The Simultaneously Removal of NOx and SO2 Processes through a Polysulfone Hollow Fiber Membrane Module

Corresponding email: sutrasno@che.ui.ac.id

Published at : 09 May 2023

Volume : IJtech

Vol 14, No 3 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i3.5544

Kartohardjono, S., Karamah, E.F., Talenta, G.N., Ghazali, T.A., Lau, W.J., 2023. The Simultaneously Removal of NOx and SO2 Processes through a Polysulfone Hollow Fiber Membrane Module. International Journal of Technology. Volume 14(3), pp. 576-583

| Sutrasno Kartohardjono | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

| Eva Fathul Karamah | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

| Grace Nathalie Talenta | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

| Thariq Ahmad Ghazali | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

| Woei Jye Lau | Advance Membrane Technology Research Center, Universiti Teknologi Malaysia, 81310 Skudai, Johor, Malaysia |

Hazardous pollutants such as NOx (NO and NO2) and SO2

generally come from fossil fuel combustion, harm the human respiratory system,

and damage environmental ecosystems. The conventional technology that has been

used so far consists of two methods: FGD (Flue Gas Desulfurization) and SCR

(Selective Catalytic Reduction) or SNCR (Selective Non-Catalytic Reduction) to

remove SO2 and NOx. The study aims to examine the performance of

polysulfone membranes in removing NOx and SO2 simultaneously using

hydrogen peroxide (H2O2) and sodium hydroxide (NaOH)

solutions as absorbents. The presence of H2O2 and NaOH in

absorbent solutions plays a role in oxidizing NOx into soluble species in water

and in absorbing SO2 gas, respectively. During the experiment, the feed

gas flowed through the lumen fiber and then passed through the fiber to the

shell side of the membrane module, where the reaction happened between NOx and

SO2 and the absorbent. The experimental results showed that the

presence of SO2 affected the NOx reduction efficiency. The NOx and

SO2 removal efficiencies decreased with the feed gas flow. This study's maximum NOx and SO2

reduction efficiencies were 93.9 and 99.8%,

respectively.

Air pollution; H2O2; NOx; Removal efficiency; SO2

Air

pollution in Indonesia increases yearly due to growing public energy

consumption. Hazardous pollutants such as NOx (NO and NO2) and SO2

generally come from fossil combustion, harm the human respiratory system, and

damage environmental ecosystems (Manisalidis et

al., 2020; Wang, Wang, and Shammas, 2020; Sharma et al., 2013). Based

on a study on the emissions prediction from the coal-fired power plants in

Indonesia in 2016-2020, there was an exponential increase of 120.0 and 798.5

ktons of NOx and SO2, respectively, in that period (Sunarno, Purwanto, and Suryono, 2021). The

Indonesian Government's efforts to prevent air pollution nationally set Ambient

Air Quality Standards (BMUA) in Government Regulation No. 41 of 1999 (RI, 1999).

However, the NOx and SO2 emissions produced by the coal-fired power

plants in Indonesia are above the value of the BMUA, so efforts are needed to

reduce emissions in PLTUs made from burning coal. Reducing NOx and SO2

emissions requires two different technologies,

namely SO2

A previous study (Kartohardjono et al.,

2019; Kartohardjono et al., 2017) has shown that the HFMM (hollow

fiber membrane module) can be used as a bubble reactor to remove NOx using H2O2

and HNO3 solutions. The fibers’ role is to distribute the feed gas

into the solutions on the shell side of the HFMM so that reactions happen between

NOx and the absorbent. NO (nitrogen monoxide) in NOx is an insoluble gas in

water, so it needs to be oxidized to increase its solubility. One of the

solutions that can be used to oxidize NO is hydrogen peroxide (H2O2).

The H2O2 is superior as it is very stable under normal

conditions, environmentally friendly, does not leave harmful residues, and the

operating costs are pretty affordable. No conventional technology in the power

generation industry can reduce NOx and SO2 simultaneously (Park et al., 2019; Si et al., 2019).

In order to remove NOx and SO2 simultaneously, an absorbent that can

oxidize NOx into water-soluble species and an alkaline solution that can absorb

SO2 are required. This study utilized the polysulfone hollow fiber

membrane module to remove NOx and SO2 simultaneously using

absorbents consisting of H2O2 as an oxidant and sodium

hydroxide (NaOH) as a base solution. The polysulfone membrane module was chosen

because of its excellent stability over a wide pH range (2-13) and oxidant

resistance (Febriasari et al., 2021; Serbanescu, Voicu, and Thakur, 2021). Therefore, it can

be expected to see the effect of SO2 in the feed gas on NOx removal

compared to NOx removal alone. The NaOH solution absorbs the reaction products

between NOx gas and SO2 and H2O2. Reactions

(1-7) are reactions that may occur in the process of simultaneously removing

NOx and SO2 using a mixture of H2O2 and NaOH

as absorbents: (Kartohardjono et al., 2020;

Sun, Zwoli?ska,

and Chmielewski, 2016):

The hollow fiber membrane module used

contains 50 polysulfone fibers with a diameter of 3 cm and an effective length

of 25 cm, supplied from GDP Filter Bandung, Indonesia. The fibers are 1.8 and 2

mm in the inside and outside diameters, respectively. The feed gas, which

contained 600 ppm of NOx and 500 ppm of SO2 in nitrogen, was supplied from

PT EIN Jakarta, Indonesia. The chemicals used, H2O2 and NaOH, are analytical grades

Merck Indonesia supplies. The feed gas flowed inside the fiber in the membrane

module throughout the experiment. The flow rate was adjusted using a CX Series

mass flow controller. The feed gas diffused across the membrane pores to the

shell side of the HFMM and contacted absorbent solutions so that reactions

occurred between NOx, SO2, H2O2, and NaOH, as shown in Reaction

(1-8). The concentrations of NOx and SO2 gases entering and leaving the

HFMM were recorded by the Gas Analyzer ECOM-D. The schematic of the experiment

is presented in Figure 1.

The amount of absorbed NOx and SO2 gases, GasAbs,

removal efficiency, R, fluxes, J, and NOx and SO2 loading, Gas-loading,

can be calculated by Equations 8-11 (Kartohardjono et

al., 2020; Ding et al., 2014):

Where Xin and Xout, QG,in, T, P, and R are the concentration of gas inlet and outlet of the membrane module, feed gas flow rate, temperature, pressure, and gas constant, respectively.

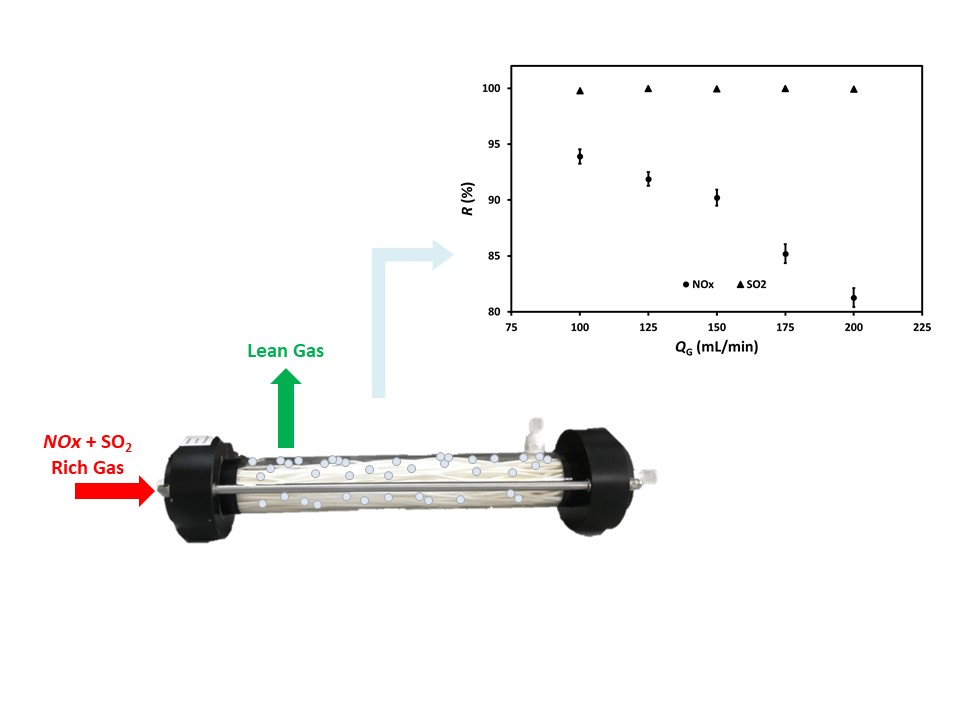

Figure 1 The experimental diagram schematic

Figure 2 shows the effect of the feed gas flow rate, containing 500 ppm SO2 and 600 ppm NOx, on the simultaneous removal of SO2 and NOx in the HFMM, which contains 0.1M of H2O2 and 0.5 M NaOH each of 200 ml. As demonstrated in Figure 2, the NOx removal efficiency declines with increasing the feed gas flow rate due to the reduced gas residence time in the HFMM (Kartohardjono et al., 2019). Meanwhile, the SO2 removal efficiency is relatively constant to the feed gas flow rate changes because it is already close to 100%. The removal efficiency of SO2 depends not only on the oxidant (H2O2), as expressed in Eq. 6, but also mainly on the alkaline solution present in the adsorbent (NaOH) so that it can be removed entirely (removal efficiency » 100%) (Chen, Chen, and Chiang, 2020; Liu et al., 2019; Huang, Ding, and Zhong, 2015). The NOx absorption efficiency decreases from 93.9 to 81.3% by increasing the feed gas flow from 100 to 200 mL/min. The NOx removal was more complex than the SO2 removal, as the SO2 solubility in water was about 700 times higher than that of NO (Fang et al., 2011). A previous study showed a slight decrease in single NOx removal efficiency from 94.6 to 94.0% by increasing the same feed gas flow rate in a polysulfone HFMM containing 48 fibers using absorbents of H2O2 and HNO3 solutions. It reveals that the presence of SO2 in the feed gas decreases the efficiency of NOx removal due to the competition factor in consuming H2O2 as an oxidation agent, as expressed in Equations 5 and 6 (Chen, Chen, and Chiang, 2020; Kartohardjono et al., 2020).

Figure 2 The dependency of NOx and SO2 reduction

efficiencies, R, on the feed gas

flow, QG

The amount of absorbed NOx and SO2 and mass transfer flux, J, rise with the feed gas flow, as presented in Figure 3. The increase in the feed gas flow increases the number of gas molecules and resulting a higher concentration of the bulk gas. This condition creates a higher concentration driving force, bringing the higher absorbed NOx and SO2 and mass transfer flux (Liu et al., 2019). The absorbed NOx and SO2 rose from 3.8 to 6.6 x 10-5 mmol/s and 4.1 to 8.1 x 10-5 mmol/s, respectively, by increasing the feed gas flow from 100 to 200 mL/min. Meanwhile, the NOx and SO2 flux increased from 4.9 to 8.4 x 10-8 mmol/cm2.s and 5.2 x 10-8 to 1.0 x 10-7 mmol/cm2.s, respectively, when the feed gas flow rate was increased from 100 to 200 mL/min. A previous study exhibited a similar result: single NOx flux increased from 5.6 x 10-8 to 1.1 x 10-7 by doubling the feed gas flow from 100 to 200 mL/min in a polysulfone HFMM with 48 fibers containing absorbents of H2O2 and HNO3 solutions. It is also revealed that the existence of SO2 in the feed gas affects the transfer flux of NOx (Kartohardjono et al., 2019).

Figure 3 The

dependency of absorbed NOx and SO2, and mass transfer fluxes, J, on the feed gas flow, QG

As with flux, NOx and SO2 loading increases with the feed gas flow rate due to the increased amount of absorbed NOx and SO2. Figure 4 shows the dependency of NOx and SO2 loading on the feed gas flow. The NOx and SO2 loading increased from 0.0019 to 0.0033 mmol/mol.s and 0.0020 to 0.0041 mmol/mol.s, respectively, by doubling the feed gas flow from 100 to 200 mL/min. Similar results were also reported that the NOx removal increased from 0.002 to 0.004 mmol/mol.s by doubling the feed gas flow rate, containing NOx 600 ppm, in the PVDF HFMM containing 0.5 wt.% H2O2 and 0.5M HNO3 each of 25 ml (Purnawan et al., 2021).

Figure 4 The

absorbed NOx and SO2 loading dependency on the feed gas flow, QG

Figure 5 shows the absorption efficiency (%R) for NOx and SO2 as a function of H2O2 concentration. The efficiency of NOX removal increases with the increase in H2O2 concentration, while in SO2 gas, the efficiency is relatively constant with the addition of H2O2 concentration. The increase in the concentration of H2O2 causes an increase in the number of moles of O2 produced in the solution to oxidize NOx. The highest absorption efficiency achieved was 97.53% for NOx and 99.79% for SO2 at a 0.1 M H2O2 concentration. This study of simultaneous removal of mixed gases (NOx and SO2) resulted in a lower %R compared to the utilization of hollow fiber membranes on single-gas NOx by H2O2/HNO3 solvents in previous studies (Kartohardjono et al., 2019). The absorption efficiency of NOx gas is about 95% at 0.25% H2O2 by mass. In the same polysulfone membrane module and H2O2 solvent, it is seen that the absorption efficiency decreases between mixed gas (NOx and SO2) and single gas (NOx only) due to SO2 compounds competing with NOx in consuming the absorbent (i.e., H2O2 and NaOH).

Figure 5 The

dependency of NOx and SO2 reduction efficiencies, R, on the H2O2 concentration in the absorbent solutions at the feed gas flow rate of 0.1 L/min

Figure 6 shows the effect of the concentration of H2O2 on the amount of gas absorbed and the mass transfer flux at a feed gas flow rate of 0.1 L/min. The amount of SO2 gas absorbed and the mass transfer flux of SO2 was constant, at about 4.05 x 10-5 mmol/s and 8.98 x 10-8 mmol/cm2.s. Meanwhile, the amount of NOx absorbed and the mass transfer flux of NOx increased with the increase in the concentration of H2O2 in the absorbent solution. The amount of NOx absorbed and the mass transfer flux of NOx increased from 3.72 to 3.96 x 10-5 mmol/s and from 8.24 to 8.77 x 10-8 mmol/cm2.s. The increase in the amount of absorbed gas and flux is relatively small, so it can be categorized as the concentration of H2O2 does not have much effect on the amount of gas absorbed and the flux of NOx and SO2. The increasing concentration of H2O2 only affects the reaction rate between NOx with H2O2. Compared with other studies (Kartohardjono, 2019), the results also show an insignificant mass transfer flux from 1.153 x 10-9 mmol/cm2.s at 0.1% w/w H2O2to 1.486 x 10-9 mmol/cm2.s at 0.4% w/w H2O2.

Figure 6 The

dependency of NOx and SO2 absorbed and flux, J, on the H2O2 concentration in the absorbent solutions at the feed gas flow rate of 0.1

L/min.

NOX and SO2 loading decreased drastically as the feed gas flow rate increased, as shown in Figure 7. The NOx loading at a feed gas flow rate of 100 mL/min was 1.86 x 10-3 mmol NOx per mole H2O2 per second. It decreased drastically to 1.98 x 10-4 mmol NOx per mole H2O2 per second if the concentration of H2O2 in the absorbent solution increased from 0.001 to 0.1 M. Meanwhile, SO2 loading decreased drastically from 2.03 x 10-2 mmol SO2 per mole H2O2 per second to 2.03 x 10-4 mmol SO2 per mole H2O2 per second if the concentration of H2O2 in the absorbent solution increases from 0.001 to 0.1 M. This decrease occurs because the increase in the amount of NOx and SO2 gas absorbed is not proportional to the increase in the concentration of H2O2 in the absorbent. Similar results were also reported: the NOx loading decreased with increasing the concentration of absorbents (Karamah et al., 2021; Purnawan et al., 2021).

Figure 7 The dependency of NOx and SO2loading on

the H2O2 concentration in the absorbent solutions at the

feed gas flow rate of 0.1 L/min

The elimination of NOx and SO2 simultaneously can be

conducted in an HFMM using absorbents such as H2O2 and

NaOH. The presence of SO2 in the feed gas could reduce the removal

efficiency of NOx because of the competition factor in consuming H2O2 in the process. The NOx and SO2 removal efficiencies decrease with

the feed gas flow rate, while the NOx and SO2 absorbed, fluxes, and

loadings increase with the feed gas flow. This study's maximum NOx reduction

efficiency was 93.9%, while SO2 can be almost entirely removed. In

future work, the methods would be applied to remove NOx and SO2 simultaneously from the flue gas resulting from fossil fuel combustion.

The authors wish to

acknowledge the PDUPT Project via the Directorate of Research and Services

Universitas Indonesia through Contract No. NKB-213/UN2.RST/ HKP.05.00/2021.

Brandenberger, S., Kröcher, O., Tissler, A.,

Althoff, R., 2008. The state of the art in selective catalytic reduction

of NOx by ammonia using metal?exchanged zeolite catalysts. Catalysis Reviews, Volume 50(4), pp. 492–531

Chang, M.B., Lee, H.M., Wu, F., Lai, C.R., 2004.

Simultaneous removal of nitrogen oxide/nitrogen dioxide/sulfur dioxide from gas

streams by combined plasma scrubbing technology. Journal of the Air & Waste Management Association, Volume 54(8), pp. 941–949

Chen, T.-L., Chen, Y.-H., Chiang, P.-C., 2020. Enhanced

performance on simultaneous removal of NOx-SO2-CO2 using a high-gravity

rotating packed bed and alkaline wastes towards green process intensification. Chemical Engineering Journal, Volume 393, p. 124678

Cheng, G., Zhang, C., 2018.

Desulfurization and denitrification technologies of coal-fired flue gas. Polish Journal of Environmental Studies, Volume

27(2), pp. 481–489

Ding, J., Zhong, Q., Zhang, S., Song, F., Bu, Y., 2014.

Simultaneous removal of NOx and SO2 from coal-fired flue gas by

catalytic oxidation-removal process with H2O2. Chemical Engineering Journal, Volume 243, pp. 176–182

Fang, P., Cen, C., Tang, Z., Zhong, P., Chen, D.,

Chen, Z., 2011. Simultaneous removal of SO2 and NOx by wet

scrubbing using urea solution. Chemical

Engineering Journal, Volume 168(1), pp. 52–59

Febriasari, A., Huriya, Ananto,

A.H., Suhartini, M., Kartohardjono, S., 2021. Polysulfone-polyvinyl

pyrrolidone blend polymer composite membranes for batik industrial wastewater

treatment. Membranes, Volume 11(1), pp. 1–17

Huang,

X., Ding, J., Zhong, Q., 2015. Catalytic decomposition of H2O2

over Fe-based catalysts for simultaneous removal of NOX and SO2.

Applied Surface Science, Volume 326, pp. 66–72.

Karamah, E.F., Arbi, D.S., Bagas, I.,

Kartohardjono, S., 2021. Hollow fiber membrane modules for NOx removal using a

mixture of NaClO3 and NaOH solutions in the shell side as absorbents.

International Journal of Technology, Volume 12(4), pp. 690–699

Kartohardjono, S., Merry, C., Rizky, MS.,

Pratita, C.C., 2019. Nitrogen oxide reduction through absorbent solutions

containing nitric acid and hydrogen peroxide in hollow fiber membrane modules. Heliyon, Volume

5(12), p. e02987

Kartohardjono, S., Paramitha, A., Putri, AA.,

Andriant, R., 2017. Effects of absorbent flow rate on CO2 absorption

through a super hydrophobic hollow fiber membrane contactor. International Journal of Technology, Volume

8(8), pp. 1429–1435

Kartohardjono, S., Rizky, M.S., Karamah, E.F.,

Lau, W.-J., 2020. The effect of the number of fibers in hollow fiber

membrane modules for NOx absorption. Chemical

Engineering, Volume 11(2), pp. 269–277

Krzyzynska, R. Hutson, N.D., 2012. Effect of

solution pH on SO2, NOx, and Hg removal from simulated coal

combustion flue gas in an oxidant-enhanced wet scrubber. Journal of the Air & Waste Management Association, Volume 62(2), pp. 212–220

Li, Y., Che, D., Zhao, H., Yang, C., Zhao, T.,

Cheng, G., Yao, M., 2020. Tributyl phosphate additive enhancing catalytic

absorption of NO2 for simultaneous removal of SO2/NOx in

wet desulfurization system. Journal of

the Energy Institute, Volume 932, pp. 474–481

Liu, X., Zhu, T., Lv, Q., Li, Y., Che, D., 2019. Simultaneous

removal of NOx and SO2 from coal-fired flue gas based on the

catalytic decomposition of H2O2 over Fe2 MoO43.

Chemical Engineering Journal, Volume 371, pp. 486–499

Manisalidis, I., Stavropoulou, E., Stavropoulos,

A., Bezirtzoglou, E., 2020. Environmental and health impacts of air pollution: a

review. Frontiers in public health, Volume 8, p. 14

Park, J.-H., Ahn, J.-W., Kim, K.-H., Son, Y.-S., 2019. Historic

and futuristic review of electron beam technology for the treatment of SO2

and NOx in flue gas. Chemical Engineering

Journal, Volume 355, pp. 351–366

Purnawan, I., Kartohardjono, S., Wibowo, L.,

Ramadhani, A.F., Lau, W.J., Febriasari, A., 2021. Effect of absorbents on NOx

removal through polyvinylidene fluoride PVDF hollow fiber membrane modules. International Journal of Chemical

Engineering, Volume 2021, p. 8277082

Republic of Indonesia (RI), 1999. Government Regulation No. 41 of 1999

concerning Air Pollution Control. pp. 1–34

Serbanescu, O.S., Voicu, SI., Thakur, V.K., 2020.

Polysulfone functionalized membranes: Properties and challenges. Materials Today Chemistry, Volume 17, p. 100302

Sharma, S.B., Jain, S., Khirwadkar, P., Kulkarni,

S., 2013. The effects of air pollution on the environment and human health. Indian Journal of Research in Pharmacy and

Biotechnology, Volume 13, pp. 391–396

Si, T., Wang, C., Yan, X., Zhang, Y., Ren, Y.,

Hu, J., Anthony, E. J., 2019. Simultaneous removal of SO2 and NOx by a

new combined spray-and-scattered-bubble technology based on preozonation: From

lab scale to pilot scale. Applied Energy, Volume

242, pp. 1528–1538

Sun, Y., Zwoli?ska, E., Chmielewski, A.G., 2016. Abatement

technologies for high concentrations of NOx and SO2 removal from exhaust gases:

A review. Critical Reviews in

Environmental Science and Technology, Volume

46(2), pp. 119–142

Sunarno, S., Purwanto, P., Suryono, S. 2021., Trend analysis of NOX

and SO2 emissions in Indonesia from the period of 1990 -2015 using data

analysis tool. Advances in Science,

Technology and Engineering Systems Journal, Volume 61, pp. 257–263

Wang, M.-H. S., Wang, L.K., Shammas, N.K., 2019. Glossary

of acid rain management and environmental protection. In: Handbook of environment and waste management: Acid rain and greenhouse

gas pollution control, Hung, Y.T., Wang, L.K., Shammas, N.K., (ed.), World

Scientific, Cleveland, USA, pp. 719-749

Wu, Y., Chu, B., Zhang, M., Yi, Y., Dong, L., Fan, M., Jin, G., Zhang, L., Li, B., 2019. Influence of calcination temperature on the catalytic properties of LaCu0.25Co0.75O3 catalysts in NOx reduction. Applied Surface Science, Volume 481, pp. 1277–1286

Zhao, M., Xue, P., Liu, J., Liao, J., Guo, J., 2021. A review of removing SO2 and NOX by wet scrubbing. Sustainable Energy Technologies and Assessments, Volume 47, p. 101451