Reducing Vehicle Heating, Ventilation and Air Conditioning Noise Using Low-Cost and Biodegradable Natural Materials from Coconut Fiber Absorber

Corresponding email: m.zulkarnain@utem.edu.my

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.7086

Yamin, L.M.S., Zulkarnain, M., Darmawan, S., Ariyanti, S., Veza, I., Bakri, M.B., 2024. Reducing Vehicle Heating, Ventilation and Air Conditioning Noise Using Low-Cost and Biodegradable Natural Materials from Coconut Fiber Absorber. International Journal of Technology. Volume 15(5), pp. 1380-1397

| Lubis M. Sobron Yamin | Department of Mechanical Engineering, Tarumanagara University, 11440 Jakarta, Indonesia |

| Muhammad Zulkarnain | Fakulti Teknologi Kejuruteraan Mekanikal, Universiti Teknikal Malaysia Melaka, 75450 Ayer Keroh, Melaka, Malaysia |

| Steven Darmawan | Department of Mechanical Engineering, Tarumanagara University, 11440 Jakarta, Indonesia |

| Silvi Ariyanti | Department of Industry Engineering, Mercubuana University, 11650 Jakarta Indonesia |

| Ibham Veza | Department of Mechanical Engineering, Faculty of Engineering, Bung Karno University, 10320 Jakarta, Indonesia |

| Mohd Badzli Bakri | Fakulti Teknologi Kejuruteraan Mekanikal, Universiti Teknikal Malaysia Melaka, 75450 Ayer Keroh, Melaka, Malaysia |

The heating, ventilation, and air conditioning (HVAC) units

in vehicles can produce significant noise, lowering the sound quality inside

the vehicle and reducing passenger comfort. While noise control methods are

available, they can be expensive and harmful to the environment. To address these

issues, this study aims to investigate using low-cost and biodegradable natural

materials, specifically coconut fibers, for vehicle HVAC noise control. The

study utilized coconut fibers, which have sound absorption properties reaching

42 dBA, to treat an actual Perodua HVAC unit. The treatment targeted the HVAC

noise spectrum at low, medium, and high blower speeds, resulting in reduced

Sound Pressure Levels (SPL) at the passenger's ear position. The composite was

applied to the air inlet head and inlet channel of the HVAC system using a

specific combination of coconut fiber content. The research identified the

sources of noise in the highest contributions that occurred at the blower fan

unit and treated the required areas. In terms of numerical data, the results

showed that the treatment significantly reduced the noise level by 11 dBA.

Additionally, the experiment found that the 8% fiber ratio at low speed

decreased by 14.28% following the treatment. Similarly, the fiber ratio at

medium and high speeds saw reductions of 15.47% and 17.56%, respectively. This

study presents a promising solution for reducing noise in vehicle HVAC units

using cost-effective and eco-friendly materials. Future research should focus

on optimizing coconut fiber ratios, evaluating long-term durability and

biodegradability, validating real-world applicability, and establishing

standardized testing protocols to improve and confirm the effectiveness of

coconut fiber-based noise control in automotive HVAC systems.

Biodegradable materials; Coconut fibers; HVAC noise control; Natural fiber absorber; Noise reduction; Vehicle acoustic comfort

A vehicle's interior sound quality is crucial and requires attention to Noise, Vibration, and Harshness (NVH). The reduction of noise inside a car improves passenger comfort and driving experience and reduces distraction. Enhanced sound quality also influences customer perception of the automotive product, making the vehicle more attractive and competitive (Jennings et al., 2010). Advancements in research and development over the past two decades have revolutionized vehicle engines, making them quieter and delivering superior sound. This progress has resulted in increased perceptibility of secondary sound sources within the vehicle cabin, such as heating, ventilation and air-conditioning (HVAC) systems, entertainment systems, and audio driver assist systems. Among these sources, the HVAC system stands out as the most dominant noise source in the vehicle's interior space, operating continuously while the vehicle is in motion (Singh and Mohanty, 2018). It is fascinating to observe the increasing attention given to the study and reduction of aeroacoustics noise generated by automotive Heating, Ventilation, and Air Conditioning (HVAC) systems, particularly in electric vehicles where other sources of noise are comparatively less significant (Fei and Wang, 2023; Hariharan et al., 2022). Improving acoustic comfort is crucial, and this involves reducing noise from the ventilation system, as well as addressing wind noise and other noise sources (Sun et al., 2024a; Zhou et al., 2023; Taheri, Hosseini, and Razban, 2022; Back et al., 2021). The HVAC noise is classified into low-frequency and high-frequency components, which helps to understand the sources and characteristics of the noise. Humming and buzzing sounds are typically associated with low-frequency noise emanating from components such as blowers and condensers. Notably, these noises may not be as perceptually irritating as high-frequency tonal noises, but they still play a significant role in overall cabin noise (Yoon et al., 2020).

Passengers can be

particularly disturbed by tonal noises at high frequencies. These noises can

come from air outlets, channels, and system discontinuities such as junctions.

These stand out against background noise and can make it seem like the overall

noise level has increased, leading to discomfort (Zhou et

al., 2023). It is essential to reduce both low-frequency

and high-frequency noise components in automotive HVAC systems to achieve

premium acoustic comfort for vehicle occupants. This may involve redesigning

components to minimize vibration and turbulence, optimizing airflow paths to

reduce turbulence and pressure fluctuations, and using sound-absorbing

materials or baffles to dampen noise propagation.

For optimal

performance, HVAC units have a blower that generates noise (Amer, 2024; Hasegawa and Sakaue, 2024; Sun et al., 2024b; Li et

al., 2024; Fei and Wang, 2023; Gowree et al., 2023; Qingyi et

al., 2023). To reduce this noise, conventional strategies

involve designing changes to the blower and its blades (Sun, Xu, and Shi, 2021; Smith, Filippone, and Bojdo, 2020;

Han et al., 2019; Jiang et al., 2019). While design changes can reduce this noise, it needs to focus on

post-production noise control strategies for existing units (Yang, Wang, and Wang, 2023; Pulvirenti, Totaro, and Parizet, 2023; Loreto et al.,

2020). Two methods for post-production noise control

are active and passive noise control. Passive noise control is more

cost-effective and works best at frequencies above 500 Hz, providing noise

reduction throughout the interior space. For example, synthetic sound-absorbing

materials such as micro-perforates, fiberglass, glass wool, and polypropylene

can achieve up to 6-10 dB noise reduction (Mohammadi

et al., 2024; Tao et al., 2021). However, these materials were expensive and had a high carbon

footprint. Additionally, they are not biodegradable or recyclable, making them

an unsustainable choice. Although active noise control can be effective, it is

expensive and only works in specific areas of the vehicle's interior space. To

minimize noise pollution and promote sustainability, the method should

prioritize passive noise control using environmentally friendly materials.

The airflow powered by

machines often generates noise due to the air flowing around them, especially

in low-mach-number flows. Flow-induced noise reduction strategies typically

fall into two categories: active control and passive control (Shige et al., 2024).

Several studies have adopted the passive control approach to reduce

flow-induced noise. This method entails replacing specific parts of the object,

which are exposed to fluid flow, with porous material. By doing so, the noise

is significantly reduced without altering the shape of the object. Notably, the

automotive industry shifted towards Natural Fiber (NR) materials for noise

control since they are sustainable, cost-effective, and effective. Materials

like jute, cotton, flax, kenaf, hemp, coconut coir, bamboo curls, and bananas

are excellent sound absorbers, affordable, lightweight, and environmentally

friendly (Bisheh, 2024; Nawawithan et al., 2024; Singh et al., 2024; 2023;

Dattatreya et al., 2023; Sahib-dua et al., 2023; Patel, Mishra, and Choudhary, 2022;

Hariprasad et al., 2020; Hadiji et al., 2020). NRs are also versatile and can be molded into

various shapes, making them a flexible option for different components. Using

NR materials, manufacturers can achieve effective noise control while reducing

production costs and meeting sustainability goals. Moreover, this trend

reflects broader industry efforts towards eco-friendly and cost-efficient

solutions in automotive design and manufacturing. According to Mago et al. (2022),

Rubber-Bamboo Biochar (BB) composite has been proven to be the most effective natural

material for sound absorption. They used NR to treat a sound absorber in an

automotive unit, and the Sound Transmission Loss (STL) was significantly

increased by 8% and 11% compared to NR composites upon adding 10 and 20 per

hundred rubber of BB, respectively. Recent studies have proven that NR/polymer

composites reinforced with porous fabric exhibit excellent sound energy

absorption properties. Notably, the hollow conjugated cross-section provides

the maximum noise absorption. Nonwoven fabrics composed of biodegradable and

recyclable jute caddies and flax comber noil also have significant noise

absorption properties despite being inexpensive. In addition, a higher punch

density results in better compactness of nonwoven fabric, which leads to improved

sound absorption properties. Meanwhile, layered nonwoven structures are

responsible for better sound absorption properties due to the presence of an

air layer (Paul, Ahirwar, and Behera, 2022).

Nearly all NRs play a

crucial role in absorbing unwanted sound. NR sound absorbers are available in

the form of raw materials, fiber assemblies, and composites. The study of

absorption materials is crucial to understanding the relationship between

material and sound absorption coefficient, as well as overall performance.

Properly designed materials can optimize the prevention of noise from the

source and enhance STL. Moreover, various studies have proposed optimization

strategies for noise control in material design. Firstly, material designs are

characterized through measurement testing and analyzed for sound transmission

characteristics of the composite using experiments (Zulkarnain

et al., 2024; Choudhary et al., 2023; Ciach et

al., 2022; Abdi et al., 2021;

Bhingare and Prakash 2021;

Yang, et al., 2020; Da-Silva et al., 2019). Secondly, numerical studies, such as Finite Element

Analysis (FEA), are utilized to optimize and validate the transmission loss and

vibration through composite materials (Lim, Yaw, and Chen, 2022;

Araújo and Madeira, 2020; Soltani et al., 2020). These studies indicate that optimized design can significantly

mitigate the spread of noise contaminants and enhance acoustical contributions.

Several studies have suggested that NR sound absorbers offer many advantages

over conventional absorbers. However, not all NRs have the necessary properties

to replace mineral fiber and glass fiber. Therefore, it is crucial to compare

the sound absorption properties of NRs and conventional absorbers. To compare

the differences among the absorbers, the sound absorption curves presented by

the previous researcher (Yang et al., 2020) have been separately displayed in the absorption

coefficient results. Thicker absorbers made of coir fiber exhibit better sound

absorption properties than thinner absorbers, such as Yucca Gloriosa fiber.

Moreover, coir fiber demonstrates good absorption agreement with a coefficient

of around 0.95 in the frequency range of 63-6,300 Hz. Thicker absorbers made of

coir fiber with a loose fiber structure demonstrate worse sound absorption

compared to thinner absorbers. Accordingly, most natural absorbers demonstrate

better sound absorption than glass fiber. The utilization of natural resources

in composite production offers a more environmentally friendly approach to

pollution reduction. The effectiveness of bamboo biochar as a filler in natural

rubber composites for vibration and noise control has been investigated by Mago et al. (2022) and Khair et al. (2015).

Materials like rubber (Corredor -Bedoya, Zoppi, and

Serpa, 2017), wool (Ilangovan

et al., 2022), single layer micro-perforated panel (Esraa et al., 2022), Sludge and Fly Ash (Hiadayani

et al., 2023), and silica (Yusoff et al., 2023) are

commonly used to absorb vibrations and noise pollution in engineering

applications. Natural fibers are favored due to their eco-friendly nature,

competitive mechanical performance, and renewable availability throughout the

year.

Furthermore, advanced

computational simulation testing methodologies can help identify noise sources

and evaluate the effectiveness of noise reduction measures. This can facilitate

the development of quieter HVAC systems for automotive applications. The

previous researcher approached reducing noise in commercial electric vehicle

HVAC systems. A multifaceted set of wind tunnel numerical simulations and

practical applications demonstrated significant reductions of over 20 dB in

their design. Researchers studied the noise generation of air outlets in a

car's HVAC system. They simulated the flow and acoustic perturbations using a

hybrid aeroacoustics simulation and also experimented to observe the

interaction between the throttle valve and fins (Ravichandran

et al., 2024). In addition,

numerical analysis has been successfully used to analyze the noise emitted by

automobiles (Zhang et al., 2022), especially the noise generated by the exhaust system, which

significantly impacts human health. To improve this situation, CFD analysis was

conducted on the existing muffler and three newly designed mufflers, considering

the inlet velocity. The results indicated that increasing the pressure drop

(improving aerodynamic performance) also reduced noise pollution (Kalita and Singh, 2022).

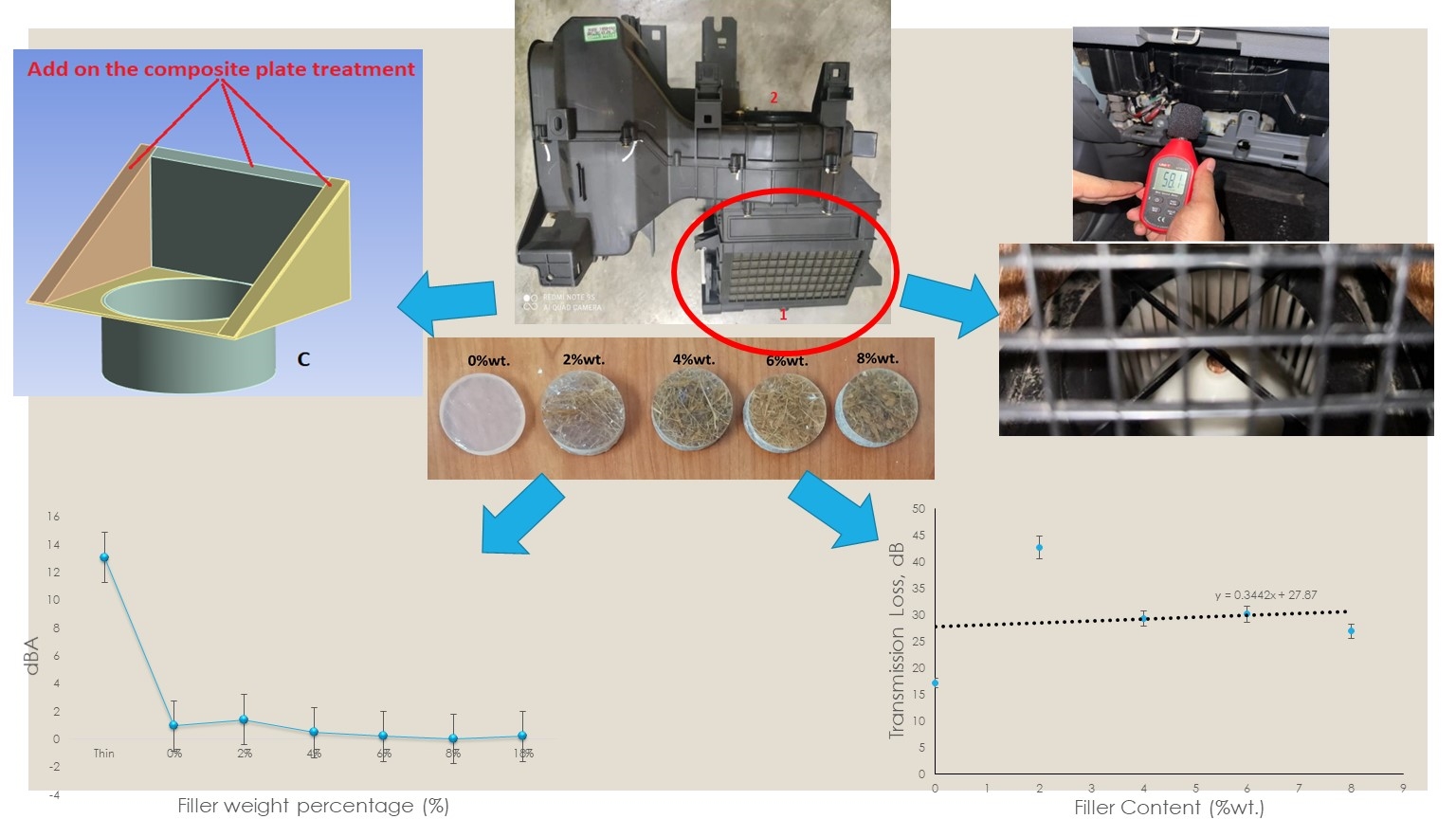

The methodology used to perform

numerical evaluations and experimental noise control methods involved four main

steps, as depicted in Appendix 1.

First, an impedance tube was used to evaluate the coconut composite's sound

absorption and transmission loss, and raw data was collected to characterize

the composite's properties in noise absorption capabilities. In the second

step, the main contribution of noise produced by the vehicle's HVAC system was

evaluated, followed by a numerical method to analyze the appropriate treatment

to be implemented in the HVAC system. Finally, the coconut composite treatment

in the HVAC system was analyzed experimentally in the last step.

2.1. Description of the HVAC unit

The HVAC unit being studied was a

Malaysian vehicle produced by Perodua. It has an 850 cc engine and is made of

plastic. The unit consists of several key components, including a fresh air

inlet, recirculation inlet, and outlet vents, as illustrated in Appendix 2. The observation focuses on

higher noise levels produced by the HVAC system based on measurements, and

several factors could contribute to this phenomenon. This includes blower

speed, air flow restriction, vibration, and restriction. The air enters the unit through the recirculation inlet vent

(number 1), passes through the blower, and then flows over the evaporator.

2.2. Coconut fiber extraction process

The process of extracting coconut fiber

from the inner flesh of coconuts involves peeling, shredding, cleaning, and

sun-drying. To reveal the inner flesh, a machete is used to peel the outer skin

of coconuts. Consequently, the shredding breaks down the fibrous material into

smaller strands, making it easier to process. The shredded coconut fiber is

then cleansed with distilled water to remove any impurities and sun-dried to

remove excess moisture. The physical coir fiber is generally short, ranging

from 15 to 18 cm, with a diameter varying from 0.1 to 0.5 mm.

2.3. Coconut coir fiber treatment

The alkali treatment process for coconut

fiber enhances its flexibility and purity. The process involves soaking the

fiber in a 2% NaOH solution to break down impurities, as displayed in Appendix 3. After rinsing, the fiber

is neutralized and dried to remove excess moisture. The completely treated

fiber is then oven-dried to ensure its purity and readiness. This treatment

process produces high-quality coconut fiber that is suitable for various

applications. By following these steps, manufacturers can produce coconut fiber

that meets industry standards.

2.4. Mixing

Process

In the composite manufacturing process

described, a mixture of polyester and hardener is combined with coconut fiber

at different weight ratios to create composite samples with varying properties.

The following outlines the measurement and mixing procedure for the polyester

and hardener, as per the provided specifications:

Polyester Measurement: Each composite

sample is measured with a total of 350 g of polyester. This specific amount

serves as the base material for the composite and plays a crucial role in

determining its overall composition and characteristics. The

Polyester used in this study was Unsaturated polyester resin (UPR), with key

ingredients such as phthalic anhydride, isophthalic acid, maleic anhydride,

styrene monomer, and glycols supplied by LEZO, China.

Hardener Measurement: The

hardener is added to the polyester at a specific weight ratio to initiate the

curing process and ensure proper adhesion between the polyester and coconut

fiber. According to Table 1, a hardener ratio of 4% is used for the ideal

mixture. Mixture Preparation: The polyester and hardener are thoroughly mixed

to ensure uniform distribution and proper activation of the curing process. To

ensure optimal composite performance, care must be taken to achieve a consistent

blend of polyester and hardener.

Table 1 Mixture of filler content in composite

|

Polyester (g) |

Hardener (g) |

Fiber (g) |

Total Weight (g) |

Fiber Weight (%) |

Hardener (%) |

|

336 |

14 |

0 |

350 |

0 |

4 |

|

329.28 |

13.72 |

7 |

350 |

2 |

4 |

|

322.56 |

13.44 |

14 |

350 |

4 |

4 |

|

315.84 |

13.16 |

21 |

350 |

6 |

4 |

|

309.12 |

12.88 |

28 |

350 |

8 |

4 |

Coconut Fiber Addition: Once the polyester and hardener mixture is

prepared, coconut fiber is added to achieve the desired weight ratio specified

for each composite sample. This step involves combining the polyester-hardener

mixture with the specified amount of coconut fiber and thoroughly mixing them

to ensure proper fiber impregnation.

Composite Sample Preparation: After

mixing the polyester, hardener, and coconut fiber, the composite mixture is

molded or cast into the desired shape or form and allowed to cure according to

the manufacturer's instructions. This results in the formation of composite

samples with varying fiber content and properties suitable for testing and

evaluation.

By following these steps and carefully

controlling the ratios of polyester, hardener, and coconut fiber, researchers

can produce composite samples with predictable and consistent properties,

allowing for accurate analysis and comparison of different formulations.

Mixing Polyester and Hardener: The

polyester and hardener mixture, as displayed in Appendix 4, is prepared. This mixture is carefully blended to

ensure proper curing process activation and achieve the desired properties in

the composite material. Pouring Polyester-Hardener Mixture: With the coconut

fiber in place within the mold, the polyester-hardener mixture is slowly poured

into the mold. The pouring process is conducted in a controlled manner to

ensure even coverage and distribution of the mixture over the entire bottom

area of the mold. This ensures a smooth and flawless finish through the lay-up

technique.: As the polyester-hardener mixture fills the mold, attention is paid

to achieving a smooth and flawless surface finish to the fiber stacking. This

may involve using tools or techniques to spread the mixture evenly and

eliminate any air bubbles or irregularities. Curing Process: Once the mold is

filled with the polyester-hardener mixture, the composite material is allowed

to cure. The curing process initiates the chemical reaction between the

polyester and hardener, forming a solid and durable composite product.

2.5. Material Testing

The ACUPRO Version 4.5 impedance tube was utilized to measure the acoustic properties of materials and systems according to ISO 10534-1 (ISO, 2002) and ASTM E2611 standards for transmission loss measurement. The ACUPRO tube is made of stainless steel and has an internal diameter of 38 mm, and it is equipped with supports and leveling screws. The operating frequency range level was from 50 Hz to 5,000 Hz, and four microphones were used for measurement. The impedance tube was employed to measure both the sound absorption coefficient and the transmission loss across the specified frequency ranges. This is where the sound absorption coefficient determines the amount of sound energy absorbed by a material and provides insights into the material's ability to absorb sound. Transmission loss, on the other hand, evaluates the reduction in sound energy as it passes through a material or system, indicating the effectiveness of the material or system in blocking sound transmission. Appendix 5 displays samples testing of 38 mm in diameter that were prepared for both the sound absorption coefficient and transmission loss testing.

2.6. Noise evaluation of the baseline HVAC unit

The binaural sounds measured at each

point have the possibility of noise produced by digital sound level meter AS804

to analyze sound quality. Correspondingly, we obtain the Sound Pressure Levels

(SPL) with decibel (dB) units in a range of 30 to 130 dB (±1.5 dB). Appendix 6 illustrates the equipment used for

detecting and measuring the noise evaluation of the HVAC system. In this

context, an anemometer is utilized to measure the airflow speed, providing

results within the range of 0 m/s - 30 m/s (±1 m/s). The temperature is

measured in degrees Celsius (°C) within a range of 0 – 50 (±0.5°C).

The process of selecting appropriate

measurement sites within an HVAC system requires several steps to ensure

precise and representative data collection. Here is a step-by-step guide on how

it can be performed: 1. Identify specific locations within the HVAC system

where measurements need to be taken. 2. Select evaluation points providing

representative information about the system's efficiency. 3. Properly position

and calibrate the experimental equipment. 4. Start the vehicle's engine and

turn on the air conditioning system. 5. Conduct measurements of airflow,

temperature, and other relevant parameters at each designated measurement

point. 6. Analyze the collected data to evaluate the HVAC system's performance

and identify improvement areas.

Decibel (dB) measurements and frequency

ranges were collected in the HVAC system, revealing that the highest A-weighted

(dBA) values occurred closest to the fresh air inlet, denoted as number 1 in Appendix 2. This is due to the

proximity to the blower (speed motor) and airflow restriction. Appendix 7 illustrates the recorded

noise level data using a mini sound meter to evaluate the noise in the

recirculation inlet section on maximum power. The measurements were obtained in

a silent environment to ensure precise readings of noise levels. Additionally,

noise, flow, and temperature were recorded from all air outlet valves in the

cabin, with 10 s readings for each. Based on the speed motor specification, it

was given at 1,500 rpm and 5 kg of mass and produced 25 Hz of frequency for

top-speed running. This critical data enables precise analysis of noise sources generated

by HVAC ductwork. Additionally, it is essential for conducting numerical

analysis during noise spectrum measurement.

2.7. Numerical Analysis

The numerical method used in designing

the HVAC system considered the documented loudness data and SPL distribution

closest to the source. ANSYS, a FEA tool, was used to analyze the composite and

help with the actual design, to reduce the SPL power. At the same time, the

acoustic solver in ANSYS used the natural frequencies and mode shapes of the

structure for simulation. Modal analysis was employed as a linear dynamics

analysis technique as presented in Equation (1). To solve the dynamic response

of the structure, the equation of motion was used, where acceleration,

velocity, and displacement for all points over the structure were the unknowns:

where M,

While for harmonic motion, the

oscillation of a simple spring-mass system, the ANSYS is using Equation (2). It

is a periodic motion, which can be described by an amplitude, frequency, and

phase angle:

where A,

2.8. Computational domain and details

The computational domain includes the

fresh air inlet head and inlet channel. The motor was placed at the inlet

channel, which is the noise source. The dimensions of the fresh air inlet can

be observed in Appendix 8(A),

while the computational domain size is 20 cm x 20 cm x 20 cm, as illustrated in

Appendix 8(B). Appendix 8(C)

presents an observation on reducing noise using coconut fiber composite.

2.9. Boundary Condition

To accurately simulate acoustic

pressure, a constant frequency of 25 Hz was set at the inlet channel boundary,

perpendicular to the flow direction. The noise frequency often matches the

frequency of the structure's vibration and is transmitted through the air or

other media. It is crucial to consider each material's specific conditions, considering

its density. Hence, an acoustic region and a radiation boundary were set at the

outer boundaries of the domain to ensure an impeccable simulation. It must be

included in the geometry to incorporate material composite for noise treatment.

Note that a solid physical interface was introduced to separate the air as the

domain and the object dimension. At the same time, the sound source was

presented using a mass source, and the model was ready to start the simulation

process. Accordingly, this approach enhances the accuracy of our acoustic

simulations and ensures the best results.

2.10. Noise

Control Experimental

The final stage of the methodology involves treating the

HVAC unit by lining the recirculation inlet or air flow paths with coconut

composite and filling the cavities inside the ductwork near the blower intake.

The detailed treatment is described in Appendix

8(C), which illustrates the recirculation inlet being covered by coconut

composite. Meanwhile, a varied ratio of coconut composite effects is observed

in airflow and noise absorption analysis.

The alkaline treatment enhances the coconut fibers

for composite applications by cleaning their surfaces, increasing roughness,

and modifying the material. In addition, this process degrades lignin and

hemicellulose, theirby improving the mechanical properties. Coconut fibers are

successfully used in cellulose mercerization before making fiber composites.

3.1.

Noise Absorption Testing

The study aimed to observe the sound absorption

coefficient based on varying filler content ranging from 0 to 8 wt.% The

results suggested that the sound absorption coefficient was diverse across

different frequency ranges. The 6 wt.% of filler content had the highest sound

absorption coefficient at 0.9869, while polyester had the lowest at 0.832, as

displayed in Figure 1. This indicates that the sound absorption coefficient is

close to 1 and had an improvement of around 18.62% compared to polyester.

Further observations discovered that the frequency absorption values at 2,268

Hz presented earlier than other composite filler content. This frequency was

valid; good results were expected for the frequency ranges between 45.6 £ f £

4,559 Hz for coconut (Da-Silva et al., 2019).

In Figure

2, it can be observed how the transmission loss in coconut fiber

composites predicted by DB is affected by filler content. As we add more

filler, the composite effectively counters the sound (dB), as the linear line

suggests. The transmission loss values increase with the addition of filler

content. However, the results reveal that only 2 wt.% of filler content

demonstrated the highest sound (dB) absorbance, which then becomes lower and

remains constant. This result was most likely caused by an uneven distribution

of the fibers and agglomeration during composite fabrication. Therefore, to

ensure the best sound-absorbing results, it is crucial to maintain an even

distribution of the fibers during the fabrication process.

Figure 1 The sound absorption average of coconut fiber

Figure 2 Transmission loss

against filler content of coconut fiber

3.2.

Numerical Analysis

3.2.1. Validation

This

study aimed to validate a proposed simulation method by comparing it to experimental

results. The simulation began by performing A-weighted Mic SPL to understand

the distribution characteristics of thin HVAC channels, which were HVAC systems

without composite treatment, to match the experimental results. The initial

observation found that the A-weighted Mic SPL closely matched the recording

level of the experimental results. This is shown in Figure 3, which

demonstrates the relationship between reading performance from the HVAC channel

and A-weighted Mic SPL within the frequency range of 1.25 Hz to 25 Hz. The

maximum frequency of 25 Hz could produce an A-weighted Mic SPL of 58.165 dB,

comparable to the experiment results, where the maximum was 58.1 from the

equipment reading.

Figure 3 Far-Field weighted Mic SPL

3.3.

A-weighted frequency band SPL Observation

This

study utilized the numerical simulation for A-weight PSL and far-field phase (o)

analysis on the HVAC channel treatment effect. Appendix 9 displays the contour distribution of the A-weighted

frequency band SPL of inlet fresh air half-cut. The simulation predicts the

measured A-weighted frequency band SPL within a combination of coconut fiber

composite treatment, and most of the contour distribution was well met. In the

A-weighted frequency band, the SPL distribution pattern was dominated by a

solid HVAC channel and then distributed to the air, especially on the inlet

fresh air part. The simulated A-weighted frequency level was higher when the

area was near the open channel. For comparison, the simulated A-weighted

frequency level without coconut treatment was higher than that measured with

coconut treatment. It can be observed by plotting the A-weighted frequency band

SPL graph against coconut fiber content (wt.%). The value in the contour was

beginning higher at 0 wt.% and then became lower by adding the coconut fiber

event; the fiber effect came down slowly. The plotting was observed at any

single point inside the channel. Meanwhile, the neck area point inside the

channel was focused on presenting the coconut fiber effect, making it a

powerful solution that should be considered for any related issues, as

illustrated in Figure 4.

Figure 5 displays how the far-field phase (o)

is affected by coconut fiber. The analysis successfully demonstrated that the

far-field phase (o) could be accurately analyzed with adding coconut

fiber. The results indicated a decreasing trend in the far-field phase (o)

as coconut fiber content increased under varied frequency loads. The fiber

effect decreased dramatically when coconut content was at 8 wt.%. Notably, at a

low frequency of 5 Hz, the far-field phase (o) was recorded higher

in the inlet channel and vice versa. As a result, the simulation proves that

coconut fiber composite treatment is an effective solution to achieve noise

control, and this method could guide the experiment to control noise.

Figure 4 A-weighted frequency band SPL effect

Figure 5 Far field phase (o) against inlet

duct system treatment

3.4. Experimental

Table

2 presents the airflow readings obtained before installing the composite

material when there was no fiber in the recirculation inlet area. The data was

collected at a frequency of 10 s, with four data sets obtained at 0 seconds.

Each type of blower speed was counted for 10 s to get the average airflow

value. The first reading at 10 s recorded a value of 3.0 m/s, followed by 4.1

m/s at 20 s and 5.9 m/s at 30 s. The airflow readings were recorded at

different blower speeds, including low, medium, and high speeds During the

experiment, we measured the noise level of the HVAC system. We specifically

focused on measuring the A-weighted SPL near the air outlets in the cabin. It

is worth noting that each blower's speed had a different noise level. However, it

is important to mention that the noise level did not fluctuate with changes in

blower speed. The noise level was measured at a point in the recirculation

inlet area where the volume was high. This point was then measured, and the

noise level was discovered to vary before the composite treatment to obtain the

actual value of the noise level. The distance from the diffuser was considered

to test the noise level, and the actual value was obtained after measuring

along a distance of 0.5 m. The noise measurement was conducted at noon for both

experiments in a quiet environment to obtain the best result.

Table 2 Airflow reading without composite treatment

|

Fan Condition |

Airflow, m/s |

Temperature, oC |

A-Weighted SPL, dB |

|

Low |

3.2 |

19.22 |

59.52 |

|

|

2.97 |

18.17 |

59.47 |

|

|

3.1 |

19.1 |

59.51 |

|

Medium |

4.12 |

19.22 |

62.72 |

|

|

4.05 |

18.17 |

62.67 |

|

|

4.1 |

19.1 |

62.71 |

|

High |

5.92 |

18.92 |

71.22 |

|

|

5.87 |

18.87 |

71.17 |

|

|

5.91 |

19.91 |

71.21 |

3.5.

Treatment Composite Plate

The

use of composite materials in a vehicle's HVAC system can enhance its

efficiency and performance, as depicted in Appendix 10. By placing the composite treatment in the

recirculation area where high sound levels are produced due to the blower's

kinetic energy, a diverse approach can be taken towards improving the system.

Table

3 compares how airflow changes with different ratios of fiber. The experiment

used fiber ratios of 0%, 2%, 4%, 6%, and 8% at low, medium, and high speeds.

The anemometer sensor measured the airflow speed in front of the duct vent

where the recirculation air area outlet is located. Consequently, each data

result was recorded for 10 s for each fiber ratio at low, medium, and high

speeds. It is crucial to obtain precise results to compare the airflow changes

before and after composite treatment. Note that the results should remain

constant. The collected data has revealed that the presence of the composite in

the recirculation inlet area does not affect the airflow speed. Furthermore, the

results have exhibited insignificant changes in the low, medium, and high

airflow speeds. As per the data depicted in Table 3, the airflow speeds at low,

medium, and high levels remained almost similar compared to those without

treatment conditions. Hence, it can be observed that no disturbance was

discovered in the airflow when the composite was located inside the critical

point of the HVAC system. Therefore, the condition relies on the consistency

and stability of airflow speeds while producing the variation speed.

Table 3 Airflow speed measurement by composite

treatment conditions

|

Fiber Content |

Low Speed, m/s |

Medium Speed, m/s |

High Speed, m/s |

|

0% |

2.62 |

3.32 |

5.2 |

|

2.57 |

3.27 |

4.97 | |

|

2.61 |

2.31 |

5.1 | |

|

2% |

2.62 |

3.52 |

5.2 |

|

2.57 |

3.47 |

4.97 | |

|

2.61 |

3.51 |

5.1 | |

|

4% |

2.62 |

3.32 |

5.2 |

|

2.57 |

3.27 |

4.97 | |

|

2.61 |

2.31 |

5.1 | |

|

6% |

2.62 |

3.32 |

5.2 |

|

2.57 |

3.27 |

4.97 | |

|

2.61 |

2.31 |

5.1 | |

|

8% |

2.72 |

3.62 |

5.72 |

|

2.67 |

3.57 |

5.7 | |

|

2.71 |

3.61 |

5.47 |

Further study focused on noise control.

Figure 6 illustrates the comparison results of the noise level in dBs by

various composite treatments. The findings are compelling and are highlighted

in Appendix 9. The data suggests

that the highest noise level occurred at 0 wt.% of composite treatment and

increased with the velocity flow. However, the study also discovered that

increasing the composite's fiber content reduced noise levels significantly.

This trend is a crucial factor in controlling noise levels in the cabin. The

recorded data indicates that the lowest noise levels occurred at 8 wt.% within

51 dB to 58.7 dB of the A-weighted scale. The method data suggests that the

temperature is constant for every sample. Furthermore, the results can be

accurately measured by measuring the time for every fiber ratio at 20 s from

low speed to high speed and repeatedly taking the time for 0%, 2%, 4%, 6%, and

8%. In addition, these findings demonstrate the significance of controlling

fiber content in the composite to reduce noise levels effectively.

Table 4 Temperature measurement by composite

treatment conditions

|

Fiber Content |

Low Speed, oC |

Medium Speed, oC |

High Speed, oC |

|

0% |

19.42 |

19.1 |

18.52 |

|

19.37 |

18.97 |

18.47 | |

|

19.41 |

18.98 |

18.51 | |

|

2% |

19.72 |

19.62 |

19.52 |

|

19.67 |

19.57 |

19.47 | |

|

19.1 |

19.61 |

19.51 | |

|

4% |

18.52 |

19.42 |

18.42 |

|

18.47 |

19.37 |

18.37 | |

|

18.51 |

19.41 |

18.41 | |

|

6% |

19.42 |

18.92 |

18.92 |

|

19.37 |

18.87 |

18.87 | |

|

19.41 |

18.91 |

18.91 | |

|

8% |

19.42 |

19.42 |

18.92 |

|

19.37 |

19.37 |

18.87 | |

|

19.41 |

19.41 |

18.91 |

The noise that enters a vehicle's HVAC system

can come from various sources (Chen

et al., 2023; Deryabin, 2022). Firstly, the noise generated by the engine, which

reverberates through the vehicle's structure, can cause a rumbling or buzzing

effect in the HVAC components. Additionally, the noise generated during air

intake through intake systems and exhaust noise produced during combustion can

contribute to cabin acoustics and impact the HVAC components. Furthermore,

specific components in the car, like fans, pumps, and belts, can produce

distinct noises that affect the HVAC system. Finally, squeaks and vibrations

caused by incorrectly installed or loose HVAC systems or vehicle components can

amplify the overall noise level of the HVAC system in vehicles. This phenomenon

is similar to that reported by previous researchers (Singh and Mohanty, 2018). They proposed using jute felt and waste

cotton for noise control in the HVAC system. After conducting various trials, a

treatment was identified that effectively minimized noise while minimizing

costs and weight. This treatment was applied to the typical HVAC noise spectrum

at medium-high blower speed, resulting in a 4 dB reduction in SPL at the

passenger's ear position, with a minimum reduction of 3.6 dBs per blower speed.

Moreover, the treatment led to a substantial 24% reduction in loudness level,

equivalent to 7 sones. Consequently, it has been determined that treating the

HVAC unit makes it safer for prolonged exposure to sound. Therefore, it can be

concluded that treating HVAC sounds significantly reduces the likelihood of

their occurrence. Furthermore, the application of this treatment has greatly

enhanced the sound quality within the vehicle's interior space. This leads to a

considerable reduction in the annoyance caused by the HVAC sound and the

overall vehicle interior soundscape.

Figure 6 Noise reading with composite treatment

The

study discovered that using coconut fiber can effectively reduce HVAC noise,

resulting in a quieter and more comfortable atmosphere for car occupants. The

numerical analysis demonstrated that coconut fiber is highly effective at

absorbing sound on high-contribution sources of noise treatment (11 dBA). The

results revealed that the airflow percentage difference between before and

after the composite treatment for an 8% fiber ratio in low-speed airflow was

6.67%. In medium speed, the percentage difference was 12.20%, while in

high-speed airflow, it was 6.78%. For temperature, the percentage difference

between before and after the composite treatment for an 8% fiber ratio in low

speed was 1.04%, while in medium and high-speed airflow, the percentage

difference was 0%. Furthermore, the noise measurement percentage difference

between before and after composite treatment of 8% fiber ratio for low speed

was 14.28%. Similarly, the fiber ratio for medium speed and high speed was

reduced by 15.47% and 17.56%, respectively. The noise measurement results

demonstrate a significant difference between before and after the composite

treatment. Therefore, future research

should prioritize the optimization of the coconut fiber ratio at different

speeds to achieve maximum efficiency in reducing noise. Additionally, it is

essential to thoroughly examine long-term durability and biodegradability to

ensure sustainability throughout prolonged usage. Comparative evaluations with

other NRs, such as jute, cotton, and flax, can help establish the most

efficient material for controlling HVAC noise.

On behalf of all the authors, the corresponding

author expresses their appreciation to Fakulti Teknologi Kejuruteraan Melaka,

Universiti Teknikal Malaysia Melaka (UTeM) for facilitating the research in the

form of laboratory equipment and simulation computer software. I would like to

express my sincere appreciation to Universitas Tarumanagara, Indonesia, for

their invaluable support. The expertise and constructive feedback from faculty

members significantly contributed to the manuscript and the research.

| Filename | Description |

|---|---|

| R2-CE-7086-20240712144511.pdf | Appendices |

Abdi, D.D., Monazzam, M., Taban, E.,

Putra, A., Golbabaei, F., Khadem, M., 2021. Sound Absorption Performance of

Natural Fiber Composite from Chrome Shave and Coffee Silver Skin. Applied Acoustics, Volume 182, p. 108264

Amer, M., 2024. An

Innovative Noise Reduction Blower Fan Housing Design Used In Electronics

Cooling. Measurement: Energy, Volume 1, p. 100002.

Araújo, A.L., Madeira, J.F.A., 2020.

Multiobjective Optimization Solutions for Noise Reduction in Composite Sandwich

Panels Using Active Control. Composite

Structures, Volume 247, p. 112440

Back, J., Lee,

S.K., Lee, S.M., An, K., Kwon, D.H., Park, D. C., 2021. Design and

Implementation of Comfort-Quality HVAC Sound Inside a Vehicle Cabin. Applied

Acoustics, Volume 177, p. 107940

Bhingare, N.H.,

Prakash, S., 2021. An Experimental and Theoretical Investigation Of Coconut

Coir Material For Sound Absorption Characteristics. Materials Today: Proceedings, Volume 43, pp. 1545–1551

Bisheh, H., 2024.

Design and Analysis of Hybrid Natural/Synthetic Fibre-Reinforced Composite

Automotive Drive Shafts. Structures, Volume 61, p. 106057

Chen, W., Liu,

Z., Hu, L., Li, X., Sun, Y., Cheng, C., He, S., Lu, C., 2023. A Low-Complexity

Multi-Channel Active Noise Control System Using Local Secondary Path Estimation

And Clustered Control Strategy For Vehicle Interior Engine Noise. Mechanical

Systems and Signal Processing, Volume 204, p. 110786

Choudhary, S.,

Haloi, J., Sain, M.K., Saraswat, P., Kumar, V., 2023. Systematic Literature

Review on Thermal and Acoustic Characteristics of Natural Fibre Polymer

Composites for Automobile Applications. In:

Materials Today: Proceedings, Volume 2023, p. 349

Ciach, M., Fara?,

H., Fröhlich, A., Fedy?, I., 2022. Contrasting

Effects of Light and Noise Pollution Interact with Natural Vegetation Remnants:

Human-Related Indicators Of The Habitat Suitability For Ungulates In The Urban

Landscape. Ecological Indicators,

Volume 142, p. 109261

Corredor-Bedoya, A.C., Zoppi, R.A., Serpa A.L., 2017.

Composites of Scrap Tire Rubber Particles and Adhesive Mortar E Noise

Insulation Potential. Cement and Concrete

Composites, Volume 82, pp. 46–66

Da-Silva, C.C.B., Terashima, F.J.H.,

Barbieri, N., De-Lima, K.F., 2019. Sound Absorption Coefficient Assessment of

Sisal, Coconut Husk and Sugar Cane Fibers For Low Frequencies Based on Three

Different Methods. Applied Acoustics,

Volume 156, pp. 92–100

Dattatreya, K.,

Kumar, S.S., Prasad, V.V.S.H., Pati, P.R., 2023. Mechanical Properties Of Waste

Natural Fibers/Fillers Reinforced Epoxy Hybrid Composites for Automotive

Applications. Materials Today: Proceedings, Volume 2023, p. 001

Deryabin, I., 2022. On Reducing the

Noise of the Internal Combustion Engine of a Motor Vehicle. Transportation

Research Procedia, Volume 61, pp. 505–509

Esraa, A.,

Putra, A., Mosa, A., Dan, R.M., Attia, O.H., 2022. An Empirical Model for

Optimizing the Sound Absorption of Single Layer MPP Based on Response Surface

Methodology. International Journal of Technology, Volume 13(3), pp.

496–507

Fei, F., Wang,

D., 2023. The Influence of The Non-Uniform Airflow on The Energy and Cooling

Performance of The Simplified Electric Vehicle Front End Cooling Module. Applied Thermal Engineering, Volume 233, p. 121216

Gowree, E.R.,

Jaroslawski, T., Mellot, B., Gojon, R., 2023. Noise Reduction on Low Reynolds

Number Rotors by Boundary Layer Transition. Applied Acoustics, Volume 210,

p. 109446

Hadiji, H.,

Assarar, M., Zouari, W., Pierre, F., Behlouli, K., Zouari, B., Ayad, R., 2020.

Damping Analysis of Nonwoven Natural Fibre-Reinforced Polypropylene Composites

Used in Automotive Interior Parts. Polymer Testing, Volume 89, p. 106692

Han, S., Wang,

X., Wang, P., Dong, H., Jin, Z., 2023. Effects of Blade Tip Thicknesses on

Hydrodynamic and Noise Performance of Ducted Propellers. Ocean Engineering,

Volume 289, p. 116270

Hariharan, C.,

Gunadevan, D., Prakash, S.A., Latha, K., Raj, V.A.A., Velraj, R., 2022.

Simulation of Battery Energy Consumption in an Electric Car With Traction and

HVAC Model For a Given Source and Destination For Reducing The Range Anxiety of

The Driver. Energy, Volume 249, p. 123657

Hariprasad, K.,

Ravichandran, K., Jayaseelan, V., Muthuramalingam, T., 2020. Acoustic and

Mechanical Characterisation of Polypropylene Composites Reinforced by Natural

Fibres for Automotive Applications. Journal of Materials Research and

Technology, Volume 9(6), pp. 14029–14035

Hasegawa, M.,

Sakaue, H., 2024. Propeller-Noise Reduction by Microfiber Coating on a Blade

Surface. Sensors and Actuators A: Physical, Volume 371, p. 115273

Hiadayani, T.R.,

Wirjosentono, B., Nasution, D.Y., Tamrin, 2023. Preparation and

Characterization of Sound-Absorbent Based on Polystyrene Reinforced Primary

Sludge and Fly Ash from Pulp Mill. International Journal of Technology,

Volume 14(3), pp. 649–658

Ilangovan, M.,

Navada, A.P., Guna, V., Touchaleaume, F., Saulnier, B., Grohens, Y., Reddy, N.,

2022. Hybrid Biocomposites with High Thermal and Noise

Insulation From Discarded Wool, Poultry Feathers, and Their Blends. Construction and Building Materials,

Volume 345, p. 128324

Jennings, P.A., Dunne, G., Williams, R.,

Giudice, S., 2010. Tools and Techniques for Understanding The Fundamentals Of

Automotive Sound Quality. In: Proceedings of the Institution of

Mechanical Engineers, Part D: Journal of Automobile Engineering, Volume 224(10),

pp. 1263–1278

Jiang, B., Wang,

J., Yang, X., Wang, W., Ding, Y., 2019. Tonal Noise Reduction by Unevenly

Spaced Blades in a Forward-Curved-Blades Centrifugal Fan. Applied Acoustics,

Volume 146, pp. 172–183

Kalita, U., Singh, M., 2022.

Optimization of a Reactive Muffler used in Four-Cylinder Petrol Engine into

Hybrid Muffler by using CFD Analysis. Materials Today: Proceedings, Volume

50, pp. 1936–1945

Khair, F., Putra,

A., Nor, M., Selamat, M., 2015. Enhancement on Acoustical Performance of Feed

‘Imperata Cylindrica’. In: Proceedings of Mechanical Engineering

Research Day, Volume 192(3), pp. 601–608

Li, T., Fang,

X., Yin, J., Wang, Y., Wang, S., Wen, J., 2024. Integrated Adjustable Acoustic Metacage

For Multi-Frequency Noise Reduction. Applied Acoustics, Volume 217, p. 109841

Lim, C.W., Yaw,

Z., Chen, Z., 2022. Periodic and Aperiodic 3-D Composite Metastructures with

Ultrawide Bandgap for Vibration and Noise Control. Composite Structures, Volume 287, p. 115324

Loreto, S.D.,

Serpilli, F., Lori, V., Squartini, S., 2020. Sound Quality Evaluation of

Kitchen Hoods. Applied Acoustics, Volume 168, p. 107415

Mago, J., Negi,

A., Pant, K.K., Fatima, S., 2022. Development of Natural Rubber-Bamboo Biochar

Composites for Vibration and Noise Control Applications. Journal of Cleaner Production, Volume 373, p. 133760

Mohammadi, M., Taban, E., Tan, W.H.,

Din, N.B.C., Putra, A., Berardi, U., 2024. Recent Progress in Natural Fiber

Reinforced Composite as Sound Absorber Material. Journal of Building

Engineering, Volume 84, p. 108514

Nawawithan, N.,

Kittisakpairach, P., Nithiboonyapun, S., Ruangjirakit, K., Jongpradist, P., 2024. Design and Performance Simulation of

Hybrid Hemp/Glass Fiber Composites for Automotive Front Bumper Beams. Composite

Structures, Volume 335, p. 118003

Patel, N.K.,

Mishra, V., Choudhary, T., 2022. Fabrication and Characterization of Epoxy

Composites Reinforced With Jute Fibers And Coconut Fibers: A Mechanical Study. In:

Materials Today: Proceedings, Volume 67, pp. 495–500

Paul, P.,

Ahirwar, M., Behera, B.K., 2022. Acoustic Behaviour Of Needle Punched Nonwoven

Structures Produced From Various Natural And Synthetic Fibers. Applied

Acoustics, Volume 199, p. 109043

Pulvirenti, G.,

Totaro, N., Parizet, E., 2023. A Perceptual Evaluation of Numerical Errors in

Acoustic FEM Simulation For Sound Quality Applications. Applied Acoustics,

Volume 207, p. 109295

Qingyi, S.,

Haodong, X., Jian, C., Jiangtao, Z., 2023. Experimental And Numerical Study On

A New Noise Reduction Design For A Small Axial Fan. Applied Acoustics, Volume

211, p. 109535

Ravichandran,

A., Logdesser, A., Peller, N., Manhart, M., 2024. Acoustic Resonances in an

Automotive HVAC Outlet. Journal of Sound and Vibration, Volume 569, p. 118051

Sahib-dua,

Khatri, H., Naveen, J, Jawaid, M.,

Jayakrishna, K., Norrrahim, M.N.F., Rashedi, A., 2023. Potential of

Natural Fiber Based Polymeric Composites For Cleaner Automotive Component

Production -A Comprehensive Review. Journal of Material Research and

Technology, Volume 25, pp. 1086–1104

Shige, K.,

Terashima, O., Inasawa, A., Komatsuzaki, T., Sakai, Y., Kusano, T., 2024. On

The Reduction of The Flow-Induced Noise Using Porous Material Plates With High

Acoustic Transmissibility. Journal of Sound and Vibration, Volume 568,

p. 117967

Singh, S.,

Mohanty, A.R., 2018. HVAC Noise Control Using Natural Materials To Improve

Vehicle Interior Sound Quality. Applied Acoustics, Volume 140, pp. 100–109

Singh, T., da

Silva Gehlen, G., Singh, V., Ferreira, N. F., de Barros, L. Y., Lasch, G., Poletto,

J.C., Neis, P.D., 2024. Selection of

Automotive Brake Friction Composites Reinforced by Agro-Waste and Natural

Fiber: An Integrated Multi-Criteria Decision-Making Approach. Results in

Engineering, Volume 22, p. 102030

Singh, T., Silva-Gehlen,

G.D., Ferreira, N.F., de Barros L.Y., Lasch, G., Poletto, J.C., Ali, S., Patric

Neis, P.D., 2023. Automotive Brake Friction Composite Materials Using Natural

Grewia Optiva Fibers. Journal of Material Research and Technology,

Volume 26 (2023), pp. 6966–6983

Smith, D.A.,

Filippone, A., Bojdo, N., 2020. Noise Reduction Of A Counter Rotating Open

Rotor Through A Locked Blade Row. Aerospace Science and Technology, Volume

98, p. 105637

Soltani, P., Taban,

E., Faridan, M., Samaei, S.E., Amininasab, S., 2020. Experimental and

Computational Investigation of Sound Absorption Performance of Sustainable

Porous Material: Yucca Gloriosa Fiber. Applied Acoustics, Volume 157, p.

106999

Sun, X., Zhang,

C., Shen, C., Cheng, W., Cui, Z., Wu, Z., Chen, Z., Zhao, L., 2024a. Reduction of

Interaction Noise using Grooved Cylinder and Wavy Leading Edge Airfoil. Journal

of Fluids and Structures, Volume 125, p. 104082

Sun, Y., Xu, G.,

Shi, Y., 2021. Numerical Investigation on Noise Reduction of Rotor Blade-Vortex

Interaction Using Blade Surface Jet Blowing. Aerospace Science and

Technology, Volume 116, p. 106868

Sun, Z., Tian,

J., Zheng, Y., Zhu, X., Du, Z., Ouyang, H., 2024b. Design of Sinusoidal-Shaped Inlet Duct For

Acoustic Mode Modulation Noise Reduction of Cooling Fan. Applied Acoustics,

Volume 216, p. 109741

Taheri, S.,

Hosseini, P., Razban, A., 2022. Model Predictive Control of Heating,

Ventilation, And Air Conditioning (HVAC) Systems: A State-Of-The-Art Review. Journal

of Building Engineering, Volume 60, p. 105067

Tao, Y., Ren,

M., Zhang, H., Peijs, T., 2021. Recent Progress in Acoustic Materials And Noise

Control Strategies–A Review. Applied Materials Today, Volume 24, p. 101141

Yang, L., Wang,

P., Wang, J., 2023. Research on Evaluation Model for Vehicle Interior Sound

Quality Based on An Optimized BiLSTM Using Genetic Algorithm. Mechanical

Systems and Signal Processing, Volume 204, p. 110827

Yang, T., Hu,

L., Xiong, X., Oetru, M., Noman, M.T., Mishra, R., Militky, J.. 2020. Sound

Absorption Properties of Natural Fibers: A Review. Sustainability MDPI, Volume 12(20), pp. 1–25

Yoon, S., Song,

D., Kim, J., Kim, J., Lim, H., Koo, J., 2020. Identifying Stack-Driven Indoor

Environmental Problems and Associated Pressure Difference In High-Rise

Residential Buildings: Airflow Noise And Draft. Building and Environment, Volume

168, p. 106483

Yusoff, N.M.,

Lee, H.K., Ng, E.K., Rosli, N.S., Abdullah, C.A.C., Alresheedi, M.T., Mahdi,

M.A., 2023. Titania-Coated Silica Nanocomposite For L-Band Noise-Like Pulse

Fiber Laser. Journal of Luminescence,

Volume 258, p. 119779

Zhang, B., Zhai,

Z., Lun, X., Cui, H., Lan, Y., 2022. Test Analysis And Numerical Simulation of

Noise From Forage Crushers. Applied Acoustics, Volume 196, p. 108873

Zhou, S.L.,

Shah, A.A., Leung, P.K., Zhu, X., Liao, Q., 2023. A Comprehensive Review of The

Applications Of Machine Learning for HVAC. DeCarbon, Volume 2, p. 100023

Zulkarnain, M.,

Harny, I., Insdrawaty, M.I., Azman, M.I.F., Azmi, M.I.A., Kusrini, E., 2024.

Study on Nature Fiber Composite for Noise Material Control. International

Journal of Technology, Volume 15(3), pp. 618–627