An Empirical Model for Optimizing the Sound Absorption of Single Layer MPP Based on Response Surface Methodology

Corresponding email: azma.putra@utem.edu.my

Published at : 01 Jul 2022

Volume : IJtech

Vol 13, No 3 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i3.5507

Esraa, A., Putra, A., Mosa, A., Dan, R.M., Attia, O.H., 2022. An Empirical Model for Optimizing the Sound Absorption of Single Layer MPP Based on Response Surface Methodology. International Journal of Technology. Volume 13(3), pp. 496-507

| Al-Ameri Esraa | Fakulti Kejuruteraan Mekanikal, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia |

| Azma putra | Centre for Advanced Research on Energy, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia |

| Ali Mosa | Department of Mechanical Engineering, Collage of Engineering, University of Baghdad, Jadriyah - Baghdad, Iraq |

| Reduan M Dan | Centre for Advanced Research on Energy, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia |

| Osam H Attia | Department of Reconstruction and Projects, University of Baghdad, Jadriyah - Baghdad, Iraq |

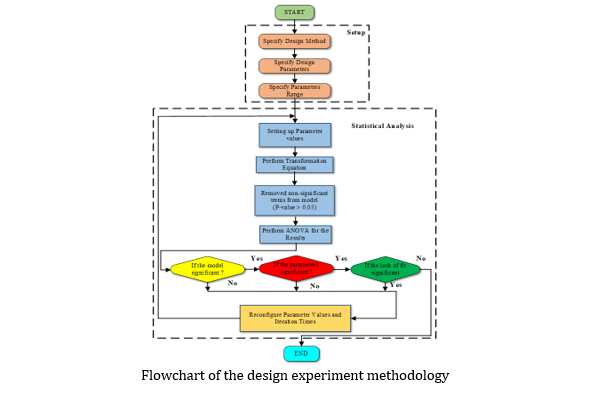

Micro-perforated panel (MPP) is a thin panel absorber capable of absorbing sound energy at a targeted frequency range by adjusting the MPP parameters. An analytical model is available, but it is not a direct, convenient method for practitioners to determine the required MPP parameters. This paper presents an optimized empirical model to calculate the sound absorption coefficient of a single-layer MPP. The response surface methodology is employed for a simple case to generate a second-order polynomial model through a sequence of designing processes to analyze the functional relationships and variation of the outcome performance (sound absorption coefficient) concerning the MPP parameters, namely the panel thickness, hole diameter, perforation ratio, and the depth of the back air layer. The analysis is carried out for frequencies between 300 to 900 Hz. The predicted data (empirical) is compared with the actual data (analytical), leading to a coefficient of variation of 0.145%. The proposed empirical model can be used as a method to select the suitable MPP parameters according to the targeted frequency bandwidth of absorption with less computational time.

Optimisation; Response Surface Methodology (RSM); Single layer MPP; Sound absorption

The optimized empirical model to calculate the

sound absorption coefficient of a ?single-layer MPP has been

presented in this paper. The model was developed using the response? surface methodology to

generate a second-order polynomial model as a function of MPP parameters,

namely the hole diameter, the perforation ratio and the depth of the back air

layer?. The predicted data is

evaluated with the actual data leading to a coefficient of variation ?of about 0.145%. The predicted

model is then verified with the analytical model with good agreement. The

proposed model in this paper is however, only valid for the frequency range of

300 – 900 Hz. The same method can be used to generate empirical models of a

single layer MPP with a different frequency range of interest. In future work,

these empirical models can be utilized as the complete set of mathematical

tools to calculate the absorption coefficient of MPP conveniently. The work can

also be extended with the more complicated configuration of the MPP structure,

such as the double-leaf MPP and the multi-cavity MPP.

The

authors would like to express their gratitude to Universiti Teknikal Malaysia

Melaka (UTeM). Part of this project is supported by the Fundamental Research

Grant Scheme ?from the Ministry of Higher

Education Malaysia No. FRGS/1/2016/ ?TK03/FTKCARE/F00323?. The corresponding author would

like to express appreciation for the University of Baghdad for its great

support.

Ahmad, S.H, Salih, R.M., 2020.

Acoustic and Thermal Insulation of Nanocomposites for Building Material. Baghdad

Science Journal, Volume 17 (2), pp. 494–501

Bimakr,

M., Ganjloo, A., Noroozi, A., 2019. Effect of Acoustic Cavitation Phenomenon on

Bioactive Compounds Release from Eryngium Caucasicum Leaves. Journal of Food

Measurement and Characterization 13 (3), Volume, pp. 1839–1851

Boulandet,

R., Lissek, H., 2010. Optimization of Electroacoustic Absorbers by Means of

Designed Experiments. Applied Acoustics, Volume 71 (9), pp. 830–842

Box, G. E.

P., & Wilson, K. B., 1951. On the Experimental

Attainment of Optimum Conditions. Journal of the Royal Statistical Society,

Volume 13(1), pp. 1–38

Bucciarelli, F., Fierro,

G.P.M., Meo, M., 2019. A Multilayer Microperforated Panel Prototype for

Broadband Sound Absorption at Low Frequencies. Applied Acoustics, Volume

146, pp. 134–144

Deeying, J.,

Asawarungsaengkul, K., Chutima, P., 2018. Multi-Objective Optimization on Laser

Solder Jet Bonding Process in Head Gimbal Assembly using the Response Surface

Methodology. Optics and Laser Technology, Volume

98, pp. 158–168

El-Basheer, T.M., Youssef, R.S., Mohamed, H.K., 2017. NIS Method for

Uncertainty Estimation of Airborne Sound Insulation Measurement in Field. International Journal of Metrology and

Quality Engineering, Volume 8, p.

19

Harahap, A.F.P., Rahman, A.A., Sadrina, I.N., Gozan, M., 2019. Optimization of Pretreatment Conditions for Microwave-assisted Alkaline

Delignification of Empty Fruit Bunch by Response Surface Methodology. International Journal

of Technology, Volume 10(8), pp. 1479–1487

Hawashi, M., Aparamarta, H., Widjaja, T., Gunawan, S., 2019. Optimization of Solid State Fermentation Conditions for Cyanide Content Reduction

in Cassava Leaves using response surface methodology. International Journal of Technology, Volume 10(3), pp. 624–633

Huang, S.,

Li, S., Wang, X., Mao, D., 2017. Micro-Perforated Absorbers with Incompletely

Partitioned Cavities. Applied Acoustics, Volume 126, pp. 114–119

Hussein,

T.M.E.-B., 2020. Calibration and Uncertainty Estimation

for the Reference Sound Source in Reverberation Room. Romanian Journal of Acoustics and Vibration, Volume 17(2), pp. 118–127

Kusaka, M., Sakagami, K., Okuzono, T., 2021. A Basic

Study on the Absorption Properties and Their Prediction of Heterogeneous

Micro-Perforated Panels: A Case Study of Micro-Perforated Panels with

Heterogeneous Hole Size and Perforation Ratio. Acoustics, Volume 3(3),

pp. 473–484

Liang, X.,

Lin, Z., Zhu, P., 2007. Acoustic Analysis of Damping Structure with Response

Surface Method. Applied Acoustics, Volume 68 (9), pp. 1036–1053

Liu, Z., Zhan, J., Fard, M., and Davy, J.L., 2017.

Acoustic Properties of Multilayer Sound Absorbers with a 3D Printed Micro-perforated

Panel. Applied Acoustics, Volume 121, pp. 25–32

Maa, D.Y., 1975. Theory and Design of Microperforated

Panel Sound-Absorbing Constructions. Scientia Sinica, Volume 18(1), pp. 55–71

Maa, D.Y.,

1987. Microperforated-Panel Wideband Absorbers. Noise Control Engineering

Journal, Volume 29(3), pp. 77–84

Mosa,

A.I., Putra, A., Ramlan, R., Esraa, A.-A., 2018. Micro-Perforated Panel

Absorber Arrangement Technique: A Review. Journal of Advanced Research in

Dynamical and Control Systems, Volume 10(7): 372–381

Mosa,

A.I., Putra, A., Ramlan, R., Prasetiyo, I., Esraa, A.-A., 2019. Theoretical

Model of Absorption Coefficient of an Inhomogeneous MPP Absorber with

Multi-Cavity Depths. Applied Acoustics, Volume 146, pp. 409–419

Niedz, R.P.,

Evens, T.J., 2016. Design of Experiments (DOE)-History, Concepts, and Relevance

to in Vitro Culture. In Vitro Cellular and Developmental Biology - Plant,

Volume 52 (6), pp. 547–562

Petrus, H.T.B.M., Olvianas, M., Astuti, W., Nurpratama, M.I., 2021.

Valorization of Geothermal Silica and Natural Bentonite through

Geopolymerization: A Characterization Study and Response Surface Design. International Journal

of Technology, Volume 12(1), pp.196–206

Prasetiyo, I., Muqowi, E., Putra, A., Novenbrianty, M., Desendra, G.,

Adhika, D.R., 2020. Modelling Sound Absorption of Tunable Double Layer Woven Fabrics.

Applied Acoustics, Volume 157, p. 107008

Prasetiyo, I., Sarwono, J., Sihar, I., 2016. Study on Inhomogeneous Perforation

Thick Micro-Perforated Panel Sound Absorbers. Journal of Mechanical Engineering and Sciences (JMES), Volume 10(3), pp. 2350–2362

Prasetiyo, I., Sihar, I., Sudarsono, A.S., 2021.

Realization of a Thin and Broadband Microperforated Panel (MPP) Sound Absorber.

Applied Acoustics, Volume 183, p. 108295

Qian,

Y.J., Cui, K., Liu, S.M., Li, Z.B., Kong, D.Y., Sun, S.M., 2014a. Development

of Broadband Ultra Micro-Perforated Panels Based on MEMS Technology. Applied

Mechanics and Materials, Volume 535, pp. 788–795

Qian, Y.J.,

Cui, K., Liu, S.M., Li, Z.B., Shao, D.S., Kong, D.Y., Sun, S.M., 2014b.

Optimization of Multi-Size Micro-Perforated Panel Absorbers using

Multi-Population Genetic Algorithm. Noise Control Engineering Journal, Volume

62(1), pp. 37–46

Saleh, B.J., Saedi, A.Y.F., Al-Aqbi, A.T.Q., Salman,

L.A., 2021. Optimum Median Filter Based on Crow Optimisation Algorithm. Baghdad

Science Journal, Volume 18(3), pp. 614–627

Tayong, R.B.,

Jacques, A., Manyo, M., Siryabe, E., Ntamack, G.E., 2018., On the Simultaneous

Inversion of Micro-Perforated Panels’ Parameters: Application to Single and

Double Air-Cavity Backed Systems. The Journal of the Acoustical Society of

America, Volume 143(4), pp. 2279–2288

Wahab, H.A.,

Rus, A.ZM., Abdullah, M.F.L., Abdullah, N.M., 2019. Design of Experiment for

Sound Absorption Materials of Microporous Polymer. In: International

Conference on Information Science and Communication Technology (ICISCT) 2019, pp.

1–7

Wang, Y.,

Qin, X., Huang, S., Lu, L., Zhang, Q., Feng, J., 2017. Structural-Borne

Acoustics Analysis and Multi-Objective Optimization by using Panel Acoustic

Participation and Response Surface Methodology. Applied Acoustics,

Volume 116, pp. 139–151

Wyantuti, S., Setyorini, Z., Ishmayana, S., Hartati, Y.,

Firdaus, M., 2020. Optimisation of Voltammetric Determination of Dysprosium

(III) using Plackett-Burman and RSM-CCD Experimental Designs. Baghdad

Science Journal, Volume 17(4), pp. 1198–1206

Yang, X., Bai, P., Shen, X., To, S., Chen, L., Zhang, X., Yin, Q., 2019. Optimal Design and Experimental Validation of Sound Absorbing Multilayer Microperforated Panel with Constraint Conditions. Applied Acoustics, Volume 146, pp. 334–344

Yu, X., Cui, F.S., Cheng, L., 2016. On the Acoustic Analysis and Optimization

of Ducted Ventilation Systems using a Sub-Structuring Approach. The Journal

of the Acoustical Society of America, Volume 139 (1), pp. 279–289