Comparison of Xylene and Ethyl Acetate as Solvent in the Isolation of Levulinic Acid from Conversion Reaction of Cellulose Rice Husk using Hierarchical Mn3O4/ZSM-5 Catalyst

Corresponding email: yuni.krisnandi@sci.ui.ac.id

Published at : 07 Oct 2022

Volume : IJtech

Vol 13, No 4 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i4.5524

Angellinnov, F., Krisnandi, Y.K., Rahayu, D.U.C., Dhaneswara, D., 2022. Comparison of Xylene and Ethyl Acetate as Solvent in the Isolation of Levulinic Acid from Conversion Reaction of Cellulose Rice Husk using Hierarchical Mn3O4/ZSM-5 Catalyst . International Journal of Technology. Volume 13(4), pp. 880-889

| Fiona Angellinnov | Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia |

| Yuni K. Krisnandi | 1. Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Indonesia, Depok, 16424, Indonesia 2. Solid Inorganic Framework Laboratory, Department of Chemistry, Faculty of Ma |

| Dyah U C Rahayu | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Indonesia, Depok, 16424, Indonesia |

| Donanta Dhaneswara | Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia |

Levulinic acid is a

platform chemical. This compound can be derived from conversion cellulose in

lignocellulosic biomass such as rice husk. Cellulose conversion to levulinic

acid can be enhanced with the help of a catalyst. Hierarchical Mn3O4/ZSM-5

was used as a catalyst in this study, which was made by wet impregnation of

ZSM-5 with Mn (II). Before the conversion reaction, rice husk was pretreated

with various chemical and mechanical methods to increase the amount of

cellulose. The chemical method used NaOH, while mechanical methods used

variations of ball milling and ultrasonication in phosphoric acid. The

pretreated rice husk was then converted to levulinic acid at 130°C for 10 h in

H3PO4 40% and H2O2 30% using hierarchical Mn3O4/ZSM-5 as a catalyst. The highest levulinic acid yield of 11.70% was

obtained from the delignification of rice husk. The product was then extracted

to obtain pure levulinic acid via solvent extraction using xylene and ethyl

acetate as the organic solvents. The GC-MS examination showed that ethyl

acetate is the best solvent and esterification agent in separating the

levulinic acid.

Catalyst; Cellulose; Hierarchical ZSM-5; Levulinic acid; Rice husk

Levulinic

acid is commonly used as a base material in many industries such as the food,

pharmaceuticals, agriculture, cosmetics, and petroleum (Kumar et al., 2019).

This compound can also be converted into biofuels, including

2methyltetrahydrofuran, ????-valerolactone, levulinate esters, and

1,4-pentanediol (Yan et al., 2015). However, precursor material used to synthesize

levulinic acid is no longer available due to its high cost. As a result,

lignocellulosic biomass is widely used as a low-cost alternative precursor (Rackemann & Doherty, 2011).

Rice

husk is a type of lignocellulosic biomass that is abundant in Indonesia. In the

conversion, the cellulose is hydrolyzed to obtain glucose, which is then can be

converted to hydroxymethylfurfural (5-HMF) as an intermediate product, and

finally to levulinic acid (Climent et al., 2014; Li et

al.,

2019).

However, cellulose in rice husk is bound to lignin and hemicellulose. To obtain pure

cellulose, pretreatment is required. The pretreatment can be performed using

chemicals via acid and/or basic solution (Harahap et al., 2019; Hermansyah et al., 2019), mechanical, or combination methods (Qu et al., 2017).

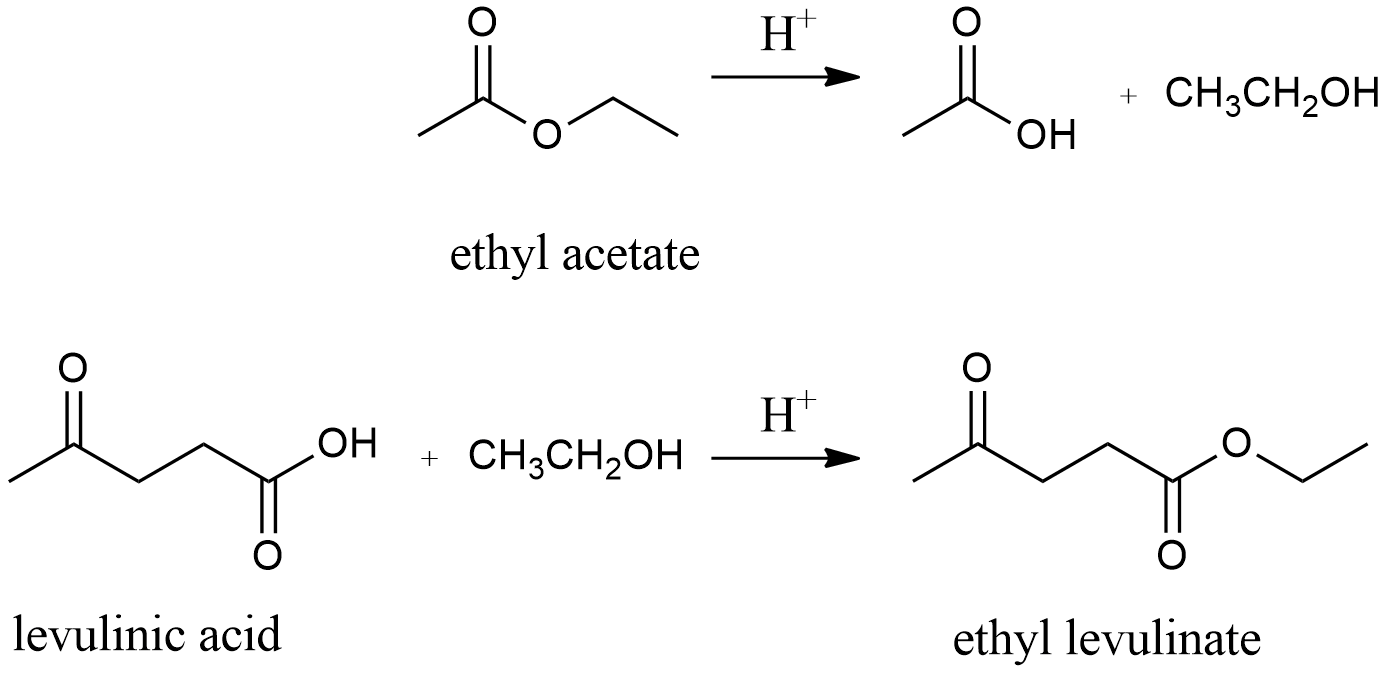

The

isolation of levulinic acid from the conversion reaction of cellulose rice husk

using xylene and ethyl acetate as solvents and hierarchical Mn3O4/ZSM-5

as a catalyst has been successfully carried out. The results of the conversion

reaction showed the highest yield of levulinic acid at the reaction time of 10

hours, with the yield from the highest to the lowest in delignified rice husk

(11.70%), dewax process only (5.17%), ball milling followed by ultrasonication

(4.43%), ball milling only (3.88%), and ultrasonication only (3.76%),

respectively. Based on the chromatogram from the GC-MS examination, 5-HMF was

not detected in the organic phase from the extraction with xylene. Meanwhile,

ethyl levulinate was seen in the chromatogram of the organic phase from the

extraction with ethyl acetate. In this case, ethyl acetate is a better solvent

than xylene for separating levulinic acid from 5-HMF. Ethyl acetate does not

only act as a solvent but also as an esterification agent that reacts with

levulinic acid resulting in ethyl levulinate.

This

work is funded by a PITTA B grant from the Directorate of Research and

Community Engagement (DRPM) Universitas Indonesia No.

NKB-0636/UN2.R3.1/HKP.05.00/2019.

| Filename | Description |

|---|---|

| R2-MME-5524-20220421203908.pdf | --- |

Ali, I., Hassan, A., Shabaan, S.,

El-nasser, K., 2017. Synthesis and Characterization of Composite Catalysts Cr /

ZSM-5 and Their Effects toward Photocatalytic Degradation of P-Nitrophenol. Arabian

Journal of Chemistry, Volume 10, pp. S2106-S2114

Angellinnov, F., Yusuf, H.,

Rahayu, D.U.C., Krisnandi, Y.K., 2020. Conversion of Rice Husks Cellulose to

Levulinic Acid on Hierarchical Mn3O4/ZSM-5 Catalyst from

Natural Aluminosilicate. AIP Conference Proceedings, Volume 2243

Brouwer, T., Blahusiak, M., Babic, K., Schuur,

B., 2017. Reactive Extraction and Recovery of Levulinic Acid, Formic Acid, and

Furfural from Aqueous Solutions Containing Sulphuric Acid. Separation and

Purification Technology, Volume 185, pp. 186–195

Chen, Y., Li, G., Yang, F., Zhang,

S., 2011. Mn / ZSM-5 Participation in the Degradation of Cellulose under

Phosphoric Acid Media. Polymer Degradation and Stability, Volume 96(5),

pp. 863–869

Climent, M.J., Corma, A., Iborra,

S., 2014. Conversion of Biomass Platform Molecules into Fuel Additives and Liquid

Hydrocarbon Fuels. Green Chemistry, Volume 16(2), pp. 516–547

Harahap, A.F.P., Rahman, A.A.,

Sadrina, I.N., Gozan, I., 2019. Optimization of Pretreatment

Condition for Microwave-Assisted Alkaline

Delignification of Empty Fruit Bunch by Response Surface Methodology. International

Journal of Technology, Volume 10(8), pp. 1479–1487

Hermansyah, H., Putri, D.N.,

Prasetyanto, A., Chairuddin, Z.B., Perdani, M.S., Sahlan, M., Yohda, M., 2019.

Delignification of Oil Palm Empty Fruit Bunch Using Peracetic Acid and Alkaline

Peroxide Combined with the Ultrasound. International Journal of Technology,

Volume 10(8), pp. 1523–1532

Siregar, Y.D.I., Saepudin, E.,

Krisnandi, Y.K., 2020. One-Pot Reaction Conversion of Delignified Sorghum

Bicolor Biomass into Levulinic Acid using a Manganese Metal Based Catalyst. International

Journal of Technology, Volume 11(4), pp. 852–861

Jakob, A., Grilc, M., Teržan, J.,

Likozar, B., 2021. Solubility Temperature Dependence of Bio-Based Levulinic

Acid, Furfural, and Hydroxymethylfurfural in Water, Nonpolar, Polar Aprotic,

and Protic Solvents. Processes, Volume 9(6), pp. 924

Kacurakova, M., Capek, P.,

Sasinkova, V., Wellner, N., Ebringerova, A., 2000. FT-IR Study of Plant Cell

Wall Model Compounds: Pectic Polysaccharides and Hemicelluloses. Carbohydrate

Polymers, Volume 43(2), pp. 195–203

Kadja, G.T.M., Mukti, R.R., Liu,

Z., Rilyanti, M., Ismunandar, Marsih, I.N., Ogura, M., Wakihara, T., Okubo, T.,

2016. Mesoporogen-free Synthesis of Hierarchically Porous ZSM-5 below 100°C. Microporous

and Mesoporous Materials, Volume 226, pp. 344–352

Krisnandi, Y.K., Nurani, D.A.,

Agnes, A., Pertiwi, R., Antra, N.F., Anggraeni, A.R., Azaria, A.P., Howe, R.F.,

2019. Hierarchical MnOx/ZSM-5 as Heterogeneous Catalysts in

Conversion of Delignified Rice Husk to Levulinic Acid. Indonesian Journal of

Chemistry, Volume 19(1), pp. 115–123

Krisnandi, Y.K., Putra, B.A.P.,

Bahtiar, M., Zahara, Abdullah, I., Howe, R.F., 2015. Partial Oxidation of Methane

to Methanol over Heterogeneous Catalyst Co/ZSM-5. Procedia Chemistry,

Volume 14, pp. 508–515

Kumar, A.K., Sharma, S., 2017.

Recent Updates on Different Methods of Pretreatment of Lignocellulosic

Feedstocks: A Review. Bioresources and Bioprocessing, Volume 4, pp. 1-19

Kumar, A., Shende, D.Z., Wasewar,

K.L., 2019. Production of Levulinic Acid: A Promising Building Block Material

for Pharmaceutical and Food Industry. Materials Today: Proceedings, Volume

29, pp. 790–793

Lechert, H., 1998. The pH Value

and Its Importance for the Crystallization of Zeolites. Microporous and

Mesoporous Materials, Volume 22(4–6), pp. 519–523

Li, X., Xu, R., Yang, J., Nie, S.,

Liu, D., Liu, Y., Si, C., 2019. Production of 5- Hydroxymethylfurfural and

Levulinic Acid from Lignocellulosic Biomass and Catalytic Up-Gradation. Industrial

Crops and Products, Volume 130, pp. 184–197

Novitasari, I., Rahayu, D.U.C.,

Krisnandi, Y.K., 2019. Effect of Rice Husk Pretreatment on Cellulose Conversion

to Levulinic Acid over the Mn3O4/ZSM-5 Catalyst. IOP

Conference Series: Materials Science and Engineering, Volume 496, p. 012014

Pratama, A.P., Rahayu, D.U.C.,

Krisnandi, Y.K., 2020. Levulinic Acid Production from Delignified Rice Husk

Waste over Manganese Catalysts: Heterogeneous Versus Homogeneous. Catalysts,

Volume 10(3), p. 327

Qu, T., Zhang, X., Gu, X., Han,

L., Ji, G., Chen, X., Xiao, W., 2017. Ball Milling for Biomass Fractionation

and Pretreatment with Aqueous Hydroxide Solutions. ACS Sustainable Chemistry

and Engineering, Volume 5(9), pp. 7733–7742

Rackemann, D.W., Doherty, W.O.S.,

2011. The Conversion of Lignocellulosic to Levulinic Acid. Biofuels,

Bioproducts and Biorefining, Volume 5(2), pp. 198–214

Reichardt, C., 2003. Solvents

and Solvent Effects in Organic Chemistry. WILEY-VCH Verlag GmbH & Co.

KGaA

Segal, L.G.J.M.A, Creely, J.J.,

Martin, A.E., Conrad, C.M., 1959. An Empirical Method for Estimating the Degree

of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Textile

Research Journal, Volume 29, pp. 786–794

Silverstein, R.M., Webster, F.X.,

Kiemle, D.J., 2005. Spectrometric Identification of Organic Compounds (7th

ed). John Wiley & Sons, Inc., USA

Treacy, M.M.J., Higgins, J.B.,

2007. Collection of Simulated XRD Powder Patterns for Zeolites (5th)

Revised Edition. Elsevier, Amsterdam, The Netherlands

Yan,

K., Jarvis, C., Gu, J., Yan, Y., 2015. Production and Catalytic Transformation

of Levulinic Acid: A Platform for Specialty Chemicals and Fuels. Renewable

and Sustainable Energy Reviews, Volume 51, pp. 986–997