A Chisel Fertilizer for In-Soil Tree-Layer Differential Application in Precision Farming

Corresponding email: snukeshev@rambler.ru

Published at : 18 Jan 2023

Volume : IJtech

Vol 14, No 1 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i1.5143

Nukeshev, S., Yeskhozhin, K., Karaivanov, D., Ramaniuk, M., Akhmetov, E., Saktaganov, B., Tanbayev, K., 2023. A Chisel Fertilizer for In-Soil Tree-Layer Differential Application in Precision Farming. International Journal of Technology. Volume 14(1), pp. 109-118

| Sayakhat Nukeshev | Department of Technical Mechanics, S. Seifullin Kazakh Agromechnical University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Kairat Yeskhozhin | Department of Technical Mechanics, S. Seifullin Kazakh Agromechnical University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Dimitar Karaivanov | Department of Applied Mechanics, University of Chemical Technology and Metallurgy, 8 Kl. Ohridski Blvd., 1797 Sofia, Bulgaria |

| Mikalai Ramaniuk | Department of Materials Mechanics and Machine Parts, Belarusian State Agrarian Technical University, 99/1, Nezavisimosti av, 220023, Minsk, Republic of Belarus |

| Erzhan Akhmetov | Department of Technical Mechanics, S. Seifullin Kazakh Agromechnical University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Bakhitbek Saktaganov | Department of Technical Mechanics, S. Seifullin Kazakh Agromechnical University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Khozhakeldi Tanbayev | Department of Technical Mechanics, S. Seifullin Kazakh Agromechnical University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

An

original technical solution is proposed that permits the application of a main

fertilizer dose once in 4-5 years at a depth of 6-25 cm with an inclined belt.

The work aims to investigate the interaction between the proposed working tool (ripper-distributor) of the

developed chisel-fertilizer with the soil, and to determine dependences that

link its traction force with the design parameters. Studying the soil

deformation pattern under the influence of working tool cutting parts based on

classical mechanics made it possible to determine the dependence between the

tractive force of the ripper-distributor and its design parameters. 3D modeling and C.F.D. analysis by

using SolidWorks Flow Simulation® made it possible to define the

fertilizer distributor parameters of the working body and flow characteristics

of fertilizers. The distribution quality studies of fertilizer granules in

compartments of the working tool distributor showed that the non-uniformity of

distribution at different dosages (from 50 to 400 kg/ha) ranges from 7.8% for

the application of granulated superphosphate up to 22.7% for the application of

powdered superphosphate. The chisel-fertilizer enables soil-friendly and

sloping site-specific fertilizer application at a depth from 5.6-9.8, 16-18, 23-25.8

cm, and a fertilizer distribution non-uniformity of 14-15% over the width of

the spreader.

Granular fertilizer; Liquid fertilizer; Precision farming; Site-specific application; Tractive force

One way to adapt to climate

change in the agricultural sector is by modifying the cropping system (Abella, Lansigan,

and Tubay,

2021) at all

technological processes. The most important of

them is the application of fertilizers, and they should be provided in an

environmentally friendly way. In addition, combining several technological

operations in one farm unit passage (reducing the number of

technological operations) decreases the risk of soil erosion (Gunawan, Sutjiningsih,

and Soeryantono, 2013).

Minimum and no-till cultivation technologies do not provide for the local application of higher doses of granular and liquid mineral fertilizers in the soil.

This leads

to soil compaction, decreased soil fertility, and changes in layer soil

structure from 0 to 30 cm (Pires et al.,

2017; Gao et al., 2017). Research shows that an important factor

for sustainable yields is optimal soil density. An increase of 0.1-0.3 g/cm3

can reduce crop yields by 20–40% (Silva et al.,

2021; Ferreira et al., 2020; Zarehaghi et al., 2017; Nosalewicz

and Lipiec, 2014). Without the extended reproduction of soil

fertility, it is impossible to ensure progressive yield growth (Campolo et al., 2021; Dai et al., 2021;

Imran, Amanullah, and M. Al-Tawaha, 2021). The analysis of long-term

cropping practices in Kazakhstan and other countries shows that soils

cultivated without the use of fertilizers, consequently sol fertility and

yields decrease over time (Ren et al., 2021;

Man et al., 2021; Nukeshev et al., 2018). The grain legume

crop rotations and vanguard technologies (Petrus et

al., 2020) can solve the problem of nitrogen replenishment, but

phosphorus deficiency under conditions without in-soil site-specific

application cannot be solved. The current state of cultivated soils shows that

80% of them do not contain mobile phosphorus and nitrogen (Nukeshev et al., 2019; Kenenbaev et al.,

2018). Therefore, the first place to revive soil fertility is through a

concern for the timely supply of soil with nutrients, and the most important

role is the optimization of the nitrogen supply to plants (Nukeshev et al., 2019; Zavalin and Sokolov, 2019;

Antonova, 2018 Walsh

and Christiaens, 2016).

The review of research

works and advanced agricultural practices show that the issues related to

mineral fertilizer application by scattering methods have been mainly resolved.

However, the mechanical and technological basics of the tiered site-specific intra-soil application of granular and liquid

mineral fertilizers have not been developed yet (Tanbayev

et al., 2022). Earlier studies (Eskhozhin

et al., 2014; Asaf et al., 2007; Alonso-Marroquín and Herrmann,

2005; Aday

and Ramadhan, 2019) did not consider

issues of interaction of the working tool of the chisel fertilizer with the

soil and dependencies connecting its tractive force with design parameters were

not defined. Thus, developing technical means for the site-specific application

of solid and liquid fertilizers into the soil and considering the nutrient

stock in each elementary area of the field and potential yields is an urgent

task. In this work, the interaction of the proposed inclined working body with

the soil and the interaction between fertilizer granules and walls of the

distributor that determine the optimal parameters of the chisel working body

are considered.

The combination of inclined

chiseling and the distribution of the main dose of fertilizers into several

soil tiers provide solving of the soil compaction and depletion problems.

Chiseling is a kind of deep no-till tillage, during which the soil is plowed

with a narrow chisel located at the bottom of the ripper-distributor stand and,

in the meantime, collapses down on the sides and in front of the stand at an

angle of ? 45° (Seifullin, 2020).

This work aims to study the

interaction between the cutting parts of the ripper-distributor and soil and

determine the relationship between traction and design parameters of the

working tool. The working tool and soil interaction are understood as a

dihedral wedge impact on the soil when it moves in soil with a certain speed

and force.

Theoretical investigations were based on

the laws of classical mechanics. In order to verify the obtained theoretical

calculation results and determine the traction resistance of the

chisel-fertilizer working tool, the laboratory experiments were conducted in

the soil channel at a fertilizer depth of 30 cm and a driving speed of 0.87 to

3.1 m/s. A measuring information system with data output to a personal computer

and an electronic dynamometer with the maximum permissible relative error of

±0.45% (DEP3-1D-10P-2) were used in laboratory experiments.

Experiments were conducted with granular

and powdered superphosphate. Before conducting experiments, humidity,

granulometric composition, and bulk density of fertilizers were determined. The

bulk density of powdered superphosphate was 0.81–083 t/m3. The bulk

density of granulated superphosphate is 0.94–0.95 t/m3. The size of

the granules is 1–5 mm; the humidity varied within 2.5–3.5 %.

2.1. Design of

the working tool of chisel fertilizer

Thus, we propose a chisel-fertilizer

(Figure 1a), which performs a layer-by-layer local application of granular or

liquid fertilizer to a working depth of from 5–8, 16–18 and 23–25 cm. During

operation, the working tool lifts and shifts the layer and breaks up and

crushes compacted soil areas (Figure 1b). The design of the working tool

permits minimal furrowing. The working tools are the paraplow type in which the

working part (1) is inclined at an angle of 40–45° to the vertical. This shape

of the working tool enables high-quality cultivation of compacted soils with

maximum retention of stubble.

Figure 1 Experimental

chisel-fertilizer

At

the end of the stand (1) of the chisel fertilizer, there is a fixed shoe (3) to

which the chisel (4) is bolted. On the front side of the stand (1), the wedge-shaped

cutting plate (2) is fixed. On the back is the rectangular distributor of

mineral fertilizers (5), which provides uniform distribution of fertilizers in

the soil with an oblique strip at a depth of 6–8, 16–18, and 23–25 cm. The

wedge-shaped cutting plate (2), which is fixed in the inclined part of the

stand (1), has an area that is 2.2–2.5 times smaller on the downward-directed

side than the area on the upward-directed side. The rectangular fertilizer

distributor (5) is flush with the upward side surface of the stand (1), and in

relation to the downward-sloping side surface of the stand (1), the lower outer

sloping side surface is shifted 2–3 mm toward the upward-sloping side surface

of the stand (1).

3.1. Determining the tractive force

3.1.1. Calculation model

The cross-section of the working tool is a dihedral wedge with a front edge at a cutting angle ? to the direction of travel and the other along the direction of travel (Figure 4).

Figure 2 Interaction of the

ripper-distributor’s working tool with the soil

The

implement moves in the soil at speed (m/s) and acts

on it with force Pb (N), resulting

from normal and friction forces on the blade face. The soil resists the

movement of the ripper-distributor through the following forces:

Q – soil layer resistance in front of the

ripper-distributor;

J – dynamic impact of soil on the working

body;

Gb – soil layer resistance on the front edge

of the blade; and

Gs – lateral impact of soil layer on the

second edge.

The lateral impact can also occur on the

second edge after point B. Obviously,

this force is much smaller than the others, so it can be disregarded.

Forces Pb, Gb and Gs are directed at an angle of friction to the normal surface (Figure 5) and characterize the soil resistance to deformations arising in it due to the impact of the ripper-distributor tool. The resistance of the soil layer at the front is directed against the movement of the working device.

Figure 3 Determination of the

direction of soil deformation reactions on the blade (a) and the lateral face

(b)

The

dynamic disturbance of the deformed soil J

represents a cyclic impact of soil particles on the working tool of the

ripper-distributor. It is directed to the beginning of the blade. This is

because the soil particles hit the surface of the ripper-distributor and reach

the absolute velocity ?a (m/s). Consequently, the dynamic

disturbance must be directed in the opposite direction to the absolute velocity

of the soil particles and act on the blade's tip. The ripper-distributor

velocity is known, and consequently the movement of soil particles over the

wedge surface must be equal to the velocity: ?rel = ?. It

should also be noted that the type of fertilizer used does not affect the

traction performance of the implement, as the fertilizer flows inside the

distributor.

3.1.2.

Theoretical solution

Determine the pulling force of the tool

as it moves in the soil. Consider the speed triangle (Figure 2 ?DLE).

Based on this, we have:

From the last expression and Figure 4, the absolute speed of the particles ?a will be directed at an angle a/2 to the direction of the y-axis.

By composing and solving the equations of

equilibrium of the forces acting to the x, and y-axes directions, eventually,

it was obtained the dependence of the traction force Pb on

the following parameters: the working body cutting angle (?);

friction angle (?); blade length, and the side edge of the wedge (ll); the working body width (b);

working depth (h); the working body

velocity (?) and the soil density (?).

The

theoretical solution and calculation have determined the equation of the

tractive force Pb (3):

|

|

The resulting equation (3) shows that the traction resistance Pb of the implement has a proportional relationship to the width b, working depth h, and cutting angle ? of the working tool and a quadratic relationship to its forward speed ?. At a working depth of h = 0.3 m and a working width of b = 0.45 m, the traction force varied within Pb=906.2 - 4038.5 N (Table 1).

Table 1 Tractive

forces Pb(N) depending on machine speed ?(m/s) and cutting

angle ? (deg)

|

v\? |

16 |

18 |

20 |

22 |

24 |

|

1.4 |

906.15 |

1022.88 |

1139.9 |

1257.06 |

1374.2 |

|

1.6 |

1183.54 |

1136.00 |

1488.85 |

1641.87 |

1794.87 |

|

1.8 |

1497.91 |

1690.88 |

1884.32 |

2077.99 |

2271.63 |

|

2.0 |

1849.28 |

2087.51 |

2326.33 |

2565.42 |

2804.49 |

|

2.2 |

2237.62 |

2525.88 |

2814.85 |

3104.16 |

3393.43 |

|

2.4 |

2662.96 |

3006.01 |

3349.91 |

3694.21 |

4038.46 |

To minimize the traction force at the

working depth of h= 0.25–0.35m and when working width of one tool b= 0.40-0.45m, the

following is recommended:

- cutting angle ?= 16–20?;

- travel speed of the

working tool v= 1.8–2.0m/s.

3.2. Study of

irregularity in fertilizer distribution

3.2.1.

Fertilizer flow simulation model

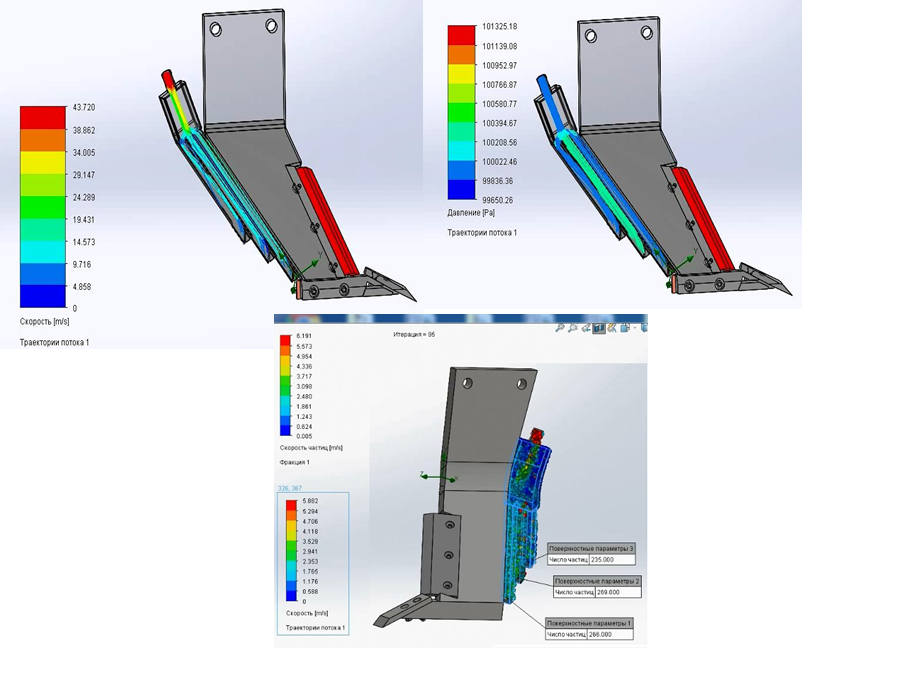

The flow of fertilizer

granules in the distributor was modeled using a C.F.D. software – SolidWorks Flow Simulation®.

The process of movement of the mineral fertilizer granules without air supply

in the distributor was simulated, and three-dimensional trajectories of the

movement in the calculation model (streamlines, fields and indicators of

velocity and pressure) were received.

From the positions of streamlines and the

field of granule velocities, we observed that the position of the lines in the

upper part of the distributor is straight, with a deflection of the jump and

wave lines increasing as the mineral fertilizer mass approaches compartments

(outlets). In the distributor's lower part, the granule discharge velocities

are approximately the same. This pattern of movement of the fertilizer mass

results in a more uniform distribution of granules in outlets of the

distributor and uniform distribution of granules at different depths. Analysis

of the fertilizer granules' movement due to gravity in the distributor show

that the highest velocity and high number of granules sown occurs in the second

compartment, and the lowest velocity and number of granules sown occurs in the

third compartment. The particle velocity and the number of grains by

compartments are shown in Figure 4: in the first compartment – n1 = 266 and v1 = 1.661…3.098 m/s; in the

second compartment – n2 =

269, and v2 = 2.480…4.964

m/s; in the third compartment, n3

= 235 and v3 =

0.05…1.243 m/s.

The analysis of particle

movement in the third compartment show that in the upper part of the

distributor, particles falling out of the distributor's neck hit the walls of

windows of the lower part of the distributor due to gravity. Furthermore, since

the distributor is mounted obliquely to the working tool, there is an

accumulation of granules at the third compartment's entrance, which decreases

the granule flow rate through the compartment and reduces the number of seeded

granules.

Figure 4 Particle velocity and flow path in the distributor

3.3. Experimental

evaluation of results

The laboratory tests of the working tool

in the soil channel showed that the force of a single tool at a depth of 0.30 m

is 1870 N, which confirms satisfactory agreement of the data from theoretical

and experimental studies (95.5%).

To check the quality of mineral

fertilizers distribution over the distributor compartments a laboratory stand

was developed that allows different rates of fertilizer to be applied to the

spreader tube.

Analysis of the results show that when varying fertilizer doses between 50-400 kg/ha, the non-uniformity of the granular distribution in the compartments varies between 7.8% for the application of granular superphosphate (curve 1), and 22.7% for the application of powdered superphosphate (curve 2) (Figure 5).

Figure 5 Uneven distribution

of the fertilizer across compartments as a function of fertilizer dose

At application rates of 200–400 kg/ha, the

non-uniformity of the seed, which varies between 8%–10%, is drastically

reduced. This is achieved through the design of the distributor, which has a

sloping part (head) with a rectangular cross-section. In this part of the

distributor, the chaotically moving granular flow receives a uniform, set-like

movement along the rectangular cross-section and is distributed in equal

portions to the compartments. At this point, it should be noted that using the

head with other types of cross-sections has not yielded positive results, even

at higher dosages. For example, when a circular cross-section, the granules

accumulated in the lower part due to the concave surface, and most of the

granules fell into the middle compartment.

The use of vertical pipes also did not affect the distribution quality.

Laboratory and field tests were conducted under two conditions at 5.82 and 8.77

km/h. The soil moisture in the test plot was 18.9%. Under the noted conditions,

the ripper-distributor ensures tillage to a depth of 32–35 cm with fertilizer

application in form of inclined belt with a width of 25–29 cm.

3.4.

Analysis of results

The cultivator-fertilizer RUN-4 "Mineral", designed for applying mineral fertilizer (50–480 kg/ha) and deep tillage to a depth of 25–30 cm, was chosen as a comparative machine. In this process, fertilizer granules are applied in a horizontal band with a width of 5–6 cm to a depth of 20.3–21.1 cm. The comparative quality indicators of the process performance are shown in Table 2.

Table 2

Comparison of the quality of the process for layer-by-layer differentiated

fertilizer granule application in form of an inclined belt

|

Name of indicators |

Fertilizing equipment | |

|

RUN-4 Mineral |

Proposed | |

|

Machine

speed, m/s |

2.44 |

2.44 |

|

Capacity

of the machine, kg/s |

0.015…0.06 |

0.013…0.06 |

|

Fertilizer

application rate, kg/ha: |

|

|

|

maximum |

480 |

480 |

|

minimum |

50 |

50 |

|

Application

rate irregularity, % |

14.22 |

12.6 |

|

Uneven distribution of fertilizer across

the width of the spreader, % |

48.3 |

14.2…14.8 |

|

Depth

of embedment, cm |

20.3…21.1 |

5.6…25.8 |

|

Fertilizer

belt width, cm |

5…6 |

32…35 |

One

of the most important indicators of distributor quality is the distribution

uniformity of the material over the entire width of seeding. The experimental

distributor's application rate irregularity is 14.2 to 14.8%, which is lower

than its counterpart. A laboratory study of site-specific liquid fertilizer

application is the aim of further work to standardize the chisel fertilizer.

The design of a working tool for

intra-soil application of fertilizers was developed, and the dependence of

traction force on its design parameters was obtained. Optimal cutting angle

?=16-20º and machine speed ?=1.8-2.0 m/s were determined based on the minimum

tractive force. Laboratory tests in the soil trench show that the traction

force of a single working tool at a depth of 0.30 m is 1870 N, which confirms

satisfactory convergence of data from theoretical and experimental studies

(95.5%). The verification of the quality of mineral fertilizer distribution in

the compartments of the working tool showed that the distribution non-uniformity

of the of fertilizer grains when changing dose D from 50 to 400 kg/ha varied

from 7.8% to 22.7%. The laboratory and field tests showed that the designed

chisel-fertilizer ensures the processing and sloping of fertilizers with a

bandwidth up to 35 cm to a depth of 5.6-25.8 cm with 14-15% non-uniformity over

the width of the spreader. A laboratory study of site-specific liquid

fertilizer application is the aim of further work to standardize the chisel

fertilizer.

The authors are grateful to the Ministry of

Agriculture of the Republic of Kazakhstan for funding the scientific work. This

research has been funded by the Department of Strategic planning and Analysis

of the Ministry of Agriculture of the Republic of Kazakhstan (Grant No. BR06349506-OT-20,

2018-2020).

| Filename | Description |

|---|---|

| R2-CE-5143-20220714104834.docx | --- |

Abella, G.P.L., Lansigan, F., Tubay, J., 2021.

Agricultural land use allocation under current and projected scenarios. International

Journal of Technology, Volume 12(5), pp. 975–988

Alonso-Marroquín, F., Herrmann, H.J., 2005.

The incremental response of soils. An investigation using a discrete-element

model. Journal

of Engineering Mathematics, Volume 52(1), pp.11–34

Antonova, O.I., 2018. Effectiveness of

liquid nitrogen fertilizers for spring wheat and oil-bearing crops // Rural

Sibri. No. 4 (07), pp. 66–67. Available online at: http://www.ids55.ru/ss/articles/132-2018-10-15-09-40-28/4324-2018-10-15-09-48-05.html

Asaf, Z., Rubinstein, D., Shmulevich, I., 2007.

Determination of discrete element model parameters required for soil tillage. Soil

and Tillage Research, Volume 92(1-2), pp. 227–242

Aday, S.H., Ramadhan, M.N., 2019. Comparison between the draft

force requirements and the disturbed area of a single tine, parallel double

tines and partially swerved double tines subsoilers. Soil and Tillage Research, Volume 191, pp. 238–244

Campolo, J., Güereña, D., Maharjan,

S., Lobell, D.B., 2021. Evaluation of soil-dependent crop yield outcomes in

nepal using ground and satellite-based approaches. Field Crops Research,

Volume 260, p. 107987

Dai, X. L. Song, D., Zhou, W., Liu, G., Liang, G., He, P.,

Sun, G., Yuan, F., Liu, Z., Yao, Y., Cui, J., 2021. Partial substitution

of chemical nitrogen with organic nitrogen improves rice yield, soil

biochemical indictors and microbial composition in a double rice cropping

system in south China. Soil & Tillage Research, Volume 205, p. 104753

Eskhozhin, D., Nukeshev, S., Eskhozhin, K.,

Karaivanov, D., 2014. Stress

distribution in soil under action of paraplow cultivator. Life science journal, Volume

11(2s), pp. 20–24

Ferreira, C.J.B., Tormena, C.A., Severiano,

E.D.C., Zotarelli, L., Betioli Júnior, E., 2020. Soil compaction

influences soil physical quality and soybean yield under long-term no-tillage. Archives

of Agronomy and Soil Science, Volume 67(3), pp. 383–396

Gao, L., Becker, E., Liang, G., Houssou, A.A., Wu, H.,

Wu, X., Cai, D., Degré, A., 2017. Effect of different tillage systems

on aggregate structure and inner distribution of organic carbon. Geoderma,

Volume 288, pp. 97–104

Gunawan, G., Sutjiningsih, D., Soeryantono,

H.W, S., 2013. Soil erosion estimation based on GIS and remote sensing for

supporting integrated water resources conservation management. International

Journal of Technology, Volume 4(2), pp. 157–166

Imran, Amanullah, M. Al-Tawaha, A.R.,2021.

Carbon sources application increase wheat yield and soil fertility. Communications

in Soil Science and Plant Analysis, Volume 52(7), pp.695–703

Kenenbaev, S.B., Ramazanova, S.B., Suleimenov,

E.T., Gusev, V.N., 2018. Application of mineral fertilizers in land cultivation

of the Republic of Kazakhstan. Soil

Science and Agrichemistry. Volume 3, pp. 31–40

Nosalewicz, A., Lipiec, J., 2014. The effect

of compacted soil layers on vertical root distribution and water uptake by

wheat. Plant and Soil, Volume 375(1), pp. 229–240

Nukeshev, S., Mamyrbaeva, I., Balabekova, A., Zhaksylykova,

Z., Eskhozhin, K., 2018. The results of

theoretical studies of the vibrator compensating chamber of the dispenser of

mineral fertilizers. Journal of Engineering and Applied Sciences, Volume

13(1), pp. 130–136

Nukeshev S., Eshozhin D.Z., Romanjuk N.N.,

Akhmetov E.S., Tleumbetov K.M., Kostabekova D.Sh., Saktaganov B.J., 2019.

Technological and technical solutions of the basic dose of mineral fertilizers

in precision agriculture system in conditions of Northern Kazakhstan. News

of Science of Kazakhstan, Volume 2, pp. 120–124

Man, M., Deen, B., Dunfield, K.E., Wagner-Riddle, C. and

Simpson, M.J., 2021. Altered soil organic matter composition and

degradation after a decade of nitrogen fertilization in a temperate

agroecosystem. Agriculture, Ecosystems and Environment, Volume 310, p. 107305

Pires, L.F., Borges, J.A., Rosa, J.A., Cooper, M., Heck,

R.J., Passoni, S., Roque, W.L., 2017.

Soil structure changes induced by tillage systems. Soil and Tillage

Research, Volume 165, pp. 66–79

Petrus, H.T.B.M., Putera, A.D.P., Wangi,

I.P., Ramadhian, M.A., Setiawan, H., Prasetya, A., 2020. Characterization of nitrogen

release in modified controlled-release-fertilizer using rice husk biochar. International

Journal of Technology, Volume 11(4), pp. 774–783

Ren, F., Misselbrook, T.H., Sun, N., Zhang, X., Zhang,

S., Jiao, J., Xu, M., Wu, L., 2021. Spatial changes

and driving variables of topsoil organic carbon stocks in chinese croplands

under different fertilization strategies. Science of the Total Environment,

Volume 767, p. 144350

Seifullin, S.,

2020. Patent 34515 RK. Soil tillage tool (No.2019/0368.1). K.A.T.U.

Silva, J.F.G., de Souza Linhares, A.J., Goncalves, W.G., de

Pinho Costa, K.A., Tormena, C.A., Silva, B.M., de Oliveira, G.C., da Costa

Severiano, E., 2021. Are the yield of sunflower and paiaguas

palisadegrass biomass influenced by soil physical quality? Soil

and Tillage Research, Volume 208, p. 104873

Tanbayev, K., Nukeshev, S., Sugirbay A.,

2022. Performance evaluation of tillage knife discharge microchannel. Acta Technologica Agriculturae, Volume 25(4),

pp. 169–175

Walsh, O.S., Christiaens, R.J., 2016. Relative Efficacy of

Liquid Nitrogen Fertilizers in Dryland Spring Wheat. International

Journal of Agronomy. Volume 2016. pp. 252-260

Zarehaghi, D., Neyshabouri, M.R., Gorji, M.,

Hassanpour, R., Bandehagh, A., 2017. Growth and development of

pistachio seedling root at different levels of soil moisture and compaction in

greenhouse conditions. Soil and Water Research, Volume 12(1), pp. 60–66

Zavalin A.A., Sokolov O.A., 2019. Utilization by plants

of nitrogen fertilizer and its regulation. International Agricultural

Journal, Volume 4(370), pp. 71–75