Structure, Density and Hardness of Spark Plasma Sintered Fe-Mn Alloys

Corresponding email: toto009@brin.go.id

Published at : 01 Dec 2025

Volume : IJtech

Vol 16, No 6 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i6.7789

| Sovian Aritonang | Faculty of Military Mathematics and Natural Sciences, Indonesia Defense University, Bogor 16810, Indonesia |

| Andy Marjono Putranto | 1. Faculty of Military Mathematics and Natural Sciences, Indonesia Defense University, Bogor 16810, Indonesia; 2. Organization and Human Resources Bureau, National Research and Innovation Agency, Jak |

| Resetiana Dwi Desiati | Research Center for Advanced Material, National Research and Innovation Agency, Tangerang Selatan 15314, Indonesia |

| Bambang Hermanto | Research Center for Advanced Material, National Research and Innovation Agency, Tangerang Selatan 15314, Indonesia |

| Michael Tulus Samuel | Faculty of Military Mathematics and Natural Sciences, Indonesia Defense University, Bogor 16810, Indonesia |

| Andi Suhandi | Research Center for Advanced Material, National Research and Innovation Agency, Tangerang Selatan 15314, Indonesia; |

| Oman Zuas | Research Center for Testing Technology and Standards, National Research and Innovation Agency, Tangerang Selatan 15314, Indonesia |

| Tony Wang | Central Analytical Research Facility (CARF), Queensland University of Technology (QUT), Brisbane, QLD 4000, Australia |

| Maykel T.E. Manawan | 1. Faculty of Military Mathematics and Natural Sciences, Indonesia Defense University, Bogor 16810, Indonesia 2. Research Center for Advanced Material, National Research and Innovation Agency, Tanger |

| Toto Sudiro | Research Center for Advanced Material, National Research and Innovation Agency, Tangerang Selatan 15314, Indonesia |

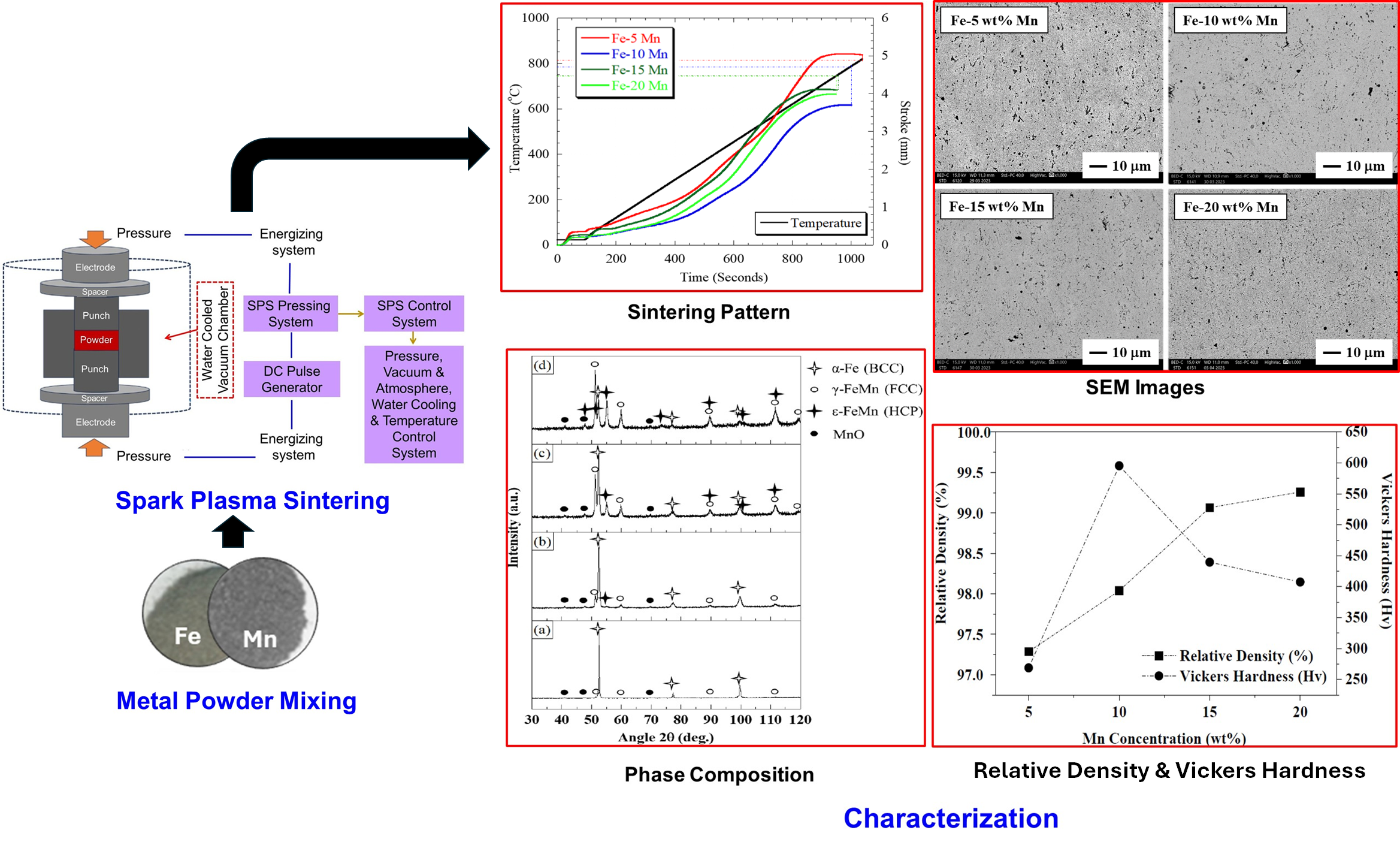

This study examines the effect of Mn content on phase evolution, density, andô its correlation with the hardness of Fe-Mn alloys produced through mechanical millingô followed by a spark plasma sintering technique. Alloys with Mn concentrations of 5,ô 10, 15, and 20 wt% were examined, revealing phase compositions primarily consistingô of BCC (-Fe, ferrite), FCC (

-FeMn, austenite), and HCP (

-FeMn, martensite), withô minor occurrences of MnO. The Mn content significantly affected the phase distribution,ô strain, crystallite size, and relative density. The evolution of phase structureãparticularlyô the balance between hard BCC, HCP, and softer FCCãemerges as a critical factor inô determining hardness. The alloy with 10 wt% Mn exhibited the highest hardness (

595.34ô Hv) despite not having the highest density, indicating that densification and the natureô and proportion of constituent phases governed the mechanical properties. While ferriteô and martensite enhance hardness, increasing the Mn content promotes the formation ofô a more ductile austenite phase, which offsets the strengthening effects and contributesô to the observed decrease in hardness at higher Mn levels. These findings highlight theô complex interplay between phase transformation, microstructure, and hardness in Fe-Mnô alloy systems.

BCC; Density; Fe-Mn; Hardness; Spark plasma sintering

Abdul, A., Yang, M., Shimizu, T., &

Furushima, T. (2021). Effect of grain misorientation and martensitic

transformation on surface roughening behavior in thin austenitic stainless

steel foils. International

Journal of Technology, 12(6), 1161ã1167. https://doi.org/10.14716/ijtech.v12i6.5180

Acet, M., Schneider, T., Gehrmann, B., & Wassermann, E. F. (1995). The

magnetic aspects of the ?ã? and ?ã? martensitic transformations in FeãMn

alloys. Journal de Physique IV, 5, C8-379ãC8-384. https://doi.org/10.1051/jp4:1995856

Amaral, R., Santos, A. D., Sousa, J.

A., & Lopes, A. B. (2017). The influence of microstructure on the

mechanical behaviour of dual phase steels. In L. F. M. da Silva (Ed.), Materials

design and applications (pp. 25ã35). Springer International Publishing. https://doi.org/10.1007/978-3-319-50784-2_3

Anwar, M. S., Melinia, R. K., Pradisti,

M. G., & Siradj, E. S. (2021). Effect of prior austenite grain-size on the

annealing twin density and hardness in the austenitic stainless steel. International

Journal of Technology, 12(6), 1149ã1160. https://doi.org/10.14716/ijtech.v12i6.5190

Ayodele, O. O., Awotunde, M. A.,

Babalola, B. J., & Olubambi, P. A. (2021). Spark plasma sintering of

CNTãNiAl nanocompositesãprocess parameter, densification mechanism, and grain

analysis. Manufacturing Review, 8, 25. https://doi.org/10.1051/mfreview/2021023

Balagurov, A. M., Bobrikov, I. A.,

Pons, J., Cifre, J., Sun, L. Y., & Golovin, I. S. (2018). Structure of the

FeãMnãSi alloys submitted to ? ? ? thermocycling. Materials

Characterization, 141, 223ã228. https://doi.org/10.1016/j.matchar.2018.04.052

Balbo, A., & Sciti, D. (2008).

Spark plasma sintering and hot pressing of ZrB?ãMoSi? ultra-high-temperature

ceramics. Materials Science and Engineering: A, 475(1), 108ã112. https://doi.org/10.1016/j.msea.2007.01.164

Cabibbo, M., Deodati, P., Libardi, S., Molinari, A., Montanari, R., &

Ucciardello, N. (2008). Damping of FeMo alloys obtained from SPS

sintering of nanostructured powders. Materials Science Forum, 604ã605,

203ã211. https://doi.org/10.4028/www.scientific.net/MSF.604-605.203

Cheary, R. W., Coelho, A. A., &

Cline, J. P. (2004). Fundamental parameters line profile fitting in laboratory

diffractometers. Journal of Research of the National Institute of Standards

and Technology, 109, 1ã25. https://doi.org/10.6028/jres.109.002

Chen, X., Duan, H., Cao, B., Sun, Q.,

& Yang, W. (2022). The evolution mechanism of an FeMo alloy catalyst for

growth of single-walled carbon nanotubes. Physical Chemistry Chemical

Physics, 24, 25480ã25486. https://doi.org/10.1039/D2CP03182E

Choi, S., Jeon, J., Seo, N., Moon, Y.

H., Shon, I.-J., & Lee, S.-J. (2020). Effect of composition on

strain-induced martensite transformation of FeMnNiC alloys fabricated by powder

metallurgy. Archives of Metallurgy and Materials, 65(3), 1001ã1004. https://doi.org/10.24425/amm.2020.133206

Citrawati, F., Dwiwandono, R., &

Firmansyah, L. (2020). The effect of Ni on the formation of bainite in FeãNi

lateritic steels through semi-continuous cooling method. International

Journal of Technology, 11(1), 60ã70. https://doi.org/10.14716/ijtech.v11i1.3178

Danninger, H., Gierl-Mayer, C.,

Prokofyev, M., Huemer, M.-C., De Oro Calderon, R., Hellein, R., Mû¥ller, A.,

& Stetina, G. (2021). Manganeseãa promising element also in high alloy

sintered steels. Powder Metallurgy, 64(2), 115ã125. https://doi.org/10.1080/00325899.2021.1886717

Ding, Z., Ding, C., Yang, Z., Zhang,

H., Wang, F., Li, H., Xu, J., Shan, D., & Guo, B. (2024). Ultra-high

strength in FCC+BCC high-entropy alloy via different gradual morphology. Materials,

17(18). https://doi.org/10.3390/ma17184535

Ekholm, M., & Abrikosov, I. A.

(2011). Structural and magnetic ground-state properties of ?-FeMn alloys from

ab initio calculations. Physical Review B, 84, 104423. https://doi.org/10.1103/PhysRevB.84.104423

Farihin, P., Suharno, B., Dani, M.,

Ngarayana, I. W., Andryansyah, Insani, A., Wardana, R. I., Huang, C. A., Aziz,

F., & Adhika, D. R. (2025). High-resolution neutron diffraction analysis of

residual stresses in oxide dispersion strengthened FeNiCrY?O? cast alloys for

advanced nuclear reactor applications. International Journal of Technology,

16(2), 625ã638. https://doi.org/10.14716/ijtech.v16i2.7241

Feng, Y. P., Blanquer, A., Fornell, J.,

Zhang, H., Solsona, P., Barû°, M. D., SuriûÝach, S., IbûÀûÝez, E., GarcûÙa-Lecina,

E., Wei, X., Li, R., Barrios, L., Pellicer, E., Noguûˋs, C., & Sort, J.

(2016). Novel FeãMnãSiãPd alloys: Insights into mechanical, magnetic, corrosion

resistance and biocompatibility performances. Journal of Materials Chemistry

B, 4, 6402ã6412. https://doi.org/10.1039/C6TB01951J

Gambaro, S., Paternoster, C.,

Occhionero, B., Fiocchi, J., Biffi, C., Tuissi, A., & Mantovani, D. (2021).

Mechanical and degradation behavior of three FeãMnãC alloys for potential

biomedical applications. Materials Today Communications, 27, 102250. https://doi.org/10.1016/j.mtcomm.2021.102250

Hasegawa, T., Kanatani, S., Kazaana,

M., Takahashi, K., Kumagai, K., Hirao, M., & Ishio, S. (2017). Conversion

of FeCo from soft to hard magnetic material by lattice engineering and

nanopatterning. Scientific Reports, 7, 13215. https://doi.org/10.1038/s41598-017-13602-x

Idhil, A., Borca, C., Uldry, A.-C.,

Zema, N., Turchini, S., Catone, D., Foelske, A., Grolimund, D., & Samaras,

M. (2012). The influence of Cr composition on the local magnetic structure of

FeCr alloys. Nuclear Instruments and Methods in Physics Research Section B,

284, 1ã5. https://doi.org/10.1016/j.nimb.2011.08.071

Kang, L., Yuan, H., Li, H., Ji, Y., Liu, H., & Liu, G. (2021). Enhanced

mechanical properties of FeãMnãAlãC low density steel via aging treatment. Frontiers

in Materials, 8. https://doi.org/10.3389/fmats.2021.680776

Kern, A., Coelho, A. A., & Cheary,

R. W. (2004). Convolution based profile fitting. In E. J. Mittemeijer & P.

Scardi (Eds.), Diffraction analysis of the microstructure of materials

(pp. 17ã50). Springer. https://doi.org/10.1007/978-3-662-06723-9_2

Khan, F., & Rashed, H. M. M. A.

(2020). Phase transformation in micro-alloyed steels. In A. Sharma, Z.

Duriagina, & S. Kumar (Eds.), Engineering steels and high entropy

alloys. IntechOpen. https://doi.org/10.5772/intechopen.91468

Kim, H., Suh, D.-W., & Kim, N. J.

(2013). FeãAlãMnãC lightweight structural alloys: A review on the

microstructures and mechanical properties. Science and Technology of

Advanced Materials, 14, 014205. https://doi.org/10.1088/1468-6996/14/1/014205

Kisku, N. (2024). Development of novel

low density ultra-high strength manganese-steel with significant ductility

through thermo-mechanical processing route. Materials Science and

Engineering: A, 901, 146591. https://doi.org/10.1016/j.msea.2024.146591

Kochma?ski, P., Chyli?ska, R., Figiel,

P., Fryska, S., Kochma?ska, A. E., Kwiatkowska, M., Kwiatkowski, K., Niemczyk,

A., S?owik, J., Maziarz, W., Rogal, L., Dybowski, K., & Baranowska, J.

(2024). Influence of chemical composition on structure and mechanical

properties of vacuum-carburized low-alloy steels. Materials, 17(2). https://doi.org/10.3390/ma17020515

Krauss, G. (2015). Steels:

Processing, structure, and performance (2nd ed.). ASM International. https://doi.org/10.31399/asm.tb.spsp2.9781627082655

Krû¥ger, J. T., Hoyer, K.-P., Huang, J.,

Filor, V., Mateus-Vargas, R. H., Oltmanns, H., Meiûner, J., Grundmeier, G.,

& Schaper, M. (2022). FeMn with phases of a degradable Ag alloy for

residue-free and adapted bioresorbability. Journal of Functional

Biomaterials, 13(4). https://doi.org/10.3390/jfb13040185

Kuhn, H., & Medlin, D. (2000). Mechanical

testing and evaluation (Vol. 8). ASM International. https://doi.org/10.31399/asm.hb.v08.9781627081764

Le Godec, Y., & Le Floch, S.

(2023). Recent developments of high-pressure spark plasma sintering: An

overview of current applications, challenges and future directions. Materials,

16(3). https://www.mdpi.com/1996-1944/16/3/997

Lemke, J. N., Fiocchi, J., Biffi, C.

A., Tuissi, A., Copes, F., Paternoster, C., Mantovani, D., & Coda, A.

(2025). Design, development and performance of a FeãMnãSiãCu alloy for

bioabsorbable medical implants. Journal of Materials Chemistry B, 13,

2737ã2752. https://doi.org/10.1039/D4TB01635A

Li, C.-M., Sommer, F., &

Mittemeijer, E. J. (2002). Characteristics of the ? ? ? transformation in FeãMn

alloys. Materials Science and Engineering: A, 325(1), 307ã319. https://doi.org/10.1016/S0921-5093(01)01459-9

Liu, T.-W., & Wu, X.-L. (2024).

Martensitic transformation pathways and crystallographic orientation

relationships in steel. Journal of Materials Science & Technology,

174, 74ã84. https://doi.org/10.1016/j.jmst.2023.06.060

Malamud, F., Guerrero, L., La Roca, P.,

Sade, M., & Baruj, A. (2018). Role of Mn and Cr on structural parameters

and strain energy during FCCãHCP martensitic transformation in FeãMnãCr shape

memory alloys. Materials & Design, 139, 314ã323. https://doi.org/10.1016/j.matdes.2017.11.017

Mani, M. K., Viola, G., Reece, M. J.,

Hall, J. P., & Evans, S. L. (2012). Structural and magnetic

characterization of spark plasma sintered Feã50Co alloys. MRS Online

Proceedings Library, 1516, 201ã207. https://doi.org/10.1557/opl.2012.1669

Milititsky, M., Van Caenegem, N., &

De Cooman, B. C. (2008). Structural and magnetic transformations in the FeãMn

binary system. Steel Research International, 79, 156ã159. https://doi.org/10.1002/srin.200806331

Mola, J., & Ren, M. (2018). On the

hardness of high carbon ferrous martensite. IOP Conference Series: Materials

Science and Engineering, 373, 012004. https://doi.org/10.1088/1757-899X/373/1/012004

Mukhopadhyay, N. K., Ali, F., Scudino,

S., Samadi Khoshkhoo, M., Stoica, M., Srivastava, V. C., Uhlenwinkel, V.,

Vaughan, G., Suryanarayana, C., & Eckert, J. (2014). Inverse

HallãPetch-like mechanical behaviour in nanophase AlãCuãFe quasicrystals: A new

phenomenon. Acta Physica Polonica A, 126, 543ã548. https://doi.org/10.12693/APhysPolA.126.543

Naik, S. N., & Walley, S. M.

(2020). The HallãPetch and inverse HallãPetch relations and the hardness of

nanocrystalline metals. Journal of Materials Science, 55, 2661ã2681. https://doi.org/10.1007/s10853-019-04160-w

Oh, S.-J., Park, D., Kim, K., Shon,

I.-J., & Lee, S.-J. (2018). Austenite stability and mechanical properties

of nanocrystalline FeãMn alloy fabricated by spark plasma sintering with

variable Mn content. Materials Science and Engineering: A, 725, 382ã388.

https://doi.org/10.1016/j.msea.2018.04.051

Oladijo, O., Popoola, A., Ujah, C.,

& Namoshe, M. (2019). Dataset of spark plasma sintering of AlãZnãSn alloy

for soft solder application. Data

in Brief, 24, 103948. https://doi.org/10.1016/j.dib.2019.103948

Paul, B., Kiel, A., Otto, M., Gemming, T., Hoffmann, V., Giebeler, L.,

Kaltschmidt, B., Hû¥ttten, A., Gebert, A., Kaltschmidt, C., & Hufenbach, J.

(2024). Inherent antibacterial properties of biodegradable FeMnC(Cu)

alloys for implant application. ACS Applied Bio Materials, 7, 839ã852. https://doi.org/10.1021/acsabm.3c00835

Qayoom, M., & Dar, G. N. (2020).

Crystallite size and compressive lattice strain in NiFe?O? nanoparticles as

calculated in terms of various models: Influence of annealing temperature. International

Journal of Self-Propagating High-Temperature Synthesis, 29, 213ã219. https://doi.org/10.3103/S1061386220040111

Sabzi, M., & Farzam, M. (2019).

Hadfield manganese austenitic steel: A review of manufacturing processes and

properties. Materials Research Express, 6, 1065c2. https://doi.org/10.1088/2053-1591/ab3ee3

Saliba, L., Sammut, K., Tonna, C.,

Pavli, F., Valdramidis, V., Gatt, R., Giordmaina, R., Camilleri, L., Atanasio,

W., Buhagiar, J., & Schembri Wismayer, P. (2023). FeMn and FeMnAg

biodegradable alloys: An in vitro and in vivo investigation. Heliyon,

9(5), e15671. https://doi.org/10.1016/j.heliyon.2023.e15671

Shongwe, M., Ramakokovhu, M., Diouf,

S., Durowoju, M., Obadele, B., Sule, R., Lethabane, M., & Olubambi, P.

(2016). Effect of starting powder particle size and heating rate on spark

plasma sintering of FeNi alloys. Journal of Alloys and Compounds, 678,

241ã248. https://doi.org/10.1016/j.jallcom.2016.03.270

Siripath, N., Suranuntchai, S., &

Sucharitpwatskul, S. (2024). Modeling dynamic recrystallization kinetics in BS

080M46 medium carbon steel: Experimental verification and finite element

simulation. International Journal of Technology, 15(5), 1292ã1307. https://doi.org/10.14716/ijtech.v15i5.6770

Sun, L., Cheverikin, V., & Golovin,

I. (2019). Mechanical spectroscopy as an in situ tool to study anelasticity of

martensitic transition in Feã16Mnã8Crã2Co alloy. Materials Letters, 256,

126635. https://doi.org/10.1016/j.matlet.2019.126635

Taryana, Y., Wahyu, Y., Manaf, A.,

Manawan, M., & Ariadi, W. (2022). Structural and microwave absorption

properties of BaFe????xSn?Zn?O?? (x = 0.05ã1.0) ceramic magnets. Materialia,

23, 101455. https://doi.org/10.1016/j.mtla.2022.101455

Tokita, M. (2013). Spark plasma

sintering (SPS) method, systems, and applications. In Handbook of advanced

ceramics (pp. 1149ã1177). Elsevier. https://doi.org/10.1016/B978-0-12-385469-8.00060-5

Wang, Y., Wu, C., Liu, Y., Tian, M.,

Lu, X., & Su, X. (2023). Insight into the FCC?HCP transformation in Co-rich

CoãCrãFeãMnãNi high-entropy alloys. Metals, 13(3). https://doi.org/10.3390/met13030504

Wei, F., Cheng, B., Chew, L. T., Lee,

J. J., Cheong, K. H., Wu, J., Zhu, Q., & Tan, C. C. (2022). Grain

distribution characteristics and effect of diverse size distribution on the

HallãPetch relationship for additively manufactured metal alloys. Journal of

Materials Research and Technology, 20, 4130ã4136. https://doi.org/10.1016/j.jmrt.2022.09.006

Xu, Z., Jin, C., Xia, A., Zhang, J.,

& Zhu, G. (2013). Structural and magnetic properties of nanocrystalline

nickel-rich FeãNi alloy powders prepared via hydrazine reduction. Journal of

Magnetism and Magnetic Materials, 336, 14ã19. https://doi.org/10.1016/j.jmmm.2013.02.007

Yan, X., Li, Q., Yin, S., Chen, Z., Jenkins, R., Chen, C., Wang, J., Ma,

W., Bolot, R., Lupoi, R., Ren, Z., Liao, H., & Liu, M. (2019). Mechanical

and in vitro study of an isotropic Ti6Al4V lattice structure fabricated using

selective laser melting. Journal of Alloys and Compounds, 782, 209ã223. https://doi.org/10.1016/j.jallcom.2018.12.220

Yin, F., Cheng, G. J., Xu, R., Zhao,

K., Li, Q., Jian, J., Hu, S., Sun, S., An, L., & Han, Q. (2018).

Ultrastrong nanocrystalline stainless steel and its HallãPetch relationship in

the nanoscale. Scripta Materialia, 155, 26ã31. https://doi.org/10.1016/j.scriptamat.2018.06.014

Zhang, X., Zhao, Q., Liu, C., Peng, Y.,

Huang, Y., Kong, J., & Wang, K. (2024). On the formation of oxide

inclusions in the high nitrogen chromiumãmanganese steel produced by wire and

arc additive manufacturing. Journal of Materials Research and Technology,

33, 3852ã3863. https://doi.org/10.1016/j.jmrt.2024.10.103

Zhang, X., Wang, Q., Kane, J. J., Rufner, J. F., & Sun, C. (2023). Graded microstructure and mechanical properties of spark plasma sintered FeãCr alloys. Journal of Alloys and Compounds, 967, 171448. https://doi.org/10.1016/j.jallcom.2023.171448