Quality System Improvement Using Sustainable Lean Manufacturing and Six Sigma in the Heavy Components Industry

Corresponding email: rinaf@trisakti.ac.id

Published at : 01 Dec 2025

Volume : IJtech

Vol 16, No 6 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i6.7758

| Rina Fitriana | Department of Industrial Engineering, Faculty of Industrial Technology, Universitas Trisakti, Jakarta, 11440, Indonesia |

| Iveline Anne Marie | Doctoral Industrial Engineering Study Program, Faculty of Industrial Technology, Universitas Trisakti, Jakarta, 11440, Indonesia |

| Debbie Kemala Sari | Department of Industrial Engineering, Faculty of Industrial Technology, Universitas Trisakti, Jakarta, 11440, Indonesia |

| Teuku Yuri M. Zagloel | Department of Industrial Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Nadiah Ahmad | Fakulti Teknologi dan Kejuruteraan Industri dan Pembuatan, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia |

| Nur Febrianti Sasmita | Department of Industrial Engineering, Faculty of Industrial Technology, Universitas Trisakti, Jakarta, 11440, Indonesia |

| Segara Dewansyah | Department of Industrial Engineering, Faculty of Industrial Technology, Universitas Trisakti, Jakarta, 11440, Indonesia |

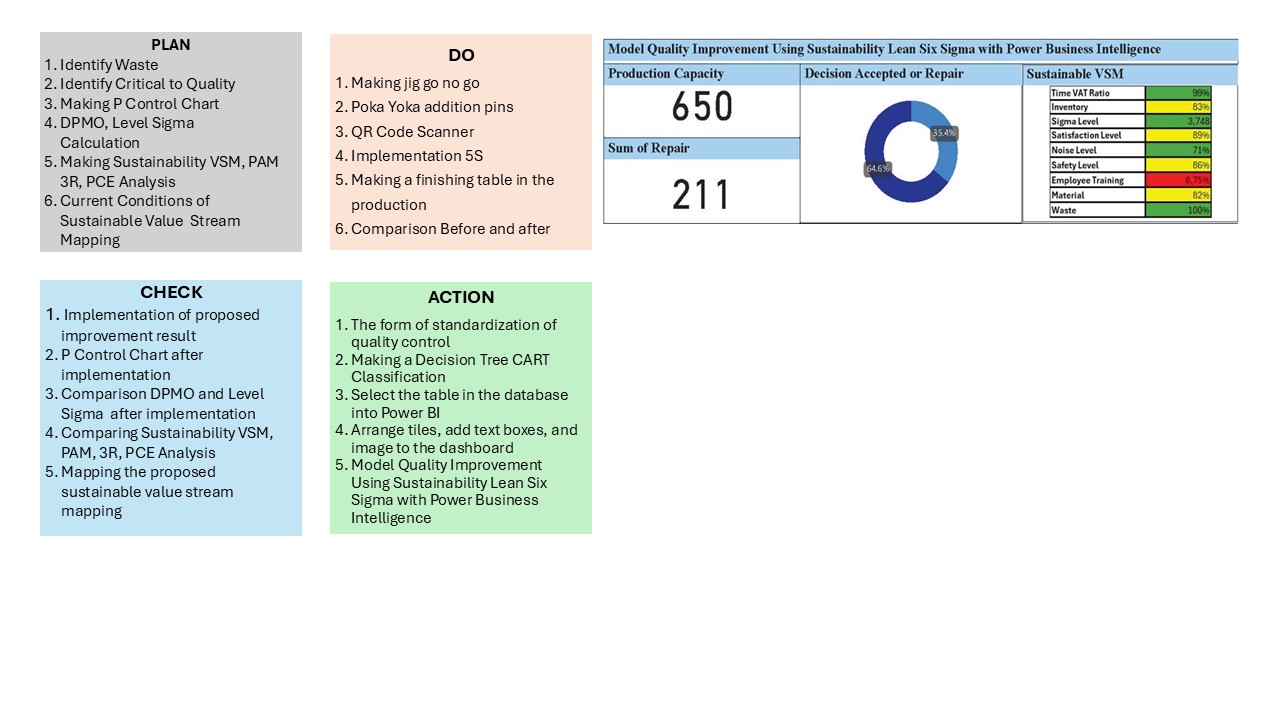

This study applied quality system improvement using sustainable lean manufacturing and the six-sigma approach in the heavy component industry using the plan–do–check–action (PDCA) cycle. This study aimed to constitute the application quality system improvement as the integration of statistical process control, lean manufacturing, Six Sigma, sustainable awareness, and Quality 4.0 in the heavy component manufacturing industry. Improvement strategies were implemented using tools such as Sustainable Value Stream Mapping (SVSM), manufacturing, Process Activity Mapping (PAM), and decision tree CART classification analysis. Key improvements included the implementation of jig redesign, use of QR code scanners, making a finishing table in the production process, regular cleaning of welding tools, and visualization of data with the Power Business Intelligence dashboard. Post-intervention analysis demonstrated an improved sigma level of 3,748 from 3,361. PCE increased from 82.71% to 83.72%. The results of the indicator values. The average sustainability category is in the yellow traffic light condition, namely 61%–90%, which means that this indicator can still be improved to achieve the company’s targets. After implementing this concept, the company can produce more efficient processes. The proposed quality system improvement model significantly enhances process quality and operational sustainability in the heavy component industry.

Lean manufacturing; Quality 4.0; Quality system; Six Sigma; Sustainable

Amrina, U., & Zagloel, T. Y. M.

(2019). The harmonious strategy of lean and green production: Future

opportunities to achieve sustainable productivity and quality. IEEE 6th

International Conference on Industrial Engineering and Applications (ICIEA).

https://doi.org/10.1109/ICIEA47049.2019

Arons, A., Tsevat, R. K., Hotez, E.,

Huang, H., Nott, R., Ahn, H. H., Mehta, N., Nguyen, L., Nguyen, V., Rebollar,

A. G., Duan, S., & Ma, J. (2024). A quality improvement initiative to

improve health care transition planning at adolescent well visits. Academic

Pediatrics, 24(6), 973–981. https://doi.org/10.1016/j.acap.2024.03.013

Bagherian, A., Gershon, M., Kumar, S., & Mishra, M. K. (2024). Analyzing the relationship between digitalization and energy sustainability: A comprehensive ISM-MICMAC and DEMATEL approach. Expert Systems with Applications, 236, 121193. https://doi.org/10.1016/j.eswa.2023.121193

Bao, W. J., Wang, C., Zhang, L. L., &

Yu, H. X. (2024). Impact of combined cluster nursing and Plan-Do-Check-Act

cycle on postoperative infection risk and clinical outcomes in patients with

open fractures and multidrug resistance. Asian Journal of Surgery, 47(10),

4613–4614. https://doi.org/10.1016/j.asjsur.2024.07.287

Benabdellah, A. C., Zekhnini, K.,

Cherrafi, A., & Reyes, J. G. (2024). Driving sustainable innovation:

Exploring lean, green, circular, and smart design. Procedia Computer

Science, 232, 880–889. https://doi.org/10.1016/j.procs.2024.01.088

Budhijanto, B., Bima, P. P., &

Danang, T. H. (2024). Enhancing the quality of cassava starch-based wood

bioadhesive using polyvinyl alcohol. International Journal of Technology, 15(6),

1886–1897. https://doi.org/10.14716/ijtech.v15i6.5789

Delgadillo, R. R., Medini, K., &

Wuest, T. (2022). A DMAIC framework to improve quality and sustainability in

additive manufacturing—A case study. Sustainability, 14(1), 1–18. https://doi.org/10.3390/su14010581

Dey, P. K., Malesios, C., De, D.,

Chowdhury, S., & Abdelaziz, F. B. (2019). The impact of lean management

practices and sustainably oriented innovation on sustainability performance of

small and medium-sized enterprises: Empirical evidence from the UK. British

Journal of Management, 31(1), 141–161. https://doi.org/10.1111/1467-8551.12388

Elnadi, M., Gheith, M. H., Troise, C., Bresciani, S., & Abdallah, Y. O. (2025). Examining the interplay of Industry 4.0, lean, agile, and circular manufacturing practices on sustainability performance. Technovation, 146, 103290. https://doi.org/10.1016/j.technovation.2025.103290

Erdil, N. O., Aktas, C. B., & Arani, O. M. (2018). Embedding

sustainability in lean six sigma efforts. Journal of Cleaner Production, 198,

520–529. https://doi.org/10.1016/j.jclepro.2018.07.048

Fatemi, S., & Franchetti, M. J.

(2016). An application of sustainable lean and green strategy with a Six Sigma

approach on a manufacturing system. International Journal of Six Sigma and

Competitive Advantage, 10(1), e08053. https://doi.org/10.1504/ijssca.2016.080453

Fitriana, R., Saragih, J., & Fauziyah, S. D. (2020). Quality improvement on common rail type-1 product using Six Sigma method and data mining on forging line in PT. ABC. IOP Conference Series: Materials Science and Engineering, 847, 012038. https://doi.org/10.1088/1757-899X/847/1/012038

Fitriana, R., Saragih, J., & Larasati,

D. P. (2020). Production quality improvement of Yamalube bottle with Six Sigma,

FMEA, and data mining in PT. B. IOP Conference Series: Materials Science and

Engineering, 847, 012011. https://doi.org/10.1088/1757-899X/847/1/012011

Fitriana, R., Sari, D. K., & Habyba, A. N. (2021). Pengendalian dan

penjaminan mutu. Wawasan Ilmu.

Garbie, I. (2016). Sustainability in

manufacturing enterprises: Concepts, analyses and assessments for Industry 4.0.

Springer Nature. https://doi.org/10.1007/978-3-319-29306-6

Gholami, H., Jamil, N., Saman, M. Z. M., Streimikiene, D., Sharif, S.,

& Zakuan, N. (2021). The application of green lean Six Sigma. Business

Strategy and the Environment, 30(4), 1913–1931. https://doi.org/10.1002/bse.2724

Ginting, R., Napitupulu, H., Ishak, A., & Supranata. (2025).

Bitewing holder and support product design using quality function deployment. International

Journal of Technology, 16(2), 551–560. https://doi.org/10.14716/ijtech.v15i6.5789

Ginting, R., Silalahi, R., &

Marunduri, M. A. (2025). The conceptual integration of quality function

deployment and value engineering for product development: A case study of water

dispenser. International Journal of Technology, 16(1), 124–135. https://doi.org/10.14716/ijtech.v16i1.6326

Guleria, P., Pathania, A., Bhatti, H.,

Rojhe, K., & Mahto, D. (2021). Leveraging lean Six Sigma: Reducing defects

and rejections in filter manufacturing industry. Materials Today:

Proceedings, 46, 8532–8539. https://doi.org/10.1016/j.matpr.2021.03.535

Hartini, S., Manurung, J., & Rumita,

R. (2021). Sustainable-value stream mapping to improve manufacturing

sustainability performance: Case study in a natural dye batik SME’s. IOP

Conference Series: Materials Science and Engineering, 1072(1), 012066. https://doi.org/10.1088/1757-899X/1072/1/012066

Hussain, K., He, Z., Ahmad, N., Iqbal,

M., & Mumtaz, S. M. T. (2019). Green, lean, Six Sigma barriers at a glance:

A case from the construction sector of Pakistan. Building and Environment,

161, 106225. https://doi.org/10.1016/j.buildenv.2019.106225

Khodeir, L. M., & Othman, R. (2016).

Examining the interaction between lean and sustainability principles in the

management process of AEC industry. Ain Shams Engineering Journal, 9,

1627–1634. https://doi.org/10.1016/j.asej.2016.12.005

Lestari, L., Marie, I. A., & Sari, E.

(2021). Sustainable Lean Six Sigma competitive manufacturing strategy for

luggage manufacturer. Journal of Modern Manufacturing System Technology, 5(2),

22–34. https://doi.org/10.15282/jmmst.v5i2.6849

Lubaba, M., Hosen, M. I., Shakur, M. S.,

& Rahman, M. A. (2025). An intuitionistic fuzzy approach to assessing the

barriers to Quality 4.0 adoption in the footwear manufacturing industry:

Implications for sustainability in emerging economy. Journal of Open

Innovation: Technology, Market, and Complexity, 11(3), 1–19. https://doi.org/10.1016/j.joitmc.2025.100604

Mahdzir, M., Yahaya, S., Fauadi, M.,

& Yeow, T. (2024). Integrating water quality model and aeration with IoT

technology in water quality management: A conceptual framework. Multidisciplinary

Science Journal, 7, 2025139. https://doi.org/10.31893/multiscience.2025139

Marie, I. A., Sari, E., & Lika, C. A.

(2020). Enhancing sustainable maintenance performance using lean competitive

manufacturing strategy: A case study in steel company. Solid State

Technology, 63(6), 943–948. https://doi.org/10.1145/3557738.3557845

Montella, E., Di Cicco, M. V., Ferraro,

A., Centobelli, P., Raiola, E., Triassi, M., & Improta, G. (2016). The

application of Lean Six Sigma methodology to reduce the risk of

healthcare-associated infections in surgery departments. Journal of

Evaluation in Clinical Practice, 23(4), 530–539. https://doi.org/10.1111/jep.12662

Montgomery, D. C. (2013). Statistical

quality control (7th ed.). John Wiley & Sons.

Rahardjo, B., Wang, F. K., Lo, S. C.,

& Chu, T. H. (2023). A sustainable innovation framework based on Lean Six

Sigma and Industry 5.0. Arabian Journal for Science and Engineering, 49,

7625–7642. https://doi.org/10.1007/s13369-023-08565-3

Ramadhani, R. A., Fitriana, R., &

Habyba, A. N. (2023). Enhancing quality control of packaging product: A Six

Sigma and data mining approach. Jurnal Optimasi Sistem Industri, 22(2),

197–214. https://doi.org/10.25077/josi.v22.n2.p197-214.2023

Rathi, R., Kaswan, M. S., Garza-Reyes, J.

A., Antony, J., & Cross, J. (2022). Green Lean Six Sigma for improving

manufacturing sustainability: Framework development and validation. Journal

of Cleaner Production, 345, 131130. https://doi.org/10.1016/j.jclepro.2022.131130

Reddy, A., Nagpal, D., & Saxena, S.

(2024). A Six Sigma approach to pharmaceutical industry: A better insight. Oriental

Journal of Chemistry, 40, 1415–1425. https://doi.org/10.13005/ojc/400525

Ruben, R. B., Vinodh, S., & Asokan,

P. (2017a). Implementation of Lean Six Sigma framework with environmental

considerations in an Indian automotive component manufacturing firm: A case

study. Production Planning & Control, 28(9), 1193–1211. https://doi.org/10.1080/09537287.2017.1357215

Ruben, R. B., Vinodh, S., & Asokan,

P. (2017b). Lean Six Sigma with environmental focus: Review and framework. International

Journal of Advanced Manufacturing Technology, 94, 4023–4037. https://doi.org/10.1007/s00170-017-1148-6

Sari, E., Ma’aram, A., Shaharoun, A. M.,

Chofreh, A. G., Goni, F. A., Klemeš, J. J., Marie, I. A., & Saraswati, D.

(2021). Measuring sustainable cleaner maintenance hierarchical contributions of

the car manufacturing industry. Journal of Cleaner Production, 312,

127717. https://doi.org/10.1016/j.jclepro.2021.127717

Sucipto, B. A., Syahputri, A. R.,

Mulyarto, A. R., & Tolle, H. (2025). Building transparency through halal

and quality traceability system for beef distribution in Malang City,

Indonesia. International Journal of Technology, 16(4), 1253–1264. https://doi.org/10.14716/ijtech.v16i4.5984

Tamher, S. D., Rachmawaty, R., &

Erika, K. A. (2021). The effectiveness of Plan–Do–Check–Act (PDCA) method

implementation in improving nursing care quality: A systematic review. Enfermería

Clínica, 31(5), S627–S631. https://doi.org/10.1016/j.enfcli.2021.07.006

Zhang, M., Zhao, S., & Xu, G. (2024). Plan–Do–Check–Act was applied to improve the first success rate of radial artery catheterization in anesthesiology residents. Asian Journal of Surgery, 48(2), 1380–1381. https://doi.org/10.1016/j.asjsur.2024.08.173