Proposing Method for Airframe Noise Prediction Benefitting Indonesian Aircraft Design

Corresponding email: aprilia.sakti.05@gmail.com

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.7094

Kusumalestari, A.S., Suryanegara, M., Sudibyo, H., Soekirno, S., Ruseno, N., 2024. Proposing Method for Airframe Noise Prediction Benefitting Indonesian Aircraft Design. International Journal of Technology. Volume 15(5), pp. 1582-1592

| Aprilia Sakti Kusumalestari | Department of Physics, Faculty of Mathematics and Natural Science, Universitas Indonesia, Campus of UI, Beji, Depok, West Java, 16424, Indonesia |

| Muhammad Suryanegara | Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Campus of UI, Beji, Depok, West Java, 16424, Indonesia |

| Harry Sudibyo | Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Campus of UI, Beji, Depok, West Java, 16424, Indonesia |

| Santoso Soekirno | Department of Physics, Faculty of Mathematics and Natural Science, Universitas Indonesia, Campus of UI, Beji, Depok, West Java, 16424, Indonesia |

| Neno Ruseno | Department of Science and Industrial Systems, Faculty of Technology, Natural Sciences, and Maritime Sciences, University of South-Eastern Norway, Hasbergsvei 36, 3616 Kongsberg, Norway |

This paper describes the

proposal for an airframe noise prediction method that can be used in Indonesian

aircraft design research and industry. Since the industry is strategic, whether

economically or securely, the country should build their own technology in all

phases. Noise assessment is one of the sophisticated procedures in designing

and manufacturing aircraft. Indonesia has not developed and manufactured

engines, therefore airframe noise prediction is a relevant object to study.

This method is proposed to be a utility to improve Indonesian aircraft design

specifications. Based on the analogy theory of aeroacoustics, the use of Ffowcs

Williams and Hawkings (FWH) equation was chosen to represent noise. The noise

prediction method was developed by simulating and modeling in OpenFOAM, an

open-source software based on the finite volume method. Its reliability has

been proven in research and industrial computational fluid dynamics. The

proposed method is developed from CFD and is compatible with using a personal

computer device. The algorithm based on boundary conditions and hardware

specifications has been built. Each step has been designed to support FWH

Equation solver uniquely for this study. Computational domains represent the

airflow area overrun a solid object. For the reason of far-field radiation, the

domain token is 20 times the dimension of the object, and wall functions are

applied. The atmosphere condition of low flight level and low to medium

subsonic speed is taken to represent various aircraft designs and

configurations. The condition represents the existing Indonesian industry of

civil and military flying vehicles, and its possibility to develop.

Aeroacoustics; Airframe noise; FWH equation; Indonesian aircraft; OpenFOAM

Aircraft design is one of the strategic technologies that has already been mastered by the Indonesian aviation industry for decades. While the global development of this industry presents distinct challenges, the implementation of the fly-by-wire system in the N250 aircraft in 1995 serves as evidence of Indonesia's technological advancement in this domain. Recently, the manufacture of N219, R80, and several types of unmanned aircraft convinced the development of the industry. For the purpose of high performance and specification, it is recommended to master all phases of aircraft design and manufacturing technology.

A study regarding the high-performance level of the

aerospace industry in a developed country showed that research and development

is one of the crucial factors. The study, focusing on Mexico,

recommends that the country prioritize maintaining and enhancing its research

and development efforts to achieve a high-performance level in the aerospace

industry (Manzo

and Rodríguez, 2022). To Indonesia as well, more advanced design

specifications will be achieved by improving appropriate research, especially

on contributing responsibility to environment, sustainability, and national

security. Establishing a harmonic aerospace ecosystem is also a commitment to

Indonesian general development (Birowo et al., 2020). Since all

engines that produce major noise in flying vehicles are manufactured abroad,

the airframe is a relevant object to be studied in Indonesia. Several methods

for predicting airframe noise have been built with specific purposes of

aircraft, depending on institutions that support them. This study has

justification for developing an airframe noise prediction method to apply

simultaneously with the progress of Indonesian aircraft research and technology

(Kusumalestari,

Soekirno, and Sudibyo, 2019).

The current study proposed key contributions as follows:

- - The

study supports the purpose of establishing the Indonesian aerospace ecosystem

- - The

result can be used as part of multidisciplinary conceptual design in

manufacturing manned and unmanned aircraft across the nation for the reason of

economic strategy

- - The

result can support military benefit of aircraft design in the mission of

national insight and security

- - The

study is an adding value of responsibility and sustainability of research and

development of Indonesian aircraft technology

2. Literature Review

To sustain the environmental issues of green aviation, research

on aircraft noise has been conducted in many countries and regions (Ali et al.,

2019). For instance, the European Union has a program to

reduce aircraft noise from engines and airframes. The ACARE (Advisory Council

for Aeronautics Research in Europe) program achieved its target of reducing

aircraft noise by 50%, from approximately 150 dB to 75 dB by 2020 and the

program aims to further reduce noise levels by more than 65% by 2050 (Kors and Collins,

2020). Since engine and jet burst exhaust noise have been

significantly reduced, further reduction will be on the same scale as the

airframe noise. It is almost equal to airframe noise on wide-body aircraft when

approaching landing (Airbus, 2003). In civil aviation, aircraft

noise usually will be reduced to meet a regulation. Out of aircraft design,

noise mitigation can be done by several methods, for example, a study on

departure trajectory (Suryo et al., 2020). In defence

or military technology, the targets are more visionary, such as Unmanned Aerial

vehicles (UAV), missiles, and aerial reconnaissance. After overcoming radar as

a major barrier, the vision of flying vehicles is to meet the silence of flying

owls (Jaworski

and Peake, 2020). Nevertheless, from the perspective of

aircraft design and manufacture, noise is also identified as a form of energy.

2.1. Indonesian Aircraft Industry

For a couple of years, aircraft design and manufacture in

Indonesia have been developing many types of flying vehicles. Aircraft such as

N219 and R80 have already been produced to get involved in regional

transportation with small to medium numbers of passengers. Today, air transport

is Indonesia's most popular regional public transportation (Badan Pusat Statistik,

2024). Furthermore, since the country is an archipelago,

flight with advanced aircraft models such as wing-in-ground effect and amphibia

are feasible to develop. UAVs such as Minibe, Ruppel Bomber, Male, and other

drones with different missions are also developed by government and private

institutions. For purposes such as farming, mapping, or other non-military

applications, UAVs are typically optimized for economic and environmental

performance. For military purposes, UAVs are expected to be more specified and

have better performance. For instance, weaponized drones and kamikaze drones

are designed to have a far operation range, long-life battery, and fast

velocity. The operational range of the drone developed and manufactured in

Indonesia could reach 50 km and a maximum velocity of 250 km/jam or about 0.2

M, where M is for Mach number. The life of batteries varies, starting from 180

minutes to 900 minutes to 24 hours. Under research and development, the

specifications and performance of the vehicles may be improved. Many studies on

noise reduction in Indonesia have been published. For instance, using composite

material to absorb sound (Zulkarnain et al., 2023).

More advanced research on optimization energy has also been studied (Akbar et al.,

2022). Further, the Indonesian research program needs to

improve to reduce noise from the conceptual design stage.

2.2. Airframe Noise Prediction

In general, noise will be directly proportional to the

reduction of aerodynamic performance and power efficiency of the aircraft (Glegg and

Devenport, 2017). However, more specific studies on airframe

noise could increase power consumption as noise is reduced (Hirschberg and Rienstra, 2004).

These could be different when the design is blended wing body aircraft, flying

wing, wing in ground aircraft, or other shape. To avoid more expensive

modifications in the manufacturing phase, noise prediction should be

implemented in the very early phase of design. Thus, to perform optimization,

study and treatment should be conducted in the phase of conceptual design and

multidisciplinary mode (Sahai, 2016; Hosder, 2004). According

to this phase, the basic shape of clean wing or clean aircraft is applied. The

geometry is calculated when the type and function of the aircraft to be built

are determined (Kundu, Price, and Riordan, 2019; Raymer, 2018).

An early study by Brooks and Hodgson describes noise generated from trailing

edge of a clean wing in their research. The study shows the field of noise

around trailing edge with a condition of low Mach number and boundary condition

flow is fully turbulent (Glegg and Devenport, 2017). The

advancement of relevant studies utilizing computation will be described in the

next subsection of this paper, as well as existing methods.

The first

term of the righthand side of Equation 2, usually named Reynold’s Stress,

contains vector velocity of a volume element and vector velocity of the main

flow. The first and second terms represent pressure inside the element volume

of flow, and the third term represents pressure around the element. Physical

illustrations of FWH derivation are described by Zinoviev to compare it with

other equation of the analogy, however, experiments to validate the equation

begin after it (Zinoviev, 2002).

2.3. Existing Methods of Noise

Prediction

To analyze the implementation of the FWH equation in the

currently proposed method had been issued (Kusumalestari et al.,

2019). The specific form of the equation was also studied by Spalart and Shur (2009)

and by Jarozs, Czajka, and

Golas (2016), which applied FWH to different objects and

conditions (Jarozs,

Czajka, and Golas, 2016; Spalart and

Shur, 2009). One of the recent studies

using the equation is carried out by Al Hawwary and Wang (2020). The method is built to predict noise sourcing

from jet streams in low subsonic (v

< 0.3 M) conditions. The result shows

good agreement with experimental data (Al Hawwary and Wang, 2020). Recent implementation of the equation on part of

airframe is a study of high lift devices noise from wings of N219 Indonesian

aircraft at BRIN (Badan

Riset dan Inovasi Nasional), an Indonesian

Research Centre. The equation is implemented on Fluent Ansys CFD software with

large eddy simulation method. The result identifies good agreement between the

computational model and existing data in a confined frequency range (Soemaryanto et al., 2021).

Recent research on noise

prediction methods includes dissertations by Sahai

(2016), and Bertsch (2013), Hosder (2004). Hosder worked on predicting

noise in clean wing conditions by defining a new noise scale based on the sound

source within the near field area. The study demonstrates that noise production

is highly dependent on the lift coefficient (CL);

specifically, as the lift coefficient increases, the generated noise also

increases (Hosder, 2004). Hosder’s method is a part of an

aerodynamic project of aircraft design research at Virginia Polytechnic

Institute and State University and is prepared to be integrated into NASA’s (National

Aeronautics and Space Administration) program of ANOPP (Aircraft Noise

Prediction Program).

A study by

Bertsch in 2013, utilizes computational aeroacoustics (CAA) software rather

than computational fluid dynamic (CFD) and is appropriate for both compressible

and incompressible fluid flow, this means is applicable for low and high

subsonic speed. The method, named PANAM (Parametric Aircraft Noise

Analysis Module),

is compatible with assessing environmental and economic performance of

different flying vehicles under various scenarios. By applying the Bertsch

method to a comprehensive program of conceptual aircraft design, the

correlation between the geometry shape of aerofoil and noise emission can be

described (Bertsch, 2013).

Another study on predicting noise in conceptual design

phase was delivered by Sahai in 2016, named INSTANT (ILR Noise Simulation and Assessment), where ILS

stands for Instrument Landing System. In this study, noise prediction is

referred to as psychoacoustics phenomena. The study utilizes CAA software and

is applicable for low subsonic speed. The result of the study shows that for

wider aerofoil surfaces, airframe noise will increase (Sahai, 2016).

The method was built to be integrated with MICADO (Multidisciplinary Integrated Conceptual Aircraft Design and Optimazion)

program held by RWTH (Rheinisch-Westfälische Technische Hochschule) for

aircraft design.

Table 1 Existing latest noise prediction methods

|

Noise Source & Flight Speed |

Tools |

Mathematical Approach |

Computational Method |

Method/ Researcher |

|

clean aircraft conceptual design phase low subsonic (< 0.3 M) |

specific CAA in Virginia Polytechnic Institute

& State University, USA |

FW-Hall and (k-w)SST turbulent model |

solved in average value (RANS) |

(Hosder,

2004) Note: applicable to ANOPP, aircraft noise prediction by NASA |

|

all components conceptual design phase low & medium subsonic (< 0.3 M) |

field simulation |

using existing noise model and flight trajectory simulator from the

Institute of Aerodynamics and Flow Technology, Braunschweig, Germany |

PANAM (Bertsch,

2013) | |

|

all components conceptual design phase low subsonic (< 0.3 M) |

field simulation |

using airframe and engine noise simulator from RWTH, Aachen, Germany

|

INSTANT (2) (Sahai,

2016) Note: applicable to MICADO, aircraft design program by RWTH | |

|

rotor blade assessment phase low subsonic (< 0.3 M) |

CFD OpenFOAM using Zeus HPC 24 core in AGH University of Science & Technology, Poland |

FWH and Spalart-Allmaras turbulent model

|

solved in average value |

Jarozs,

Czajka, and Golas, 2016) |

|

airframe and jet assessment phase transonic (0.8 - 1.2 M) |

CFD hpMusic using high-specification computers at the University of Kansas |

FWH and turbulent flow simulation |

solved in direct value (LES) |

Al

Hawwary and Wang (2020) Note: part of USA Department of Defense project

|

|

clean aircraft conceptual design phase low subsonic (< 0.3 M) |

CFD OpenFOAM using PC

|

FWH and Spalart-Allmaras turbulent model |

solved in average value |

PROPOSED METHOD |

In many research issues based on fluid dynamics or similar studies,

open-source software is not as widely used as commercial software. For more

specialized fields such as aeroacoustics, there are still far fewer. In research assessing the reliability of open-source

software for academic and industrial studies, Shademan and the team compared

OpenFOAM, an open-source software, with one of the popular commercial software.

The results show very good agreement between booth simulation performance

dynamic flow. (Shademan, Barron, and Balachandar, 2013). OpenFOAM has already been used as an aerodynamics

research tool in industrial environments, including automotive and aviation.

Thus, the advantage of OpenFOAM is not only because it can be used for free,

but also because it is reliable for performing fluid dynamics computations (Tofany, 2023;

Marbona, 2018; Jasak, Jemcov, and

Tukovic, 2017).

Initially, this proposed

method begins with a brief study on the probability of utilizing OpenFOAM to

build an FWH solver (Kusumalestari et al., 2020). One reference of this study is research by Jarozs

and team in 2016. In this research, OpenFOAM is utilized to build a method and

solve the FWH for low speed on the Mach scale, namely < 0.3 M. The solid

object chosen for an obstacle in the aerodynamic flow is a double cylinder, and

the observer is placed in nearfield area. Overall, the model shows good

agreement between OpenFOAM calculation results, and the experiments (Jarozs, Czajka, and Golas, 2016). Resumes of

existing recent methods are described in Table 1. Older methods have already

been developed and are referred to by those newer methods.

In addition, in

applying FWH as a governing equation to solve the computational noise model, a

turbulence model is needed. Considering

there is no general model for turbulence, analyzing a proper turbulence model

for fluid flow cases is very important (Sodja

and Podgornik, 2007). In a technical study conducted by

NASA in 1997, four turbulence models were compared to show their

specifications. Generally, it is concluded that has advantages

over other models. In terms of computational performance, certain criteria and

conditions, Spalart-Allmaras has advantages over the other models, as far as it

is not used for jet stream simulations. This model is suitable for transition

conditions between laminar and turbulent that occur in most areas around the aerofoil.

Using one equation for modeling also makes this model more efficient and

requires a smaller number of grids than other models to reach the same accuracy (Bardina, Huang, and Coakley, 1997). Another

consideration is that the Spalart-Allmaras model has been tested quite well for

modeling turbulence in compressible flow conditions as well, namely at speeds

higher than 0.3 Mach (Raje, 2015).

3. Proposed Method

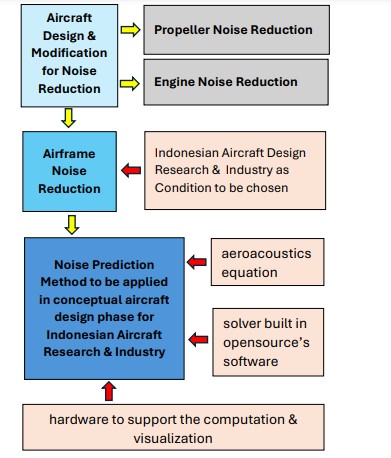

Figure 1 The proposed method is built in OpenFOAM, implementing

the FWH equation, and Spalart-Allmaras turbulent model, visualized in ParaView,

for conditions of low to medium subsonic speed

To

build the method in OpenFOAM, at least three directories must be made, “0”

directory, “constant” directory,

and “system”

directory. The first is where pressure

are declared. Meshing and discretization of the computational domain are

figured in the second directory, while geometry is taken from a given file (in

.stl format). Characteristics flow used in the equation is also defined in this

directory in the mode of Newtonian flow and Spalart-Allmaras turbulence model.

The solver of the FWH equation is designed from existing flow equation solvers,

combined with aeroacoustics pressure tensor,

and completed by the

Spalart-Allmaras turbulence model. The solver computes each element’s volume

and iterates within the domain as large as 20 times of solid object. Compared

to Jarozs’s study, this proposed method uses wall function and y+ of 50 to identify

noise around the far field area. Visualization of geometry and the

computational domain is seen in paraView application, as well as analysis the

result.

4.1. The Boundary Condition of

Indonesian Aircraft Design

In the proposed method's

algorithm, the setting of boundary conditions is crucial for the successful

execution and performance of the model. A Mach number of 0.2 will be selected,

and incompressible flow conditions will be applied as required. Furthermore, up to 0.4 M will apply to probability of

improvement. In the second condition, the flow is given to be compressible and

4.2.

Descritization and Meshing

In Indonesia today, computers with very high

specifications for aircraft design are only owned by large institutions. If the

nation is projecting aeroacoustics research and aircraft design can be further

developed, the research should be carried out by many institutions, especially

academic researchers. Therefore, it is important to determine optimal precision

in discretization and meshing to optimize the calculation (Alimin,

1995). To optimize aircraft design process, clean

wing geometry is used to apply in stage of conceptual design (Hosder,

2010). An aerofoil with one meter length is

selected as the solid object within the aerodynamic flow. This proposed method

uses 1,500,000 volume elements to represent the computational domain. The width

of the domain is set to 20 times the aerofoil geometry.

4.3.

Meshing Control and Time Step

To

optimize the accuracy and a load of computational tasks, utilizing mesh control

and time steps is important. This study uses “snappyHexMesh” dictionary to improve the number of grids through

the aerofoil geometry surface. Inside the dictionary code, the minimum level of

mesh refinement is set to be twice, and maximum level is set to be four times.

To monitor the calculation of the program, time step is set as least as

possible where the program is still controllable, and the value could be

changed while analyzing. These calculations are determined on consideration of

hardware capabilites, which is using personal computer.

4.4.

Solving of FWH Equation

In this case, the solver

is designed to be hybrid and therefore can be used for pressure-based cases for

incompressible flows and density base for compressible flows. The temperature

gradient is not calculated, because, in the case of sound propagation, the

atmosphere is assumed to be homogenic. This calculation is still in the

subsonic range for the chosen flow velocity. The calculation of the density

base with the temperature gradient only needs to be applied if the flight speed

enters transonic, supersonic, and hypersonic. This solver solves the

pressure-velocity couple equation for unstable flow conditions, and turbulence

transient flows, as the characteristics of FWH equation.

4.5.

Applying Spalart-Allmaras Turbulence Model

To close the solution of

the equation, the turbulence model of Spalart-Allmaras has been chosen. In this

study of aircraft design and its condition in Indonesia, no special turbulence

model is required. This model was selected based on the analysis from Bardina’s

research on several turbulence models. The Spalart-Allmaras model is considered

more efficient for numerical applications because it requires relatively fewer

grids than other models. The use of one equation also makes this model more

efficient than a model that uses two equations. This model is

suitable for the transition conditions between laminar and turbulent, which

occur in most areas around the aerofoil (Bardina,

Huang, and Coakley, 1997).

4.6.

The Use of ParaView for Visualization and Analysis

The visualization of

aerofoil geometric shapes in the computational domain is shown in the paraView

application, which is also taken from open source. This software can also be

utilized to analyse the results of noise prediction calculations which is computed

by OpenFOAM. If Indonesia wants to develop aircraft design research, then

consideration of appropriate and efficient tools is needed.

4.7.

The Advantage of the Proposed Method to Indonesia

Comparing the proposed with the

existing methods, the use of equipment for computational aeroacoustic, or high

specification of industrial computers is not needed. Utilizing open-source

software with high conformity performance is another advantage. Whether a

similar method has been built, or or whether it is compatible with the

Indonesian design and manufacturing industry of aircraft still needs to be

studied. The use of methods that utilize foreign equipment certainly will cost

and threaten national security when applied to military aircraft.

4.8.

Harmonize with global development and regulation

Additionally, in

developing the method for airframe noise prediction, it is important to

consider the future prospects of Indonesian aviation. Supporting the ongoing

development of the Indonesian aviation ecosystem should be a key consideration.

Updated regulations by the International Civil Aviation Organization (ICAO) and

the Directorate General of Civil Aviation of Indonesia should be followed. A

review of Molin on airframe noise modelling and prediction in an issued paper

and a study by Guo and Thomas on future work of airframe noise prediction

should be taken as an outline (Guo and Thomas, 2022; Molin, 2019).

This study is supported by the Aerospace University

of Air Marshal Suryadarma, and the Foundation of Adi Upaya, Jakarta, Indonesia.

Aprilia Sakti Kusumalestari is a full-time lecturer home-based at the Aerospace

University of Air Marshal Suryadarma carrying out this research as part of

Doctoral study at Universitas Indonesia.

Airbus,

2003. Getting to Grips with Aircraft Noise. Series of Flight Operation

Support and Line Assistance. Airbus Customer Services, Airbus Company, France

Akbar, M., Ramadhani, M.J.,

Izzuddin, M.A., Gunawan, L., Sasongko, R.A., Kusni, M., Curiel-Sosa, J.L.,

2022. Evaluation

of Piezoaeroelastic Energy Harvesting Potential of a Jet Transport Aircraft

Wing with Multiphase Composite using Iterative Finite Element Method. International

Journal of Technology, Volume 13(4), pp. 803–815

Al Hawwary,

M.A., Wang, Z.J., 2020. Implementation

of a FWH Approach in a High-Order LES Tool for Aeroacoustic Noise Predictions, In:

AIAA SciTech Forum, p. 1724

Ali, A.,

Alonso, J., Carmo, M., Collin, D., Gransi, C., Huising, M., Humphreys, M.,

Khaletski, Y., Kopiev, V., Lempereur, P., Majjigi, M., McCormick, D., Nesbitt,

E., Oishi, T., Peters, J., Piercy, S., 2019. Status of

Noise Research Aimed at Subsonic Transport Technology solutions.

ICAO Environmental Report (Chapter 2 Art. No. 5), International Civil

Aviation Organization, pp. 72–80

Alimin, E.K., 1995. Dissipation

and Discretization in Time Marching CFD Calculation (Doctoral Thesis).

School of Mechanical Engineering, Cranfield University

Badan

Pusat Statistik (Center of Statistical Board),

2024, During January-November 2023, The Number of International Air Transport

Passengers Increased By 135.11 Percent Compared to The Same Period In 2022.

Available Online at: https://www.bps.go.id/id/pressrelease/2024/01/02/2358/selama-januarinovember-2023--jumlah-penumpang-angkutan-udara-internasional-naik-135-11-persen-dibandingkan-periode-yang-sama-tahun-2022-.html

Bardina,

J., Huang, P.G., Coakley, T.J., 1997. Turbulence

Modelling Validation, Testing and Development. NASA Technical Memorandum

110446. The USA

Bertsch, L., 2013. Noise

Prediction within Conceptual Aircraft Design. Dissertation, Deutsches

Zentrum für Luft- und Raumfahrt, Institut für Aerodynamik und Strömungstechnik,

Braunschweig, Germany

Birowo, I., Waskito, T.,

Darwanto, B.S., Sekar, W., Amretasari, R., Setiawan, P.A., Ridho, M.

Widyasanti, A. A., Prijambodo, B., Sambodo, L.A.A.T., Harsudiono, Y., Ashari,

A.S., Ardhana, A.K., Amalia, I., Andhika D.K., Annisa, F., Zulazmi., Anwar, M.,

2020. Kajian Peta Jalan Pengembangan Ekosistem Industri Kedirgantaraan

Indonesia 2020-2045 (Study of the Roadmap for the Development of the

Indonesian Aerospace Industry Ecosystem 2020-2045). Ministry of National

Development Plan (Bappenas) and Deutsche Gesellschaft fur Internationale

Zusammenarbeit (GIZ) GmbH, Jakarta, Indonesia

Glegg, S., Devenport, W., 2017. Aeroacoustics

of Low Mach Number Flows: Fundamentals, Analysis and Measurement. Elsevier

Inc.

Guo, Y., Thomas,

R.H., 2022. Assessment of Next Generation Airframe Noise Prediction Methods

with PAA and ASN Flight Test Data. In: AIAA Aeroacoustics Conference.

Southampton, Great Britain

Hirschberg,

A., Rienstra, S.W., 2004. An Introduction to Aeroacoustics. Seminar

Paper, Eindhoven University of Technology, The Netherlands

Hosder,

S., 2004. Clean Wing Airframe Noise Modeling for Multidisciplinary

Design and Optimization. Dissertation,

Virginia Polytechnic Institute and State University. The

USA

Hosder,

S., Schetz, J.A., Mason, W.H., 2010. Computational-Fluid-Dynamics-Based

Clean-Wing Aerodynamic Noise Model for Design. Journal of Aircraft,

Volume 47(3), pp. 754–762

Jarozs,

K., Czajka, I., Golas, A., 2016. Implementation of Ffowcs Williams

and Hawkings aeroacoustics analogy in OpenFOAM. Vibration in Physical

Systems. Volume 27 p. 161–168

Jasak, H., Jemcov, A., Tukovic,

Z., 2007. OpenFOAM: A C++ Library for Complex Physics Simulations. In:

International Workshop on Coupled Methods in Numerical Dynamics,

Inter-University Center (IUC). Dubrovnik, 19-21 September 2007, Croatia

Jaworski, J.W., Peake, N., 2020.

Aeroacoustics of Silent Owl Flight. Annual Review of Fluid Mechanics,

Volume 52, pp. 395-420

Kors, E., Collin, D., 2020. Perspective

on 25 Years of European Aircraft Noise Reduction Technology Efforts and Shift

Towards Global Research Aimed at Quieter Air Transport. In: Aviation Noise

Impact Management, Springer, Germany, pp. 57–116

Kundu, A.K., Price, M.A.,

Riordan, D., 2019. Conceptual Aircraft Design: An Industrial Approach. United

Kingdom: John Wiley & Sons Ltd

Kusumalestari,

A.S., Soekirno, S., Sudibyo, H., 2019. Prediksi

Kebisingan Airframe Pesawat Terbang Dengan Aplikasi Ffowcs Williams and

Hawkings (Airframe Noise Prediction for Aircraft Using Williams and

Hawkings' Ffowcs Application). In: Seminar

Nasional Sains Teknologi dan Inovasi Indonesia (SENASTINDO AAU),

Yogyakarta, 25 September 2019, Indonesia

Kusumalestari,

A.S., Soekirno, S., Sudibyo, H., Suryanegara, M., Kukusan, B., 2020. Penggunaan Perangkat Lunak dari Opensource dan Metode Komputasi

untuk Prediksi Kebisingan yang Ditimbulkan oleh Airframe Pesawat Terbang (Use

of Open Source Software and Computational Methods for Prediction of Aircraft

Airframe Noise). Wahana Fisika, Volume 5 (2). pp. 71–82

Kusumalestari,

A.S., Sukirno, S., Suryanegara, M., Sudibyo, H., 2019. On

Developing The Noise Reduction Model For Indonesian Aviation. AVIA International

Journal of Aviation Science and Engineering, Volume

1(1), pp. 21–28

Manzo, M.A., Rodríguez, J.C., 2022. Ensuring

the High Performance of Desing and Engineering Firms in Mexico’s Aerospace

Industry: A Qualitative Comparative Analysis. International Journal of

Technology, Volume 13(1), pp. 5–15

Marbona, H.,

2018. Private discussion on Aerodynamics with OpenFOAM at Aerodynamic

Technology Division. P.T. Dirgantara Indonesia. Bandung, Indonesia.

Mendez, S.,

Shoeybi, M., Lele, S.K., Moin, P., 2013. On

The Use of The Ffowcs Williams-Hawkings Equation to Predict Far-Field Jet Noise

from Large-Eddy Simulations, International

Journal of Aeroacoustics Volume 12 (1-2), pp. 1–20

Molin, N., 2019. Airframe Noise Modelling and

Prediction. CEAS Aeronautical Journal Volume 10, Springer, pp. 11–29

Nitzkorski,

Z.L., Mahesh, K., 2015. A Novel Porous Ffowcs-Williams and Hawkings Acoustic Methodology for Complex Geometries.

Doctoral Thesis, The

University of Minnesota, USA

Raje, P.V., 2015. Spalart – Allmaras Turbulence

Model for Compressible Flow. PhD Seminar, Indian Institute of Technology.

Bombay, India.

Raymer, D.P., 2018. Aircraft

Design: A Conceptual Approach. American Institute of Aeronautics and

Astronautics, Inc. Washington D.C., USA

Sahai,

A.K., 2016. Consideration of Aircraft Noise Annoyance During Conceptual

Aircraft Design. Dissertation, Rheinisch-Westfälischen

Technischen Hochschule (RWTH) Aachen University, Germany

Shademan, M.,

Barron, R., Balachandar, R., 2013. Evaluation of OpenFOAM in Academic

Research and Industrial Applications. In: 21st Conference of

the CFD Society of Canada, Sherbrooke, Canada

Sodja,

J., Podgornik, R., 2007. Turbulence Models in CFD. In: University Seminar, University of Ljubljana, March 2007, Slovenia

Soemaryanto,

A.R., Fajar, M., Ichwanul Hakim, T.M., Pinidriya, S.T., Hidayat, K., 2021,

Identification of Flow-Induced Noise Sources on Two-Dimensional High Lift

Devices of Commuter Aircraft. Jurnal Teknologi Dirgantara, Volume 19(2),

pp. 127–134

Spalart,

P.R., Shur, M.L., 2009. Variants of the Ffowcs Williams & Hawkings Equation

and Their Coupling with Simulation of Hot Jets. International Journal of

Aeroacoustics Volume 8(5), pp. 477–492

Suryo, V.N.S.,

Grüter, B., Diepolder, J., Ruseno, N., Holzapfel, F., 2020. Departure

Trajectory Optimization for Noise Abatement Procedure in Soekarno-Hatta

International Airport. Jurnal Teknologi Dirgantara, Volume 18 (2), pp.

141–158

Tofany, N., 2023. Private

Discussion on the Application of OpenFOAM Software at the Indonesian Research

Center (BRIN). Bogor, Indonesia.

Zinoviev,

A., 2002. Application of

Ffowcs Williams and Hawkings

Equation to Sound

Radiation by Vibrating

Solid Objects in A Viscous

Fluid: Inconsistencies and The

Correct Solution, In: Annual

Conference, Australian

Acoustical Society

Zulkarnain,

M., Harny, I., Insdrawaty, M.I., Azman, M.I.F., Azmi., M.I.A., Kusrini, E.,

2023. Study on Nature Fiber Composite for Noise Material Control. International

Journal of Technology, Volume 15(3), pp. 618–627