Behavior of Double Skin Composite Shear Wall with Different Faceplate Configuration towards Cyclic Loading

Corresponding email: madamu@psu.edu.sa

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.7324

Joseph, A., Dhruvan, A., Anandh, K., Adamu, M., Ibrahim, Y.E, 2024. Behavior of Double Skin Composite Shear Wall with Different Faceplate Configuration towards Cyclic Loading. International Journal of Technology. Volume 15(6), pp. 1632-1643

| Asha Joseph | Department of Civil Engineering, Federal Institute of Science and Technology, Angamaly, 683577, Kerala, India |

| Aiswarya Dhruvan | Department of Civil Engineering, Federal Institute of Science and Technology, Angamaly, 683577, Kerala, India |

| K.S Anandh | Department of Civil Engineering, Faculty of Engineering and Technology, SRM Institute of Science and Technology, Kattankulathur 603203, Tamil Nadu, India |

| Musa Adamu | 1. Engineering Management Department, College of Engineering, Prince Sultan University, 11586, Riyadh, Saudi Arabia 2. Structures and Materials Research Laboratory, College of Engineering, Prince Sul |

| Yasser E. Ibrahim | 1. Engineering Management Department, College of Engineering, Prince Sultan University, 11586, Riyadh, Saudi Arabia 2. Structures and Materials Research Laboratory, College of Engineering, Prince Sul |

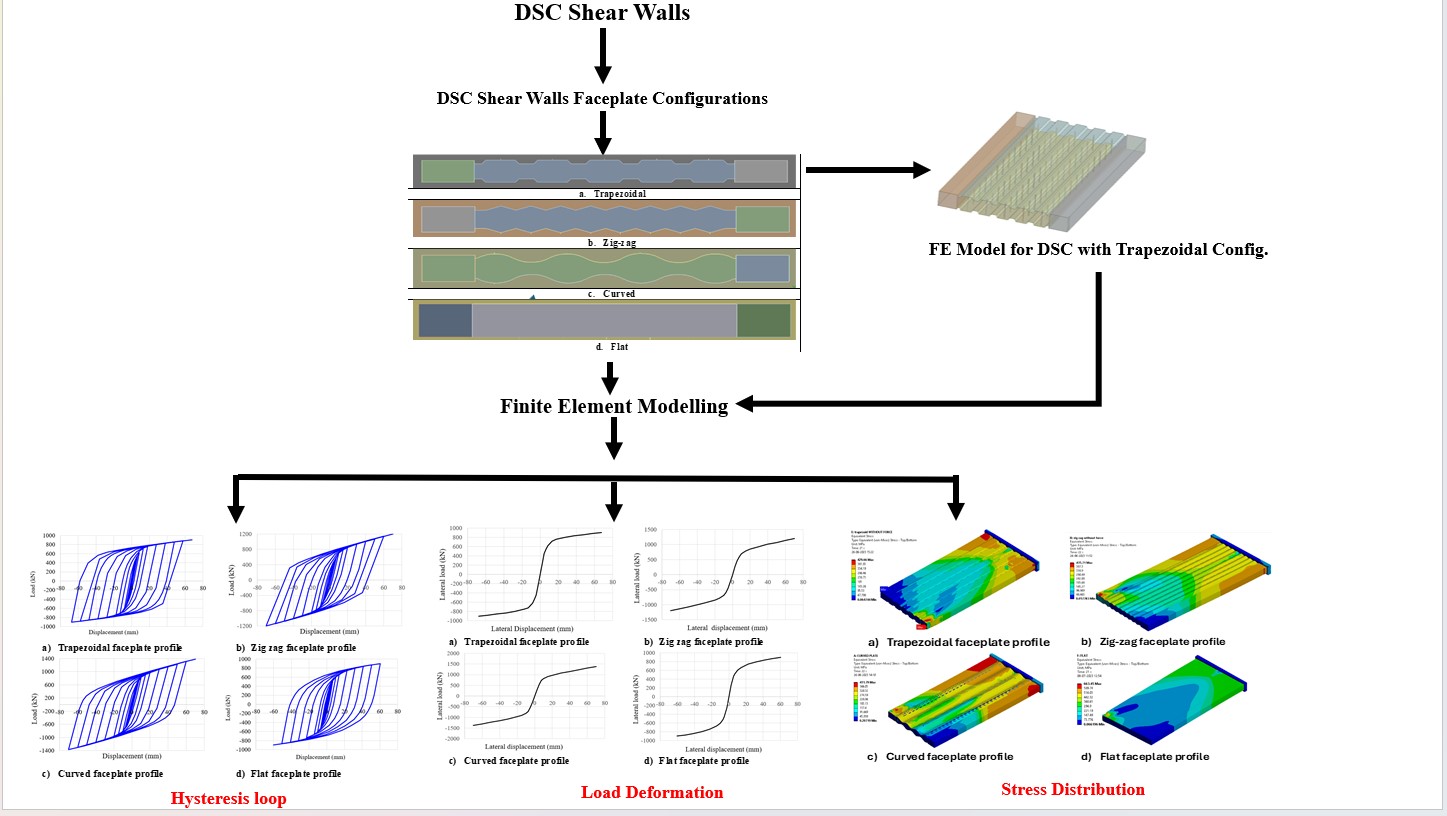

Double skin composite (DSC) shear wall is composed of two exterior steel faceplate connected to each other by connectors and infilled with concrete. In terms of axial and lateral strengths, stiffness, ductility, and energy dissipation capacity, DSC wall performs better than standard Reinforced Concrete (RC). There are two patterns DSC faceplate of DSC, namely flat and corrugated which offers significantly higher out-of-plane bending stiffness. Therefore, this study aimed to explore the effect of faceplate configuration on cyclic behavior of DSC shear wall. Comparison was made regarding the patterns of faceplate including trapezoidal, zig-zag, and curved profiles with flat. This was followed by finite element analysis with ANSYS software to investigate the response of DSC towards cyclic loading. The results showed that among the four profiles, trapezoidal profiles had better energy dissipation and ductility ratio. Trapezoidal pattern offered several advantages in the manufacturing field, including better contact between concrete and good aesthetic appearance. Energy dissipation of DSC wall with trapezoidal faceplate was found to be 37.57%, 23%, and 42.66% more than zigzag, curve, and flat, respectively. There was a reduction in stress by providing corrugated profiles, where the maximum of 54.3% was induced in DSC wall with flat faceplate compared to trapezoidal. This showed that optimizing faceplate configuration further increased the benefits of DSC wall, offering a robust option for seismic design.

Cyclic loading; Energy dissipation; Double skin composite wall; Finite element analysis; Faceplate configuration

Shear wall is often used in structures to resist lateral loads such as wind and earthquake (Annamdasu et al., 2024; Mustafa et al., 2023; Titiksh and Bhatt 2017). In lower stories of tall buildings, reinforced concrete (RC) are subjected to large axial forces that can be resisted by increasing RC thickness. However, increasing thickness consumes usable floor space, leading to higher self-weight of the building (Zhao, Li, and Tian, 2020; Alarcon, Hube, and De la Llera, 2014; Pecce et al., 2014). This challenge can be addressed by developing double skin composite (DSC) for structures exposed to significant lateral forces, such as earthquakes and wind. The composite design combining steel faceplate with a concrete core enhances structural strength, stability, and load distribution, causing greater resilience against buckling and deformation. Absorbs seismic forces are also absorbed, causing improved energy dissipation by minimizing damage and enhancing safety. This wall reduced thickness, leading to lighter structural weight, material savings, and increased usable space. Additionally, steel plates in DSC wall provide extra ductility that allows larger deformations without sudden failure, serving as ideal option for seismic regions.

Because of insulating concrete core, DSC shear wall

offers superior fire resistance capable of protecting the

steel from high temperatures. Based on corrosion resistance, DSC walls

are more durable, protecting the

steel from environmental exposure. Prefabrication further simplifies

construction, allowing faster and more controlled installation processes. It also offers a

robust, efficient, and durable solution combining the

benefits of steel and concrete to improve structural

performance and longevity ( Qiao et al., 2024; Senthilkumar, Karunakaran,

and Chandru, 2023; Yang, Liu, and Fan, 2016). However, the complex

design of DSC wall requires specialized analysis, expertise

needs, and high costs. This is due to the

use of steel faceplate, precision

requirements, and the weight demands of strong foundations. In seismic areas,

DSC wall adds design complexity to meet standards, balancing their benefits

with practical constraints (Senthilkumar, Karunakaran and Chandru, 2023; Yan,

Li, and Wang, 2018). DSC wall is

composed of two exterior steel faceplates joined through connectors and filled

with concrete. External faceplate acts as the main reinforcement for the

concrete infill, enabling resistance in-plane shear and

out-of-plane moment. It also acts as in-situ

formwork to prevent spalling of concrete (Gharaei-Moghaddam, Meghdadian and Ghalehnovi, 2023; Ghodratian-Kashan

and Maleki, 2021; Huang et al., 2018; Varma et al., 2014).

In this context, Hitachi Ltd. had proposed DSC wall for

coastal structures to withstand impact stresses induced by icebergs or waves Zhao et al.,

(2020). This was followed by the development of DSC wall for use in

nuclear safety-related facilities and infrastructures. During the

development, different kinds of connectors were used, including headed

studs (McKinley and Boswell 2002; Shanmugam, Kumar, and Thevendran, 2002),

bi-Steel connectors (McKinley and Boswell 2002; Clubley, Moy, and Xiao,

2003), and

J-hook connectors (Huang and Liew, 2016; Liew and Sohel, 2009). Studies have

also been carried out using concrete-filled steel tubes (CFTs) as the

boundary elements and faceplate connected by tie bolts, as lateral

load-resisting system (Zhao, Li, and Tian, 2020; Ji et al., 2017; Rassouli

et al., 2016).

Steel faceplate serves as a

formwork for casting concrete to increase the efficiency of construction (Zhao, Li, and Tian, 2020; Yan, Wang, and Wang, 2018; Bruhl

and Varma, 2017). Due to

the demand for high lateral strength by

high-rise buildings, the use of DSC wall is being promoted (Ji et

al., 2017; Ma, Ma, and Liu, 2019) to

withstand axial load ratio of approximately 0.7 without significant

reduction in ductility (Liu et al., 2024; Zhao et al., 2020). Ductility

and energy dissipation capacity of RC shear wall are

mostly affected by the axial force ratio and reinforcement ratio of wall (Zhang et

al., 2020).

According to (Bhardwaj

and Varma, 2016), DSC wall

consisted of flat faceplate which had tendency to develop

deficiencies when transporting and assembling due to the

pressure exerted by pouring concrete (Bhardwaj

and Varma, 2016). For DSC

wall with thin faceplate, there is significant reduction in

capacity (Yang et

al., 2023; Yan, Li, and Wang, 2018). Flat

faceplate is classified as slender or non-slender according to the

width-to-thickness ratio (AISC 2010). Non-slender DSC wall

may not have a substantial decrease in performance due to the

out-of-plane deformations and defects. In comparison, slender

faceplate offers a significant reduction in capacity (Zhang et al., 2019; Bhardwaj and Varma, 2016). A

recent study reported that bond slip between flat steel plate

and concrete of DSC wall easily occurred (Senthilkumar, Karunakaran and Chandru, 2023;

Wang et al., 2019b). Corrugated

plate also has significantly superior out-of-plane flexural

stiffness and better buckling resistance than flat plates (Alatoum and Musmar, 2022; Wang et al., 2019a; Qiu

et al., 2018; Zhao et al., 2017).

Deformation and energy dissipation capacity can be enhanced by providing the

boundary columns to DSC wall, thereby improving resistance to

seismic loads (Miao et al., 2022; Qian, Jiang, and Ji, 2012).

Based on the description, this study aimed to examine the impact of faceplate profile on cyclic behavior of DSC shear wall. The performance of trapezoidal, zig-zag, and curved profiles were compared with flat DSC shear wall. Cyclic behavior was evaluated in terms of energy dissipation, hysteretic response, deformation, ductility, damage, and failure patterns. The numerical investigation was performed using finite element software ANSYSProvide an adequate background, context of the problems based on the literature review. Subsequently, the study objectives were stated, and originality was emphasized (state of the art).

2.1. Numerical Study

Finite Element (FE) Analysis is an efficient method for

analyzing the mechanical behavior of complex structures to show

important insights into performance under diverse loading conditions (Hamza et al., 2023; Kholil et al., 2023). This

method uses ANSYS to execute the numerical study. FE model comprised the

steel faceplate, shear studs, concrete wall, and concrete-filled steel tube.

The concrete was used as the infill between the steel faceplate and

tubes. The infilled concrete was of compressive

strength 29.2GPa and Poisson’s ratio 0.15.

2.1.1. Finite element modeling

DSC wall having corrugated faceplate with

three different profiles such as trapezoidal, zigzag, and curved were considered

for analysis, and a comparison was made with flat

faceplate. The thickness of faceplate and wall were fixed for flexural

rigidity of 1.28 x 1014 N/mm2 to be the same for

all the four models considered. A bilinear kinematic hardening property with 1%

strain hardening was adopted. Shear connectors were used to

connect the steel faceplate to the infill concrete. Plates were joined using an

equal number of 8 mm diameter high-strength bolts for all models. For

trapezoidal plate profile, studs were provided at a spacing

of 140 mm in horizontal and 150 mm in vertical directions,

respectively.

Concrete-filled

steel (CFS) tubes were provided on the two boundaries to resist

the induced bending moment. The columns functioned as

anchors for the steel plate’s tension field and bearing

supports for the compression diagonals in the concrete wall. The steel tubes were 150 mm

x100 mm in size with 4 mm thickness and were placed at

both ends of the shear wall. The material properties of steel faceplate, shear

studs, and CFS are shown in Table 1.

Table 1 Mechanical Properties of Steel faceplate,

CFS tube, and Bolt (Luo et

al., 2021)

|

|

Yield strength (MPa) |

Ultimate Strength (MPa) |

|

Steel plate |

307 |

445 |

|

CFS tube |

328 |

386 |

|

Bolt |

640 |

800 |

The

geometric properties of CFS wall with different faceplate profiles are shown in Table 2. Figure 1 shows the

cross-section of the models developed in ANSYS software and Figure 2 represents

FE model of DSC wall with trapezoidal faceplate.

Table 2 Geometrical properties of DSC wall with different faceplate profile

|

Description |

Faceplate profile | |||

|

Trapezoidal |

Zig zag |

Curved |

Flat | |

|

Wall Width (mm) |

1000 |

1000 |

1000 |

1000 |

|

Web Width (mm) |

700 |

700 |

700 |

700 |

|

Wall thickness (mm) |

100 |

80 |

85 |

80 |

|

Height (mm) |

2000 |

2000 |

2000 |

2000 |

|

Faceplate thickness (mm) |

3 |

4 |

4 |

4 |

Figure 1 Cross

sections of DSC shear wall

Figure 2 FE model of

DSC wall with trapezoidal faceplate

The concrete is modeled using Solid 186

element available in ANSYS element library. Solid 186 is a 3D 20-node element

with 3 degrees of freedom (translation in x, y, and z directions). Faceplate is

modeled using shell 181element, which is a 3D 4-node element with 6 DOF (translations

in x,y,z direction and rotations about x,y,z direction). Beam 188, 3D 2-node

element with 6 DOF is used for the modeling of shear studs.

2.1.2. Loading and Boundary

Conditions

Cyclic

loading in the horizontal direction in Figure 3 is applied at the top of wall.

The drift ratio and the corresponding displacement value for the model of 2000

mm height are shown in Table 3. Fixed support is

provided at the base of the foundation with all degrees of freedom restricted.

Table 3 Displacement corresponding to the drift ratio

|

Drift Ratio (%) |

0.13 |

0.25 |

0.38 |

0.50 |

0.75 |

1.0 |

1.5 |

2.0 |

2.5 |

3.0 |

3.5 |

|

Displacement (mm) |

2.6 |

5 |

7.6 |

10 |

15 |

20 |

30 |

40 |

50 |

60 |

70 |

Figure 3 Cyclic

loading protocol

2.2. Validation of Models

In this study, the numerical investigation carried out by Zhao, Li, and Tian (2020) was used for the

verification of FE model of DSC wall with trapezoidal faceplate profile, as shown in

Figure 2. The geometric details of the model are given in Table 2. DSC wall

with trapezoidal profile was analyzed and energy dissipation was found to

be 1.21x107 J. For the drift ratio of 1.5% and the corresponding

displacement of 30 mm, the load value obtained in the present study was 640 kN.

Meanwhile, through the numerical analysis conducted by Zhao, Li, and Tian (2020), the

maximum load was 624kN. The load-displacement curve was plotted, as

shown in Figure 4.

Behavior of composite shear

wall with different faceplate configurations was evaluated under

displacement-controlled cyclic load. The examination was carried

out regarding the response parameters such as

energy dissipation, maximum stress, total deformation, yield load, ultimate

load, yield displacement, ultimate displacement, and ductility ratio. Energy

dissipation was obtained from the hysteresis loop given in Figure 5 for DSC wall of

different profiles.

Figure 5 Hysteresis

loop of DSC wall

Load-deflection curve in

Figure 6 was used to compute energy

dissipations, with the results

shown in Table 4. Energy

dissipation was found to be the maximum of 1.65x107 J for DSC wall with

trapezoidal faceplate profile. Meanwhile, zig

zag, curved, and flat profiles had 1.03x107J, 1.27 x107J, and 9.45 x106J, respectively. Energy dissipation of

trapezoidal faceplate was 37.57%, 23%, and

42.66% more than zig-zag, curved, and flat faceplate

profiles, respectively.

The maximum stress in

faceplate was 429.66 MPa, 435.71 MPa,

411.79MPa and 663.45 MPa for DSC wall with trapezoidal, zig zag, curved, and flat faceplate profiles, respectively, as shown in Figure 7. By

providing corrugated profiles for faceplate, the stresses induced can be considerably reduced. The maximum stress developed in

the steel tubes of boundary elements of DSC wall with trapezoidal, zig zag,

curved, and flat faceplate profiles

were 402.34 MPa, 388.48 MPa,

365.32MPa, and 346.58 MPa, respectively. The

stress distribution along faceplate and steel tube was found to be more uniform in DSC wall with trapezoidal profile.

Figure 6 Load

deformation plot of DSC wall

Table 4 Response

of the specimens to cyclic loading

|

|

Trapezoidal |

Zig-zag |

Curved |

Flat |

|

Yield load (N) |

6.21 x 105 |

6.89 x105 |

8.14 x105 |

6.06 x 105 |

|

Yield displacement (mm) |

8.44 |

10 |

9.97 |

10.3 |

|

Ultimate load (N) |

9.04 x 105 |

1.2 x 106 |

1.38 x 106 |

8.96 x105 |

|

Ultimate displacement (mm) |

67.58 |

70 |

69.9 |

60.35 |

|

Ductility ratio |

8 |

7 |

7 |

5.83 |

Figure 7 Stress

distribution of DSC wall (cont.)

Figure 7 Stress

distribution of DSC wall

The

results showed that trapezoidal provided additional points of plastic deformation, allowing the formation of multiple hinges to absorb and dissipate more energy

(Ma, Chai, and Chen, 2022). In composite shear wall, plastic deformation significantly contributed to energy dissipation capacity.

Compared to curved or zig-zag, trapezoidal profiles showed a higher out-of-plane stiffness,

which prevented unwanted

deformations and enhanced energy dissipation capacity. Although trapezoidal profiles showed good energy dissipation, their

response to seismic forces varied based on load patterns and cyclic loading. Trapezoidal shape could lead to uneven stress

distribution along the profile, potentially creating stress concentration

points capable of reducing the structure’s efficiency or causing premature failure. Furthermore,

trapezoidal profiles are more complex to manufacture than flat or curved,

requiring precise formation processes and specialized equipment to

create trapezoidal folds leading to higher production costs.

In

conclusion, this study analyzed cyclic

behavior of DSC shear wall using ANSYS software based on trapezoidal, zigzag, curved, and flat faceplate profiles. To identify

the best configuration, cyclic analysis was performed by examining energy dissipation, load-carrying

capacity, and ductility parameters. The results showed that DSC shear wall with corrugated faceplate under horizontal cyclic loading performed

better than flat type. Among the four profiles,

trapezoidal faceplate showed superior

energy dissipation and ductility, indicating

37.57%, 23%, and 42.66% higher energy dissipation than the zigzag, curved, and

flat profiles, respectively. Furthermore, trapezoidal faceplate showed a higher ductility ratio, providing greater

stability against lateral loads, with ductility ratios of 8, 7, 7, and 5.83 for

trapezoidal, zigzag, curved, and flat faceplate, respectively. The

load-carrying capacity was also higher for wall with corrugated profiles, and

the stresses induced in trapezoidal were significantly lower, with the flat

faceplate experiencing 54.3% more stress. Considering these response

parameters, trapezoidal profile was found to be the most effective, offering additional benefits such as

improved concrete contact and aesthetic appeal. Therefore, DSC wall with trapezoidal faceplate were recommended as the superior option among

composite shear wall.

The authors are grateful for the support of the Structures and

Materials Research Lab of Prince Sultan University. The authors would like to

thank Prince

Sultan University for paying the Article Processing Charges (APC) of this

publication.

Conflict of Interest

The authors declare no conflicts of interest.

Alarcon, C.M., Hube, De la Llera, J., 2014. Effect of Axial Loads in the Seismic Behavior of Reinforced Concrete Walls with Unconfined Wall Boundaries. Engineering Structures, Volume 73, pp. 13–23. https://doi.org/10.1016/j.engstruct.2014.04.047

Alatoum, Y.A, Musmar, M.A., 2022. Structural Performance of Different Forms of Corrugated Plate Shear Walls under Dynamic Loading. Civil Engineering and Architecture, Volume 10(3), pp. 976–995. https://doi.org/10.13189/cea.2022.100317

Annamdasu, M.L., Lingeshwaran, N., Challagulla, S.P., Ahmed, O.S., Adamu, M., 2024. Investigating the Influence of Dynamic Interaction Between Primary and Secondary Structures on Elastic Floor Response Spectra During Near- and Far-Field Earthquakes: A Comparative Analysis with EC8 Formulation. International Journal of Technology Volume 15(5), pp. 1331–1348. https://doi.org/10.14716/ijtech.v15i5.7084

Bhardwaj, S.R., Varma, A.H., 2016. Effect of Imperfections on the Compression Behavior of SC Walls. In: Proceedings of the Annual Stability Conference, Orlando, Florida, USA.

Bruhl, J.C., Varma, A.H., 2017. Experimental Resistance and Available Ductility of Steel-Plate Composite Walls in One-Way Bending. Journal of Structural Engineering, Volume 143(4), p. 04016222. https://doi.org/10.1061/(ASCE)ST.1943-541X.0001714

Clubley, S.K., Moy, S.S., Xiao, R.Y., 2003. Shear Strength of Steel–Concrete–Steel Composite Panels. Part I—Testing and Numerical Modeling. Journal of Constructional Steel Research, Volume 59(6), pp. 781–794. https://doi.org/10.1016/S0143-974X(02)00061-5

Gharaei-Moghaddam, N., Meghdadian, M., Ghalehnovi, M., 2023. Innovations and Advancements in Concrete-Encased Steel Shear Walls: A Comprehensive Review. Results in Engineering, Volume 19, p. 101351. https://doi.org/10.1016/j.rineng.2023.101351

Ghodratian-Kashan, S., Maleki, S., 2021. Numerical Investigation of Double Corrugated Steel Plate Shear Walls. Journal of Civil Engineering and Construction, Volume 10(1), pp. 44–58. https://doi.org/10.32732/jcec.2021.10.1.44

Hamza, S., Heidari, M., Ahmadizadeh, M., Dashtizadeh, M., Chitt, M., 2023. Modification of Horizontal Wind Turbine Blade: A Finite Element Analysis. International Journal of Technology, Volume 14(1), pp. 5–14. https://doi.org/10.14716/ijtech.v14i1.5255

Huang, S.-T., Huang, Y.-S.., He, A., Tang, X.-L., Chen, Q.-J., Liu, X., Cai, J., 2018. Experimental Study on Seismic Behaviour of an Innovative Composite Shear Wall. Journal of Constructional Steel Research, Volume 148, pp. 165–179. https://doi.org/10.1016/j.jcsr.2018.05.003

Huang, Z., Liew, J.R., 2016. Structural Behaviour of Steel–Concrete–Steel Sandwich Composite Wall Subjected to Compression and End Moment. Thin-Walled Structures, Volume 98, pp. 592–606. https://doi.org/10.1016/j.tws.2015.10.013

Ji, X., Cheng, X., Jia, X., Varma, A.H., 2017. Cyclic In-Plane Shear Behavior of Double-Skin Composite Walls In High-Rise Buildings. Journal of Structural Engineering, Volume 143(6), p. 04017025. https://doi.org/10.1061/(ASCE)ST.1943-541X.0001749

Kholil, A., Kiswanto, G., Al Farisi, A., Istiyanto, J., 2023. Finite Element Analysis of Lattice Structure Model with Control Volume Manufactured Using Additive Manufacturing. International Journal of Technology, Volume 14(7), pp. 1428–1437. https://doi.org/10.14716/ijtech.v14i7.6660

Liew, J.R., Sohel, K., 2009. Lightweight Steel–Concrete–Steel Sandwich System with J-Hook Connectors. Engineering Structures, Volume 31(5), pp. 1166–1178. https://doi.org/10.1016/j.engstruct.2009.01.013

Liu, H., Shi, N., Fu, X., Zhang, J., 2024. Seismic Performance of Precast Double-Skin Composite Shear Wall with Horizontal Connection Region. Buildings, Volume 14(6), p. 1617. https://doi.org/10.3390/buildings14061617

Luo, Q., Wang, W., Sun, Z., Xu, S., Wang, B., 2021. Seismic Performance Analysis of Corrugated-Steel-Plate Composite Shear Wall Based on Corner Failure. Journal of Constructional Steel Research, Volume 180, p. 106606. https://doi.org/10.1016/j.jcsr.2021.106606

Ma, J., Chai, S., Chen, Y., 2022. Geometric Design, Deformation Mode, and Energy Absorption of Patterned Thin-Walled Structures. Mechanics of Materials, Volume 168, p. 104269. https://doi.org/10.1016/j.mechmat.2022.104269

Ma, K., Ma, Y., Liu, B., 2019. Seismic Behavior of Double Steel Concrete Composite Walls. The Structural Design of Tall and Special Buildings, Volume 28(11), p. e1623. https://doi.org/10.1002/tal.1623

McKinley, B., Boswell, L., 2002. Behaviour of Double Skin Composite Construction. Journal of Constructional Steel Research, Volume 58(10), pp. 1347–1359. https://doi.org/10.1016/S0143-974X(02)00015-9

Miao, L., Jin, L., Li, D., Du, X., Zhang, B., 2022. Effect of Shear-Span Ratio and Vertical Reinforcement Ratio on the Failure of Geometrical-Similar RC Shear Walls. Engineering Failure Analysis, Volume 139, p. 106407. https://doi.org/10.1016/j.engfailanal.2022.106407

Mustafa, S.A., Mashaal, M., Shaalan, O., Khfaga, M., 2023. Shear Walls against Lateral Load s: A Review. The Egyptian International Journal of Engineering Sciences and Technology, 42(1), pp. 1–14. https://doi.org/10.21608/eijest.2022.128054.1146

Pecce, M., Ceroni, F., Bibbò, F.A., De Angelis, A., 2014. Behaviour of RC Buildings with Large Lightly Reinforced Walls Along the Perimeter. Engineering structures, Volume 73, pp. 39–53. https://doi.org/10.1016/j.engstruct.2014.04.038

Qian, J., Jiang, Z., Ji, X., 2012. Behavior of Steel Tube-Reinforced Concrete Composite Walls Subjected to High Axial Force And Cyclic Loading. Engineering Structures, Volume 36, pp. 173–184. https://doi.org/10.1016/j.engstruct.2011.10.026

Qiao, W.-T., Huang, Z.-Y., Wang, T., Cui, Z.-Y., Meng, L-.J., 2024. Study on Flexural Capacity of Profiled Steel Sheet-Polyurethane Sandwich Slabs. Advanced Steel Construction, Volume 20(1), pp. 53–59. https://doi.org/10.18057/IJASC.2024.20.1.6

Qiu, J., Zhao, Q., Yu, C., Li, Z., 2018. Experimental Studies on Cyclic Behavior of Corrugated Steel Plate Shear Walls. Journal of Structural Engineering, Volume 144(11), p. 04018200. https://doi.org/10.1061/(ASCE)ST.1943-541X.0002165

Rassouli, B., Shafaei, S., Ayazi, A., Farahbod, F., 2016. Experimental and Numerical Study on Steel-Concrete Composite Shear Wall Using Light-Weight Concrete. Journal of Constructional Steel Research, Volume 126, pp. 117–128. https://doi.org/10.1016/j.jcsr.2016.07.016

Senthilkumar, R., Karunakaran, P., Chandru, U., 2023. Progress and Challenges in Double Skin Steel–Concrete Composite Walls: A Review. Innovative Infrastructure Solutions, Volume 8(1), p. 32. https://doi.org/10.1007/s41062-022-00973-y

Shanmugam, N., Kumar, G., Thevendran, V., 2002. Finite Element Modelling of Double Skin Composite Slabs. Finite Elements In Analysis And Design, Volume 38(7), pp. 579–599. https://doi.org/10.1016/S0168-874X(01)00093-2

Titiksh, A., Bhatt, G., 2017. Optimum Positioning of Shear Walls For Minimizing the Effects of Lateral Forces in Multistorey-Buildings. Archives of Civil Engineering, Volume 63(1), pp. 151–162. https://doi.org/10.1515/ace-2017-0010

Varma, A.H., Malushte, S.R., Sener, K.C., Lai, Z., 2014. Steel-Plate Composite (SC) Walls For Safety Related Nuclear Facilities: Design For In-Plane Forces and Out-Of-Plane Moments. Nuclear Engineering and Design, Volume 269, pp. 240–249. https://doi.org/10.1016/j.nucengdes.2013.09.019

Wang, W., Ren, Y., Han, B., Ren, T., Liu, G., Liang, Y., 2019a. Seismic Performance of Corrugated Steel Plate Concrete Composite Shear Walls. The Structural Design of Tall and Special Buildings, Volume 28(1), p. e1564. https://doi.org/10.1002/tal.1564

Wang, W., Song, J., Hou, M., Liu, G., Wang, W., 2019b. Experimental Study and Numerical Simulation of Replaceable Corrugated Steel Plate-Concrete Composite Shear Walls. Soil Dynamics and Earthquake Engineering, Volume 127, p. 105827. https://doi.org/10.1016/j.soildyn.2019.105827

Yan, J.-B., Li, Z.-X., Wang, T., 2018. Seismic Behaviour of Double Skin Composite Shear Walls With Overlapped Headed Studs. Construction and Building Materials, Volume 191, pp. 590–607. https://doi.org/10.1016/j.conbuildmat.2018.10.042

Yan, J.-B., Wang, X.-T., Wang, T., 2018. Compressive Behaviour of Normal Weight Concrete Confined by the Steel Face Plates in SCS Sandwich Wall. Construction and Building Materials, Volume 171, pp. 437–454. https://doi.org/10.1016/j.conbuildmat.2018.03.143

Yang, Y., Liu, J., Fan, J., 2016. Buckling Behavior of Double-Skin Composite Walls: An Experimental And Modeling Study. Journal of Constructional Steel Research, Volume 121, pp. 126–135. https://doi.org/10.1016/j.jcsr.2016.01.019

Yang, Y., Wu, B., Yao, Y.-P., Xu, L.-Y., Zhang, D., Wang, S.-H., 2023. Study on Axial Compression Performance of Double Steel Plate-Concrete Composite Walls with Stiffening Ribs and Tie Plates. Engineering Structures, Volume 274, p. 115182. https://doi.org/10.1016/j.engstruct.2022.115182

Zhang, H., Zhang, Y., Lu, X., Duan, Y., Zhang, H., 2020. Influence of Axial Load Ratio on the Seismic Behavior of Steel Fiber–Reinforced Concrete Composite Shear Walls. Journal of Structural Engineering, Volume 146(1), p. 04019171. https://doi.org/10.1061/(ASCE)ST.1943-541X.0002444

Zhang, W., Wang, K., Chen, Y., Ding, Y., 2019. Experimental Study on the Seismic Behaviour of Composite Shear Walls with Stiffened Steel Plates and Infilled Concrete. Thin-Walled Structures, Volume 144, p. 106279. https://doi.org/10.1016/j.tws.2019.106279

Zhao, Q., Li, Y., Tian, Y., 2020. Cyclic Behavior of Double-Skin Composite Walls with Flat and Corrugated Faceplates. Engineering Structures, Volume 220, p. 111013. https://doi.org/10.1016/j.engstruct.2020.111013

Zhao, Q., Li, Y., Tian, Y., Li, Z., 2020. Cyclic Behavior of Corrugated Double-Skin Composite Walls with Different Aspect Ratios. Journal of Structural Engineering, Volume 146(10), p. 04020214. https://doi.org/10.1061/(ASCE)ST.1943-541X.0002783

Zhao, Q., Sun, J., Li, Y., Li, Z., 2017. Cyclic Analyses of Corrugated Steel Plate Shear Walls. The Structural Design of Tall and Special Buildings, Volume 26(16), p. e1351. https://doi.org/10.1002/tal.1351