Impact of Size Reduction, Drying Temperature, and Drying Time on Overripe Tempe Powder Quality Parameters

Corresponding email: maria.gunawanputeri@sgu.ac.id

Published at : 01 Dec 2025

Volume : IJtech

Vol 16, No 6 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i6.7684

Fortunata, S., Wijaya, C., Suyatma, N., & Puteri, M. (2025). Impact of size reduction, drying temperature, and drying time on overripe tempe powder quality parameters. International Journal of Technology, 16 (6), 2084–2100.

| Stacia Andani Fortunata | 1. Department of Food Science and Technology, Faculty of Agricultural Engineering and Technology, IPB University, Bogor, Jl. Raya Dramaga, 16680, Indonesia 2. Department of Food Technology, Faculty o |

| Christofora Hanny Wijaya | Department of Food Science and Technology, Faculty of Agricultural Engineering and Technology, IPB University, Bogor, Jl. Raya Dramaga, 16680, Indonesia |

| Nugraha Edhi Suyatma | Department of Food Science and Technology, Faculty of Agricultural Engineering and Technology, IPB University, Bogor, Jl. Raya Dramaga, 16680, Indonesia |

| Maria Dewi Puspitasari Tirtaningtyas Gunawan Puteri | Department of Food Technology, Faculty of Life Sciences and Technology, Swiss German University, Tangerang, Jl. Jalur Sutera Barat, 15143, Indonesia |

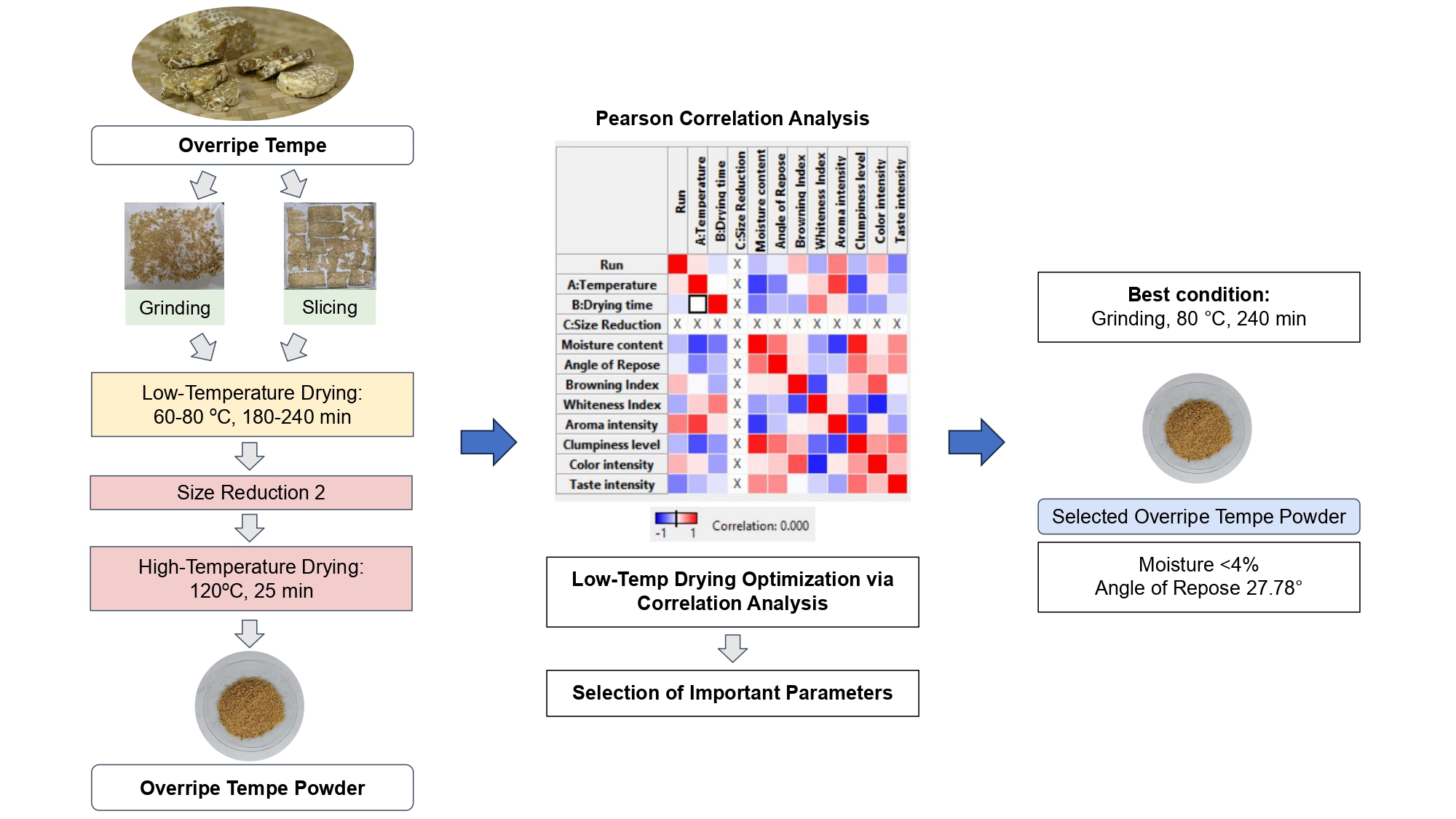

Tempe is a popular Indonesian plant-based protein source. Overripe tempe, an extended fermentation period of fresh tempe, has been explored as a flavor enhancer in various Indonesian cuisines. This study aimed to determine the optimal processing conditions for overripe tempe powder using RSM and central composite design in Design Expert 13.0®. Drying temperature (60°C - 80°C) and time (180 - 240 min) were tested as numerical factors, while sample shape (slices or pellets) was a categorical factor, resulting in 20 randomized experiments. The quality parameters of the produced powder—moisture content, angle of repose, browning index, whiteness index, and sensory attributes (clumpiness, color, aroma, and taste intensity)—were used to develop model equations. Correlation analysis of the models showed that drying temperature and time significantly influenced moisture content, clumpiness, and aroma intensity. Optimization of the response models identified grinding and drying at 80°C for 240 min as the best conditions. Validation confirmed that the resulting powder met the regulated moisture content standard and offered benefits such as shorter drying time and improved flowability compared to previous methods.

Drying; Overripe tempe powder; Powder quality; Response surface methodology; Size reduction

Akhtaruzzaman, M., Mondal, M. H. T.,

Sarker, M. S. H., Biswas, M., Shanta, S. A. A., & Sheikh, M. A. M. (2022).

Evaluation of drying characteristics, energy consumption and quality of

parboiled paddy: Two stage drying. Journal of Agriculture and Food Research,

8, 100284. https://doi.org/10.1016/j.jafr.2022.100284

Andriani, M., Baskoro, K., & Nurhartadi, E. (2014). Studies on

physicochemical and sensory characteristics of overripe tempeh flour as food

seasoning. Academic Research International, 5(5), 36–45.

AOAC. (2005). Official methods of

analysis. Association of Official Analytical Collaboration International.

Arifan, F., Dewi, A. L., Yudanto, Y.

A., Sapatra, E. F., Broto, R. T. D. W., Sutaryo, & Sumardiono, S. (2022).

Effect of thermal pretreatment of pineapple peel waste in biogas production

using response surface methodology. International Journal of Technology, 13(3),

619–632. https://doi.org/10.14716/ijtech.v13i3.4747

ASTM. (2005). Standard test method

for measuring the angle of repose of free-flowing mold powders ASTM C1444-00.

American Society for Testing and Materials.

Bourdoux, S., Li, D., Rajkovic, A.,

Devlieghere, F., & Uyttendaele, M. (2016). Performance of drying

technologies to ensure microbial safety of dried fruits and vegetables. Comprehensive

Reviews in Food Science and Food Safety, 15, 1056–1066. https://doi.org/10.1111/1541-4337.12224

BSN. (1996a). SNI 01-4273-1996:

Bumbu rasa sapi (Beef flavored seasoning). https://akses-sni.bsn.go.id/viewsni/baca/8568

BSN. (1996b). SNI 01-4281-1996:

Bumbu rasa ayam (Chicken flavored seasoning). https://akses-sni.bsn.go.id/viewsni/baca/1741

Ergüne?, G., & Tarhan, S. (2006).

Color retention of red peppers by chemical pretreatments during greenhouse and

open sun drying. Journal of Food Engineering, 76(3), 446–452. https://doi.org/10.1016/j.jfoodeng.2005.05.046

Errat, F. N. (2022). Upscaling

evaluation of dried overripe tempe for the production process plant-based

instant stock (Master’s thesis). Swiss German University, Tangerang.

Esraa, A., Putra, A., Mosa, A., Dan, R.

M., & Attia, O. H. (2022). An empirical model for optimizing the sound

absorption of single layer MPP based on response surface methodology. International

Journal of Technology, 13(3), 496–507. https://doi.org/10.14716/ijtech.v13i3.5507

Gunawan Puteri, M. D. P. T., Fortunata,

S. A., Prabawati, E. K., Kristianti, F., & Wijaya, C. H. (2018). Overripe

tempe as source of protein in development of ready-to-eat porridge. International

Food Research Journal, 25. https://api.semanticscholar.org/CorpusID:209954522

Gunawan-Puteri, M. D. P. T., Christli,

L., Prabawati, E. K., & Marpaung, A. M. (2018). Development of rice

porridge with overripe tempeh extract for infants. In R. Nur et al. (Eds.), Advances

in Engineering Research (pp. 188–193). https://doi.org/10.2991/fanres-18.2018.39

Gunawan-Puteri, M. D. P. T., Hassanein, T. R., Prabawati, E. K., Wijaya, C.

H., & Mutukumira, A. N. (2015). Sensory characteristics of seasoning

powders from overripe tempeh. Procedia Chemistry, 14, 263–269. https://doi.org/10.1016/j.proche.2015.03.037

Gunawan-Puteri, M. D. P. T., Samuel,

K., Felicya, Kartawiria, I. S., & Wijaya, C. H. (2017). Potential

application of overripe tempe dried powder as plant-based instant stock. Proceeding

International Postgraduate Symposium on Food, Agriculture, and Biotechnology

(IPSFAB) 2017, 34–44. https://doi.org/10.14457/MSU.res.2017.20

Harefa, A. P. P. (2020). Pengembangan

nugget berbahan tempe busuk untuk remaja (Master’s thesis). IPB University,

Bogor.

Hassanein, T. R., Prabawati, E. K.,

& Gunawan-Puteri, M. D. P. T. (2015). Analysis of chemical and microbial

changes during storage of overripe tempeh powder as seasoning material. International

Journal of Science and Engineering, 8(2), 131–134.

Herawati, H., Kamsiati, E., Afifah, D.

N., Kusumaningtyas, E., Bachtiar, M., Sunarmani, & Agustinisari, I. (2023).

Characteristics of GABA, antioxidant, and sensory quality of modified tempeh. International

Journal of Food Properties, 26(2), 3532–3543. https://doi.org/10.1080/10942912.2023.2290440

Herawati, H., Kamsiati, E., &

Sunarmani. (2021). Formulation of food ingredients to characteristics of

gluten-free noodles. International Journal of Technology, 12(3),

602–612. https://doi.org/10.14716/ijtech.v12i3.4139

Ismail, S. N. A. S., Ishak, M. A. M.,

Ahmad, R., & Ismail, K. (2025). Impact of optimized molar ratio,

temperature and time on organic sulfur transformation and thermophysical

properties of high-sulfur coal. International Journal of Technology, 16(2),

395–410. https://doi.org/10.14716/ijtech.v16i2.7257

Koç, B., Koç, M., & Baysan, U.

(2021). Food powders bulk properties. In E. Ermi? (Ed.), Food Powders:

Properties and Characterization (p. 17). Springer. https://doi.org/10.1007/978-3-030-48908-3

Kustyawati, M. E., Subeki, Murhadi,

Rizal, S., & Astuti, P. (2020). Vitamin B12 production in soybean

fermentation for tempeh. AIMS Agriculture and Food, 5(2), 262–271. https://doi.org/10.3934/agrfood.2020.2.262

Kusumawaty, N., Sulaeman, A.,

Marliyati, S. A., & Laily, N. (2020). Cookies from tempeh semangit as

supplemental food for pregnant women. In Proceedings of the 1st IPB

International Conference on Nutrition and Food 2020 (pp. 107–108).

Kusumawaty, N., Sulaeman, A., Marliyati, S. A., Laily, N., & Fitriyah,

H. (2023). The effect of semangit tempeh cookies on MUAC, Hb, and serum

ferritin. Jurnal Gizi Pangan, 18, 108–110. https://doi.org/10.25182/jgp.2023.18.Supp.1.108-110

Metty, Inayah, Widiany, F. L., &

Shayida, H. (2022). Analisis

kesukaan tepung tempe semangit... Prosiding Seminar Nasional Universitas

Respati Yogyakarta, 49–53.

Mulyana, Susanto, W. H., & Purwantiningrum, I. (2014). Pengaruh

proporsi tepung tempe semangit terhadap karakteristik kerupuk. Jurnal

Pangan dan Agroindustri, 2(4), 113–120.

Namsanguan, Y., Tia, W., Devahastin,

S., & Soponronnarit, S. (2004). Drying kinetics of shrimp undergoing

two-stage drying. Drying Technology, 22(4), 759–778. https://doi.org/10.1081/DRT-120034261

Nuraini, V., Puyanda, I., Kunciati, W.,

& Margareta, L. (2022). Perubahan

kimia dan mikrobiologi tempe busuk selama fermentasi. Jurnal

Agroteknologi, 15, 127–137. https://doi.org/10.19184/j-agt.v15i02.25729

Ostermeier, R., Parniakov, O., Töpfl,

S., & Jäger, H. (2020). Applicability of pulsed electric field

pre-treatment for a convective two-step drying process. Foods, 9(4). https://doi.org/10.3390/foods9040512

Pamungkas, S. (2022). Hubungan

penggunaan bumbu instan terhadap kepuasan konsumen di Kota Semarang

(Undergraduate thesis). Universitas Katolik Soegijapranata.

Paul, A., & Martynenko, A. (2022).

Effect of material thickness and humidity on EHD-dried apples. Foods, 11(18).

https://doi.org/10.3390/foods11182765

Rawat, S. (2015). Food spoilage:

Microorganisms and their prevention. Asian Journal of Plant Science &

Research, 5. https://api.semanticscholar.org/CorpusID:7269230

Rifna, E. J., & Dwivedi, M. (2021).

The microbiological safety of food powders. In E. Ermi? (Ed.), Food Powders:

Properties and Characterization (pp. 169–193). Springer. https://doi.org/10.1007/978-3-030-48908-3

Shofinita, D., Bindar, Y., Samadhi, T.

W., Jaelawijaya, A., Achmadi, A. B., & Theodric, D. (2024). Effect of

extraction and spray drying temperatures on bioactive compounds in red dragon

fruit skin. International Journal of Technology, 15(5), 1282–1291. https://doi.org/10.14716/ijtech.v15i5.6040

Shurtleff, W., & Aoyagi, A. (2022).

History of tempeh and tempeh products (1815–2000). Soyinfo Center.

Skowron, K., Budzy?ska, A.,

Grudlewska-Buda, K., Wiktorczyk-Kapischke, N., Andrzejewska, M.,

Wa?ecka-Zacharska, E., & Gospodarek-Komkowska, E. (2022). Two faces of

fermented foods. Frontiers in Microbiology, 13. https://doi.org/10.3389/fmicb.2022.845166

Torbica, A., Hadnaev, M., &

Dap?evi? Hadnaev, T. (2012). Rice and buckwheat flours related to cookie

quality. Food Research International, 48(1), 277–283. https://doi.org/10.1016/j.foodres.2012.05.001

US Food and Drug Administration

(USFDA). (2023). Food code 2022 [Viewed 11 Nov 2024].

Utami, R., Wijaya, C. H., & Lioe,

H. N. (2016). Taste of water-soluble extracts from over-fermented tempe. International

Journal of Food Properties, 19(9), 2063–2073. https://doi.org/10.1080/10942912.2015.1104509

Verevka, T., & Gao, Y. (2025).

Market valuation of high-tech companies in IT and automotive industries. International

Journal of Technology, 16(2), 585–601. https://doi.org/10.14716/ijtech.v16i2.7418

Yando, A., & Paramita, V. (2018). Studi pengaruh suhu dan ketebalan irisan terhadap karakteristik ubi kayu dan ubi jalar. METANA, 13(1), 23–29.