Impact of Optimized Molar Ratio, Temperature and Time on Organic Sulfur Transformation and Thermophysical Properties of High-Sulfur Coal

Corresponding email: syarifah_nursyimi@uitm.edu.my

Published at : 25 Mar 2025

Volume : IJtech

Vol 16, No 2 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i2.7257

Ismail, SNAS, Ishak, MAM, Ahmad, R & Ismail, K 2025, ‘Impact of optimized molar ratio, temperature and time on organic sulfur transformation and thermophysical properties of high-sulfur coal’, International Journal of Technology, vol. 16, no. 2, pp. 395-410

| Syarifah Nursyimi Azlina Syed Ismail | Faculty of Applied Sciences, Universiti Teknologi Mara, Perlis Branch, Arau Campus, 02600 Perlis, Malaysia |

| Mohd Azlan Mohd Ishak | Faculty of Applied Sciences, Universiti Teknologi Mara, Perlis Branch, Arau Campus, 02600 Perlis, Malaysia |

| Razi Ahmad | Faculty of Civil Engineering Technology, Universiti Malaysia Perlis (UniMAP), 02600 Arau, Perlis, Malaysia |

| Khudzir Ismail | Faculty of Applied Sciences, Universiti Teknologi Mara, Perlis Branch, Arau Campus, 02600 Perlis, Malaysia |

Coal desulfurization is important for improving air quality and addressing environmental issues. A preliminary study found that treating coal with a potassium carbonate-ethylene glycol mixture under optimized sonication parameters (molar ratio 1:16, 60 min at 40°C) reduced organic sulfur in coal by 65.68%. Therefore, this study aims to determine the physicochemical properties of the treated coal. The ultimate analysis shows a decrease in carbon (57.43%), hydrogen (4.67%), nitrogen (0.74%) and total sulfur (1.28%). The reduction in organic sulfur content is in accordance with the results from Fourier Transform Infrared Spectroscopy (FTIR) and X-ray Photoelectron Spectroscopy (XPS) analyses. The results showed changes in wavenumbers and surface area with increased oxygen (35.89%) content after pretreatment due to the formation of oxidation products, such as sulfoxides and sulfones. Furthermore, the proximate analysis showed a lower volatile matter (VM) (40.12%) and ash (A) (5.73%) content in the treated coal. In contrast, the fixed carbon (FC) (54.15%) value increased, which indicated the efficient combustion of coal with lower emissions. The increase in FC content resulted in a high fuel ratio (1.35), which enhanced fuel performance. However, the calorific value (CV) (20.90 MJ/kg) decreased due to the lower sulfur content. Based on the thermogravimetric (TG) analysis, a slower rate of weight loss was observed across various temperatures, indicating enhanced thermal stability and increased energy content. In conclusion, coal pretreated with DES-16 represented a significant improvement in coal strength. This method can impact coal utilization while aligning positively with sustainability goals.

Coal desulfurization; Deep eutectic solvent; Potassium carbonate-ethylene glycol; Sulfur transformation; Thermal stability

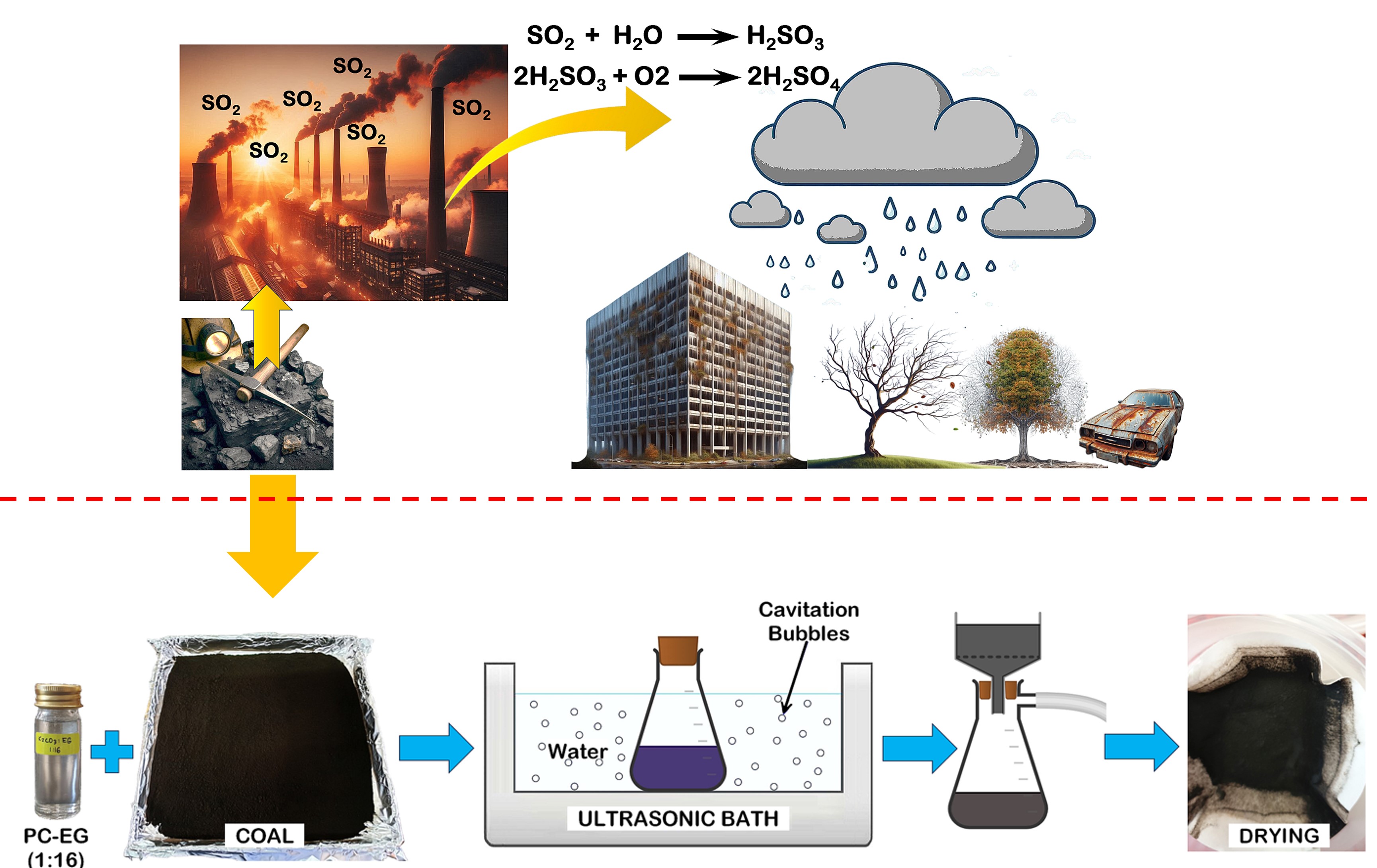

Sulfur in coal is categorized into inorganic and organic, with the inorganic form found in pyrite (PS) and sulfate (SS) (Kuang et al., 2022). Meanwhile, the organic (OS) form consists of thiophene, mercaptan, sulfoether, sulfone, and sulfoxide (Xu et al., 2020). Zhao et al. (2021) stated that sulfur content in coal was considerable high when it contains more than 3% of total sulfur (TS). The major challenge in coal desulfurization is the extraction of organic sulfur (Liu et al., 2020). The strong chemical bonds between coal matrix and organic sulfur compounds, particularly benzothiophene, led to difficulties during the extraction process (Tang et al. 2020). The sulfur in coal release sulfur dioxide (SO2) into the atmosphere during combustion (Ahmad et al., 2020). The reaction of SO2 with water and oxygen leads to the formation of acid rain (Liu et al., 2020), which has damaging effects on the environment (Kartohardjono et al., 2024; Cai et al., 2021). Previous studies reported that a high concentration of aromatic content reduced fuel quality, therefore, it was essential to separate aromatic chemicals from aliphatic hydrocarbons (Tang et al. 2020).

The traditional hydrodesulfurization (HDS) method is effectively used to extract sulfur from aliphatic hydrocarbons. However, it was difficult to remove heterocyclic sulfurs such as thiophene, benzothiophene, and the derivatives due to steric hindrance. HDS process requires the use of hydrogen gas under high temperatures and pressures (Haruna et al., 2022), contributing to increase costs and the potential for oil losses. Various alternatives methods had been explored, including extraction, oxidation, adsorption, and bio-desulfurization. The combination of extraction and oxidative desulfurization (EODS) is reportedly the most cost-effective alternative to the conventional method (Jha et al., 2023). Additionally, EODS operates under mild conditions, using environmentally friendly extractants and catalysts to eliminate aromatic sulfur compounds (Guan et al., 2023). A major drawback of using this method is the dependence on hazardous organic solvents. Significant concerns had led to increased demand for alternative methods relying on the use of environmentally friendly solvents such as deep eutectic solvents (DESs) (Lima et al., 2021; Mulia et al., 2018). DESs can be used for extraction rather than volatile and flammable organic solvents to enhance the process (Makos and Boczkaj, 2019).

DESs consist of hydrogen bond donors (HBD) and hydrogen bond acceptors (HBA) that interact through hydrogen bonding, resulting in the production of a eutectic mixture. Furthermore, this unique mixture has a lower melting point, remaining liquid at room temperature (Jablonský and Šima, 2022). DESs are cost-effective, biodegradable, and non-toxic (Jha et al., 2023), also characterized by low flammability and volatility, including excellent thermal stability (Kumorow et al., 2024; Lima et al., 2021) making it a preferable option. Another significant feature is the ability to absorb gases such as SO2, CO2, and NOx from the atmosphere, even at low concentrations (Chen and Mu, 2021). Moreover, DESs with strong H-bonding capabilities easily interact with sulfur compounds, making the transfer from the oil to DESs phase more accessible (Ravi et al., 2024). Factors, including molar ratio, HBA or HBD type, and extraction temperature tend to affect DESs performance in sulfur removal (Wazeer et al., 2020). DESs containing choline chloride (ChCl)-glycerol, imidazole-glycerol, and ChCl-ethylene glycol (EG) had shown significant potential in efficiently absorbing SO2 (Yang et al., 2018). Tahir et al. (2021) also reported that alcohol-based HBD are more effective than the acid-based. Additionally, ChCl-EG (glycol-based DES) exhibited superior desulfurization efficiency of 56% compared to the 32% realized by ChCl-orcinol (glycol-based DES). Rogošic and Kucan (2019) reported that increasing EG percentage enhanced thermal conductivity and temperature diffusivity but reduced heat capacity. Additionally, the research reported that the highest molar ratio of DESs to model fuel led to the most effective extraction.

Although Deep Eutectic Solvents (DESs) had shown remarkable effectiveness in various industrial applications, their potential in coal desulfurization remains underexplored. The heterogeneous coal composition and the embedded nature of organic sulfur made desulfurization less efficient and more challenging compared to liquid fuels. Most existing literature predominantly addressed fuel desulfurization, leaving a gap in knowledge regarding coal pretreatment. This gap presented an opportunity for further exploration in this critical area. Previous studies (Ismail et al., 2023) reported that coal treated with PC-EG mixture at optimized parameter (denoted as DES-16) achieved the best sulfur removal efficiency of approximately 65.77%. The PC-EG mixture represented a novel solvent with significant potential for effectively desulfurizing coal. Furthermore, the results showed that the combination of HBA and HBD targeted organic sulfur exceptionally, particularly when used at the optimal molar ratio and lower temperature range of 1:16 and 30 to 40°C, respectively.

Ultrasonic-assisted extraction (UAE) is another effective method frequently adopted in coal desulfurization (Shen et al., 2023). The method generated acoustic cavitation in slurries when ultrasonic waves induced alternating cycles of high and low pressure, resulting in the formation of bubbles. The bubbles continued to grow until it could not absorb additional energy, leading to the collapse and generation of shockwaves. The resulting shockwave caused cracks on coal surface, aiding in the removal of the released chemicals (Carreira-Casais et al., 2021).

This study explored the physicochemical properties of treated coal, focusing on ultimate and proximate analyses, calorific value (CV), thermal stability, changes in functional groups, and sulfur transformations, while expanding on previous reviews. Furthermore, understanding the physicochemical properties of coal after desulfurization played an essential role in assessing the quality, efficiency, and environmental impact. The reaction mechanism for dibenzothiophene (DBT) compounds was also proposed based on sulfur transformation data obtained from FTIR and XPS analyses. Additional study on the reaction mechanism enabled adequate understanding of the fundamental interactions between PC-EG mixture and coal. This knowledge also optimized the efficiency of organic sulfur removal by targeting specific sulfur species.

2.1. Preparation of coal sample and PC-EG mixture

The high-sulfur coal sample from Jambi Province, Indonesia, was supplied by SGS (Malaysia) Sdn. Bhd. Potassium carbonate anhydrous (Hmbg) and 98% ethylene glycol (Supelco) were obtained from R&M Chemicals and Merck (M) Sdn. Bhd., respectively. These chemicals were used without further purification. Coal preparation and PC-EG synthesis procedures were carried out by adopting the methods detailed in previous publication (Ismail et al., 2023).

2.2 Extraction of coal with PC-EG mixture and Sulfur Assay Studies

The pretreatment was based on methods proposed by Ismail et al. (2023). A schematic representation of desulfurization process conducted with potassium carbonate-ethylene glycol mixture is shown in Figure 1.

Figure 1 Schematic diagram on desulfurization process of coal using potassium carbonate-ethylene glycol mixture

2.3. Ultimate, proximate and caloric value (CV) analysis

Thermo Scientific Flash 2000 Organic Elemental Analyzer was used to validate the total sulfur values determined in accordance with ASTM standard guidelines D3174-11. The analysis was also used to validate total sulfur (TS) values outlined in ASTM D3177 (02). The proximate analysis of treated and untreated coal was determined using Mettler Toledo Thermogravimetric (TG) Analysis following the guidelines set by ASTM D2974. Additionally, CV analysis of treated and untreated coal was carried out using an IKA bomb calorimeter model C200.

2.4. Fourier Transform Infrared (FTIR) Spectroscopy Analysis

FTIR analysis was conducted on both untreated and treated coal samples to detect changes in absorption peaks related to functional groups. The samples were dried overnight in a vacuum oven at 60°C before the analysis to eliminate moisture. Then, the coal samples were pulverized with KBr salt and compacted into small pellets at a mass ratio 1:800 of coal to KBr. A Perkin Elmer FTIR Spectrometer with a scan ranging in 400 to 4000 cm-1 was used to analyze the solid pieces, scanned 64 times at a resolution of 4 cm-1 (Ismail et al., 2023).

2.5. Thermogravimetric (TG) Analysis

Thermal analyses were carried out using NETZSCH TG 209F3 thermal analyzer (TGA209F3A-0107-L). Each sample, weighing approximately 5 to 10 mg, was placed in an alumina pan under nitrogen (N2) atmosphere with a flow rate of 50 ml/min. The temperature increased from 30 to 1000°C at a heating rate of 20°C/min (Tang et al., 2020). TG experiments were conducted twice to guarantee the accuracy of the results, and the Differential Thermogravimetric (DTG) graph was derived using the Origin Pro 2022 software.

2.6. X-ray Photoelectron Spectroscopy (XPS) Analysis

X-ray photoelectron spectroscopy (XPS) analysis of coal samples was conducted using Thermo Fisher Scientific Model Nexsa G2. The peak binding energy (BE) for sulfur functional groups, derived from XPS data, was calibrated in respect to literature sources (Yang et al., 2021; Xu et al., 2020).

3.1. Physicochemical Properties of Untreated and Treated Coal under Optimized Condition

Table 1 shows a comparative analysis of the ultimate and proximate sulfur forms, including CV of both untreated and treated coal samples. This study was conducted using samples under optimized parameters, specifically a molar ratio, temperature and extraction time of 1:16, 40°C, and 60 min, respectively.

3.1.1. Ultimate Analysis

Untreated coal was enriched with 61.26% carbon (C), 5.03% hydrogen (H), 1.38% nitrogen (N), 3.94% total sulfur (S), and 28.09% oxygen (O). Based on the carbon concentration, coal was classified as lignite (Cheepurupalli and Anuradha, 2019). The value of oxygen also showed that the coal was lignite (Solomon et al., 2016). The total sulfur content exceeded 3% and was considered as high sulfur coal (Zhao et al., 2021), due to 0.89% sulfate, 1.39% pyritic, and 1.69% organic. This characterization made the sample particularly relevant to the objectives of the study. Nitrogen content which is less than 2% does not correlate with coal rank. In addition, low nitrogen composition played a beneficial role as it reduced coal oxidation (Adekunle et al., 2015).

The total sulfur content for treated coal, determined by ASTM standard, was 1.17%. However, the elemental analyzer showed a slightly higher reading of 1.28%. This discrepancy of approximately ±0.11% was in acceptable limits, depicting consistency in the testing procedures. The composition of C, H, N, and S for treated coal reduced to 57.43%, 4.67%, 0.74%, and 1.28%, respectively, while O content increased to 35.89%. The reductions observed in C, H, N, and S compositions was attributed to certain processes such as volatilization, oxidation, or various chemical reactions that occurred during the pretreatment of coal with PC-EG mixture. Simultaneously, the increase in oxygen content was associated to the oxidation of specific coal components and the formation of oxygen-containing functional groups during the pretreatment with DES-16. Furthermore, the pyritic (PS) and sulfate sulfur (SS) values were reduced to 0.47% and 0.12%, respectively.

The atomic-to-carbon ratio after coal pretreatment was in line with the information above. O/C ratio increased to 0.469, while H/C and S/C ratios of treated coal were reduced to 0.574 and 0.008, respectively. Lower H/C and O/C ratios are more advantageous for solid fuel usage as they minimize energy loss during combustion (Yang et al., 2024). After analyzing S/C ratio of untreated and treated coal, sulfur removal reached 66.67%, falling in the expected range of the validated analysis.

Following the discussion, the desulfurization process significantly reduced sulfur content using a PC-EG mixture, depicting successful progress towards the targeted objectives of coal desulfurization. However, more detailed analytical results would be presented in the following sections.

3.1.2. Proximate Analysis

Volatile matter (VM) represents the components of coal, excluding moisture and ash, that are released when coal is heated in an oxygen-free environment (Morley et al., 2017). The VM of treated coal was reduced to 40.12% compared to untreated coal at 47.84%. The result obtained represented a 16.14% decrease in VM, depicting that DES-16 pretreatment effectively transformed coal aromatic and long-chain hydrocarbons into short-chain. Higher VM content in coal was associated with enhanced reactivity, facilitating easier ignition and increased combustion rates (Cheepurupalli and Anuradha, 2019). However, other studies reported that coal with high volatility produces more smoke, while lower volatile matter levels lead to better combustion efficiency and reduced emissions (Sajid et al., 2022).

Fixed carbon (FC) referred to the amount of carbon that remained in coal after the removal of moisture and VM (Dwivedi, 2022). A higher FC content depicted effective heat generation during combustion, implying higher quality coal (Le et al., 2018). Additionally, coal with a higher FC proportion burnt more gradually due to slower gas-solid combustion reactions than rapid gas-gas combustion processes (Rasheed et al., 2015). For treated coal, the FC content increased to 54.15%, equivalent to a 26.08% improvement compared to the untreated coal at 40.03%. This enhancement made the treated coal a better solid fuel compared to untreated coal.

Ash (A) is the inorganic residue or mineral matter that remained after combustion (Dwivedi, 2022). Throughout the pretreatment process, the ash content of coal was reduced to 5.73%, perceived as a significant decrease from the original ash content of 12.13% detected in untreated coal. This significant reduction of 52.76% suggested the effective elimination or conversion of volatile components such as CO2, SO2, and H2O from mineral compounds (Sajid et al., 2022). The results showed that treated coal was the optimal choice for achieving a low ash-content fuel. Meanwhile, the accumulation of ash in the boiler tubes affected heat transfer efficiency, leading to a decline in the overall performance of the boiler (Samsudin et al., 2021).

The ratio of FC to VM is an essential parameter for evaluating solid fuel quality. The evaluation required analyzing the ratio of FC and VM and then comparing it using Equation 1 (Aich et al., 2020).

For treated coal, the fuel ratio increased from 0.84 to 1.35. The measured value supporting the expected results, as a significant increase was experienced in FC content. A marked reduction was observed in VM as a result of desulfurization process. The low fuel ratio typically correlated with an increase in flaming combustion, reducing char combustion, a more rapid burnout process. However, increasing the fuel ratio promoted a stable and prolonged combustion process, specifically in boiler applications (Adeleke et al., 2020).

In this context, the pretreatment of coal with DES-16 reduced VM and ash content while increasing FC content. The reduction of VM content in coal directly decreased the total mass. Additionally, it confirmed the reductions in C, H, N and S as depicted by the ultimate analysis. The correlation was expected, as these elements are the key components of VM.

3.1.3. Calorific or Heating Value

The heat generated during coal combustion is known as CV. The prediction through proximate analysis is easier and more cost-effective (Onifade et al., 2022). For treated coal, CV was found to be 20.90 MJ/kg, approximately a 9.37% decrease compared to untreated coal's value of 23.06 MJ/kg. Solomon et al. (2016) reported that coal with higher carbon content typically exhibited a greater CV. In the case of untreated coal, the increased carbon and sulfur concentrations significantly enhanced CV compared to treated coal. Although sulfur improved heat generation during combustion, reducing the content is better as it minimized the production of sulfur dioxide and trioxide acids. These could cause corrosion in combustion equipment, contributing to environmental pollution (Solomon et al., 2016).

Hydrogen plays a crucial role in coal combustion and is primarily found in VM. The appropriate proportion of hydrogen and a higher oxygen content significantly enhance the combustibility of coal, making it an efficient fuel source (Solomon et al., 2016). Nitrogen does not contribute calorically, and its presence in coal should be minimized to reduce oxidation and the release of flammable gases (Adekunle et al., 2015). CV of coal was observed to be influenced by the presence of C, H and S in the composition (Solomon et al., 2016). Therefore, a decrease in these compounds after coal desulfurization led to a lower CV.

The proximate analysis of coal is crucial in determining CV. The moisture in coal reduces CV as additional energy is required to evaporate the water during combustion (Akbar et al., 2020). However, several studies (Sajid et al., 2022; Dwivedi, 2022; Akbar et al., 2020) reported that higher levels of VM and FC correlated with an increase in CV, with low ash content contributing to the correlation process (Akbar et al., 2020).

In this study, treated coal exhibited a decrease and an increase in ash content and FC levels, respectively. The changes did not significantly impact the CV, depicting that organic component plays a dominant role in energy content (Dwivedi, 2022). It was observed that the removal of organic sulfur in coal led to a reduction of CV. Sulfur, predominantly found in organic forms, significantly contributes to the overall energy content of coal. During desulfurization, sulfur compounds are removed, reducing the overall energy density of the treated coal.

Table 1 Characterization of untreated and treated coal under optimized conditions

db = dry basis weight unit, * = calculated by differences, ** use the S value from ultimate analysis

3.2. Thermal Stability

TG and DTG curves in Figures 2(a) and 2(b) show the mass loss of coal as a function of temperature. These analyses were conducted during pyrolysis, providing valuable insights into thermal decomposition and degradation processes (Wang et al., 2023). The pyrolysis of low-rank coal was analyzed in three phases. As shown in Figure 2(a), the TG curve depicted weight loss (wt.%) of coal samples as a function of increasing temperature in an inert nitrogen (N2) atmosphere.

In Phase I, both coal samples exhibited minimal weight loss in the temperature range of 30 to 120°C, mainly due to moisture evaporation. However, untreated coal showed a continuous moisture loss extending to 200°C. This prolonged moisture decrease was associated with thermal degradation of the unstable organic sulfur compounds, such as thiols, sulfides, and disulfides, which tend to decompose at relatively low temperatures (Shen et al., 2021). The emission of SO2 is observed in low-temperature regions in 200 to 300°C and at higher temperatures between 400 to 600°C (Wang et al., 2023). Furthermore, mercaptans (thiols) start to emit SO2 and various free radicals at approximately 130°C (Xi et al., 2023), consistent with results from several studies (Hassid et al., 2022; Mittal et al., 2021;Tang et al., 2020; Dong et al., 2019).

Phase II represented the main devolatilization phase, occurring in a temperature range of 130 to 480°C or 200 to 600°C (Dwivedi et al., 2019). During this phase, coal samples are subjected to significant decomposition, releasing VM, known as the zone for active pyrolysis (Hou et al., 2023; Dwivedi et al., 2019). Untreated coal started to experience weight loss at a temperature of 300°C. This transformation depicted a weight loss of volatile components, due to a high cracking process. The slower mass reduction of untreated coal was caused by the larger quantity of minerals and organically bound sulfur in the macromolecular structure. The gradual process led to challenges associated with the release of carbon, hydrogen, and oxygen-containing compounds. Moreover, the emission of gases such as carbon monoxide (CO), carbon dioxide (CO2), and methane (CH4) (Tang et al., 2020) alongside trace amounts of sulfur dioxide (SO2), carbonyl sulfide (COS), and carbon disulfide (CS2) contributed to the observed decline on TG curve (Wang et al., 2023). Treated coal, started to experience gradual weight loss at a lower temperature of 150°C, with TG curve showing a secondary decline at 400°C.

In Phase III, secondary devolatilization occurred at temperatures ranging in 480 to 600°C. Both treated and untreated coal samples experienced weight loss, with the decomposition rate of the treated coal significantly slower compared to untreated. At approximately 480°C, higher concentrations of organic sulfur significantly increased the production of gases such as hydrogen sulfide (H2S) and carbonyl sulfide (COS) (Wang et al., 2023). The devolatilization process stopped after reaching 600°C, supporting the results reported by Dwivedi et al. (2019). Furthermore, the treated coal showed a greater mass percentage than untreated coal, depicting enhanced thermal stability.

DTG curve in Figure 2(b) illustrates that the mass loss rate (wt.%/min) varies as a function of temperature for both samples. The initial peak observed in the curve depicted moisture evaporation occurred in both materials, supporting the phase in Figure 2(a). Meanwhile, in Phase II, both samples exhibited a sloped peak preceding the peak temperature on the DTG curve. The peak corresponding to the most active point of thermal decomposition, characterized by the highest rate of mass loss. During this phase, the coal was subjected to interaction with desulfurization reagent, resulting in the fragmentation of VM into smaller molecular weight compounds (Dwivedi et al., 2020). The result showed that untreated and treated coals reached the peak temperature at 480°C during combustion, and 430°C, respectively. The delay encountered in reaching peak temperature depicted that untreated coal contained higher concentration of VM, including both short and long-chain hydrocarbons. Therefore, more energy and a longer time were required to reduce these volatile components (Sajid et al., 2022). For treated coal, a significant amount of VM was extracted from the coal during desulfurization process. Therefore, the treated coal required less energy to reach the thermal decomposition point due to the lower volatile content. The reduction in volatile materials made the heating process more efficient, enabling the peak decomposition temperature to be attained earlier at 430°C. These results were in line with the study conducted by Dwivedi et al. (2020), which reported significant weight loss in low-rank coals in the temperature range of 450°C to 560°C. The results from the proximate analysis further supported this result, showing significantly lower levels of VM in treated coal.

At 550°C, both coal types showed stable pyrolysis behaviour. Shen et al. (2021) reported that in the temperature range of 550 to 850°C, a transformation occurred involving disulfide sulfur oxides and aromatic sulfur compounds. Moreover, when temperatures exceeded 750°C, the decomposition of organic sulfur was completed, reflected by the smooth curve observed in the reaction profile. At temperatures exceeding 800°C, the coal was subjected to a carbonization process, resulting in the conversion to coke. This transformation destroyed the coal structure, resulting in the significant release of CO2. Further oxidation was stopped due to the inert atmosphere, leading to the preserved portion of FC (Dong et al., 2019). However, on completion of the pyrolysis process at 900°C, untreated coal retained 48.92% of the original mass, with the treated coal exhibiting a greater retention of 57.38%.

The results showed that the pretreatment with DES-16 significantly decreased the weight loss rate of coal. This pretreatment process also reduced VM content, introducing structural changes that enhanced coal resistance to thermal decomposition. Furthermore, the modifications increased the energy content. The improved characteristics of the treated coal were perceived as a more advantageous option for applications that required high thermal conditions.

(a) (b)

Figure 2 (a) TG and (b) DTG analysis of untreated and treated coal

3.3. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

Figure 3 shows the FTIR spectroscopy of untreated and treated coals used to assess the functional group presence, as well as analyze the chemical bonds before and after coal pretreatment. The broad peak observed in the 3600-3200 cm-1 range signified OH stretching vibration (Wang, et al., 2019), suggesting the presence of moisture or hydroxyl groups in untreated and treated coal. For untreated coal, the peak appeared at 3392 cm-1, but for treated coal, it shifted to 3417 cm-1, depicting a reduction of the OH molecule following the pretreatment. This observation was in line with the TGA results in Figure 2(a), demonstrating that minimal weight loss was detected between 30 to 120°C. This result was further supported by the decrease in peak intensity or transmittance, depicting a reduction in moisture content after pretreatment.

The peaks observed in 2970 to 2845 cm-1 depicted the stretching vibrations of aliphatic CH2 and -CH3 (Nandiyanto et al., 2019). For untreated coal, the peaks appeared at 2935, 2926, and 2855 cm-1. After pretreatment with DES-16 at optimum conditions, the two peaks of C-H vibration remained at the original wavenumbers, except for the peak at 2935 cm-1, which shifted slightly to 2938 cm-1. The reduction of these peaks in treated coal was attributed to the breaking of the saturated alkane chain in the coal structure, leading to greater visibility and accessibility of C-H groups (Xu et al., 2020). Additionally, the results were supported by a reduction in the carbon and hydrogen values observed in the ultimate analysis, as shown in Table 1.

The peaks in 1680 to 1450 cm-1 and 1400 cm-1 were associated with C=C stretching vibrations and thiophene rings (Tang et al., 2021), suggesting the presence of aromatic and heterocyclic compounds. Untreated coal displayed peaks at 1659 cm-1 and 1411 cm-1, signifying the existence of aromatic C=C stretching and thiophene rings, respectively. After pretreatment, the aromatic ring peak shifted to 1623 cm-1, while the thiophene peak splitted into two at 1380 cm-1 and 1446 cm-1. The peaks shifted towards the higher wavenumber, suggesting a decrease in the mass of the molecules. The observed phenomenon clearly showed an inverse correlation between the vibrational frequency and the mass of vibrating molecule. Specifically, those with lower mass tend to vibrate at higher frequencies, resulting in increased wavenumbers. The reduction of some aromatic and heterocyclic thiophene compounds were supported by the decrease in both the total and organic sulfur in Table 1. However, the thiophene ring which splitted into two peaks mainly due to the degradation of the original compound or the breakdown of coal macromolecules into smaller particles after pretreatment.

The peaks recorded at 1122 cm-1 and 1034 cm-1 in coal sample were attributed to sulfoxide (S=O) and sulfone (O=S=O) (Wang et al., 2019). For treated coal, the sulfoxide peak decreased and shifted to 1167 cm-1, while two new peaks for sulfone appeared at 1101 cm-1 and 1036 cm-1. The shift in peaks represented a reduction in some sulfones and the potential formation of new peak due to sulfoxide oxidation. The results explained the observed increase in oxygen levels identified in the ultimate analysis. Meanwhile, the peaks between 705 to 507 cm-1 corresponded to disulfide (S-S) and sulfide (R-S-R) bonds (Xu et al., 2020). Untreated coal analysis showed the presence of disulfide (S-S) and sulfide (R-S-S) bonds, with prominent peaks recorded at 705 cm-1, 620 cm-1, and 539 cm-1. After pretreatment, only a slight peak at 536 cm-1 was observed, potentially representing sulfide (R-S-S) bond. This showed the breakage of the more accessible disulfide (S-S) bond. Additionally, the presence of sulfonates (R-SO3-) resulting from sulfide oxidation was represented by the smaller peak at 670 cm-1. The peak at 473 cm-1 in untreated coal depicted the presence of mercaptans or thiols (S-H) (Xu et al., 2020). The peak shifted slightly to the right, showing an increase in the compound.

Following the discussion, the treated coal reduced peak intensities related to O-H, C-H, and C=O functional groups. This suggested that the treatment extracted some of the groups, potentially improving thermal stability and energy content of the coal. The variations in peak intensities showed that chemical transformations occurred during the pretreatment process. The transformations led to the modified molecular structure of the coal while still maintaining the overall integrity of the macromolecular framework. Moreover, to comprehensively understand the sulfur changes in the chemical composition and properties of coal after pretreatment with DES-16, additional analytical methods such as Gas Chromatography-Mass Spectrometry (GCMS) would be essential.

Figure 3 FTIR results of raw and treated coal

3.4. X-ray Photoelectron Spectroscopy (XPS) Analysis

In Figures 4(a) and 4(b), the XPS fitting curve shows the binding energy of electrons in electron volts (eV) versus the intensity of detected electrons in counts per second (cps). The data in Table 2 shows binding energy of sulfur and peak area in untreated and treated coal, supporting the figures. This analysis examined the changes in sulfur elements during the pretreatment with PC-EG mixture at coal surface by observing peak positions (Gao et al. 2022). The FTIR spectroscopy only detected sulfur functional groups, but it does not show the actual transformation of sulfur before and after desulfurization (Xu et al., 2020). Meanwhile, the sulfur discussed consisted of heterocyclic organic compounds, as the study only focused on removing organic rather than inorganic sulfate. Figure 4(a) shows that untreated coal contained various forms of organic sulfur, including thioether (sulfide), thiophene, sulfoxide, sulfone, and sulfate, consistent with previous study (Yang et al. 2021; Xu et al. 2020). Sulfone had the highest peak area, followed by thiophene, sulfate, sulfoxide, and sulfoether.

Considering untreated coal, thioether (sulfide) showed two peaks at binding energies of 162.91 eV and 163.69 eV. After pretreatment, the first peak shifted to 163.00 eV, depicting a change in the oxidation state of sulfur. As shown in Table 2, a 54.81% reduction in the peak area of the treated coal suggested the conversion of some sulfoether to sulfone (167.01 eV). The extension of the extraction time effectively eliminated or convert any remaining sulfur. Furthermore, a longer extraction time should be considered to enhance sulfur removal. The second peak recorded at 163.69 eV was completely reduced and oxidized to sulfoxide (165.12 eV) and sulfone (168.40 eV). Higher binding energies were observed when the oxidation state increased, leading to the formation of new chemical bonds. In XPS, the lowest binding energy corresponded with the least oxidized form of the component (Mogk, 2021).

For untreated coal, a single thiophene peak was observed at 164.01 eV, while in treated coal, two peaks were detected at 164.12 eV and 165.15 eV. The original thiophene peak shifted to 164.12 eV, experiencing a 90.71% reduction in surface area after pretreatment with DES-16, suggesting effective thiophene removal. Furthermore, the thiophene was oxidized to sulfoxide (166.19 eV), sulfate (169.70), and sulfone (167.61 eV). After pretreatment, the new thiophene peak at 165.15 eV was oxidized to sulfone (168.65 eV) with a 26.72% reduction in surface area. The peak was formed by decomposing large molecular structures containing dibenzo- or benzothiophene, sulfide, sulfoxide, and sulfone components. The formation of sulfate was also obtained from the decomposition of sulfides (Wang et al., 2022).

Untreated coal initially showed peaks for sulfoxide and sulfone at 165.06 eV and 168.78 eV, respectively. However, after pretreatment, sulfoxide peak shifted to 167.01 eV, suggesting complete oxidation to sulfone. In treated coal, sulfone peak completely disappeared, while three new peaks of sulfone appeared at 167.65 eV, 168.40 eV, and 168.65 eV, suggesting the oxidation of thioether and thiophene compounds. FTIR analyses of treated coal also showed peak changes at 1330-1125 cm-1 and 1060-1030 cm-1 for sulfoxide and sulfone, respectively, which supported these results. After the pretreatment, two peaks were detected for sulfone at 1101 cm-1 and 1036 cm-1. The results showed that some sulfones were reduced, while others were generated from sulfoxide oxidation and remained in the coal. The result was consistent with the study by Tang et al. (2018), which investigated coal desulfurization using peroxyacetic acid through microwave irradiation and ultrasonic methods. It was reported that the increase in sulfone content after pretreatment was due to the oxidation of sulfoether, sulfoxide, and thiophene into sulfone.

The initial analysis of untreated coal showed a sulfate peak at 170.44 eV, depicting the presence of inorganic sulfur compounds such as pyrite and barium sulfate. However, after pretreatment, the peak decreased to 169.70 eV, with the area under the curve reduced by approximately 86%, suggesting the removal of inorganic sulfur. The barium sulfate in untreated coal was eliminated after pretreatment with DES-16. It was also believed that the remaining sulfates detected by ASTM D2492-02 (2012) originated from the conversion of thiophenes, sulfones, or the reoxidation of thioether (sulfides) (Sandfeld et al., 2020). For example, diphenyl sulfide tended to be decomposed into smaller compounds. The results obtained by Samaila et al. (2020) indicated that sulfur was converted into sulfate. Moreover, the study also reported that soluble sulfates was dissolved in diluted hydrochloric acid for subsequent analysis. Some pyrite was found in coal after pretreatment, due to the limited processing time in DES-16. Extending the processing time could be a solution to achieving better results.

In summary, the treated coal exhibited a reduction in surface area and an increase in binding energy, depicting that DES-16 effectively removed and oxidized certain sulfur compounds. This process also eliminated the initial inorganic sulfur, including barium sulfate and certain pyrite. However, residual sulfate detected through sulfur assay studies originated from thioether and thiophene residues. A deep understanding of desulfurization mechanisms enabled the investigation of heterocyclic sulfur transformation before and after pretreatment.

Table 2 Peak binding energy (BE) and area of sulfur from the raw and treated coal

(a)

(b)

Figure 4 XPS fitting curve of sulfur forms on (a) untreated and (b) treated coal surface

3.5. Proposed Reaction Mechanism for Dibenzothiophene

The removal of DBT depended significantly on HBA and molar ratio of DESs (Lima et al., 2021). Zeng et al. (2024) reported that the coordination configuration with EG-K+ was only one. Simultaneously, numerous hydrogen bonds were observed in PC-EG mixtures, suggesting the formation of the H-bonds between the hydroxyl groups (OH) of EG and the carbonate anion (CO32-). When the number of EG molecules bound to the K+ ion increased, it produced a more crowded environment around the ion, influencing the bonding interactions with the CO32- and EG molecules. According to Meng et al. (2020), this mixture contained a high concentration of OH and C-O groups, offering many active H and O atoms. This study reported that a higher molar ratio of EG in DES-16 resulted in a greater impact of EG-carbonate ion interactions. The studied depicted that sulfur extraction methods using DESs were mainly conducted at temperatures between 30 and 40°C. Additionally, the process of extracting sulfur from DBT at 50°C produced comparable outcomes to those achieved at 30°C (Guan et al., 2023), in line with desulfurization process.

The reaction mechanism was proposed for DBT compounds based on the results of sulfur transformation from FTIR and XPS. Sulfur atom in DBT was subjected to nucleophilic attack by the oxygen atoms of the carboxyl groups in PC-EG molecule under ultrasonication. This process led to the oxidation of DBT to produce DBT sulfoxide in a low oxidative state. Following the reaction, the sulfur atoms in DBT sulfoxide were further attacked by the oxygen atoms of carboxyl groups in other PC-EG molecules, leading to the oxidation to a high state and the formation of DBT sulfone. The proposed reaction mechanism is shown in Figure 5. However, further study using GC-MS should be conducted to obtain a deeper understanding of the fundamental interactions between PC-EG mixture and coal, improving the efficiency of organic sulfur removal by targeting specific related compounds.

Figure 5 Proposed mechanism for the oxidation of DBT-to-DBT sulfoxide and DBT sulfone by PC-EG mixture

In conclusion, coal pretreated with DES-16 under optimized parameters showed a significant reduction in organic sulfur content while enhancing the physicochemical properties of coal. The ultimate analysis showed a minor reduction in C and H compared to the original values. Meanwhile, S and N levels also showed a significant reduction of approximately 67.51% and 46.38%, respectively. The reduction was beneficial for coal quality as it significantly minimized SO2, SO3 and NOx emission during combustion. High-quality coal played a crucial role in the promotion of safe and environmentally sustainable practices in energy production, including public health protection, thereby preserving the impact of climate change. The results also showed a significant increase in O content after pretreatment. The validation of these changes was achieved through analytical methods such as FTIR and XPS, which identified the formation of oxidation products, namely sulfoxides and sulfones, generated from the process. The proximate analysis further depicted a decline in VM and ash content, while FC content increased after pretreatment. Low VM and high FC were good combination, as greater FC content suggested a high fuel ratio, generally favourable for fuel performance. Simultaneously, reducing the ash content contributed to a more efficient combustion process, enhancing CV of coal. The analysis showed a reduction in CV, which supported the observed decrease in carbon and sulfur levels in coal. Although sulfur enhanced the heat generated during combustion, minimizing the presence was advantageous for reducing the emission of oxide gases, helping to minimize environmental pollution. TG-DTG analysis showed a slower rate of weight loss at various temperatures, suggesting that the pretreatment process improved thermal stability of coal, increasing the energy content. The results suggested that PC-EG mixture significantly improved thermal properties and structural strength of treated coal. The findings from FTIR and XPS analyses were used to propose the reaction mechanism of DBT. The data suggested that the oxygen atoms in carboxyl groups of PC-EG molecules functioned as nucleophiles during the ultrasonic assistant extractions. These nucleophiles attacked the electrophilic sulfur in DBT, resulting in the oxidation of the compound to the corresponding sulfoxides and sulfones. This study presented an innovative pretreatment method for coal using a biodegradable solvent, which contributed to the development of safer and more sustainable energy production. This method was in line with the objectives of the 2030 Agenda for Sustainable Development, addressing critical environmental issues, improving resource efficiency, and promoting the transition to cleaner energy generation

The authors thank the Universiti Teknologi MARA (UiTM) and the Ministry of Higher Education Malaysia for the invaluable support and financial assistance provided through the Fundamental Research Grant Scheme (FRGS) under grant registration code FRGS/1/2022/STG04/UITM/02/19.

Author Contributions

Syarifah Nursyimi Azlina Syed Ismail: Gathering experimental, data processing and analysis, as well as writing and revising the manuscript. Mohd Azlan Mohd Ishak: developing the research idea, analysis method and supervising the research process. Razi Ahmad: providing essential equipment and technical support. Khudzir Ismail: refining the research idea, mechanism framework and managing the research progress.

Conflict of Interest

The authors declare no financial conflicts of interest or personal relationships that could have impacted the research presented in this paper.

Adekunle, J, Ibrahim, J & Kucha, E 2015, ‘Proximate and ultimate analyses of biocoal briquettes of Nigerian’s Ogboyaga and Okaba sub-bituminous coal’, British Journal of Applied Science and Technology, vol. 7, pp. 114–123, https://doi.org/10.9734/bjast/2015/15154

Adeleke, AA, Odusote, JK, Ikubanni, PP, Lasode, OA, Malathi, M & Paswan, D 2020, ‘The ignitability, fuel ratio and ash fusion temperatures of torrefied woody biomass’, Heliyon, vol. 6, no. 3, e03582, https://doi.org/10.1016/j.heliyon.2020.e03582

Ahmad, R, Ishak, MAM, Ismail, K, Kasim, NN, Mohamed, AR, Ani, AY, Deris, RRR & Radzun, KA 2020, ‘The effect of pretreated palm kernel shell and Mukah Balingian coal co-gasification on product yield and gaseous composition’, International Journal of Technology, vol. 11, pp. 501–510, https://doi.org/10.14716/ijtech.v11i3.2916

Aich, S, Behera, D, Nandi, BK & Bhattacharya, S 2020, ‘Relationship between proximate analysis parameters and combustion behaviour of high ash Indian coal’, International Journal of Coal Science and Technology, vol. 7, pp. 766–777, https://doi.org/10.1007/s40789-020-00312-5

Akbar, H, Laha, SK & Saini, R 2020, ‘A correlation study of gross calorific value with parameters of proximate analysis of coal’, Rasayan Journal of Chemistry, vol. 13, pp. 2515–2522, https://doi.org/10.31788/RJC.2020.1345842

Cai, S, Zhang, S, Wei, Y, Sher, F, Wen, L, Xu, J, Dang, J & Hu, L 2021, ‘A novel method for removing organic sulfur from high-sulfur coal: Migration of organic sulfur during microwave treatment with NaOH-H2O2’, Fuel, vol. 289, 119800, https://doi.org/10.1016/j.fuel.2020.119800

Carreira-Casais, A, Otero, P, Garcia-Perez, P, Garcia-Oliveira, P, Pereira, AG, Carpena, M, Soria-Lopez, A, Simal-Gandara, J & Prieto, MA 2021, ‘Benefits and drawbacks of ultrasound-assisted extraction for the recovery of bioactive compounds from marine algae’, International Journal of Environmental Research and Public Health, vol. 18, https://doi.org/10.3390/ijerph18179153

Cheepurupalli, NR & Anuradha, B 2019, ‘Proximate and ultimate characterization of coal samples from southwestern part of Ethiopia’, International Journal of Engineering and Advanced Technology, vol. 9, pp. 1643–1648, https://doi.org/10.35940/ijeat.B3046.129219

Chen, Y & Mu, T 2021, ‘Revisiting greenness of ionic liquids and deep eutectic solvents’, Green Chemical Engineering, vol. 2, pp. 174–186, https://doi.org/10.1016/j.gce.2021.01.004

Dong, L, Wang, Z, Zhang, Y, Lu, J, Zhou, E, Duan, C & Cao, X 2019, ‘Study on pyrolysis characteristics of coal and combustion gas release in inert environment’, Journal of Chemistry, vol. 9, pp. 1–9, https://doi.org/10.1155/2019/1032529

Dwivedi, A 2022, ‘Investigations of the ultimate and proximate analysis of coal samples from the Singrauli Coalfield, India’, International Journal of Current Science Research and Review, vol. 5, no. 1, pp. 198-202, https://doi.org/10.47191/ijcsrr/V5-i1-23

Dwivedi, KK, Chatterjee, PK, Karmakar, MK & Pramanick, AK 2019, ‘Pyrolysis characteristics and kinetics of Indian low-rank coal using thermogravimetric analysis’, International Journal of Coal Science and Technology, vol. 6, pp. 102–112, https://doi.org/10.1007/s40789-019-0236-7

Dwivedi, KK, Prabhansu, Karmakar, MK & Chatterjee, PK 2020, ‘Thermal degradation, characterization and kinetic modeling of different particle size coal through TGA’, Thermal Science and Engineering Progress, vol. 18, 100523, https://doi.org/10.1016/j.tsep.2020.100523

Gao, F, Jia, Z, Shan, YF, Teng, Y, Li, YD, Pu, XG 2022, ‘Influence of organic sulfur on low-temperature oxidation of coal and its transition characteristics’, ACS Omega, vol. 7, pp. 39830–39839, https://doi.org/10.1021/acsomega.2c03824

Guan, S, Li, Z, Xu, B, Wu, J, Han, J, Guan, T, Wang, J & Li, K 2023, ‘Deep eutectic solvents with excellent catalytic ability for extractive and oxidative desulfurization under room temperature’, ACS Sustainable Chemistry & Engineering, vol. 11, pp. 6292–6301, https://doi.org/10.1021/acssuschemeng.2c07647

Haruna, A, Merican Aljunid, Z & Gani Musa, S 2022, ‘Sulfur removal technologies from fuel oil for safe and sustainable environment’, Fuel, vol. 329, 125370, https://doi.org/10.1016/j.fuel.2022.125370

Hassid, A, Klinger, M, Krzack, S & Cohen, H 2022, ‘TGA-DSC combined coal analysis as a tool for QC (quality control) and reactivity patterns of coals’, ACS Omega, vol. 7, pp. 1893–1907, https://doi.org/10.1021/acsomega.1c05296

Hou, X, Duan, H, He, R, Zhou, H, Ban, Y, Li, N, Zhi, K, Song, Y & Liu, Q 2023, ‘Effect of ionic liquids on the microstructure and combustion performance of Shengli lignite’, RSC Advances, vol. 13, pp. 23669–23681, https://doi.org/10.1039/d3ra03976e

Ismail, SNAS, Ishak, MAM, Ismail, K, Nawawi, WI, Kasim, NN, Ani, AY, Alias, AB & Ahmad, R 2023, ‘Optimization studies of coal organic sulfur removal using potassium carbonate and ethylene glycol as a deep eutectic solvent’, Malaysian Journal of Chemistry, vol. 25, no. 3, pp. 97-106, https://doi.org/10.55373/mjchem.v25i3.97

Jablonský, M & Šima, J 2022, ‘Is it correct to name DESs deep eutectic solvents?’, Bioresources, vol. 17, no. 3, pp. 3880-3882, https://doi.org/10.15376/biores.17.3.3880-3882

Jha, D, Maheshwari, P, Singh, Y, Haider, MB, Kumar, R & Balathanigaimani, MS 2023, ‘A comparative review of extractive desulfurization using designer solvents: Ionic liquids & deep eutectic solvents’, Journal of Energy Institute, vol. 110, 101313, https://doi.org/10.1016/j.joei.2023.101313

Kartohardjono, S, Karamah, EF, Hayati, AP, Talenta, GN, Ghazali, TA & Lau, WJ 2024, ‘Effect of oxidants in the utilization of polysulfone hollow fiber membrane module as bubble reactor for simultaneously removal of NOx and SO2’, International Journal of Technology, vol. 15, pp. 63–74, https://doi.org/10.14716/ijtech.v15i1.6415

Kuang, Y, Cai, S, Zhang, L & Zhang, S 2022, ‘Transformation behaviour of pyrite during microwave desulfurization from coal: Phase and structural change of Fe-S compounds’, Fuel, vol. 316, 123284, https://doi.org/10.1016/j.fuel.2022.123284

Kumorow, AC, Wardhani, DH, Kusworo, TD, Djaeni, M, Ping, TC & Alhanif, M 2024, ‘Deep eutectic solvents and natural deep eutectic solvents for extraction and purification of proteins from animal and botanical sources - A review’, International Journal of Technology, https://doi.org/10.14716/ijtech.v15i5.6925

Le, BT, Xiao, D, Mao, Y & He, D 2018, ‘Coal analysis based on visible-infrared spectroscopy and a deep neural network’, Infrared Physics & Technology, vol. 93, pp. 34–40, https://doi.org/10.1016/j.infrared.2018.07.013

Lima, F, Branco, LC, Silvestre, AJD & Marrucho, IM 2021, ‘Deep desulfurization of fuels: Are deep eutectic solvents the alternative for ionic liquids?’, Fuel, vol. 293, 120297, https://doi.org/10.1016/j.fuel.2021.120297

Liu, J, Wang, Z, Qiao, Z, Chen, W, Zheng, L & Zhou, J 2020, ‘Evaluation on microwave-assisted chemical desulfurization for organic sulfur removal’, Journal of Cleaner Production, vol. 267, article 121878, https://doi.org/10.1016/j.jclepro.2020.121878

Mako?, P & Boczkaj, G 2019, ‘Deep eutectic solvents based highly efficient extractive desulfurization of fuels – Eco-friendly approach’, Journal of Molecular Liquids, vol. 296, 111916, https://doi.org/10.1016/j.molliq.2019.111916

Meng, X, Zhou, P, Li, L, Liu, L, Guo, M & Sun, T 2020, ‘A study of the desulfurization selectivity of a reductive and extractive desulfurization process with sodium borohydride in polyethylene glycol’, Scientific Reports, vol. 10, pp. 1–9, https://doi.org/10.1038/s41598-020-67235-8

Mittal, S, Pathak, S, Dhawan, H & Upadhyayula, S 2021, ‘A machine learning approach to improve ignition properties of high-ash Indian coals by solvent extraction and coal blending’, Chemical Engineering Journal, vol. 413, 127385, https://doi.org/10.1016/j.cej.2020.127385

Mogk, D 2021, Physical Instruments 5600 XPS instrument at the X-Ray Photoelectron Spectroscopy (XPS; aka Electron Spectroscopy for Chemical Analysis, ESCA), tersedia online di: https://serc.carleton.edu/msu_nanotech/methods/xps.html

Morley, RJ, Scaroni, AW & Pisupati, SVLN 2017, Coal utilization, tersedia online di: https://www.britannica.com/technology/coal-utilization

Mulia, K, Adam, D, Zahrina, I & Krisanti, EA 2018, ‘Green extraction of palmitic acid from palm oil using betaine-based natural deep eutectic solvents’, International Journal of Technology, vol. 9, pp. 335–344, https://doi.org/10.14716/ijtech.v9i2.1008

Nandiyanto, ABD, Oktiani, R & Ragadhita, R 2019, ‘How to read and interpret FTIR spectroscope of organic material’, Indonesian Journal of Science and Technology, vol. 4, pp. 97–118, https://doi.org/10.17509/ijost.v4i1.15806

Onifade, M, Lawal, AI, Aladejare, AE, Bada, S & Idris, MA 2022, ‘Prediction of gross calorific value of solid fuels from their proximate analysis using soft computing and regression analysis’, International Journal of Coal Preparation and Utilization, vol. 42, pp. 1170–1184, https://doi.org/10.1080/19392699.2019.1695605

Rasheed, MA, Rao, PL, Boruah, A, Hasan, SZ, Patel, A, Velani, V & Patel, K 2015, ‘Geochemical characterization of coals using proximate and ultimate analysis of Tadkeshwar Coals, Gujarat’, Geosciences, vol. 5, pp. 113–119, https://doi.org/10.5923/j.geo.20150504.01

Ravi, T, Masri, AN & Ibrahim, IM 2024, ‘Choline-based deep eutectic solvent for extractive oxidative desulfurization of model oil’, E3S Web of Conferences, vol. 488, 03004, https://doi.org/10.1051/e3sconf/202448803004

Rogoši?, M & Ku?an, KZ 2019, ‘Deep eutectic solvents based on choline chloride and ethylene glycol as media for extractive denitrification/desulfurization/dearomatization of motor fuels’, Journal of Industrial and Engineering Chemistry, vol. 72, pp. 87–99, https://doi.org/10.1016/j.jiec.2018.12.006

Sajid, M, Khan, N, Shah, F, Kashif, M & Khan, S 2022, ‘Geochemical characteristics of coal seams within the Paleocene Patala formation, central salt range coal mines (Punjab), Northern Pakistan’, Journal of Sedimentary Environments, vol. 7, pp. 251–260, https://doi.org/10.1007/s43217-022-00098-3

Samaila, MB, Muhammad, BG, Adam, AH, Moumouni, A & Bello, S 2020, ‘Characterization of coal obtained from the Sahelian regions of Nigeria and Niger Republic’, Journal of Applied Sciences and Environmental Management, vol. 24, pp. 299–302, https://doi.org/10.4314/jasem.v24i2.16

Samsudin, S, Aziz, NA, Hairuddin, AA & Masuri, SU 2021, ‘Developing sub-bituminous coal sintering ratio for predicting coal ash slagging factors’, International Journal of Technology, vol. 12, pp. 791–801, https://doi.org/10.14716/ijtech.v12i4.4892

Sandfeld, T, Marzocchi, U, Petro, C, Schramm, A & Risgaard-Petersen, N 2020, ‘Electrogenic sulfide oxidation mediated by cable bacteria stimulates sulfate reduction in freshwater sediments’, ISME Journal, vol. 14, pp. 1233–1246, https://doi.org/10.1038/s41396-020-0607-5

Shen, L, Pang, S, Zhong, M, Sun, Y, Qayum, A, Liu, Y, Rashid, A, Xu, B, Liang, Q & Ma, H 2023, ‘A comprehensive review of ultrasonic assisted extraction (UAE) for bioactive components: Principles, advantages, equipment, and combined technologies’, Ultrasonics Sonochemistry, vol. 101, 106646, https://doi.org/10.1016/j.ultsonch.2023.106646

Shen, Y, Hu, Y, Wang, M, Bao, W, Chang, L & Xie, K 2021, ‘Speciation and thermal transformation of sulfur forms in high-sulfur coal and its utilization in coal-blending coking process: A review’, Chinese Journal of Chemical Engineering, vol. 35, pp. 70–82, https://doi.org/10.1016/j.cjche.2021.04.007

Solomon, AR, Aliyu, J, Jukius, DP & Ronald, MK 2016, ‘Ultimate analysis of some Nigerian coal: Ranking and suitable application’, International Journal of Engineering and Applied Sciences, vol. 3, pp. 31–35, https://www.ijeas.org/download_data/IJEAS0310002

Tahir, S, Qazi, UY, Naseem, Z, Tahir, N, Zahid, M, Javaid, R & Shahid, I 2021, ‘Deep eutectic solvents as alternative green solvents for the efficient desulfurization of liquid fuel: A comprehensive review’, Fuel, vol. 305, 121502, https://doi.org/10.1016/j.fuel.2021.121502

Tang, L, Chen, S, Gui, D, Zhu, X, He, H & Tao, X 2020, ‘Effect of removal organic sulfur from coal macromolecular on the properties of high organic sulfur coal’, Fuel, vol. 259, 116264, https://doi.org/10.1016/j.fuel.2019.116264

Tang, L, Fan, H, Guo, J, Zeng, W & Tao, X 2018, ‘Investigation on the mechanism of coal desulfurization by ultrasonic with peroxyacetic acid’, Energy Sources, Part A: Recovery, Utilization and Environmental Effects, vol. 40, pp. 999–1009, https://doi.org/10.1080/15567036.2018.1468512

Tang, Y, Chen, C, Li, X, Wei, Q, Guo, X, Finkelman, RB, Li, W & Xuan, H 2021, ‘The evolution characteristics of organic sulfur structure in various Chinese high organic sulfur coals’, Energy Exploration and Exploitation, vol. 39, no. 1, pp. 336–353, https://doi.org/10.1177/0144598720975142

Wang, L, Jin, G & Xu, Y 2019, ‘Desulfurization of coal using four ionic liquids with [HSO4]?’, Fuel, vol. 236, pp. 1181–1190, https://doi.org/10.1016/j.fuel.2018.09.082

Wang, L, Zhou, C, Shen, L, Long, Y & Shen, D 2023, ‘Sulfur transformation and thermogravimetric analysis of model compounds in oxygen carrier aided pyrolysis/gasification process’, Chemical Engineering Journal, vol. 474, 145856, https://doi.org/10.1016/j.cej.2023.145856

Wang, Z, Cui, H, Xu, H & Sheng, Y 2022, ‘Decorated reduced graphene oxide transfer sulfides into sulfur and sulfone in wastewater’, RSC Advances, vol. 12, pp. 28586–28598, https://doi.org/10.1039/d2ra04323h

Wazeer, I, Hadj-Kali, MK & Al-Nashef, IM 2020, ‘Utilization of deep eutectic solvents to reduce the release of hazardous gases to the atmosphere: A critical review’, Molecules, vol. 26, pp. 1–34, https://doi.org/10.3390/molecules26010075

Xi, Z, Xi, K & Lu, L 2023, ‘Study on oxidation characteristics and conversion of sulfur-containing model compounds in coal’, Fuel, vol. 331, 125756, https://doi.org/10.1016/j.fuel.2022.125756

Xu, Y, Liu, Y, Xie, H, Chen, M & Wang, L 2020, ‘Experimental study on organic sulfur removal in bituminous coal by a 1-carboxymethyl-3-methyl imidazolium bisulfate ionic liquid and hydrogen peroxide solution’, ACS Omega, vol. 5, pp. 21127–21136, https://doi.org/10.1021/acsomega.0c02795

Yang, D, Zhang, S, Jiang, DE & Dai, S 2018, ‘SO2 absorption in EmimCl-TEG deep eutectic solvents’, Physical Chemistry Chemical Physics, vol. 20, pp. 15168–15173, https://doi.org/10.1039/c8cp02250j

Yang, X, Liu, J, Zhong, X, Jiang, Y & Jiang, X 2021, ‘Synergistic mechanisms of mechanochemical activation on the mild oxidative desulfurization of superfine pulverized coal’, Fuel, vol. 303, 121253, https://doi.org/10.1016/j.fuel.2021.121253

Yang, X, Wang, B, Guo, Y, Yang, F & Cheng, F 2024, ‘Co-hydrothermal carbonization of sewage sludge and coal slime for clean solid fuel production: A comprehensive assessment of hydrochar fuel characteristics and combustion behavior’, Biomass Conversion and Biorefinery, vol. 14, pp. 14491–14503, https://doi.org/10.1007/s13399-022-03601-y

Zeng, P, Wu, D, Wang, T, Liu, P & Jia, D 2024, ‘Redefine the existence form and function of water in potassium carbonate-based deep eutectic electrolyte’, Fuel, vol. 357, 129738, https://doi.org/10.1016/j.fuel.2023.129738

Zhao, Q, Qin, S, Zhao, C, Sun, Y, Panchal, B & Chang, X 2021, ‘Origin and geological implications of super high sulfur-containing polycyclic aromatic compounds in high-sulfur coal’, Gondwana Research, vol. 96, pp. 219–231, https://doi.org/10.1016/j.gr.2021.04.012