavior of mortar represents a wide range of

cement-made products such as paving blocks, concrete, and masonry. Three types

of aggregate were used: virgin aggregate (VA), recycled asphalt aggregate

(RAA), and RAA after removing the thin asphalt film using the pyrolysis method

(designated as pyrolysis recycled asphalt aggregate (PRAA)). The Pyrolysis

method is a unique new surface treatment method to remove and stabilize the

residual asphalt film by heating and is expected to contribute to increasing

the mechanical properties of the mortar due to an aggregate-to-mortar bond

improvement.

Research on pyrolysis of recycled asphalt aggregates is limited.

Most of the work on improving recycled aggregates does not focus on pyrolysis

to stabilize the residual film surrounding the aggregates. Comparing the impact

of methods in general, recycled aggregates result in a decrease in compressive

and tensile strengths due to the residue of previous binding agents and the

non-standard quality of the original material, as stated in the majority of

previous research works. The attempt to remove the residual film using a broad

range of methods showed that the mechanical properties of the new composite

using mortar or asphalt as the binder improved, but could never reach the

strength of the original virgin aggregates (VA).

The findings in this study showed that, in compression, the

decrease was independent of mortar age; the strength reduction was 55% and 30%

for the RAA and PRAA mortars. The strength loss of the RAA predominantly

originated from the surface conditions: the thickness of asphalt film, smoother

surface, pre-existing micro-cracks, which promote crack initiation and

propagation under loading, and the decrease in abrasion resistance, in

combination with the presence of loose, unstable particles. The PRAA had a

better compression strength, but, despite the removal of the asphalt film, a

thin layer of residue remained. The PRAA had a relatively high abrasion rate,

weakening the bond between the aggregate and the cement. While no preliminary

micro-cracks were present in the aggregate surface and the absorption rate was

better compared to RAA, substantial pre-existing cracks were detected in the

aggregate-to-mortar interface.

In tension, both the RAA and PRAA exhibited a 40% strength

decrease, which is slightly fluctuates with age and stabilises at 28 days. The

pyrolysis did not substantially affect the tensile behavior due to the presence

of pre-existing cracks. The relationship between the tensile and compression

strength can be represented by the coefficient C ranging from 1.3 and 1.2 for the VA and RAA, and 1.0 for the

PRAA, using the equation at any age from 14 to 180 days.

The RAA had a 1.49% absorption, but the PRAA had a substantially

lower absorption of 0.59%. The pyrolysis stabilized the surface and prevented

water intrusion into the aggregate's inner pores.

The pyrolysis method applied on RAA had a number of advantages:

the compression strength increased, and the absorption decreased, reducing the

formation of a water film surrounding the aggregate during the cement hydration

process. The pyrolysis procedure did not have any impact on the tensile

strength for both the RAA and PRAA, however, the overall tensile strength

decrease was relatively low, with a minimum reduction of 42% in the VA mortar.

The pyrolysis procedure offers a solution to rejuvenate the RAA for mortar

usage. The reuse of RAA supports the conservation of natural aggregates.

This

research was financially supported by the Faculty of Engineering, Diponegoro

University, Indonesia through the Excellent Research Grant 2021 [grant number

3179/U/1/UN7.5.3.2/PP/2021].

Abraham, S.M., Ransinchung, G.D.R.N., 2018.

Strength and Permeation Characteristics of Cement Mortar with Reclaimed Asphalt

Pavement Aggregates. Construction and Building Materials, Volume 167,

pp. 700–706

Abraham, S.M., Ransinchung, G.D.R.N., 2019a.

Effects of Reclaimed Asphalt Pavement Aggregates and Mineral Admixtures on Pore

Structure, Mechanical and Durability Properties of Cement Mortar. Construction

and Building Materials, Volume 216, pp. 202–213

Abraham, S.M., Ransinchung, G.D.R.N., 2019b.

Pore Structure Characteristics of RAP-Inclusive Cement Mortar and Cement

Concrete Using Mercury Intrusion Porosimetry Technique. Advances in Civil

Engineering Materials, Volume 8(3), pp. 431–453

Ahmad, S., Maslehuddin, M., Shameem, M.,

Faysal, R.M., Adekunle, S.K., 2022. Effect of Abrasion and Chemical Treatment

of Recycled Aggregate on the Workability, Strength, and Durability Properties

of Concrete. European Journal of Environmental and Civil Engineering, Volume

26(8), pp. 3276–3291

Akbarnezhad, A., Ong, K.C.G., Zhang, M.H.,

Tam, C.T., Foo, T.W.J., 2011. Microwave-Assisted Beneficiation of Recycled

Concrete Aggregates. Construction and Building Materials, Volume 25(8),

pp. 3469–3479

An, H., Cheng, Y., Li, T., Li, Y., Cheng, Y.,

2018. Modeling of Asphalt Pyrolisis Based on Chemical Percolation

Devolatilization Theory. In: The 25th International Symposium on

Chemical Reaction Engineering, Florence, 20-23 May 2018, Italy, pp. 1–2

Ashadi, H.W., Aprilando, B.A., Astutiningsih,

S., 2015. Effects of Steel Slag Substitution in Geopolymer Concrete on

Compressive Strength and Corrosion Rate of Steel Reinforcement in Seawater and

an Acid Rain Environment. International Journal of Technology, Volume

6(2), pp. 227–235

Benedetto, A., Calvi, A., 2013. A Pilot Study

on Microwave Heating for Production and Recycling of Road Pavement Materials. Construction

and Building Materials, Volume 44, pp. 351–359

Bittencourt, S.V., da Silva Magalhães, M., da

Nóbrega Tavares, M.E., 2021. Mechanical Behavior and Water Infiltration of

Pervious Concrete Incorporating Recycled Asphalt Pavement Aggregate. Case

Studies in Construction Materials, Volume 14, p. e00473

Brand, A.S., Roesler, J.R., 2017a. Bonding in

Cementitious Materials with Asphalt-Coated Particles: Part I – The Interfacial

Transition Zone. Construction and Building Materials, Volume 130, pp.

171–181

Brand, A.S., Roesler, J.R., 2017b. Bonding in

Cementitious Materials with Asphalt-Coated Particles: Part II – Cement-Asphalt

Chemical Interactions. Construction and Building Materials, Volume 130, pp. 182–192

Chaidachatorn, K., Suebsuk, J., Horpibulsuk,

S., Arulrajah, A., 2019. Extended Water/Cement Ratio Law for Cement Mortar

Containing Recycled Asphalt Pavement. Construction and Building Materials,

Volume 196, pp. 457–467

Chen, J.J., Guan, G.X., Ng, P.L., Kwan,

A.K.H., Chu, S.H., 2021. Packing Optimization of Paste and Aggregate Phases for

Sustainability and Performance Improvement of Concrete. Advanced Powder

Technology, Volume 32(4), pp. 987–997

Cheng, Y., Li, T., An, H., Li, Y., Cheng, Y.,

2017. Modeling Pyrolysis of Asphalt using Chemical Percolation Devolatilization

Theory. Fuel, Volume 206, pp. 364–370

Choi, H., Lim, M., Choi, H., Kitagaki, R.,

Noguchi, T., 2014. Using Microwave Heating to Completely Recycle Concrete. Journal

of Environmental Protection, Volume 5(7), pp. 583–596

Debbarma, S., Selvam, M., Singh, S., 2020.

Can Flexible Pavements’ Waste (RAP) be Utilized in Cement Concrete Pavements? –

A Critical Review. Construction and Building Materials, Volume 259, p. 120417

Dong, M., Sun, W., Li, L., Gao, Y., 2020.

Effect of Asphalt Film Thickness on Shear Mechanical Properties of

Asphalt-Aggregate Interface. Construction and Building Materials, Volume

263, p. 120208

Gao, C., Huang, L., Yan, L., Jin, R., Chen,

H., 2020. Mechanical Properties of Recycled Aggregate Concrete Modified by

Nano-Particles. Construction and Building Materials, Volume 241, p. 118030

Ghasemi, Y., Emborg, M., Cwirzen, A., 2019.

Effect of Water Film Thickness on the Flow in Conventional Mortars and

Concrete. Materials and Structures/Materiaux et Constructions, Volume

52(3), pp. 1–15

Gulisano, F., Gallego, J., 2021. Microwave Heating

of Asphalt Paving Materials: Principles, Current Status and Next Steps. Construction

and Building Materials, Volume 278, p. 121993

Jing-Song, G., Wei-Biao, F., Bei-Jing, Z.,

2003. A Study on the Pyrolysis of Asphalt. Fuel, Volume 82(1), pp. 49–52

Kazmi, S.M.S., Munir, M.J., Wu, Y.F.,

Patnaikuni, I., Zhou, Y., Xing, F., 2019. Influence of Different Treatment

Methods on the Mechanical Behavior of Recycled Aggregate Concrete: A Comparative

Study. Cement and Concrete Composites, Volume 104, p. 103398

Königsberger, M., Hlobil, M., Delsaute, B.,

Staquet, S., Hellmich, C., Pichler, B., 2018. Hydrate Failure in ITZ Governs

Concrete Strength: A Micro-To-Macro Validated Engineering Mechanics Model. Cement

and Concrete Research, Volume 103, pp. 77–94

Kwan, A.K.H., Li, L.G., 2012. Combined Effects

of Water Film Thickness and Paste Film Thickness on Rheology of Mortar. Materials

and Structures/Materiaux et Constructions, Volume 45(9), pp. 1359–1374

Li, L., Xuan, D., Sojobi, A.O., Liu, S., Chu,

S.H., Poon, C.S., 2021. Development of Nano-Silica Treatment Methods to Enhance

Recycled Aggregate Concrete. Cement and Concrete Composites, Volume 118,

p. 103963

Mousa, E., El-Badawy, S., Azam, A., 2020.

Evaluation of Reclaimed Asphalt Pavement as Base/Subbase Material in Egypt. Transportation

Geotechnics, Volume 26, p. 100414

Purnomo, H., Baskoro, H., Muslim, F., 2021.

Stress and Strain Behavior of Confined Lightweight Concrete using Sand Coated

Polypropylene Coarse Aggregate. International Journal of Technology,

Volume 12(6), pp. 1261–1272

Qiang, W., Peiyu, Y., Ruhan, A., Jinbo, Y.,

Xiangming, K., 2011. Strength Mechanism of Cement-Asphalt Mortar. Journal of

Materials in Civil Engineering, Volume 23(9), pp. 1353–1359

Shen, Y., Wang, Y., Yang, Y., Sun, Q., Luo,

T., Zhang, H., 2019. Influence of Surface Roughness and Hydrophilicity on

Bonding Strength of Concrete-Rock Interface. Construction and Building

Materials, Volume 213, pp. 156–166

Shi, X., Grasley, Z., Hogancamp, J.,

Brescia-Norambuena, L., Mukhopadhyay, A., Zollinger, D., 2020. Microstructural,

Mechanical, and Shrinkage Characteristics of Cement Mortar Containing Fine

Reclaimed Asphalt Pavement. Journal of Materials in Civil Engineering,

Volume 32(4), pp. 1–11

Sola, Ö.Ç., Ozyazgan, C., 2017. Mechanical Properties

of Mortar Containing Recycled Asphalt. Journal of the Croatian Association

of Civil Engineers, Volume 69(10), pp. 933–940

Sola, Ö.Ç., Ozyazgan, C., 2019. Analyses of Cement

Mortars Containing Reclaimed Asphalt Pavement by using DTA/TG and FTIR. Journal

of the Croatian Association of Civil Engineers, Volume 71(4), pp. 273–282.

Sun, T., Sheng, H., 2020. Heat Transfer

Analysis of Microwave Hot Recycling for Asphalt Pavement. The Journal of

Engineering, Volume 2020(1), pp. 1–5

Tam, V.W.Y., Wattage, H., Le, K.N., Buteraa,

A., Soomro, M., 2021. Methods to Improve Microstructural Properties of Recycled

Concrete Aggregate: A Critical Review. Construction and Building Materials,

Volume 270, p. 121490

Tufail, M., Shahzada, K., Gencturk, B., Wei,

J., 2017. Effect of Elevated Temperature on Mechanical Properties of Limestone,

Quartzite and Granite Concrete. International Journal of Concrete Structures

and Materials, Volume 11(1), pp. 17–28

Tugrul-Tunc, E., Alyamac, K.E., 2020.

Determination of the Relationship between the Los Angeles Abrasion Values of

Aggregates and Concrete Strength using the Response Surface Methodology. Construction

and Building Materials, Volume 260, p. 119850

Turu’allo, G., 2015. Using ggbs for Partial

Cement Replacement in Concrete: Effects of Water-Binder Ratio and ggbs Level on

Activation Energy. International Journal of Technology, Volume 6(5), pp.

790–799

Wang, J., Zhang, J., Cao, D., Dang, H., Ding,

B., 2020. Comparison of Recycled Aggregate Treatment Methods on the Performance

for Recycled Concrete. Construction and Building Materials, Volume 234, p.

117366

Wang, R., Yu, N., Li, Y., 2020. Methods for

Improving the Microstructure of Recycled Concrete Aggregate: A Review. Construction

and Building Materials, Volume 242, p. 118164

Wang, X., Dong, S., Ashour, A., Zhang, W.,

Han, B., 2020. Effect and Mechanisms of Nanomaterials On Interface Between

Aggregates and Cement Mortars. Construction and Building Materials,

Volume 240, p. 117942

Wei, W., Shao, Z., Chen, W., Zhang, P.,

Cheng, J., 2021a. Experimental Study on Thermal and Mechanical Behavior of

Mortar-Aggregate under Microwave Irradiation. Journal of Building

Engineering, Volume 34, p. 101947

Wei, W., Shao, Z., Qiao, R., Chen, W., Zhang,

P., Cheng, J., 2021b. Workability and Mechanical Properties of Microwave

Heating for Recovering High Quality Aggregate from Concrete. Construction

and Building Materials, Volume 276, p. 122237

Wei, W., Shao, Z., Zhang, P., Chen, W., Qiao,

R., Yuan, Y., 2021c. Experimental Assessment of Microwave Heating Assisted

Aggregate Recycling from Dried and Saturated Concrete. Materials and

Structures, Volume 54(4), pp. 142–155

Xu, F., Tian, B., Xu, G., 2021. Influence of the ITZ Thickness on the Damage Performance of Recycled Concrete. Advances in Materials Science and Engineering, Volume 2021, p. 6643956

Zhou, X., Zhao, G., Tighe, S., Chen, M., Wu, S., Adhikari, S., Gao, Y., 2020. Quantitative Comparison of Surface and Interface Adhesive Properties of Fine Aggregate Asphalt Mixtures Composed of Basalt, Steel Slag, and Andesite. Construction and Building Materials, Volume 246, p. 118507