Numerical Study on Relocation Process of Al, Fe, and Pb by Using the Moving Particle Semi-Implicit Method During Severe Accident of Reactor

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.5240

Yulianto, Y., Mustari, A.P.A., 2023. Numerical Study on Relocation Process of Al, Fe, and Pb by Using the Moving Particle Semi-Implicit Method During Severe Accident of Reactor. International Journal of Technology. Volume 14(4), pp. 800-810

| Yacobus Yulianto | Physics Department, Halu Oleo University, Jl. H.E.A. Mokodompit, Kendari 93232, Indonesia |

| Asril Pramutadi Andi Mustari | Physics Department, Bandung Institute of Technology, Jl. Ganesha 10, Bandung 40132, Indonesia |

Reactor safety is one of the essential parts of

reactor research, especially to appropriately respond when melts down occurred

during a severe accident. In this study, the relocation process of Al, Fe, and

Pb was simulated by using the Moving Particle Semi-Implicit method to study the

relocation mechanism of the liquids when they experienced an interaction

between liquids at high temperatures. It is obtained that, to reach the

stratified condition, Pb-Al needs 0.63 seconds, Al-Fe and Al-Pb need 1.14

seconds, and Fe-Al needs more than three seconds. Overall, the results indicate

that the difference in viscosity and density between two liquids influences the

time to reach the stratified condition. The greater the density difference

between two liquids, the faster the stratification process.

Liquid flow; Moving particle semi-implicit; Relocation process; Severe accident of a reactor

Reactor safety is one of the substantial

matters that should be concerned in the study of the reactor. The reactor

accidents of Three Miles Island, Chernobyl, and Fukushima have warned nuclear

researchers to care about the importance of reactor safety. Information about

the behavior of some reactor materials (Talaat et al., 2019; Chandran

et al., 2018) is very urgent to be provided.

The relocation of melting material during a severe accident is an important

phenomenon due to its influence on the heat transfer to the lower plenum of the

reactor, which may affect the breaching of the reactor.

Several

studies have been conducted regarding the relocation of molten corium.

Moreover, stratification during the accident is also important to be understood

to predict the failure of the reactor pressure vessel (Li et al., 2013). During a severe accident, the variation of

materials may lead to several combinations of interaction between two materials.

In the research reactor, Fe-Al interaction may need to be understood since Al

is the main material with parts of Fe (Hainoun, Ghazi, and Alhabit, 2019; Farrell, 2012). On the other hand, in the LFR (Lead-cooled

Fast Reactor), a study of Pb-Fe interaction in the liquid phase is needed. The

reason is that Pb is the main coolant and Fe is the main structural material (Mustari and

Takahashi, 2011; Machut et al., 2007), where Al is proposed as the

outer layer of structural material (Knebel et al., 2000) in the Accelerator Driven System

(ADS). Unfortunately, investigations on these material combinations in the

liquid phase are very limited.

Some experiments about reactor core

accidents are complicated or costly to be performed. Although experiments are

still principal for some cases, computational simulations (Aliffrananda et

al., 2022; Utama et al., 2021) can be an alternative to reduce

the complexity or the cost of experiments. On the other hand, the conventional

mesh methods face difficulty in explaining several melted core phenomena, i.e.

stratification case, free-surface flow, and phase transitions. The Moving

Particle Semi-Implicit (MPS) method introduced first by Koshizuka and Oka (1996) is one of the alternative mesh-free methods

utilized to simulate the relocation process of some nuclear materials. This

method has been applied successfully (Duan, Yamaji, and Sakai, 2022; Masumura, Yamaji, and Furuya 2015; Mustari et al., 2015; Li, Oka, and Furuya, 2014; Kawahara and Oka, 2012) as reviewed by Li et al. (2020).

While there are many studies analyzing

melting interactions between the melted core and solid materials during reactor

core melting, there is still limited simulation on the relocation of molten

fluids. Studies of the relocation process of some liquids were performed by

some researchers, such as Li et al. (2013) with silicon oil and salt water, Ilham et al. (2018) with freshwater, and Hidayati et al. (2021) with cooking oil and freshwater. In this

study, the liquids of Al, Fe, and Pb are utilized. The simulation of the

relocation process is one of the visible solutions for understanding the

phenomena in the reactor accident. Therefore, the study of the relocation

process is utterly substantial to be performed for nuclear materials. Due to

the lack of study on the materials in the case of a severe accident, where most

materials are in the liquid phase, the objective of this study is to simulate

the relocation process of some liquids of nuclear materials (Al, Fe, and Pb)

and the contact process between two liquids with various temperatures.

2.1. Mathematical Model and Numerical Method

The

Moving Particle Semi-Implicit method assumes that a particle only exercises an

interaction with a limited number of its nearest particles as shown in Figure

1. To

accommodating this assumption, the weight function exists as described well in

the paper of Koshizuka and Oka (1996),

including the explanation of the particle number density, the gradient, the

divergence, and the Laplacian models. All equations in the MPS method follow

the mass and the momentum conservation equations as the commonly used governing

equations for incompressible flow where (Koshizuka

and Oka, 1996).

2.2. Simulation

In

this study, two types of liquids were used, namely, the fallen liquid placed

inside the 2D containment and the target liquid placed inside a bottle located

102 mm above the surface of the target liquid. Both liquids are chemically

miscible, and it was assumed that the stratification process in

thermal-hydraulic is faster than in the chemical process, as supported by

references (Mustari

et al., 2015; Mustari and Oka, 2014), these liquids can be considered as an immiscible

liquid. The temperature, density, and kinematic viscosity of each used liquid

can be seen in Table 1. The simulation was performed by using 4139

particles and a similar code of these references (Yulianto et al., 2019; Ilham et al.,

2018).

Figure 1 Boundary (a) and initial (b)

condition (in mm)

Table 1 The parameters of each

liquid (IAEA, 2008)

|

Component |

Tmelting (°C) |

Tboiling (°C) |

Tsimulation

(°C) |

Density (kg m-3) |

Kinematic viscosity (m2

s-1) |

|

Al |

660 |

2,519 |

1,600 |

2.084890 × 103 |

7.382931 × 10-4 |

|

1,800 |

2.022690 × 103 |

7.083604 × 10-4 | |||

|

2,000 |

1.960490 × 103 |

6.846094 × 10-4 | |||

|

Fe |

1,538 |

2,861 |

1,600 |

6.977548 × 103 |

2.050208 × 10-3 |

|

1,800 |

5.115362 × 103 |

1.784475 × 10-3 | |||

|

2,000 |

4.930162 × 103 |

1.591594 × 10-3 | |||

|

Al |

660 |

2,519 |

1,200 |

2.209290 × 103 |

8.295089

× 10-4 |

|

1,400 |

2.147090 × 103 |

7.771429

× 10-4 | |||

|

1,600 |

2.084890 × 103 |

7.382931

× 10-4 | |||

|

Pb |

327 |

1,745 |

1,200 |

9.590534 × 103 |

8.123931 × 10-8 |

|

1,400 |

9.342134 × 103 |

6.835953 × 10-8 | |||

|

1,600 |

9.093734 × 103 |

5.823038 × 10-8 |

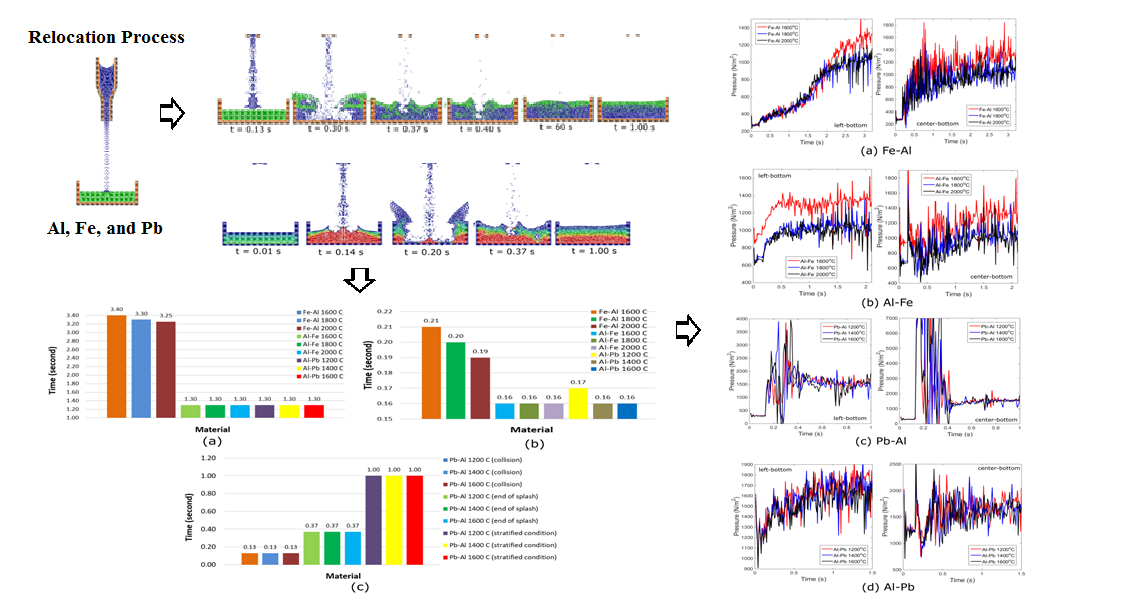

3.1. The Relocation Profiles

The

relocation process of Fe-Al can be seen in Figure 2 where all temperatures have a similar pattern, where Fe made a contact

with Al, broke through the Al layer, dived, created a layer under the Al layer,

and reached the stratified condition. When colliding with the target liquid, Fe

could break through Al as presumed that Fe has a greater density than Al. The

relocation process of Al-Fe can be seen in Figure 3 where all temperatures have a

similarity in its pattern where Al made a contact with Fe, floated above the Fe

layer, made a layer in that position, and finally reached the stratified

condition. When colliding with the target liquids, Al cannot equalize the

buoyancies of Fe. It forces Al to move on top of Fe and create a layer above

that liquid. It is because Al has a lower density than Fe. It is presumed that

the liquid with greater density needs more effort to break the layer of the

target liquid and dives under that layer. In the stratification process, the

lower density moves down gradually to form a layer under the higher density.

The higher viscous force that dominates the stratification process is expected

as the reason for this phenomenon. The collision time and the time to reach the

stratified condition for all used temperatures are similar. The collision time

was reached in 0.16 seconds and the stratified condition was reached in 1.30

seconds.

The

relocation process of Al-Fe can be seen in Figure 4. The relocation process in this

case has a similar pattern to the relocation process of Al-Fe. The time

collision and the time to reach the stratified condition are similar to those

of Al-Fe, except for the collision time at 1,400°C where Al-Pb reached it in 0.17

seconds. The relocation process of Al-Fe can be seen in Figure 5 where Pb collided with Al in

0.13 seconds and made splashes that reached up to the height of the

containment. These splashes were gone out at 0.37 seconds. After that, Pb

formed gradually a layer below Al and commenced the stratification process at

0.37 seconds. The stratified condition of Pb-Al is achieved at about a second

for all temperatures. These obtained results are similar to the cases of Pb-Al

although the temperature was different.

From those results above,

compared to Al and Fe, Pb left the bottle and reached the surface of the target

liquid in the fastest time among the used combinations. It results because,

still as the presumption, the density of Pb is the greatest among them.

Besides, the kinematic viscosity of Pb is the smallest among them. It makes Pb

flow out of the bottle container easily. However, it still needs further study

for verification. Next, the focus is targeted at the collision between liquids.

In this study, the relocation process without splashes has been found in the

cases of Fe-Al, Al-Fe, and Al-Pb. The relocation process with splashes has been

found in the Pb-Al. When Pb-Al was run, the splashes were obtained. When

switching to Al-Pb, the splashes were not obtained. It means that the splash

will arise if the fallen liquid has a higher density when the difference in

density between the two is great enough. The time duration was counted as

follows. The timing of collision started when the two liquids made direct

contact. Both liquids are considered to reach the stratified state if two

layers have formed along the length of the container. The summary of time, for

all cases, is performed in Figure 6 where at 2,000°C, to make a contact and to reach

the stratified condition, Al has the fastest time among the other temperatures.

Figure 2 Relocation process of Fe-Al

Figure 3 Relocation process of Al-Fe

Figure 4 Relocation process of Al-Pb

Figure 5

Relocation process of Pb-Al

Figure 6 The time summary for the relocation process

3.2. The Pressure Profiles

The

pressure profiles of Fe-Al can be seen in Figure 7. The higher pressure commenced

in the middle of the container and expanded to the corner of the container. In Figure 8 part (a), the pressure profiles

in two spots at the bottom of the container were investigated, i.e the

left-bottom side and the center-bottom side. The center-bottom side has higher

pressure than the left-bottom side. The results of Fe-Al at 1,600°C have higher

pressure than the other temperatures in this case. The pressure profiles of

Al-Fe can be seen in Figure 9. The patterns of these results

are similar to the pattern of Fe-Al. The higher pressure is still found in the

bottom of the container. The pressure profiles inside the container in Al-Fe

can be seen in Figure 8 part (b). The results of Al-Fe

at 1,600°C have the highest pressure among the results in this case as found in

Fe-Al.

The

pressure profiles of Pb-Al can be seen in Figure 10. In that figure, it can be seen

that the pressure profiles are similar to those of Fe-Al and Al-Fe. The bottom

side of the container has higher pressure than the wall. The pressure profiles

inside the container are displayed in Figure 8 part (c). In that figure, it can

be seen that the pressure is higher between 0.2 seconds and 0.4 seconds than

the others. It is the condition when the splash was arising. The splashes make

the pressure high. The pressure profile of Al-Pb can be seen in Figure 11. The results of this case are similar

to those of Fe-Al and Al-Fe. The pressure profiles inside the container in this

case can be seen in Figure 8 part (d). The pressures are

mostly in a disarray pattern. In regards to stratification, the difference in

density is the driving mechanism. Therefore, a higher density difference will

accelerate the stratification formation. The stratification will start from the

below area of the less dense material (Yulianto et

al., 2018; Li et al., 2013).

From

the obtained results, the relocation pattern of the liquids is similar to the

results obtained by Ilham et al. (2018) using a different liquid, where the MPS

result is compared to the experiment. Therefore, it is expected that the

temperature did not significantly impact the relocation process, which agrees

with Hidayati et al. (2020). Furthermore, the splash pattern of this

study is similar to the results of Hidayati et

al. (2021). The splash will arise if the fallen liquid

has a higher density where the difference in density between the two is big

enough. The viscosity also affects the formation of the splash. High-viscosity

fluid will show less splash formation than molten tin relocation (Li, Oka, and Furuya, 2014).

Figure 7 The pressure profiles of Fe-Al (The pressure unit is in N/m2)

Figure 8 The pressure profiles (in N/m2) inside the container

for all configurations

Figure 9 The pressure profiles of Al-Fe (The unit of pressure is in N/m2)

Figure 10 The pressure profiles of Pb-Al (The unit of pressure is in N/m2)

Figure 11 The pressure profiles of Al-Pb (The unit of pressure is in N/m2)

Ideally, the present result should be

validated by the experiment result; however, it is very difficult to find a

study on Pb, Al, and Fe interactions. Regarding Pb-Al, there is an experiment

of melting and solidification, however, it is for crystalline size (Grabaek and Bohr, 1965). In the case of the melting behavior of

Pb-alloy with silicone oil, Masumura et al. (2015) successfully validated the experiment with

numerical simulation.

During

severe reactor accidents with several thousand degrees Celsius of temperature,

the existence of the splash may significantly affect the heat transfer process

and thus melting progression. In that regard, a study on the splash effect on

melting progression is the area to be investigated. The results give an important

understanding of how the pressure may affect the lower plenum of the reactor

when the liquids are relocated. Based on the results above, the bottom side has

higher pressure than the wall side. In a nuclear reactor, the pressure profiles

during a severe accident can provide essential information for the prediction

of the breaching and also give insight to the manufacturer of the reactor. The

present results are focused on the relocation process and its splash, in the

future, more realistic geometry and condition close to the reactor situation

during the accident is necessary to give a better understanding of the

relocation. It is also essential to compare the results with the experiment or

the other methods.

The

relocation process of some liquids has been investigated in this study. The MPS

method has been utilized to simulate the stratification process of these

liquids. This study shows that Pb-Al needs 0.13 seconds to reach collision,

Al-Fe and Al-Pb need 0.16 seconds, and Fe-Al needs more than 0.19 seconds. To

get the stratified condition, Pb-Al needs 0.63 seconds, Al-Fe and Al-Pb need

1.14 seconds, and Fe-Al needs more than three seconds. It is also found that

the difference in viscosity and density between two liquids influences the time

to reach the stratified condition — the more significant the density difference

between two liquids, the faster the stratification process. The obtained

results in this study are in a preliminary stage, which means that further

study needs to be conducted in both experiment and simulation.

AJG Ramalho, JG Marques, F. C. (1999). The Portuguese research reactors: a

tool for the next century. In International symposium on research reactor

utilization, safety and management (pp. 5–10). International Atomic Energy

Agency (IAEA): IAEA. Retrieved from http://www.iaea.org/worldatom/books

Aliffrananda,

M. H. N., Sulisetyono, A., Hermawan, Y. A., & Zubaydi, A. (2022). Numerical

analysis of floatplane porpoising instability in calm water during takeoff. International

Journal of Technology, 13(1), 190–201.

Daisuke,

M., Akifumi, Y., & Masahiro, F. (2015). Analysis of Pb-Bi Vessel Wall

Ablation Experiment with High Temperature Liquid by MPS Method. Journal of

Energy and Power Engineering, 9(11), 7401–7413.

Daisuke

Masumura, Akifumi Yamaji, & Masahiro Furuya. (2015). Analysis of Pb-Bi

Vessel Wall Ablation Experiment with High Temperature Liquid by MPS Method. Journal

of Energy and Power Engineering, 9(11), 944–954.

Duan,

G., Yamaji, A., & Sakai, M. (2022). A multiphase MPS method coupling

fluid–solid interaction/phase-change models with application to debris

remelting in reactor lower plenum. Annals of Nuclear Energy, 166,

108697.

Farrell,

K. (2012). Performance of Aluminum in Research Reactors. Comprehensive

Nuclear Materials. Elsevier Inc.

Fathonah,

N. N., Nurtono, T., Kusdianto, Madhania, S., Wahyudiono, & Winardi, S.

(2019). Numerical study of the hydrodynamic characteristics in an agitated tank

with side-entry mixer: The effect of stirrer entry angle. International

Journal of Technology, 10(3), 521–530.

Grabaek,

L., & Bohr, J. (1965). Superheating and Supercooling of Lead Precipitates

in Aluminum. Nature, 207(5003), 1238–1238.

https://doi.org/10.1038/2071238d0

Hainoun,

A., Ghazi, N., & Alhabit, F. (2019). Syria’s Benchmark Results against

Experimental Data from ETRR-2. International Atomic Energy Agency (IAEA).

Retrieved from

https://www.iaea.org/publications/13547/benchmarking-against-experimental-data-of-neutronics-and-thermohydraulic-computational-methods-and-tools-for-operation-and-safety-analysis-of-research-reactors

Hidayati,

A. N., Mustari, A. P. A., Waris, A., Yulianto, Y., & Ilham, M. (2021).

Study on Fluid Descends Vertically on Static Fluid Using Moving Particle

Semi-Implicit Method. Journal of Physics: Conference Series, 1772(1),

012007.

Hidayati,

A. N., Waris, A., Mustari, A. P. A., Apriani, N. A., Ifthacharo, M., &

Wulandari, R. (2020). The Effect of Temperature Variations on Wood’s Metal

Plate Melting Simulation by Using MPS. Journal of Physics: Conference Series,

1493(1), 012024.

IAEA.

(2008). Thermophysical Properties of Materials For Nuclear Engineering: A

Tutorial and Collection of Data. Vienna: IAEA.

Ilham,

M., YuLianto, Y., & Mustari, A. P. A. (2018). Simulation on Relocation of

Non-Compressed Fluid Flow using Moving Particle Semi-Implicit (MPS) Method. In IOP

Conference Series: Materials Science and Engineering (Vol. 407).

Kawahara,

T., & Oka, Y. (2012). Ex-vessel molten core solidification behavior by

moving particle semi-implicit method. Journal of Nuclear Science and

Technology, 49(12), 1156–1164.

Knebel,

J. U., Cheng, X., Müller, G., Schumacher, G., Konys, J., Wedemeyer, O., …

Carteciano, L. (2000). Thermalhydraulic and Material Specific Investigations

into the Realization of an Accelerator Driven System ( ADS ) to Transmute Minor

Actinides. Karlsruhe, Germany. Retrieved from

https://publikationen.bibliothek.kit.edu/270048483/3814007

Koonen,

E., Fabry, A., Chaouadi, R., Verwerft, M., Raedt, C. D. E., Winckel, S. V. A.

N., … Verwimp, A. (2000). Life Extension of the Br2 Aluminium Vessel Xa9952359.

In Research reactor utilization, safety and management Proceedings (pp.

67–68). International Atomic Energy Agency (IAEA): IAEA. Retrieved from

http://www.iaea.org/worldatom/books

Koshizuka,

S., & Oka, Y. (1996). Moving-particle semi-implicit method for

fragmentation of incompressible fluid. Nuclear Science and Engineering.

Retrieved from http://cat.inist.fr/?aModele=afficheN&cpsidt=3155698

Li, G.,

Gao, J., Wen, P., Zhao, Q., Wang, J., & Yan, J. (2020). A review on MPS

method developments and applications in nuclear engineering. Computer

Methods in Applied Mechanics and Engineering, 367, 113166.

Li, G.,

Oka, Y., & Furuya, M. (2014). Experimental and numerical study of stratification

and solidification/melting behaviors. Nuclear Engineering and Design, 272,

109–117.

Li, G.,

Oka, Y., Furuya, M., & Kondo, M. (2013). Experiments and MPS analysis of

stratification behavior of two immiscible fluids. Nuclear Engineering and

Design, 265, 210–221.

Machut,

M., Sridharan, K., Li, N., Ukai, S., & Allen, T. (2007). Time dependence of

corrosion in steels for use in lead-alloy cooled reactors. Journal of

Nuclear Materials, 371(1–3), 134–144.

Mustari,

A. P. A., & Oka, Y. (2014). Molten uranium eutectic interaction on

iron-alloy by MPS method. Nuclear Engineering and Design, 278,

387–394.

Mustari,

A. P. A., Oka, Y., Furuya, M., Takeo, W., & Chen, R. (2015). 3D simulation

of eutectic interaction of Pb-Sn system using Moving Particle Semi-implicit

(MPS) method. Annals of Nuclear Energy, 81, 26–33.

Mustari,

A. P. A., & Takahashi, M. (2011). Study on corrosion of welded steel for

LBE-cooled fast reactors. Progress in Nuclear Energy, 53(7),

1073–1077.

N.

Chandran, J. Gunasekaran, D. Nithyanand, & C. Vinoth Kumar. (2018). Flow

Analysis of Molten Metal through various Ingates using water models. International

Journal of Engineering Research and Technology, 06(02), 5–7.

Rivai,

A. K., & Takahashi, M. (2010). Corrosion investigations of Al-Fe-coated

steels, high Cr steels, refractory metals and ceramics in lead alloys at 700

°C. Journal of Nuclear Materials, 398(1–3), 146–152.

Saha,

S. K., & Nandi, N. (2017). Numerical study about the change in flow

separation and velocity distribution in a 90o pipe bend with/without

guide vane conditions. International Journal of Technology, 4,

681–689.

Su’ud,

Z., Irka, F. H., Imam, T. T., Sekimoto, H., & Sidik, P. (2013). Desain

study of Pb-Bi cooled fast reactors with natural uranium as fuel cycle input

using special shuffling strategy in radial direction. Advanced Materials

Research, 772, 530–535.

Talaat,

K., Lee, S., Lee, Y., Anderoglu, O., Cakez, C., Ghosh, S., … Ferroni, P.

(2019). Numerical investigation of molten lead flow in a closed loop to

estimate pressure demand. Transactions of the American Nuclear Society, 121,

1787–1790.

Utama,

I. K. A. P., Aryawan, W. D., Nasirudin, A., Sutiyo, & Yanuar. (2021).

Numerical Investigation into the Pressure and Flow Velocity Distributions of a Slender-Body

Catamaran Due to Viscous Interference Effects. International Journal of

Technology, 12(1), 149–162.

Widiawati,

N., Su’ud, Z., Irwanto, D., & Sekimoto, H. (2018). Neutronic Comparison

Study between Pb(208)-Bi and Pb(208) as a Coolant in the Fast Reactor with

Modified CANDLE Burn up Scheme. Journal of Physics: Conference Series, 1090,

012071.

Yulianto,

Y., Hidayati, A. N., Mustari, A. P. A., Ilham, M., & Pramuditya, S. (2018).

Moving Particle Semi-implicit (MPS) Utilization in Analyzing the Stratification

Behavior of Immiscible Liquid. IOP Conference Series: Materials Science and

Engineering, 407, 012189.

Yulianto,

Y., Mustari, A. P., Ilham, M., Hidayati, A. N., & Hatmanti, S. (2019).

Moving Particle Semi-implicit Method in Simulating Water-Oil Penetration. Indonesian

Journal of Physics, 30(2), 24–33.