Material Flow Cost Accounting in Palm Oil: Promoting Transparency in the Use of Materials and Appropriate Scenario in Resource Saving and Waste Reduction

Corresponding email: adidjoko@tip-ugm.org

Published at : 25 Jan 2024

Volume : IJtech

Vol 15, No 1 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i1.4393

Kurniawan, M.P., Guritno, A.D., Purwantana, B., Supartono, W., 2024. Material Flow Cost Accounting in Palm Oil: Promoting Transparency in the Use of Materials and Appropriate Scenario in Resource Saving and Waste Reduction. International Journal of Technology. Volume 15(1), pp. 28-38

| Muhammad Prasetya Kurniawan | Departement of Agro-Industrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Adi Djoko Guritno | Departement of Agro-Industrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Bambang Purwantana | Departement of Agricultural Engineering and Biosystem, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Wahyu Supartono | Departement of Agro-Industrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

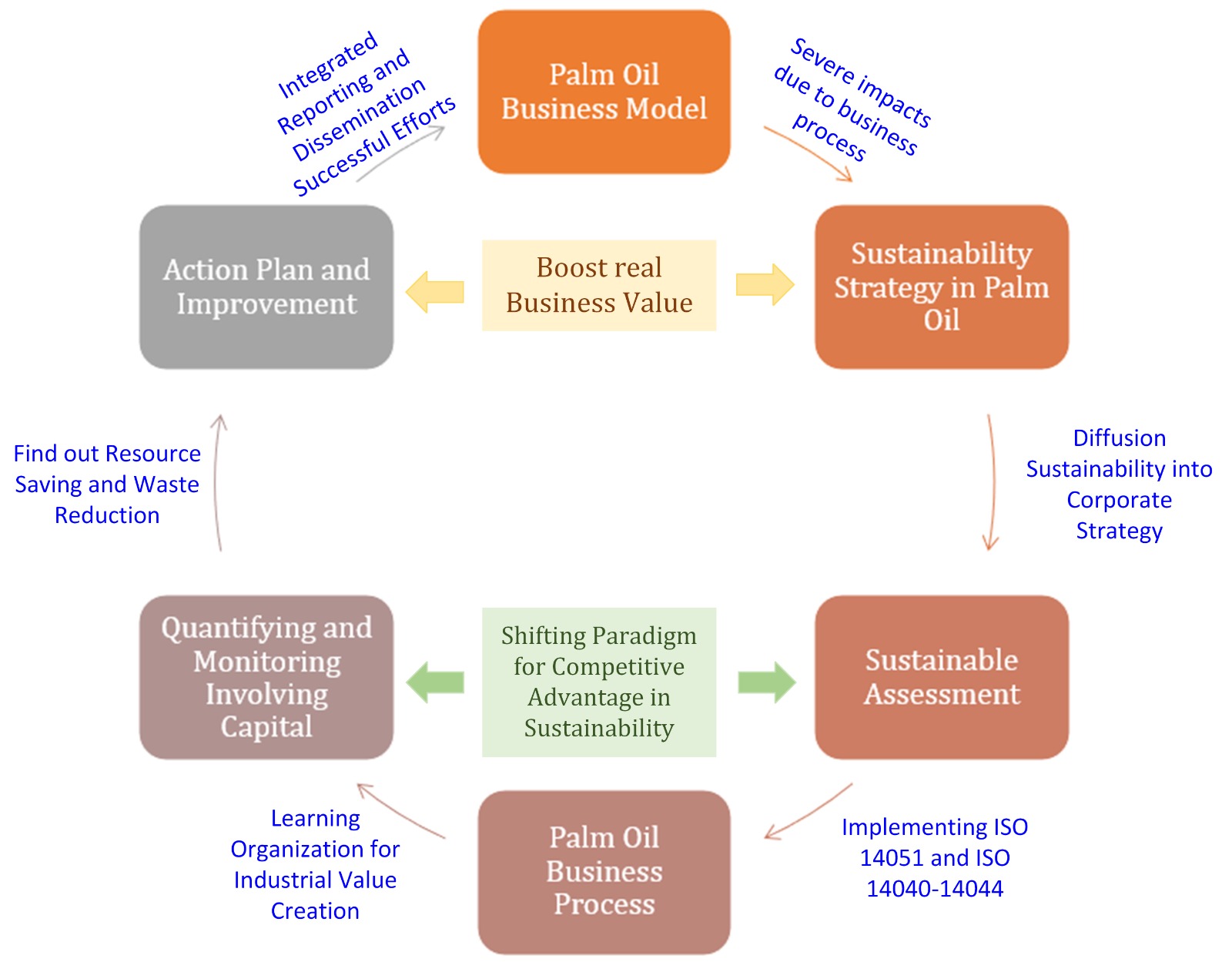

The sustainability aspect of the palm oil

business strategy is a significant part of dealing with changes in the future.

The rest of the processed products that have not been handled perfectly is a

form of material loss that reduces income and environmental sustainability.

Even though the company has reported and compiled its responsibilities, the actual

productivity of the company is much lower because the amount of hidden waste

has not been fully considered. This research involves companies introducing

material flow cost accounting in tracing and calculating physical resources and

financing. This method helps companies to determine the number of negative and

positive products as a basis for evaluation for saving resources and reducing

environmental impacts through reducing oil losses and increasing yields. This

effort will become a competitive advantage and encourage the ability of

business actors to increase revenue and reduce waste. Scenarios of improving

the quality of fresh fruit bunches, optimizing the sterilization process, and

increasing the amount of pulp are adaptive choices in terms of availability and

resource capacity. Dissemination of efforts and successes in improving resource

efficiency to stakeholders is vital to increasing the value and sustainability

of the palm oil business.

Material flow cost accounting; Palm oil; Resource-saving; Waste reduction

The Indonesian palm oil industry contributes significantly to foreign exchange, promotes energy sovereignty, builds people's economy, and provides employment opportunities to face the dynamics of change (Directorate General Crop Estate, 2019). On the other hand, the Indonesian palm oil industry also contributes as a source of pollutants from agricultural land residues associated with palm oil production (fertilizers, pesticides, and other hazardous wastes). Global production and demand for palm oil and its derivatives are increasing rapidly. Expansion of the palm oil business requires investment and high awareness of environmental sustainability. Therefore, Palm Oil Mills (POM) are required to produce products with predetermined quality standards, save energy during the process, and sustainably manage natural resources (Hambali and Rivai, 2017). This condition encourages more effective management techniques that increase organizational output and performance (Ministry of Environment and Forestry, 2019). Palm oil companies must make improvements to milestones, identify hotspots (areas for improvement), conserve resources, and meet the requirements for sustainable adaptation (Ghadimi, Kara, and Herrmann, 2014).

In

reality, many palm oil companies have not fully considered the relationship

between efficiency, finance, and environmental impact as a system that shows

unexpected costs (Harahap et al.,

2019). Conventional handling of waste and

by-products has contributed to saving energy resources and reducing waste.

However, this activity has not been able to balance the rate of environmental

damage because of limited technology, cost allocation, and the availability of

adequate land for waste disposal. This situation must be immediately followed

up by increasing the scope of the hidden waste value, which is still low.

Increasing resources transparency using material flow cost accounting (MFCA) is

very important to illustrate the level of waste, inventory, and cost

allocation, as has been done by Walz and Guenther

(2021), Tran and Herzig (2020), and Kokubu and Tachikawa (2013)

Various

problems, which may occur in supply chain activities, such as waste, incompatibility

of processes and results, and even fraud, can be overcome by reconciling the

calculated numbers, which sometimes become hidden things. The purpose of this

study is to analyze the production process using a material flow cost

accounting (MFCA) framework that can be used to find opportunities to reduce

material use and/or material losses, increase material and energy efficiency,

and reduce adverse environmental impacts. To our best knowledge, there has been

no studies on transparency of the materials involved in palm oil production

with the production cost approach as a form of application of material flow

cost accounting. While this topic is very important to show the value of costs

invested as waste that should be reduced for efficiency improvement. Therefore,

this study give insight on the value of negative products waste treatment cost

to encourage evaluation, improvement, and mapping of savings in the utilization

of negative products for the sustainable palm oil industry.

The main contribution of this study was

providing valuable insights for policymakers seeking to promote sustainable

practices in the palm oil industry. By identifying opportunities for reducing

waste and improving resource efficiency, policymakers can develop policies and

regulations that incentivize sustainable practices and reduce the industry's

environmental impact.

This research was conducted from March to April 2018 at the

government-owned palm oil mills (POM) and plantations in Banten Province and in

February 2020 in North Sumatra. The production system at the Banten palm oil

mill is used as the initial object of the primary data measurement and the

secondary data collection, starting from the seedling, cultivation, and

processing of palm fruit bunches through interviews, observations, and direct

calculations during the activity. Adopting the ISO 14051 standard, plant

implementers are involved in identifying achievements and evaluating

undocumented waste management. This activity has not been included in the

determination of the costs of materials, energy, and systems involved in the

quantity center. Secondary data was collected from the 2016-2018 PTPN VIII

database and annual report. Supporting data for the benchmarking, including the

processing of fresh fruit bunches, is also obtained, with a restricted permit

and authority at the Palm Oil Mills (POM) at PTPN IV North Sumatra (POM Pasir

Mandoge and POM Tinjowan) and the Ministry of Environment and Forestry Forum

for discussion on sustainable topics. The four elements used to compose an MFCA

are as follows:

1) Supply chain

of raw materials, such as fresh fruit bunches (FFB), water, and chemicals for

water treatment and laboratory consumables.

2) Process

sequence flow; there are 37 stages based on the number of groups of machines

and facilities installed in the factory; in this study, the processing chain

was simplified into five main processes for the CPO, and one for the kernel,

energy generation, and water treatment.

3) The

allocation of costs related to materials (as the basis of quantity centers) is

determined by limit and period.

4) A material

flow model is built to visualize the relative quantity, product cost, and flow

loss shown in the quantity center.

2.1. Mass and Energy Balance

All the said palm oil mills have an average installed capacity of 60

tons of FFB/hour, two work shifts, minimum production of around 2,500-3400 tons

of oil, and operate in 25 working days per month with almost 80-90 percent of

the employees being the residents. Most of the factory's products are marketed

in the form of palm oil and palm kernel for domestic use. The mass and energy

balances are prepared based on the calculated size of one ton of fresh fruit

bunches (FFB) as a functional unit. The flow and inventory of materials in the

palm oil mills are traced and calculated with variable i, the balance of

materials in mill system j, and the energy generation for the

boiler is calculated. The flow rate of the input material (fresh fruit bunches)

is expressed in the variable Fi, and the energy (steam and

electricity) from the turbine and generator is distributed to process j, and the flow rate is F_ij (Equation 1). The time of harvesting season related to fluctuations in the cost of

these materials is shown as s, where the given input i

will vary, and the maturity fraction (which determines the price) at The handling of raw materials in the processing system follows the

methodology of previous research conducted by Foong

et al. (2018) and Foong et al.

(2019) (Equation 1-5).

The amount of oil percentage and palm kernel

from input material is determined by Equation 2.

Input material i is

processed into intermediate product p with a conversion . The total production rate for intermediate product p (Fp) applying technologies j is distributed to an advanced

process j' to produce final product p' (including oil recovery

treatment), as calculated by Equation 3.

The amount of intermediate product after

processing p is shown in Equation 4, where

Where B_(j^') represents the advanced process technology j? that

utilizes and manages resources to convert the intermediate product p (

This

formula is used repeatedly for several processing steps in this study. The

value of the cost estimation system becomes the most challenging part to

identify because of the lack of variation in the variations of costs

allocations involved. Based on the value of the same production-consumption

balance, all inputs to the process must be traced to the flow to output in

physical form (weight), and the costs used are based on the

plan–do-check–action (PDCA) cycle in the ISO 14051 guide (Dekamin and Barmaki, 2019; Tachikawa, 2014).

2.2. Cost Accounting

This section is to identify the

flow costs and availability of fresh fruit bunches, biomasses, intermediate

products, and fossil fuels within the mill. The search and calculation (in

units of mass and volume) are performed with the proportion of use and its

weight to be referred to in the quantity center with the following allocation:

a) Material

costs; for the materials involved (with input and output units of measurement

for MFCA analysis), including fresh fruit bunches in the initial processing,

intermediate products to product, chemicals for water treatment, and quality

testing in the laboratory. Exposure can be used to promote transparency in

material and energy flows.

b) Energy

costs; the cost allocated to energy sources, such as electricity, fuel, steam,

heat from biomass, and compression for process purposes, which are calculated

together with the energy audit.

c) System

costs; the cost allocated to material handling, employee wages and salaries,

depreciation, maintenance, overhead costs, and non-material and energy

allocations.

d) Waste

management costs; the cost allocated to handling several aspects, including

residual biomass, solid waste, palm oil mill effluent, and emissions with other

particles from boilers.

These

production costs are the primary budget components for the palm oil production

processes (Dierkes and Siepelmeyer, 2019).

2.3. Material Flow Model

The

formulation of the flow model began with determining the scope and boundaries

of the process and establishing a material flow scheme (Tran

and Herzig, 2020). Material flow analysis models have generally been

used to track production, utilization, and materials consumption (Suh and

Heijungs, 2007). Buchner et

al. (2015) emphasized the need for a comprehensive sensitivity

analysis that considers the interaction between parameters and the effect of

time delays in dynamic material flow models. The identification of the model

uncertainty is made by tracing the structure of the model and its parameters.

The assumption used in this study is that no remaining products are used after

the end of the production period, which may considerably impact the remaining amount

of the inventory used. This condition will affect the model results on the

production and inventory used. Fresh fruit bunches (FFB) must be processed as

soon as possible to anticipate the reduction of the palm oil quality; hence,

there should be no leftovers or supplies.

2.4. Formulation of Resource Saving and Waste Reduction Scenarios

The first step in this study is assessing the

hotspots (areas for improvement) for the material used in crude palm oil

production. In most palm oil mills, the produced non-product output is 70-75%,

while the rest is CPO & kernel. Palm oil mills with relatively high FFB use

require adequate facilities and infrastructure capacity to keep pace with

economic growth (usually related to infrastructure investment) and regulations

referring to, among others, ISPO (Indonesia Sustainable Palm Oil) and PROPER

(Company Performance Rating Program).

3.1. Mass and Energy Balance

The amount of energy consumption for the production process is 16.78-17.53 kWh/ton FFB is obtained from the turbine generator in the palm oil mill (POM) (at an average of 14.07 – 14.92 kWh/ton FFB), and the rest is from the State Electricity Company (PLN) supply (Figure 1). Meanwhile, fiber and shell are used as fuel for water tube boilers to produce hot steam with an average efficiency of 74.5% and feeding water of 87.6oC.

Figure 1 Material and Energy Balance of

Palm Oil Processing

The average FFB processed amount is 1,574 tons per month, with a

minimum operation of 30 tons/hour for an average processing capacity. However,

a shortage of FFB supply occurred during the data collection; thus, 10,558

tons/month were used for calculations instead. All materials involved in the

total initial input were identified as 25% product, 72% solid waste, and 84%

liquid waste from supplementary usage of production water and steam. In a

previous study, it was stated that recycling waste streams would reduce water

consumption and the amount of palm oil mill effluent (POME) by 65-68% and 67%,

respectively (Chungsiriporn, Prasertsan and Bunyakan, 2006).

3.2. Cost

Accounting

Even though the yield and

utilization of waste have increased, unwanted materials are still generated and

require considerable energy and cost to treat. With a minimum average of 10,558

tons of the processed FFB, the product capacity that can be achieved is 2,147.5

tons of CPO (20.34% yield; 1.65% loss) and 385.37 tons of kernel (3.85% yield;

oil loss of 0.5%). Therefore, the current converted average price levels are

USD 686 for CPO per tonne and USD 567 for kernels per tonne. Meanwhile, the

total expected revenue from sales is USD 1,691,689.79 (Tables 2 and 3). The

material flow cost can be seen in Supplementary 1.

Based on the mass balance and

material flow model, the negative product output consists of the following:

1. Solid waste,

such as petals, leaves, insects, dirt, and other impurities in the grading

area, which is in a minute amount compared to the number of fresh fruit bunches

(FFB), empty fruit bunches (EFB) (including fruit and oil loss in EFB

2,470±14); fiber (760±3 tonnes); and, shells (675±64 tonnes) and light

particles (±52.79 tonnes).

2. Liquid

waste, such as condensate (water and oil) from the sterilization process

(1,583±28 tonnes), effluent from the clarification (5384±443 tonnes), and

effluent from palm kernel recovery plan (hydro-cyclone 844±147 tonnes), boiler

blowdown (1,266±137 tonnes), and others (±1,055 tonnes).

Although waste management reporting and evaluation are conducted

annually, there has not been much improvement in mitigating the accumulation of

residual waste. Lagoon systems and solid waste final disposal are the most

commonly used methods in most palm oil mills due to their suitability for use

in Indonesia. These waste management methods are chosen because they require

limited technology, have low maintenance costs, are energy-efficient, and have

a simple design. However, these systems have some drawbacks, such as long

hydraulic retention times, large lagoon areas (Hayawin

et al., 2018), and the potential release of significant

amounts of greenhouse gases like methane.

One of the

discussions in this study results in the comparison between the percentage of

solid and liquid waste produced that is not much different from the output

produced by the POM Agency in North Sumatra. The average value of the negative

products is USD 537,718 (46.43%), and the value of the positive products is USD

723,706 (53.57%), along with the waste treatment costs (9.475%), including the

allocation of the costs for handling empty fruit bunches (EFB), drying process

fibers, and shells for boiler feed, and other processes for the treatment of

residual solid waste. The waste treatment costs include monetary allocations

for handling POME, around 27 percent from sterilization (fat-fit), 44 percent

from sludge decanter, and 29 percent from hydro-cyclone. This material is used

to show the value of all negative losses/products produced (Dierkes and Siepelmeyer, 2019). The most compelling finding of this study is the role of biomass

in energy cost reduction. Its contribution comes from 96% energy (85% fiber and

15% shell) and 4% from diesel, with a total efficiency of 56.05%. These results

can be used to control the level of target costs reached in real time and

introduce prompt corrections regarding the planned costs according to external

and internal changes (Burova et al.,

2021).

Another interesting finding is the potential for recovering trapped oil in each process phase and by-product to increase the oil extraction rate (OER). The trapped oil was found in empty fruit bunches (EFB) 0.31±0.08%, cakes 0.78±0.05%, nuts 0.10±0.05%, fruit in FFB 0.13±0.04 %, condensate (fat-fit) 0.16±0.04%, fiber cyclone (0.2%), light tenera dry separating (LTDS) 0.23±0.08%, and clay-bath ±0.07 % with a total oil loss of 1.67 – 1.96%. The types of losses that occur within the scope of the calculation affect the quality of the results, process losses, and quality degradation. Based on the material flow cost table (Table 3), every 0.5% increase in the oil extraction rate (OER) will increase USD 8,458.45 or USD 3.94 per tonne of CPO. It has revived the company to carry out improvement scenarios as an added value to the industry.

Table 1 Material Flow Cost of Palm Oil Processing

|

Item |

QC 1 (Grading -

loading ramp) |

QC 2 (Sterilization) |

QC 3 (Threshing) |

QC (Pressing) |

QC 5 (Clarification) |

QC 6 (Kernel

Processing) |

QC 7 (Energy

generation) |

QC 8 (Water

Treatment) |

|

Product

(total material cost in USD) |

1,192,422 |

1,202,653 |

959,021 |

787,356 |

746,962 |

715,696 |

717,638 |

723,705 |

|

Allocation

cost |

99,99% |

88.30% |

64.60% |

42.92% |

21.24% |

4.52% |

NA |

NA |

|

Waste (from

fresh fruit bunch) |

0,01% |

11,69% |

23.40% |

49.26% |

71.54% |

~74.23% |

NA |

NA |

|

System cost |

4.23 |

14,095 |

24,136 |

25,806 |

25,836 |

36,565 |

44,038 |

47,887 |

|

Energy cost |

205 |

464 |

727 |

571 |

421 |

422 |

784 |

802 |

Table

2 Total Output

and Contribution in Cost Allocation

|

Output |

Total material (ton) |

Percentage |

Total cost (USD) |

Percentage |

|

Positive product |

2726 |

24.19%* |

723,706 |

57.37% |

|

Negative product |

7854 |

75.81% |

537,718 |

42.63% |

*positive product = palm oil and kernel

Table

3 Potential Scenario for Oil Losses Reduction

|

Potential Scenario |

Main activities |

Achievement |

|

To recover trapped oil in mesocarp (residual oil

recovery system) |

(a)

Using a washing

technique at a particular temperature,

followed by pressing in the digester and screw press to recover oil |

(a)

Increased potential oil recovery/reduced oil loss |

|

(b)

Utilizing ± 7.8% of

biomass (shell and fiber); and |

(b)

more solid waste is utilized as biomass energy | |

|

(c)

Reallocating resources and schedule to conduct these

activities. |

(c)

Determination of method, quality, and quantity of palm oil

standard | |

|

To recover oil from the empty fruit bunch |

(a)

Re-sterilization of poorly recovered un-stripped bunches. |

(a)

Report of a feasibility study for remaining shell and fiber utilization as biomass energy |

|

(b)

Using aqueous extraction (water and steam) to

increase the oil extraction rate (using hydro solvent) |

(b)

Improved combustion efficiency of EFB after this treatment | |

|

(c)

Performing the setup and installation to improve the

lab-scale capacity to the pilot plant |

(c)

Collaboration with academics to conduct further

studies on oil-water emulsion using micro-separation technologies, such as column flotation | |

|

To ensure the maturity level & good handling

practices on harvesting for audit data assessment enhancement |

(a)

Enhancing harvesting strategy for bunch analysis of the minimum number of detached fruits per bunch |

(a)

Mitigation of

insufficient harvesters by estimating potential product contents of

individual FFB deliveries |

|

(b)

Strictly maintaining

audit data with harvesting round to estimate oil content before the delivery to the mill. |

(b)

Reliable assessment

and supervision system for oil recovery efficiency (ORE) from the plantation

until the mill | |

|

(c)

Cutting only ripe

bunches and ensuring no ripe is left behind |

(c)

Provision of an accurate account and information to improve

crop recovery plantation | |

|

(d)

Disseminating best

practices and supervision to picking up all loose fruits |

(d)

Reduced unstandardized

FFB in POM | |

|

To combine three potential scenarios |

(a)

Developing standard operations and procedures to drive the

roles of line managers and human resources of palm oil mills and plantation |

(a)

Adjustments to some working operations and resources based on

improvement results |

|

(b)

Developing appropriate skills and awareness of employees

and upgrading them to required

levels. |

(b)

Assessment and

monitoring conducted in the factual working situation

without less investment | |

|

(c)

Synergizing with

academics, the government, and

industry to enhance capacity building for farmer |

(c)

Requirement of assessment and policies in a coherent approach

and supported by an IT-based environment for integrated resource efficiency

analysis |

Efforts to increase

yield/oil require additional costs for material handling, labor wages, and

system maintenance have not been studied because of the limited authority of

researchers. This activity requires a continuous evaluation and contribution to

the system improvement. Recommendations and follow-up scenarios are decided

based on a quantity center analysis that does not much change the work patterns

without new technology addition, low investment, and synergies with the

increase of employee capabilities (Table 3). Reducing losses and increasing oil

yield are two scenario options that can improve the quality of fresh fruit

bunches. This can be achieved by optimizing the sterilization of empty bunches

and suppressing mesocarp. The chosen scenario aligns with previous research

conducted by Noorshamsiana et al. (2013),

Subramaniam et al. (2013), Cock et al. (2014), and Gomez et al. (2015). By implementing this

scenario, it is expected that the value of a sustainable business will

increase.

Scenario formulations for oil

loss are available by gradually expanding the scope of material flow analysis

(MFA) to material flow cost accounting (MFCA) following the given authority.

The identified 'Hotspots' will later be used to assess the success of these

efforts. Documentation of the production stage to waste handling plays a

significant role in material efficiency and waste management as the innovative

potential of alternative energy at the level of an economic entity in the

context of increasing the global significance of the transition to the circular

economy (Zaytsev et al., 2021).

3.3. Material Flow Model

The material flow model is in

line with the use of the processing costs usage model that involved materials,

labor, energy, utilities, depreciation, and other usage costs. The amount of

each use is still hard to identify because the production process runs

continuously (Let, Weng, and Wahid 2010). Improvement scenarios require

the approval and involvement of all stakeholders for the amount of material and

costs spent. To address several limitations,

such as those related to authority, documentation, and reporting capabilities,

the flow scheme is presented in a simple manner by comparing inputs and

outputs, as illustrated in Supplementary 2. This scheme provides a

comprehensive assessment of the proportion of each material and energy use,

products, by-products, waste, and losses to assess the achievement and

justification of the applied instruments, as noted by Egorova

et al. (2021).

Standardization

of improvement and calculation of resource use with sensitivity requires

technology to actualize transparency, especially regarding the price,

traceability of fresh fruit bunches, quality, process, and waste treatment as a

monitoring system for the palm oil industry and policymakers (Heryani et al., 2022). The

standardization is vital in increasing the transparency of the resources used

as these activities sometimes interfere with the processing at the factory, and

there is limited reporting authority. Therefore, these results are needed to

stimulate the integration of the analysis of each scenario using life cycle

assessments for the feasibility of a sustainable palm oil industry.

The calculation of the production process data

using information obtained from a POM in Banten showed a high percentage of

negative products (±75.81%), with a waste treatment cost of 42.63% of the

expenditure. MFCA also illustrates that the allocation of financing for

materials is a hidden waste so that the flow of supporting resources

transparency becomes the basis for evaluation, improvement, and mapping of

savings in a more detailed supply chain. Investing in research and development

to improve oil recovery and material efficiency and to identify new

opportunities for resource optimization play important role in complying with

sustainability standards such as the Indonesian Sustainable Palm Oil and

Roundtable on Sustainable Palm Oil (RSPO), which require companies to minimize

their environmental impact and promote sustainable practices. By implementing

MFCA, palm oil companies can demonstrate their commitment to sustainability,

differentiate themselves from competitors who may not be taking similar steps,

and enhancing a company's reputation among consumers and stakeholders.

The authors

gratefully acknowledge support from the Directorate of Research &

Development Universitas Gadjah Mada, Palm Oil Mill PTPN VIII Kertajaya, Palm

Oil Mill PTPN IV Pasir Mandoge, Palm Oil Mill PTPN IV Tinjowan, and the data

gathering team from Vocational School of Agro-Industry Universitas Gadjah Mada

for the support and contribution to conduct these projects.

| Filename | Description |

|---|---|

| R4-IE-4393-20240118152423.jpg | --- |

| R4-IE-4393-20240118152436.jpg | --- |

| R4-IE-4393-20240118152445.docx | --- |

Buchner, H.,

Laner, D.,

Rechberger, H., Fellner,

J. 2015. Dynamic

Material Flow Modeling: An Effort to Calibrate and Validate Aluminum Stocks and

Flows in Austria. Environment Science and Technology, Volume 49, pp. 5546?5554

Burova, E., Grishunin, S.,

Suloeva, S., Stepanchuk, A., 2021. The Cost Management of Innovative Products

in an Industrial Enterprise Given the Risks in the Digital Economy. International

Journal of Technology, Volume 12(7), pp. 1339–1348

Chungsiriporn, J., Prasertsan S.,

Bunyakan C. 2006. Toward Cleaner Production of Palm Oil Mills: Part 2

Minimization of Water Consumption and Process Optimization. Asian Journal

Energy Environment, Volume 7(1), pp. 246–257

Cock, J., Donough C.R., Oberthür

T., Indrasuara K., Rahmadsyah, Gatot A.R., Dolong T., 2014. Increasing Palm Oil

Yields by Measuring Oil Recovery Efficiency from the Fields to the Mills. In:

Proceeding on the 5th International Oil Palm Conference (IOPC): Food Security

and Renewable Energy

Dekamin, M., Barmaki M. 2019. Implementation of Material Flow Cost

Accounting (MFCA) in Soybean Production. Journal of Cleaner Production,

Volume 210, pp. 459–465

Dierkes, S., Siepelmeyer D. 2019. Production and Cost Theory-Based

Material Flow Cost Accounting. Journal of Cleaner Production, Volume

(235), pp. 483–492

Directorate General Crop Estate, 2019. Palm Oil: Tree Crop Estate

Statistics of Indonesia 2018 – 2020.

Ministry of Agriculture Republic of Indonesia, Jakarta, 2019.

Egorova, S., Kistaeva, N., Kulachinskaya, A., Nikolaenko, A.,

Zueva, S., 2021. Development of Methods for Assessing the Impact of

Environmental Regulation on Competitiveness. International Journal of

Technology, Volume 12(7), pp. 1349–1358

Foong, S.Z.Y., Lam Y.L., Andiappan V., Foo D.C.Y., Ng D.K.S. 2018.

A Systematic Approach for the Synthesis and Optimization of Palm Oil Milling

Processes. Journal of Industrial and Engineering Chemistry Research, Volume

57(8), pp. 2945–2955

Foong, S.Z.Y., Goh C.K.M., Supramaniam C.V., Denny K.S.N. 2019.

Research article: Input-Output Optimisation Model for Sustainable Oil Palm

Plantation Development. Sustainable Production and Consumption, Volume

(17), pp. 31–46

Ghadimi, P., Li W., Kara S., Herrmann C. 2014. Integrated Material

and Energy Flow Analysis towards Energy Efficient Manufacturing. Procedia

CIRP, Volume 15,

pp. 117–122

Gomez, J.C., Mokhtar M.N., Sulaiman A., Zakaria R., Baharuddin

A.S., Busu Z. 2015. Study on Residual Oil Recovery from Empty Fruit Bunch by

Combination of Water and Steam Process. Journal of Food Process Engineering,

Volume (38), pp. 385–394

Hambali, E., Rivai, M. 2017. The Potential of Palm Oil Waste

Biomass in Indonesia in 2020 and 2030. In: International Conference on Biomass:

Technology, Application, and Sustainable Development. In: IOP Conference

Series: Earth and Environmental Science 65, 012050

Harahap, F., Leduc, S., Mesfun, S., Khatiwada, D., Kraxner, F., Silveira, S. 2019. Opportunities to Optimize the Palm Oil Supply Chain in Sumatra, Indonesia. Energies, Volume 12, p. 420

Hayawin, Z., Astimar, A.A., Idris, J., Jalani, N.F., Mamat, R.,

Ibrahim, M., Hassan, M., Abd-Aziz, S., 2018. Reduction of POME Final Discharge

Residual Using Activated Bio Adsorbent from Oil Palm Kernel Shell. Journal

of Cleaner Production, Volume (182), pp. 830–837

Heryani, H., Legowo, A.C., Yanti, N.R., Marimin, Raharja, S.,

Machfud, Djatna, T., Martini, S., Baidawi, T., Afrianto, I., 2022.

Institutional Development in the Supply Chain System of Oil Palm Agroindustry

in South Kalimantan. International Journal of Technology, Volume 13(3),

pp. 643–654

Kokubu, K., Tachikawa H., 2013. Material Flow Cost Accounting:

Significance and Practical Approach. In: Kauffman J., Lee KM. (eds)

Handbook of Sustainable Engineering. Springer, Dordrecht

Let, C.C., Weng, C.K., Wahid, M.B. 2010. Material Flow Cost

Accounting (MFCA): A Brief Introduction. Oil Palm Bulletin, Volume (60),

pp. 28 – 37

Ministry of Environment and Forestry of The Republic of Indonesia, 2019. PROPER 4.0 as SIMPEL as it

is. Company Performance Rating Assessment Programme in Environmental

Management. PROPER Secretariat Directorate General of Pollution &

Environmental Damage Control Ministry of Environment & Forestry- The

Republic of Indonesia.

Noorshamsiana, A.W., Astimar, A.A., Nor Hayati, M., Nor Faizah,

J., Mohamadiah, B. Norhayati, S. 2013. Optimisation of Enzymatic Sludge Palm

Oil Recovery from Palm Oil Mill Effluent Using Response Surface Methodology. Journal

of Oil Palm Research, Volume 25(3), pp. 348– 356

PT Perkebunan Nusantara VIII.

Annual Report: Asset and Optimization Through Property Investment 2016 -

2018. Available online at https://www.ptpn8.co.id/laporan-annual-report/ ,

Accessed on March 13, 2019

Subramaniam V., Menon N.R., Sin H., May C.Y. 2013. The Development

of a Residual Oil Recovery System to Increase the Revenue of a Palm Oil Mill. Journal

of Oil Palm Research, Volume 25(1), pp. 116– 122

Suh, S., Heijungs, R. 2007. Power

Series Expansion and Structural Analysis for Life Cycle Assessment. International Journal of Life Cycle Assessment,

Volume 12(6), pp. 381–390

Tachikawa, H. 2014. Manual on Material Flow Cost Accounting: ISO

14051. Asian Productivity Organization. Tokyo-Japan. ISBN 978-92-833-2450-8

(PDF)

Tran, T.T., Herzig, C. 2020. Material

Flow Cost Accounting in Developing Countries: A Systematic Review. Sustainability,

Volume 12, 5413

Walz, M, Guenther, E, 2021. What Effects Does Material Flow Cost

Accounting Have for Companies? Evidence from a Case Studies Analysis. Journal

of Industrial Ecology, Volume 25, pp. 593–613

Zaytsev,

A., Dmitriev, N., Rodionov, D., Magradze., T., 2021. Assessment of the

Innovative Potential of Alternative Energy in the Context of the Transition to

the Circular Economy. International Journal of Technology, Volume 12(7),

pp. 1328–1338