Comprehensive Characteristics of High-Performance Concrete with Nickel Slag as Fine and Coarse Aggregate

Corresponding email: lisa@trisakti.ac.id

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.7184

Nelfia, L.O., Haq, A.B.N., Nugroho, A., Rinanti, A., Yuwono, B.E., Syamsunur, D., Sunarno, Y., Amiri, O., 2024. Comprehensive Characteristics of High-Performance Concrete with Nickel Slag as Fine and Coarse Aggregate. International Journal of Technology. Volume 15(6), pp. 1613-1631

| Lisa Oksri Nelfia | Department of Civil Engineering, Faculty of Civil Engineering and Planning, Universitas Trisakti, Jakarta 11440, Indonesia |

| Ananda Bima Nurul Haq | Department of Civil Engineering, Faculty of Civil Engineering and Planning, Universitas Trisakti, Jakarta 11440, Indonesia |

| Ananto Nugroho | Research Center for Biomass and Bioproducts, BRIN, Cibinong 16911, Indonesia |

| Astri Rinanti | Department of Environmental Engineering, Faculty of Landscape Architecture and Environmental Technology, Universitas Trisakti, Jakarta 11440, Indonesia |

| Bambang Endro Yuwono | Department of Civil Engineering, Faculty of Civil Engineering and Planning, Universitas Trisakti, Jakarta 11440, Indonesia |

| Deprizon Syamsunur | Department of Civil Engineering, Faculty of Engineering, Technology and Built Environment, UCSI University, Kuala Lumpur 56000, Malaysia |

| Yohans Sunarno | Department of Civil Engineering, Faculty of Engineering, Bosowa University, Makasar 90231, Indonesia |

| Ouali Amiri | 1. Polytech’Nantes, Nantes Université, 44603 Saint-Nazaire, France. 2. Nantes Université, Ecole Centrale Nantes, CNRS, GeM, UMR 6183, F-44000 Nantes, France |

This study aimed to

determine the effect of using nickel slag as an alternative aggregate for

high-performance concrete. To achieve the aim, nickel slag aggregate with

particle sizes of 0/5 mm and 10/20 mm was considered, using X-ray Diffraction

(XRD) to analyze the compounds and minerals contained in the slag content. The

investigation incorporated up to 20% Ground Granulated Blast-furnace Slag

(GGBFS) as a cement substitute, while systematically replacing natural

aggregate with nickel slag at a varying proportions of 0%, 20%, 40%, 60%, 80%,

and 100%. The experimental result showed that Mix 2 combination achieved the

highest compressive strength of 69.43 MPa. This outcome exceeded the reference

concrete by 11.56% and fulfilled the classification of high-performance

concrete. Additionally, XRD testing of Mix 2 samples identified the dominant

compounds as C6H6O2, (Fe, Mg)SiO3,

and SiO2. The results signified the promising potential of using

nickel slag aggregate in concrete production, suggesting significant economic

benefit for the construction industry. The outcome of this study could

contribute to the growth of construction industry and reassure stakeholders

about the financial viability of the project. Finally, this potential for

high-performance concrete using nickel slag aggregate would create more

opportunities for the future of construction industry.

Compressive strength; Construction; Granulated blast-furnace slag; High-performance concrete; Nickel slag aggregate

Indonesia is considered a country with largest nickel reserve in the world, amounting to approximately 52% of the global reserves according to the latest data from Ministry of Energy and Mineral Resources in 2020 (Radhica, 2023). However, the production capacity of nickel in the country remains limited, at around 1 million metric tons, contributing only about 37.04% to the total global nickel production.

This limitation often becomes a focal point of concern,

specifically with the continuously increasing demand for industrial raw

materials in the international market, such as electric vehicle batteries and

other green technologies. Anticipating the constantly rising demand, Indonesian

government has taken proactive measures, such as implementing a policy banning

the export of raw minerals in early 2020. Despite the challenges, these

measures show the commitment of government to maintaining a reliable global

supply of nickel. Government plays a crucial role in managing nickel reserves

of the country, providing essential context for the study and signifying its

broader implications (Radhica, 2023; U.S.G.S.,

2022). Therefore, this policy aims to stimulate growth in the local

processing industry, improve domestic economic value, and safeguard nickel

reserves for the sustainable development of the national economy. The strategic

steps reflect unwavering commitment of Indonesia to harness its natural

resource potential while prioritizing the need to address the increasing global

environmental concerns. The initiatives of government to promote the use of

nickel slag in various industries such as construction are crucial, creating

opportunities for a more sustainable future and reassuring stakeholders about

the commitment of the country to responsible development.

The introduction of policy prohibiting export of

unprocessed minerals is expected to stimulate growth in nickel production

sector in Indonesia. However, the rise in nickel production requires a

corresponding increase in the generation of nickel waste. The waste produced

during nickel smelting process typically consists of solid or agglomerated

substances. Solid waste and nickel slag can generate up to fifty times more

nickel products than the quantity created during refining nickel. This

potential for increased productivity is a promising aspect of the policy change

(Aprianto and Triastianti, 2018). The

amendment shows the importance of concerted efforts to mitigate the

environmental impact of nickel waste through study and technological

innovation.

This study aims to develop the use of nickel slag and

reduce its negative environmental impact. Waste handling systems should be

performed correctly to avoid provoking ecological problems (Oksri-Nelfia, Akbar, and Astutiningsih, 2020; Mustika, Salain,

and Sudarsana, 2016). In addition, the slag shows potential for

effective use in concrete production, replacing coarse as well as fine

aggregate and a substitute for cement. The study signifies that incorporating

nickel slag in concrete can improve properties such as compressive strength,

pulse velocity, and stiffness while reducing Poisson's ratio compared to

traditional concrete mixes (Amir et al.,

2022). Combining the slag with fly ash in concrete mixtures has further

improved mechanical strength and durability, particularly in marine

environments (Ahmad et al., 2022).

Moreover, nickel slag powder shows promise as a cement substitute in

high-performance concrete, with favorable split tensile strength values

observed in studies (Nabiilah, Nelfia, and

Astutiningsih, 2019). The material composition, containing 41.47% Silica

(Si) and 30.44% Ferro (Fe), renders it suitable for cement substitution (Sugiri, Saloma, and Yulianti, 2007; Aprianto and Triastianti,

2018).

Despite the future application of nickel slag in Indonesia,

international studies show its broad applicability in concrete buildings (Saha and Sarker, 2020) conducted a comprehensive

review of the global use of the materials, signifying its efficacy in improving

mechanical properties and durability under several climatic conditions.

Similarly, (Nuruzzaman et al., 2020)

tested high-strength self-compacting concrete such as ferronickel slag as fine

aggregate in Australia, finding significant improvements in compressive

strength and workability. (Saha and Sarker, 2017b)

study showed the sustainability of incorporating ferronickel slag into

concrete, signifying its environmental benefits in waste reduction and

conserving resources. (Sun, Feng, and Chen, 2019) found

that ferronickel slag improved compressive strength and chloride ion resistance

in concrete in Taiwan, allowing it to be appropriate for coastal applications

(Han et al., 2023). Additionally, the material proved the cost-effectiveness

and durability of nickel slag in large-scale infrastructure projects in the

Middle East, implying its global value as an environmentally friendly

construction material.

Previous studies used nickel slag to replace cement and

aggregate in concrete compositions. Consequently, using the material to replace

aggregate has often been restricted to a single material category. There is a

scarcity of studies that use nickel slag to replace all categories of

aggregate, including fine and coarse in top-notch concrete. Based on

accumulating evidence, recent studies have shown that nickel slag can replace

all forms of aggregate in high-quality concrete. However, further results and

experimentation are still needed to fully optimize the use of the material in

different types of concrete groups to guarantee its efficacy and sustainability

in the building sector.

Study by (Nuruzzaman et al.,

2020) investigated the use of nickel slag as coarse aggregate, with

varying compositions of 0%, 20%, 40%, and 60%. The result reported that the

highest compressive strength achieved was 65.78 MPa, observed at a composition

of 40% Ferro Nickel Slag (FNS). Additionally, the maximum tensile strength

recorded was 4.96 MPa for FNS40 composition. The study included evaluations of

sportive properties and RCPT (Rapid Chlorite Penetration Test). Significantly,

the lowest tensile strength, measured at 8.0 x 10-3 mm/s0.5, was

observed for FNS40 composition, showing relatively poor performance. RCPT

results for this composition were categorized as very low, signifying potential

durability concerns.

Recent investigations have shown that ferronickel slag can

potentially replace fine and coarse aggregate. (Zhang

et al., 2020b) described that incorporating this slag rather than

natural aggregate in high-performing concrete improved mechanical properties

such as compressive strength. (Sun, Feng, and Chen,

2019) found that ferronickel slag used as fine aggregate significantly

increased the durability and strength of concrete. Further studies validate

using the material as coarse and fine aggregate. The process shows that this

industrial by-product can improve concrete characteristics when used in

appropriate ratios (Nuruzzaman, Kuri, and Sarker,

2022; Zhang et al., 2020b). Further studies signify that the

combined application of ferronickel slag as coarse and fine aggregate may

increase the mechanical properties of concrete. Adding the material in both

forms in high-performance concrete significantly increased compressive

strength, showing the combined effects of this dual method (Ernawan et al., 2023). Following this

discussion, an investigation by (Han et al.,

2023) described that using a combination of ferronickel slag as both

fine and coarse aggregate increased compressive and flexural strengths and

improved the entire workability of concrete mixture. Study by (Saha and Sarker, 2017a) and (Nuruzzaman et al., 2024) showed that the

material might improve compressive and flexural strength, proving the

possibility of using nickel slag for different concrete applications.

Improving scalability of ferronickel slag has been a

significant focus of recent studies. (Ngii et

al., 2021) investigated methods to handle nickel slag for

application in concrete. Based on the results of (Jaganmohan,

2024), largest nickel reserves globally are in Indonesia, with 55

million metric tons, followed by Australia, 24 million metric tons, and Brazil,

16 million metric tons. According to this finding, the most significant nickel

production during 2023 was in Indonesia, with a production of 1.8 million

metric tons, followed by Philippines, which produced 400 thousand metric tons,

and New Caledonia, which produced 230 thousand metric tons. Signifying the

importance of standardizing these procedures for improving accessibility, (Huang, Wang, and Shi, 2017) and

(Saha and Sarker, 2016) showed that cooperation between mining and

construction industries could potentially overcome logistical optimization

constraints as well as source difficulties. (Han et

al., 2023) and (Ojha and Singh, n.d.) described

that innovative methods were also found to improve the general quality of

ferronickel slag, increasing its long-term economic potential. Finally, (Edwin et al., 2016) and (BPK RI, 2014) signified that inspiring local

policies could facilitate using nickel slag in buildings. Although the availability

and scalability of the material remained challenging, continuing studies and

strategic methods have created opportunities for its increasingly broad

application in environmentally friendly construction.

This study explores the feasibility of incorporating nickel

slag as a partial or complete replacement for all types of aggregate in

concrete production, including fine and coarse. The physical, chemical, and

mineralogical characteristics of the material were comprehensively examined to

assess its suitability for such applications. The study included comprehensive

testing of physical and mechanical properties as well as durability aspects of

concrete, consisting of workability, compressive strength, tensile strength,

permeability, X-ray diffraction (XRD), and Fourier-Transform Infrared

Spectroscopy (FTIR). During this study, testing was conducted on samples aged

for 28 days, with the composition of nickel slag used, substituting up to 0%,

20%, 40%, 60%, 80%, and 100% of the total required amount for each coarse and

fine aggregate.

2.1. Material

Binder

material used was cement OPC, which was from Semen Tiga Roda industry, and

Ground Granulated Blast Furnace Slag (GGBFS), produced by PT. Krakatau Semen

Indonesia (KSI). Table 1 showed the characteristics of binder used in this

study. The chemical composition of this binder was assessed through X-ray

fluorescence (XRF) using EPSILON 5 analyzer tool, following the standard test

method reviewed in (ASTM, 2013b) for

chemical analysis of metal samples, and the results were shown in Table 2. The

superplasticizer (SP) used in this study was Sika Viscocrete 3115N, which

described the density in Table 1.

Table 1 Density of Ordinary Portland Cement, GGBFS, and Superplasticizer

|

Material |

Density (g/cm3) |

|

OPC Type 1 Tiga

Roda |

3.13 |

|

GGBFS |

2.83 |

|

Superplasticizer |

1.05 |

Table 2 Chemical Composition of Binders

|

Chemical

Composition |

OPC |

GGBFS |

Nickel Slag |

|

CaO |

63.2 |

44.71 |

24.71 |

|

Al2O3 |

4.96 |

14.74 |

9.69 |

|

SiO2 |

18.45 |

35.93 |

41.24 |

|

Fe2O3 |

2.86 |

1.02 |

1.71 |

|

SO3 |

2.18 |

0.55 |

0.90 |

|

MgO |

3.52 |

0.28 |

19.29 |

|

K2O |

0.31 |

0.29 |

0.17 |

|

Na2O |

0.15 |

0.02 |

0.24 |

|

LOI |

3.42 |

1.98 |

- |

|

TiO2 |

- |

0.33 |

0.26 |

|

Mn2O3 |

- |

0.14 |

0.83 |

|

IR |

- |

0.32 |

- |

|

C3S |

68.72 |

- |

- |

|

C3A |

8.3 |

- |

- |

|

C4AF |

8.7 |

- |

- |

Nickel slag used in

this investigation was obtained from Southeast Sulawesi, Indonesia. The

physical characteristics of the material varied by area depending on

differences in ore composition, smelting methods, and cooling process.

Moreover, nickel slag used in this study was obtained from PT-Growth Java in

Cilegon, Indonesia, which processed lateritic nickel ores from Southeast

Sulawesi. Lateritic ores included substantial amounts of iron and aluminum,

producing nickel slag with elevated iron oxide levels, affecting its structural

performance. Consequently, the material deriving from sulfide ores, such as

those in Russia or Canada, had higher levels of sulfur and magnesium, causing

variances in mineralogical properties as well as leaching behavior (Putera et al., 2023).

This study comprehensively analyzed the

chemical and physical properties of nickel slag, verifying the effectiveness as

a substitute for fine and coarse aggregate in concrete across geographic

sources. Previous investigations confirmed that the material from different

locations was efficiently used as building materials (Saha

and Sarker, 2020; Zhang et al., 2020b; Wu et al., 2018; Lee et

al., 2015).

The analysis included the use of two

nickel slag aggregate including fine (0/5 mm), which replaced natural fine, and

coarse (10/20 mm), as substitute for natural coarse. The particle size of the

material was categorized based on sieve size. Moreover, the fractions of 0- 5

mm and 10 - 20 mm represented particles that passed through 5 mm and 20 mm

sieves, respectively, with the lower number showing the minimum size as well as

the upper number the maximum amount.

During the investigation, the

experiment derived natural coarse aggregate from Quarry of Mount Holcim, Bogor.

Following the discussion, natural fine was obtained from Quarry of MBS, Bogor.

The specifications of the characteristics of nickel slag and natural aggregate

were shown in Table 3. In addition, the chemical composition of the slag was

obtained through XRF as shown in Table 2.

Table 3 Physical Characteristics of Aggregates

|

Materials |

Specific gravity |

Water

absorption (%) |

Content

weight (kg/m3) |

Fineness

Modulus |

|

Natural

Fine Aggregate |

2.51 |

2.78 |

1487.01 |

3.12 |

|

Nickel

Slag Fine Aggregate |

3.06 |

0.91 |

2034.97 |

2.8 |

|

Natural

Coarse Aggregate |

2.6 |

1.68 |

1489.76 |

- |

|

Nickel

Slag Coarse Aggregate |

2.95 |

0.86 |

1588.41 |

- |

The specific gravity and water absorption of

ferronickel slag were determined using (ASTM, 2015a)

(coarse) and (ASTM, 2015b) (fine

aggregate). Sieve analysis determined the particle size distribution of

ferronickel slag according to (ASTM, 2014).

Nickel slag and GGBFS were industrial solid wastes polluting the environment.

Therefore, the potential for leaching or the leaching of heavy metals in

industrial solid waste was determined by testing Toxicity Characteristic

Leaching Procedure (TCLP). The standard method for TCLP testing was published

by (EPA, 1992). The following results

obtained during this process were shown in Table 4. The concentrations of Heavy

metals in leachate were compared with legal limits, including those set by U.S.

Environmental Protection Agency (EPA) for hazardous waste categorization. The

legal limit of EPA for nickel in leachate was 5 mg/L (EPA,

1990). However, TCLP result for nickel from nickel slag was 7.47 mg/L,

above this restriction. The results showed that concrete using the slag

material required further treatment or incorporation to avert environmental

pollution from nickel leaching and might not be immediately appropriate for use

in groundwater-sensitive places.

The level of other elements, including lead (Pb),

arsenic (As), cadmium (Cd), and hexavalent chromium (Cr), remained lesser than

individual respective regulatory thresholds. The lead content in nickel slag

was 0.06 mg/L, which was less than threshold of EPA of 5 mg/L. These results

signified that the primary concerns of the material were related to nickel

leaching while leaching risks for other analyzed metals were minimal. Although

nickel slag concrete had potential for various applications, the elevated nickel

content was mitigated to guarantee environmental safety and obedience to

regulatory standards. Additional investigation into treatment methodologies or

other applications with less leaching hazards was required (Astuti et al., 2024; Wanta et al., 2022).

Table 4 Toxicity Characteristic

Leaching Procedure (TCLP) of Nickel Slag and GGBFS

|

Parameters |

Nickel

Slag |

GGBFS |

|

Antimony

(Sb) |

<

0.04 |

0.4 |

|

Arsenic

(As) |

<

0.07 |

< 1 |

|

Barium

(Ba) |

0.03 |

- |

|

Beryllium

(Be) |

<

0.03 |

- |

|

Boron

(B) |

0.05 |

- |

|

Cadmium

(Cd) |

<

0.01 |

2.27 |

|

Hexavalent

Chromium (Cr) |

<

0.01 |

<3 |

|

Copper

(Cu) |

<

0.01 |

46.35 |

|

Lead

(Pb) |

0.06 |

1.87 |

|

Mercury

(Hg) |

<

0.018 |

<

0.2 |

|

Molybdenum

(Mo) |

<

0.01 |

- |

|

Nickel

(Ni) |

7.47 |

< 1 |

|

Selenium

(Se) |

<

0.13 |

16.98 |

|

Silver

(Ag) |

<

0.03 |

- |

|

Tributyltin

Oxide |

<

0.02 |

- |

|

Zinc

(Zn) |

0.22 |

53.28 |

|

Cobalt

(Co) |

- |

< 2 |

|

Thallium

(Ti) |

- |

<

0.5 |

|

Vanadium

(V) |

- |

134.90 |

2.2. Mix

Proportion

Concrete

used ACI 211.4R-93 standard because the type of concrete pursued aims to be

included as high-performance concrete. The composition of the standard concrete

mix used a cement-water ratio (w/c+p) of 0.317. Moreover, natural fine with a

specific gravity (SSD) of 2.51 kg/m3, fineness modulus of 3.12, and

natural coarse aggregate with a particular gravity (SSD) of 2.60 kg/m3

were used. The composition of concrete mixture had a targeted compressive

strength of fc' = 60 MPa. During this process, concrete was created by

substituting the cement mass with GGBFS up to 20% and substituting nickel slag

of 0%, 20%, 40%, 60%, 80%, and 100%, respectively, of the required totality of

the type of aggregate.

The names as well as

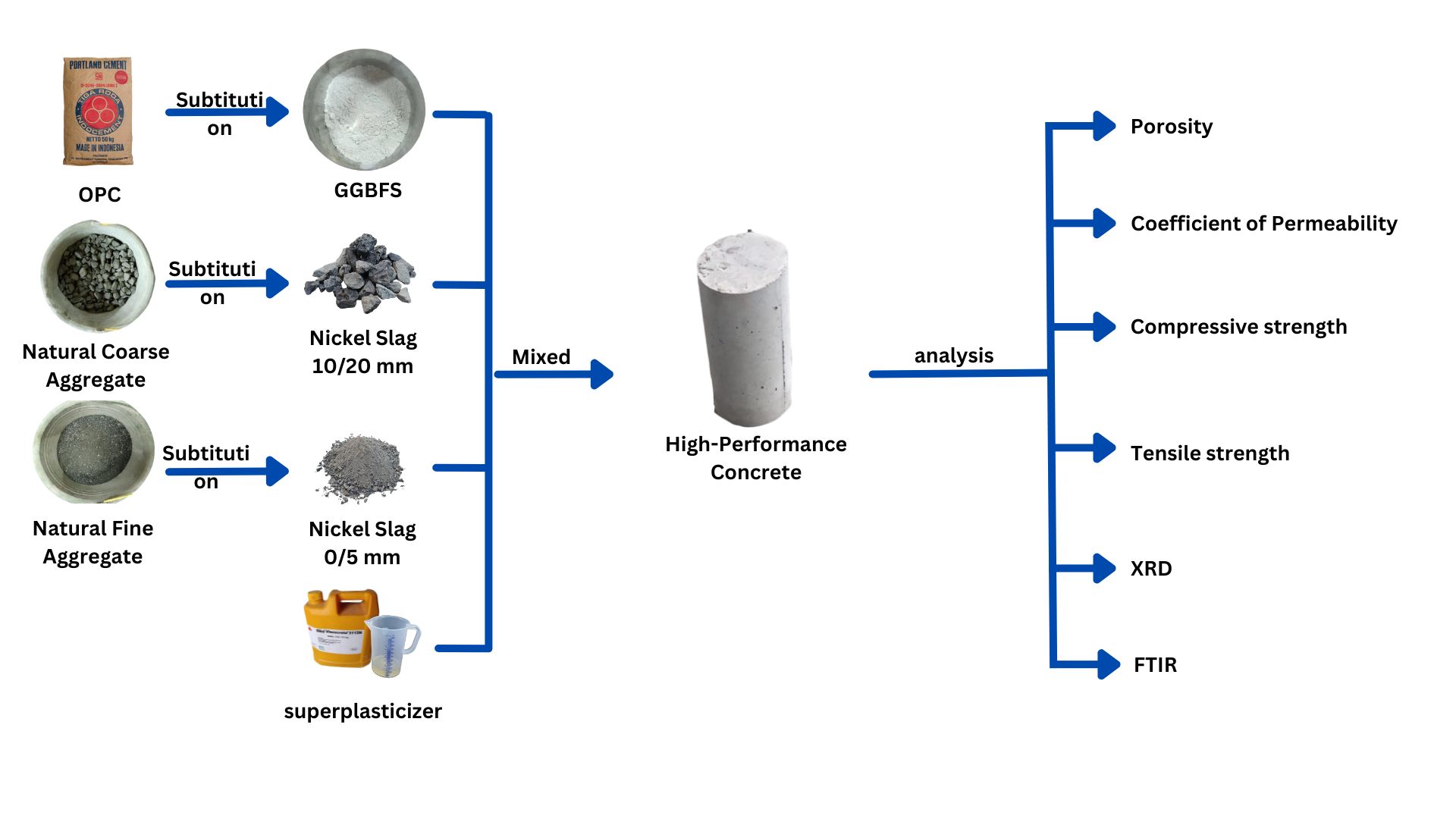

compositions of each planned mixture used were shown in Figure 1 and explained

as follows:

a. a. aRef was a reference concrete in which the mixture used 100% OPC, natural

fine aggregate, as well as natural coarse, water, and 1% superplasticizer of

the total weight of the binders.

b. b. Mix 1 consisted of concrete with 80% OPC, 20% GGBFS, 20% nickel slag fine

aggregate, 80% natural fine, 20% nickel slag coarse, 80% natural coarse, water,

and 1% superplasticizer of the total weight of binders.

c. c. Mix 2 was concrete with 80% OPC, 20% GGBFS, 40% nickel slag fine aggregate,

60% natural fine, 40% nickel slag coarse, 60% natural coarse, water, and 1%

superplasticizer of the total weight of binders.

d. d. Mix 3 comprised concrete with 80% OPC, 20% GGBFS, 60% nickel slag fine

aggregate, 40% natural fine, 60% nickel slag coarse, 40% natural coarse, water,

and 1% superplasticizer of the total weight of binders.

e. e. Mix 4 was concrete with 80% OPC, 20% GGBFS, 80% nickel slag fine aggregate,

20% natural fine, 80% nickel slag coarse, 20% natural coarse, water, and 1%

superplasticizer of the total weight of binders.

Figure 1 Composition of Concrete Mixes, Including Variations in Binder Proportion

(OPC and GGBFS), Aggregate Types (Nickel Slag and Natural Aggregates), and 1%

superplasticizer dosage

Table 5 Mix Design of the studied concrete (in

kg/m3)

|

Mix id |

Binders |

Fine aggregate |

Coarse aggregate |

Water |

SP | |||

|

OPC |

GGBFS |

Natural |

Nickel Slag |

Natural |

Nickel Slag | |||

|

Ref |

638.95 |

0,00 |

460.69 |

0.00 |

1013.04 |

0.00 |

202.63 |

6.38 |

|

Mix 1 |

511.16 |

127.79 |

368.55 |

92.14 |

810.43 |

202.61 |

202.63 |

6.38 |

|

Mix 2 |

511.16 |

127.79 |

276.41 |

184.27 |

607.82 |

405.21 |

202.63 |

6.38 |

|

Mix 3 |

511.16 |

127.79 |

184.27 |

276.41 |

405.21 |

607.82 |

202.63 |

6.38 |

|

Mix 4 |

511.16 |

127.79 |

92.14 |

368.55 |

202.61 |

810.43 |

202.63 |

6.38 |

|

Mix 5 |

511.16 |

127.79 |

0.00 |

460.69 |

0.00 |

1013.04 |

202.63 |

6.38 |

According

to Table 5, the quantity of cement used in this concrete reference was 581.52

kg/m3. This quantity remained in the permissible limits for concrete

mixes since the material did not exceed 593 kg/m3, as stated in ACI standards 211.4R-08 (ACI 211.4R-08, 2008).

2.3. Test Methods

During this study, compressive strength

referred to (ASTM, 2021a) C39 standard.

Compressive strength of concrete samples aged 28 days was evaluated using 2000

kN digital concrete compression machine manufactured by MBTES. Following this

discussion, tensile solid strength referred to (ASTM,

2020) C1583 standard. Tensile strength was tested on samples aged 28

days using the same compressive strength tools from MBTES brand.

Testing the permeability of concrete in

this study used gas or air permeability method. This test referred to (UNI, 2005) 11164 standard applying controls Mod.

58-E0031 tool. The examination used the pressure of oxygen gas passing through

concrete to measure the permeability coefficient. Porosity testing conducted in

this investigation aimed to determine the percentage of pores in concrete,

which was referred to (ASTM, 2021b) C642-90

standard.

XRD was used to identify the crystal

structure of a mineral by using the diffraction in the crystal lattice. During

the study, ASTM D934-13 standard provided methodologies to conduct XRD

analysis, permitting accurate determinations of crystalline phases in

ferronickel slag or related materials. Comprehensive sample preparation,

precise tool calibration, and accurate database reference were essential for

reliable findings. This process led to a diffraction pattern that reflect the

crystal structure. Relating to the process, the instrument used was Shimadzu

XRD-7000 type. A diffractometer with a Cu source that had a wavelength of at a scanning speed of 2s/step and a diffraction angle between 5° and

50° was used for conduction testing, as XRD was based on Bragg's law. The

specimens used in this experiment were first smoothened, and each specimen

passed No. 200 sieve. The tested sample consisted of conventional/Ref concrete,

and concrete test specimens achieved the highest compressive strength.

3.1. Workability

Workability testing in this study was conducted using slump test method, which was referred to (ICONTEC, 2018) NTC 396 or (ASTM, 2015c) C143/C143M-15. The test was conducted using Abrams cone apparatus with dimensions of 150 mm in height and 100 mm in diameter. Following the completion of slump test, concrete was poured into a cylindrical formwork with a diameter of 100 mm and a height of 200 mm. After 24 hours, concrete was then extracted from the formwork and placed in curing bath for a full day before the desired age was achieved.

Figure 2 showed the results of slump test during the investigation. The slump value predominantly increased by 4% to 6%, except for Mix 3, which decreased by 2%. This outcome supported the results of (Edwin et al., 2019), where a slump value increase was observed in nickel slag concrete. Additional studies supported this result and signified that as the percentage of nickel slag in concrete mix increased, the slump value also increased, reflecting improved workability. Moreover, investigations into using the slag material as a fine aggregate in concrete showed varying effects on slump values across different mixtures, ranging from a decrease of 39.47% to an increase of 55.26% (Ngii et al., 2021). These results implied a positive impact of incorporating nickel slag in concrete, leading to improved workability characterized by higher slump values as the slag content increased.

Figure 2 Results of the Slump Test Conducted Using Abrams Cone Apparatus Under Standard Conditions

During the analysis of this study, GGBS significantly affected the workability of concrete. Replacing GGBS had shown to increase the slump of concrete, signifying its impact on the properties of fresh concrete (Ahmad et al., 2020). This observation was supported by a review discussing the use and efficiency of GGBS. (Özbay, Erdemir, and Durmu?, 2016). Khan et al. (2014) provided additional insights into the effects of mineral admixtures, including GGBS, on fresh concrete properties.

GGBS, a by-product of iron-making process, served as a high-volume cement replacement, improving the sustainability and strength of concrete. (Onn et al., 2019). The broader effect of GGBS on concrete properties, including structural performance, was shown through an investigation of precast concrete beams with varying GGBS replacement ratios. (Lee et al., 2021). Moreover, incorporating GGBS into concrete improved workability, sustainability, and structural performance, allowing it to be a valuable mineral admixture in concrete production.

3.2. Compressive strength

Compressive strength was tested at 28 days using a Digital Concrete Compression Machine 2000 kN MBTES, and the results for each sample were shown in Figure 3. According to the graph, compressive strength value increased in Mix 2 by 11.56% compared to reference concrete. Meanwhile, the other mixtures decreased by 20.28% compared to reference concrete. This process showed that using nickel slag increased the strength of concrete up to a certain amount (Nuruzzaman et al., 2024; Ahmad et al., 2022; Ngii, Mursidi, and Umar 2020; Nuruzzaman et al., 2020; Edwin et al., 2019). Compressive strength of concretes using nickel slag increased slightly before it decreased. Other studies also signified that concrete mixes containing the slag content showed increased compressive strength and improved workability, achieving higher strength values. (Edwin et al., 2019).

(Dewiandratika, Sukandar, El-Akmam, 2018) signified that concrete strength might decrease with higher nickel slag content due to the larger surface area of the slag per unit volume exposed, potentially leading to inadequate cement content for binding concrete matrix together. These results showed that using nickel slag in concrete formulations improved the strength of the resulting concrete structures. According to (Lee et al., 2015), when the amount of slag in concrete mixtures increased, specifically when the mixtures were older than 365 days, compressive strength also raised. The idea that concrete with a higher nickel slag concentration could eventually have stronger concrete was supported by this study. Some studies showed a positive relationship between the slag content and compressive strength, others proposed potential limitations due to factors such as surface area and cement binding. Therefore, the impact of nickel slag as a substitute for aggregate content on concrete compressive strength was affected by various factors that should be considered in concrete mix design and application.

Figure 3 Compressive Strength Results at 28 Days Tested Using a Digital Concrete Compression Machine

3.3. Tensile strength

Tensile strength was tested at 28 days using a Digital Concrete Compression Machine 2000 kN MBTES, and the results for each sample were shown in Figure 4. Based on the graph, tensile strength obtained had increased compared to reference concrete. Following the discussion, optimum tensile strength was at Mix 3, which was 5.27 MPa. This outcome implied that using GGBFS as a substitute for cement and nickel slag as a replacement for coarse and fine aggregate increased tensile strength of concrete. According to (Nuruzzaman et al., 2020; Suwindu, Parung, and Sandy 2020; Sun, Feng, and Chen, 2019), those that experienced an increase in the value of individual tensile strength were compared to reference concrete.

Figure 4 Tensile Strength Results at 28 Days Tested Using a Digital Concrete Compression Machine

3.4. Gas Permeability Coefficient and Porosity

The test was conducted using air permeability type 58-E0031 by Controls. Oxygen gas pressures of 150, 200, 250, 300, and 350 kPa, were used (Lliso-Ferrando et al., 2023). Figure 5 showed the results of testing and calculating concrete permeability coefficient during the study. Based on Figure 5, permeability coefficient for reference concrete was 6.11E-08. The graph showed an increase in the coefficient compared to reference concrete. However, a decrease of 31.06% in the coefficient was observed in Mix 2.

Figure 5 Permeability Coefficient Results Tested Using an Air Permeability Apparatus

Figure 6 The Results of the Porosity Test Indicate an Increasing Trend Correlated with the Permeability

The results of porosity test conducted in this study were shown in Figure 6. The proportion of porosity showed an upward trend in comparison to permeability. Consequently, Mix 2 reduced porosity percentage by 11.57% compared to reference concrete. The reduction showed a direct proportionality between porosity and permeability coefficient. This process signified that higher porosity values were associated with an increase in permeability coefficient.

Figure 7 Comparison of Porosity and Compressive Strength

The percentage of porosity was also compared to compressive strength, as shown in Figure 7. According to the Figure, as porosity decreased, compressive strength also increased, showing an inverse correlation between the two properties. Therefore, the outcome was hypothesized that the percentage of porosity was inversely proportional to compressive strength. The presence of more pores in concrete led to a decrease in its compressive strength.

GGBFS effectively substituted cement in concrete mixes to reduce gas permeability. Investigation showed that incorporating GGBFS in concrete formulations improved durability by decreasing porosity and capillarity, leading to lower gas permeability (Srikanth et al., 2022). Studies signified that GGBFS increased compressive strength of concrete, with optimal replacement levels around 30% to 40% producing the best results (Chi, Chi, and Wu, 2018). Using slag cement containing GGBFS in concrete mixtures with heavyweight aggregate had shown significant improvements in compressive strength and reduced chloride ingress, further increasing durability. (Jó?wiak?Nied?wiedzka et al., 2020). Therefore, using GGBFS as a partial substitute for cement, specifically in combination with slag cement, effectively reduced gas permeability and improved the general performance of concrete structures.

3.5. X-ray Diffraction (XRD)

This study conducted XRD analysis using 2 Theta ranging from 5° to 70°. The samples examined included nickel slag aggregate with particle sizes of 0/5 and 10/20, conventional concrete (Ref), and Mix 2, selected for optimal compressive strength.

Figure 8 X-ray Diffraction Results of Nickel Slag Aggregate.

Figure 8 showed XRD results for nickel slag samples during the study. In the slag fine aggregate, the predominant compounds identified were CaMg(CO3)2, SiO2, Mg2SiO4, and iron oxide, with a significant peak at 31° as well as a minor peak at 20° (Nuruzzaman, Kuri, and Sarker 2022; Wu et al., 2018). Moreover, the dominant compounds observed in nickel slag coarse aggregate were Mg3Al2(SiO4)3, iron oxide, and SiO2.

Figure 9 Comparison of X-ray Diffraction (XRD) Results for Concrete Composition Mix 2 and High-Performance Concrete as Reference (Ref)

Figure 9 showed XRD results for reference concrete sample and Concrete Mix 2, which signified optimal compressive strength. In reference concrete, the dominant compounds detected were SiO2, Ca1.5SiO3.5 x H2O, and Ca(OH)2. Consequently, Concrete Mix 2 showed dominant compounds such as C6H602, (Fe, Mg) SiO3, and SiO2, supporting XRF results signifying the presence of SiO2 and Al2O3 compounds. These silicon-rich compounds in Mix 2, specifically SiO2 and (Fe, Mg)SiO3, were significant. Studies showed that the silicate chemicals promoted the formation of a denser matrix, strengthening its mechanical properties and durability by improving the pozzolanic reaction and decreasing pore structure in concrete mixture (Lee et al., 2015).

During the study, an increased SiO2 percentage in minerals improved compressive strength tests. Solid matrices in concrete from silicon dioxide (SiO2) and (Fe, Mg)SiO3 increased strength and durability. This study showed how Mix 2 exceeded reference concrete in compressive strength by 11.56%. The increased microstructure of the compound decreased porosity and improved mechanical interlock, surging stress-splitting resistance as well as tensile strength.

Modifying predominant chemicals improved compressive strength and durability, with no immediate concerns about negative impacts on general performance of concrete. Future studies should prioritize investigating the long-term performance and durability of the materials, with a focus on individual ability to resist freeze-thaw damage and fatigue under dynamic loading conditions. A recent study showed that nickel slag in concrete generally increased durability and mechanical properties by affecting the microstructure (Chi, Chi, and Wu, 2018).

3.6. Fourier-Transform Infrared Spectroscopy (FITR)

Figure 10 Fourier-Transform Infrared Spectroscopy (FTIR) Results, (A) Nickel slag aggregate, and (B) Concrete from Mix 2 and High-Performance Concrete as Reference (Ref)

Figure 10(A) showed FTIR results of nickel slag aggregate, signifying no substantial difference between nickel slag aggregate with particles sized 0/5 and 10/20. Meanwhile, Figure 10(B) showed FTIR results of reference concrete and Concrete Mix 2. In these ranges, an absorption peak at 977 cm-1 signified asymmetric vibrations of Si-O bond in (SiO)4- group. Peaks observed at 3406 cm-1 and 1417 cm-1 corresponded to the combined bending vibration of water and stretching vibration, respectively (Zhang et al., 2020a).

In conclusion, the effect of using nickel slag rather than coarse aggregate and partial or complete fine aggregate on high-quality concrete was evaluated. Binders contained OPC and GGBFS as substitutes for Portland cement, and the water-to-binder ratio was 0.317. Moreover, nickel slag used to replace coarse and natural fine aggregate was 20%, 40%, 60%, 80%, and 100%, respectively. The characteristics of concrete were evaluated by testing compressive and tensile strength, as well as the durability of concrete, which was examined by testing permeability of gas and porosity of concrete. During this study, optimum compressive strength obtained in Mix 2 concrete was 69.43 MPa. The partial substitution of a coarse and fine aggregate of nickel slag as aggregate increased by 11.56% compared to reference concrete, which was interpreted as an improvement in the performance of concrete that used nickel slag. To maintain optimal concrete performance, the use of slag should be limited to recommended levels, as excessive slag content could lead to diminished quality. The percentage of porosity in concrete that used nickel slag as natural fine and coarse aggregate was less than 10%. In addition, the smallest percentage of porosity was found in Mix 2, amounting to 6.52%.

The authors are

grateful for PT Jaya Beton Indonesia and I-Lab BRIN (National et al. Agency)

continuous contribution and support. Indonesian Ministry of Research,

Technology, and Higher Education funded this project in 2024 through a competitive

grant under Fundamental Research Scheme. The contract numbers are

832/LL3/AL.04/2024, 170/A/LPPM-P/USAKTI/VI/2024.

Ahmad, J., Manan, A., Asim, M., Ullah, S., Ullah, R., Ali, A., 2020. Characteristics of Concrete Modified with Ground Granulated Blast-Furnace Slag (GGBS) as Binding Material. International Journal of Emerging Trends in Engineering Research, Volume 8, pp. 4711–4718. https://doi.org/10.30534/ijeter/2020/105882020

Ahmad, S.B., Irmawaty, R., Aly, S.H., Amiruddin, A., 2022. Performance of Fly Ash Concrete with Nickel Slag Fine Aggregate in the Marine Environment. Civil Engineering Journal (Iran), Volume 8(12), pp. 61–68. http://dx.doi.org/10.28991/CEJ-2022-08-12-010

American Concrete Institute (ACI) 211.4R-08., 2008. Guide for Selecting Proportions for High-Strength Concrete with Portland Cement and Other Cementitious Materials. ACI Committee 211

American Standard Testing and Material (ASTM), 2013a. Standard Practices for Identification of Crystalline Compounds in Water-Formed Deposits by X-Ray Diffraction. American Standard Testing and Material (ASTM) D934-13

American Standard Testing and Material (ASTM), 2013b. Standard Test Method for Chemical Analysis of Metals American Standard Testing and Material (ASTM) D 4326: 2013 Standard Test Method for Major and Minor Elements

American Standard Testing and Material (ASTM), 2014. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Standard Testing and Material (ASTM) C136/C136M-14

American Standard Testing and Material (ASTM), 2015a. Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. American Standard Testing and Material (ASTM) C127/C127M-15

American Standard Testing and Material (ASTM), 2015b. Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate. American Standard Testing and Material (ASTM) C128/C128M-15

American Standard Testing and Material (ASTM), 2015c. Standard Test Method for Slump of Hydraulic-Cement Concrete. American Standard Testing and Material (ASTM) C143/C143M-15. https://doi.org/10.1520/C0143_C0143M-1

American Standard Testing and Material (ASTM), 2020. Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method). American Standard Testing and Material (ASTM) C1583/C1583M-20. https://doi.org/10.1520/C1583_C1583M-13.13

American Standard Testing and Material (ASTM), 2021a. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Standard Testing and Material (ASTM) C39/C39M-21. https://doi.org/10.1520/C0039_C0039M-2

American Standard Testing and Material (ASTM), 2021b. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Standard Testing and Material (ASTM) C642-21. https://doi.org/10.1520/C0642

Amir, A.A., Sukman, S., Mahmud, M., Hasrudin, H., 2022. Use of Nickel Slag Waste as Coarse Aggregate In Concrete. PENA TEKNIK: Jurnal Ilmiah Ilmu-Ilmu Teknik (PENA TEKNIK: Scientific Journal of Engineering Sciences), Volume 7(2), pp. 3803–3814. https://doi.org/10.51557/pt_jiit.v7i2.1270

Aprianto, Y., Triastianti, R.D., 2018. Pemanfaatan Limbah Padat Slag Nikel, Abu Sekam Padi, dan Fly Ash Menjadi Paving Block (Utilization of Nickel Slag Solid Waste, Rice Abusekam, and Fly Ash into Paving Blocks). Jurnal Rekayasa Lingkungan (Journal of Environmental Engineering), Volume 18, pp. 1–12

Astuti, W., Avista, D., Prihutami, P., Wanta, K.C., Prakosa, A., Anggara, F., Petrus, H.T.B.M., 2024. Atmospheric Leaching Behavior and Kinetics of Nickel and Cobalt from Halmahera Limonite Ore. International Journal of Technology, Volume 15(4), pp. 824–833. https://doi.org/10.14716/ijtech.v15i4.5607

Audit Board of the Republic of Indonesia (BPK RI)., 2014. Peraturan Pemerintah Republik Indonesia Nomor 101 Tahun 2014 Tentang Pengelolaan Limbah Bahan Berbahaya dan Beracun (Government Regulation of the Republic of Indonesia Number 101 of 2014 Concerning Management of Hazardous and Toxic Waste). Audit Board of the Republic of Indonesia (BPK RI)

Chi, M., Chi, J., Wu, C., 2018. Effect of GGBFS on Compressive Strength and Durability of Concrete. Advanced Materials Research, Volume 1145, pp. 22–26. https://doi.org/10.4028/www.scientific.net/AMR.1145.22

Dewiandratika, M., Sukandar, El-Akmam, M.T., 2018. Study on the Leaching Performance of Chromium (Cr) And Cadmium (Cd) from the Utilization of Solidified Nickel Slag as Concrete Floors. In: MATEC Web of Conferences, Volume 147, p. 04010. https://doi.org/10.1051/matecconf/201814704010

Edwin, R.S., Ngii, E., Talanipa, R., Masud, F., Sriyani, R., 2019. Effect of Nickel Slag as A Sand Replacement in Strength and Workability of Concrete. In: IOP Conference Series: Materials Science and Engineering, Volume 615(1). https://doi.org/10.1088/1757-899X/615/1/012014

Edwin, R.S., De-Schepper, M., Gruyaert, E., De-Belie, N., 2016. Effect of Secondary Copper Slag as a Cementitious Material in Ultra-High Performance Mortar. Construction and Building Materials, Volume 119, pp. 31–44. https://doi.org/10.1016/j.conbuildmat.2016.05.007

Ente Nazionale Italiano di Unificazione (UNI)., 2005. Concrete - Determination of permeability to oxygen (UNI 11164:2005). Ente Nazionale Italiano di Unificazione (UNI)

Environmental Protection Agency (EPA), 1990. Hazardous Waste Management System; Identification and Listing of Hazardous Waste; Toxicity Characteristic Revisions (55 FR 11798). Environmental Protection Agency (EPA). Available online at https://www.epa.gov/sites/default/files/2013-09/documents/55fr30645.pdf, Accessed on September 30, 2024

Environmental Protection Agency (EPA), 1992. Toxicity Characteristic Leaching Procedure (TCLP). US EPA SW-846 Method 1311. Available online at https://www.epa.gov/hw-sw846/sw-846-test-method-1311-toxicity-characteristic-leaching-procedure Accessed on September 30, 2024

Ernawan, E., Sjah, J., Handika, N., Astutiningsih, S., Vincens, E., 2023. Mechanical Properties of Concrete Containing Ferronickel Slag as Fine Aggregate Substitute using Digital Image Correlation Analysis. Buildings, Volume 13(6), p. 1463. https://doi.org/10.3390/buildings13061463

Han, F., Zhang, H., Li, Y., Zhang, Z., 2023. Recycling and Comprehensive Utilization of Ferronickel Slag in Concrete. Journal of Cleaner Production, Volume 414, p. 137633. https://doi.org/10.1016/j.jclepro.2023.137633

Huang, Y., Wang, Q., Shi, M., 2017. Characteristics and Reactivity of Ferronickel Slag Powder. Construction and Building Materials, Volume 156, pp. 773–789. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2017.09.038

Jaganmohan, M., 2024. Leading Countries Based on Nickel Reserves Worldwide as of 2023. Available Online at: https://www.statista.com/statistics/273634/nickel-reserves-worldwide-by-country/, Accessed on October 17, 2024

Jó?wiak-Nied?wiedzka, D., D?browski, M., Bogusz, K., Glinicki, M.A., 2020. Influence of Slag Cement on the Permeability of Concrete for Biological Shielding Structures. Energies, Volume 13(17), p. 4582. https://doi.org/10.3390/en13174582

Khan, S. U., Nuruddin, M. F., Ayub, T., Shafiq, N., 2014. Effects of Different Mineral Admixtures on the Properties of Fresh Concrete. The Scientific World Journal, Volume 2014, pp. 1–11. https://doi.org/10.1155/2014/986567

Lee, H.-S., Wang, X.-Y., Zhang, L.-N., Koh, K.-T., 2015. Analysis of the Optimum Usage of Slag for the Compressive Strength of Concrete. Materials, Volume 8, pp. 1213–1229. https://doi.org/10.3390/ma8031213

Lee, J.-Y., Kim, H.-G., Kim, K.-H., 2021. Effect of Ground Granulated Blast Furnace Slag Replacement Ratio on Structural Performance of Precast Concrete Beams. Materials, Volume 14(23), p. 7159. https://doi.org/10.3390/ma14237159

L'Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC), 2018. Concretos. Método De Ensayo Para Determinar El Asentamiento Del Concreto (Concrete. Test Method for Determining the Settlement of Concrete) (NTC 396). Instituto Colombiano De Normas Técnicas Y Certificación. Instituto Colombiano De Normas Técnicas Y Certificación, Bogotá D. C., Colombia

Lliso-Ferrando, J. R., Gandía-Romero, J. M., Soto, J., Valcuende, M., 2023. OC, HPC, UHPC, and UHPFRC Corrosion Performance in the Marine Environment. Buildings, Volume 13(10), p. 2439. https://doi.org/10.3390/buildings13102439

Mustika, W., Salain, I.M.A.K., Sudarsana, I.K., 2016. The use of nickel slag as an aggregate in concrete mixtures. Jurnal Spektran (Spectran Journal), Volume 4(2), pp. 36–45. https://doi.org/10.24843/spektran.2016.v04.i02.p05

Nabiilah, B.Y., Nelfia, L.O., Astutiningsih, S., 2019. An Innovation of High-Performance Concrete by Replacing Cement with Nickel Slag Powder. International Journal on Livable Space, Volume 4(2), pp. 77–83. https://doi.org/10.25105/livas.v4i2.5602

Nelfia, L.O., Rahmawati, M., Astutiningsih, S., 2021. Experimental Study on Blast Furnace Nickel Slag Powder and Fly Ash as a Binder for Geopolymer Concrete. In: ICCOEE2020: Proceedings of the 6th International Conference on Civil, Offshore and Environmental Engineering (ICCOEE2020), pp. 385–395

Ngii, E., Kadir, A., Rachman, R.M., Serah, M., 2021. Optimum Combination of Ferro-Nickel Slag (Feni4) to the Normal Sand for the Concrete Compressive Strength. In: IOP Conference Series: Earth and Environmental Science, Volume 622(1), pp. 1–9. https://doi.org/10.1088/1755-1315/622/1/012038

Ngii, E., Mursidi, B., Umar, Y.Y., 2020. Potential Use of Pomalaa Nickel Slag as a Substitute for Sand in Brick Making. In: IOP Conference Series: Materials Science and Engineering, Volume 797(1), p. 012012. https://doi.org/10.1088/1757-899X/797/1/012012

Nuruzzaman, M., Almeida, J., Amin, M.T.E., Sarker, P.K., 2024. Performance of Sustainable Green Concrete Incorporating Quarry Dust and Ferronickel Slag as Fine Aggregate. Materials, Volume 17(10), p. 2326. https://doi.org/10.1088/1757-899X/797/1/012012

Nuruzzaman, M., Kuri, J.C., Sarker, P.K., 2022. Strength, Permeability, and Microstructure of Self-Compacting Concrete with the Dual use of Ferronickel Slag as Fine Aggregate and Supplementary Binder. Construction and Building Materials, Volume 318, p. 125927. https://doi.org/10.1016/j.conbuildmat.2021.125927

Nuruzzaman, M.D., Casimiro, J.O.C., Sarker, P.K., 2020. Fresh and Hardened Properties of High-Strength Self-Compacting Concrete Using By-Product Ferronickel Slag Fine Aggregate. Journal of Building Engineering, Volume 32, p. 101686. https://doi.org/10.1016/j.jobe.2020.101686

Ojha, P.N., Singh, B., n.d., Alternative Aggregates for Sustainable Concrete - A Way Forward Towards Circular Economy in Construction. National Council for Cement and Building Materials Haryana. Available online at: https://www.researchgate.net/publication/ 376028402_Alternative_Aggregates_for_Sustainable_Concrete_-_A_Way_Forward_To wards_Circular_Economy_in_Construction, Accessed on September 30, 2024

Oksri-Nelfia, L., Akbar, R., Astutiningsih, S., 2020. A Study of the Properties and Microstructure of High-Magnesium Nickel Slag Powder used as a Cement Supplement. In: IOP Conference Series: Materials Science and Engineering Volume 829(1), p. 012007. https://doi.org/10.1088/1757-899X/829/1/012007

Onn, C.C., Mo, K.H., Radwan, M., Liew, W., Ng, C., Yusoff, S., 2019. Strength, Carbon Footprint, and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag. Sustainability, Volume 11(24), p. 7194. https://doi.org/10.3390/su11247194

Özbay, E., Erdemir, M., Durmu?, H.?., 2016. Utilization and Efficiency of Ground Granulated Blast Furnace Slag on Concrete Properties – a Review. Construction and Building Materials, Volume 105, pp. 423–434. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2015.12.153

Putera, A.D.P., Warmada, I.W., Amijaya, D.H., Astuti, W., Sukadana, I.G., Petrus, H.T.B.M., 2023. A Comparison Study of Nickel Laterite Reduction using Coal and Coconut Shell Charcoal: A FactSage Simulation. International Journal of Technology, Volume 14(2), pp. 267–275. https://doi.org/10.14716/ijtech.v14i2.5808

Radhica, D.D., 2023. Proteksionisme Nikel Indonesia dalam Perdagangan Dunia (Indonesian Nickel Protectionism in World Trade). Cendekia Niaga (Business Scholar), Volume 7(1), pp. 74–84

Saha, A.K., Sarker, P.K., 2016. Expansion Due to The Alkali-Silica Reaction of Ferronickel Slag Fine Aggregate in OPC and Blended Cement Mortars. Construction and Building Materials, Volume 123, pp. 135–142. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2016.06.144

Saha, A.K., Sarker, P.K., 2017b. Sustainable Use of Ferronickel Slag Fine Aggregate and Fly Ash in Structural Concrete: Mechanical Properties And Leaching Study. Journal of Cleaner Production, Volume 162, pp. 438–448. https://doi.org/10.1016/j.jclepro.2017.06.035

Saha, A.K., Sarker, P.K., 2020. Effect of Sulfate Exposure on Mortar Consisting of Ferronickel Slag Aggregate and Supplementary Cementitious Materials. Journal of Building Engineering, Volume 28, p. 101012. https://doi.org/10.1016/j.jobe.2019.101012

Saha, A.K., Sarker, P.K., 2017a. Compressive Strength of Mortar Containing Ferronickel Slag as Replacement of Natural Sand. Procedia Engineering, Volume 171, pp. 689–694. https://doi.org/10.1016/j.proeng.2017.01.410

Srikanth, S., Krishna, C.B.R., Srikanth, T., Sai Nitesh, K.J.N., Nadh, V.S., Kumar, S., Thanappan, S., 2022. Effect of Nano Ground Granulated Blast Furnace Slag (GGBS) Volume % on Mechanical Behaviour of High-Performance Sustainable Concrete. Journal of Nanomaterials, Volume 2022(1), p. 3742194. https://doi.org/10.1155/2022/3742194

Sugiri, Saloma, Yulianti, 2007. Correlation Equation of Mechanical Properties of High-Quality Concrete with Natural Aggregates and Nickel Slag. Civil Engineering Journal Bandung Institute of Technology (ITB), Volume 14(1), pp. 27–40

Sun, J., Feng, J., Chen, Z., 2019. Effect of Ferronickel Slag as Fine Aggregate on Properties of Concrete. Construction and Building Materials, Volume 206, pp. 201–209. https://doi.org/10.1016/j.conbuildmat.2019.01.187

Suwindu, K.S., Parung, H., Sandy, D., 2020. Characteristics of High-Quality Concrete with Substitution of Steel Slag and Nickel Slag as Coarse Aggregate. Paulus Civil Engineering Journal (PCEJ), Volume 2, pp. 1–8

United States Geological Survey (U.S.G.S)., 2022. Mineral Commodity Summaries 2022. In: Angewandte Chemie International Edition, Volume 6(11) pp. 951–952

Wanta, K.C., Astuti, W., Petrus, H.T.B.M., Perdana, I., 2022. Product Diffusion-Controlled Leaching of Nickel Laterite using Low Concentration Citric Acid Leaching at Atmospheric Conditions. International Journal of Technology, Volume 13(2), pp. 410–421. https://doi.org/10.14716/ijtech.v13i2.4641

Wu, Q., Wu, Y., Tong, W., Ma, H., 2018. Utilization of Nickel Slag as Raw Material in the Production of Portland Cement for Road Construction. Construction and Building Materials, Volume 193, pp. 426–434. https://doi.org/10.1016/j.conbuildmat.2018.10.109

Zhang, T., Jin, H., Guo, L., Li, W., Han, J., Pan, A., Zhang, D., 2020a. Mechanism of Alkali-Activated Copper-Nickel Slag Material. Advances in Civil Engineering, Volume 2020(1), p. 7615848. https://doi.org/10.1155/2020/7615848

Zhang, T., Zhi, S., Li, T., Zhou, Z., Li, M., Han, J., Li, W., Zhang, D., Guo, L., Wu, Z., 2020b. Alkali Activation of Copper and Nickel Slag Composite Cementitious Materials. Materials, Volume 13(5), p. 1155. https://doi.org/10.3390/ma13051155