Synthesis, Characterization, and Application of Polyurethane-Acrylic Hybrids as Anticorrosion Coatings

Corresponding email: a.negim@kbtu.kz

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.7044

Negim, E., Shalash, M., Al Azzam, K.M., Sagatbekovna, M.Z., Kairatovna, B.A., Konstantinovich, A.T., Adlikhanovna, N.A., Ermekovna, K.A., Ravindran, B., 2024. Synthesis, Characterization, and Application of Polyurethane-Acrylic Hybrids as Anticorrosion Coatings. International Journal of Technology. Volume 15(6), pp. 2009-2023

| Elsayed Negim | 1. School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole Bi, 59, Almaty 050000, Kazakhstan. 2. School of Petroleum Engineering, Satbayev University, 22 Sat |

| Marwan Shalash | Faculty of Pharmacy, Zarqa University, Zarqa 13110, Jordan |

| Khaldun M. Al Azzam | Department of Chemistry, Faculty of Science, The University of Jordan, 11942 Amman, Jordan |

| Mukatayeva Zhazira Sagatbekovna | Department of Chemistry, Faculty of Natural Science and Geography of KazNPU named after Abai, St. Kazybek Bi, 30, Almaty 050010, Kazakhstan |

| Baidullayeva Ainash Kairatovna | Department of Engineering Disciplines and Good Practices, School of Pharmacy, Kazakh National Medical University named after S.D. Asfendiyarov St. Tole Bi, 94, Almaty 050000, Kazakhstan |

| Alferov Temirlan Konstantinovich | School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole Bi, 59, Almaty 050000, Kazakhstan |

| Nurtazina Adeliya Adlikhanovna | School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole Bi, 59, Almaty 050000, Kazakhstan |

| Karabayeva Aykumis Ermekovna | School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole Bi, 59, Almaty 050000, Kazakhstan |

| Balasubramani Ravindran | 1. Department of Civil & Energy System Engineering, Kyonggi University, Suwon, Gyeonggi -Do, 16227, South Korea. 2. Department of Medical Biotechnology and Integrative Physiology, Institute of Biotech |

In the current study, the synthesis, and properties of polyurethane (PU) and acrylic copolymer (AK), as well as polyurethane/acrylic polymer hybrid (PU/AK), were examined. Polyurethane (PU) was synthesized by the polyaddition polymerization of isocyanates [Isophorone diisocyanate (IPDI) and hexamethylene diisocyanate (HDI)] and polyols (GP 2000 and GP 4000) at an NCO/OH ratio of 0.85 and a temperature of 100°C. The acrylic copolymer (AK) based on methyl methacrylate (MMA) and butyl methacrylate (BuMA) was synthesized using a bulk polymerization process using benzoyl peroxide as a catalyst. Polyurethane/acrylic hybrids (PU/AK) were created by combining PU with varying amounts of AK (5, 10, 20, 30, 40 wt.%). Several formulations were created to examine the impact of AK content on the physical and mechanical characteristics of PU/AK hybrid polymers, as well as the anticorrosion resistance of hybrid coatings (PU/AKC). To verify that the PU polymerization reaction had finished and to characterize AK, IR spectroscopy was used. The physical and mechanical properties of PU, AK, and PU/AK including viscosity, thixotropic index (TI), tensile, elongation, hardness, adhesion, contact angle, impact test, crosshatch, and anticorrosion properties were significantly affected by the concentration of AK. The viscosity, TI, tensile strength, hardness, contact angle, and adhesion increased with increasing concentration in the PU/AK hybrid. The cross-linking of PU and AK in the hybrids increases the mechanical characteristics. However, the hybrid coating containing 10% AK had the highest chemical and corrosion resistance compared to the other contents of AK and PU.

Acrylic; Anti-corrosion; Coating; Hybrid; Polyurethane

The primary effect of

metal corrosion in the oil and gas industry is to shorten the lifespan of

numerous equipment, which can lead to significant financial losses and safety

issues (Vakili et al., 2024; Lawal et

al., 2023; Solovyeva, Almuhammadi, and

Badeghaish, 2023; Bender et al., 2022; Marathe

and Gite, 2016). Since polyurethane polymers (PUs) are renewable and

versatile resources, they have been employed in coatings to protect metals

against corrosion and continue to play an essential role (Alshabebi et al., 2024; Maurya, de-Souza, and Gupta, 2023; Patil et al., 2021;

Cao et al., 2020; Negim et al., 2020; Jiang et al., 2019; Ur-Rahman

et al., 2018; Deng et al., 2017; Syrmanova

et al., 2016). By adding polymerization between isocyanates and

polyol, PUs are made (Ramezanzadeh et al.,

2015).

Anti-corrosion

coating is a surface treatment that can be applied to both concrete and steel

reinforcement. The primary purpose of concrete surface coating in terms of

anti-corrosion is to reduce the penetration of aggressive agents such as carbon

dioxide, chloride ions, oxygen, and water, or to lower the conductivity and

corrosion rate of the concrete (Hu et al.,

2022).

PUs have

achieved enormous success in the paint industry after being created to improve

their mechanical and physical qualities (Yeligbayeva et

al., 2024; Akhanova

et al., 2024; Syrmanova et al., 2016). In the coating

sector, some of the value of polyurethane resins has decreased due to the

emergence of new polymers. Compared to polyurethane resins, the new coating

materials had fewer volatile organic compounds (VOCs) and were based on water,

which was the primary factor responsible for the environmental impact. In

addition, the surface characteristics of water-based coatings might be

adversely affected by their relatively high surfactant concentrations (Bartman et al., 2023; Kurpanik et al.,

2022; Zhang et al., 2021; Negim et al., 2020; Negim et al.,

2019; Marathe and Gite, 2016; Butler, Fellows, and Gilbert, 2004). Also,

polyurethane-water-based, and polyurethane-solvent-based have low mechanical

and physical properties. To improve the properties of polyurethane, modified

polyurethane resins are made of modifiers integrated into the polyurethane

fiber structure by using a hybrid process. Performance improvements in the

resultant materials are anticipated when acrylics and PUs are combined (Wang et al., 2023; Lovato et al., 2023;

Bichu et al., 2023; Yan et al., 2023; Zhang et al., 2020; Son et al., 2011).

Acrylic

and PU have advantages including high mechanical properties and excellent

chemical resistance (Bui et al., 2020).

Styrene and (meth)acrylates are used to produce the most common hybrids with

PUs. The primary goal of creating these hybrids is to combine the advantages of

these different kinds of polymers to create materials with improved

functionality. Polyurethane-acrylic latex has been extensively researched as a

potential replacement for PU-based coatings (Zhu et

al., 2008). The unique characteristics of each component—PUs and

polyacrylates—are combined to create the resulting copolymer. Positive attributes

that are often desired include fast drying, good adherence to the substrate,

high gloss of the PUs, oxidative drying, good film formation, and chemical

resistance of the acrylic latexes. The incompatibility of hydrophobic polymeric

units (PUs) and aqueous dispersions of acrylic polymers limits their use as

blends in several applications. For instance, using incompatible.

PU-acrylate

mixes often lead to decreased gloss and the formation of haze in films. In

order to address this problem, polyurethane and acrylates are chemically bonded

together to create PU-acrylic copolymer latexes. In contrast, Negim et al. (2024) combined polyurethane

and 2-hydroxy ethyl acrylate to create polyurethane-acrylic hybrids with an

NCO/OH ratio of 2.2. The findings showed that, in comparison to those of pure

polyurethane, the physical and mechanical qualities of the hybrids improved with

an increase in the quantity of 2-hydroxy ethyl methacrylate. The structure of

the pure polyurethane and the finished qualities of the PU were altered by the

addition of the acrylic component to the hybrids (Peruzzo

et al., 2010). A 50% acrylic content exhibited the excellent

properties of PU.

Anticorrosive

nanocoatings provide significant protection for metals and alloys in different

environments. They enhance functionality and extend shelf life by preventing

corrosion from water, microbial biofilm formation, dirt, and other

contaminants. These coatings also offer self-cleaning, antifouling, and active

corrosion protection through self-healing. They are categorized into metallic,

ceramic, and polymeric nanocoatings based on the matrix type, and

graphene/carbon-based nanocoatings as nanofillers. Examples of commercialized

anti-corrosion agents are also discussed below (Susai

et al., 2020).

Commercial

anticorrosion products such as NanoTech HPC, NC-310, Supertemp 316, Superlife

316 DTMR, and Nasiol MP55 are available. NanoTech HPC generates covalent bonds,

increasing pipes' strength and longevity by three to eight times. It offers

hardness and elasticity, is 10–20 microns thick, and doesn't cause galling or

seizing. It's used in the oil and gas sector to protect pipelines. NC-310 is a

biologically modified ceramic coating used for anticorrosion on aluminum and

other metals. Supertemp 316 and Superlife 316 DTMR are liquid stainless-steel

coatings injected with 316L stainless steel flakes. The FDA and USDA propose

these coatings for meat, poultry, and chicken processing plants. Nasiol MP55 is

an ultratransparent, time-saving, and easy-to-clean nanocoating ideal for

protecting metallic bodies and alloys from corrosion (Susai

et al., 2020).

In this

study, PU was coated by a hybrid with an acrylic copolymer containing methyl

methacrylate and butyl methacrylate at a feed composition of 5:5. The PUs were

prepared based on a mixture of isocyanates and different polyols with an NCO/OH

ratio of 0.85. The obtained acrylic copolymer and PU were characterized by

FTIR. The mechanical properties of the PU/AK hybrid films were investigated.

Additionally, the chemical and corrosion resistance of the PU/AKC hybrid

coatings were tested through standard methods.

2.1. Materials

Polypropylene

glycol (GP-2000) (Mw

= 2000 g/mol, OH number = 56 mg KOH/g), GP-4000 (Mw = 4000

g/mol, OH number = 29.5 mg KOH /g), GP-3000 (Mw = 3000 g/mol,

OH number = 37 mg KOH /g), and GP-2100 (Mw

= 3000 g/mol, OH number = 56 mg KOH /g) were purchased from Korea PTG, Korea

and were dried at 80oC, and 1-2 mm Hg, for 2 h before use. Dibutyltin dilaurate (DBTDL), isophorone diisocyanate

(IPDI), and hexamethylene diisocyanate (HDI) were purchased from Bayer AG,

Germany.

Additionally, solvents including xylene, methyl ethyl ketone (MEK purity

> 99.9%), hydrochloric acid (ACS reagent, 37%), sulfuric acid (ACS reagent,

37%), ethanol (ACS reagent 20%), and sodium chloride (ACS reagent 10%) were

purchased from Sigma Aldrich, USA. The ESOL N100 plasticizer from VISTALINE in

Russia and the BYK-054 defoamer from BYK in the USA were also used. Calcium

carbonate (filler) and TiO2-R-996 (pigment) were purchased from Elementis in

Malaysia and used without requiring additional purification.

2.2. Polyurethane Polymer Synthesis

The polyurethane

polymer was prepared using the previously published methods (Wang et al., 2023; Zhang et al., 2020;

Negim et al., 2019). Polymerization took place in a 500 mL

round-bottom, four-necked separable flask equipped with a drying tube,

condenser, and thermometer. In an oil bath at a constant temperature, the

reaction was conducted in an N2 environment. The di-n-butylamine

titration technique was used to estimate the theoretical NCO value, which was

attained after charging the reactor with isophorone diisocyanate (IPDI),

hexamethylene diisocyanate (HDI), and polyols (GP 2000 and GP 4000) (ASTM D

2572). The mixture was then heated at 100oC for 3 h.

The polyurethane polymer was produced

in the same manner as previously described in the literature (Wang et al., 2023; Zhang et al., 2020;

Negim et al., 2019). Polymerization was carried out in a 500 mL

round-bottom, four-necked separable flask equipped with a mechanical stirrer,

thermometer, condenser, and drying tube. The reaction took place in a

constant-temperature oil bath in an N2 environment. Isophorone

diisocyanate (IPDI), hexamethylene diisocyanate (HDI), and polyols (GP 2000 and

GP 4000) were added to the reactor, and the mixture was heated at 100°C for 3 hours until

the theoretical NCO value was attained, as evaluated by the di-n-butylamine

titration technique (ASTM D 2572-19, 2019).

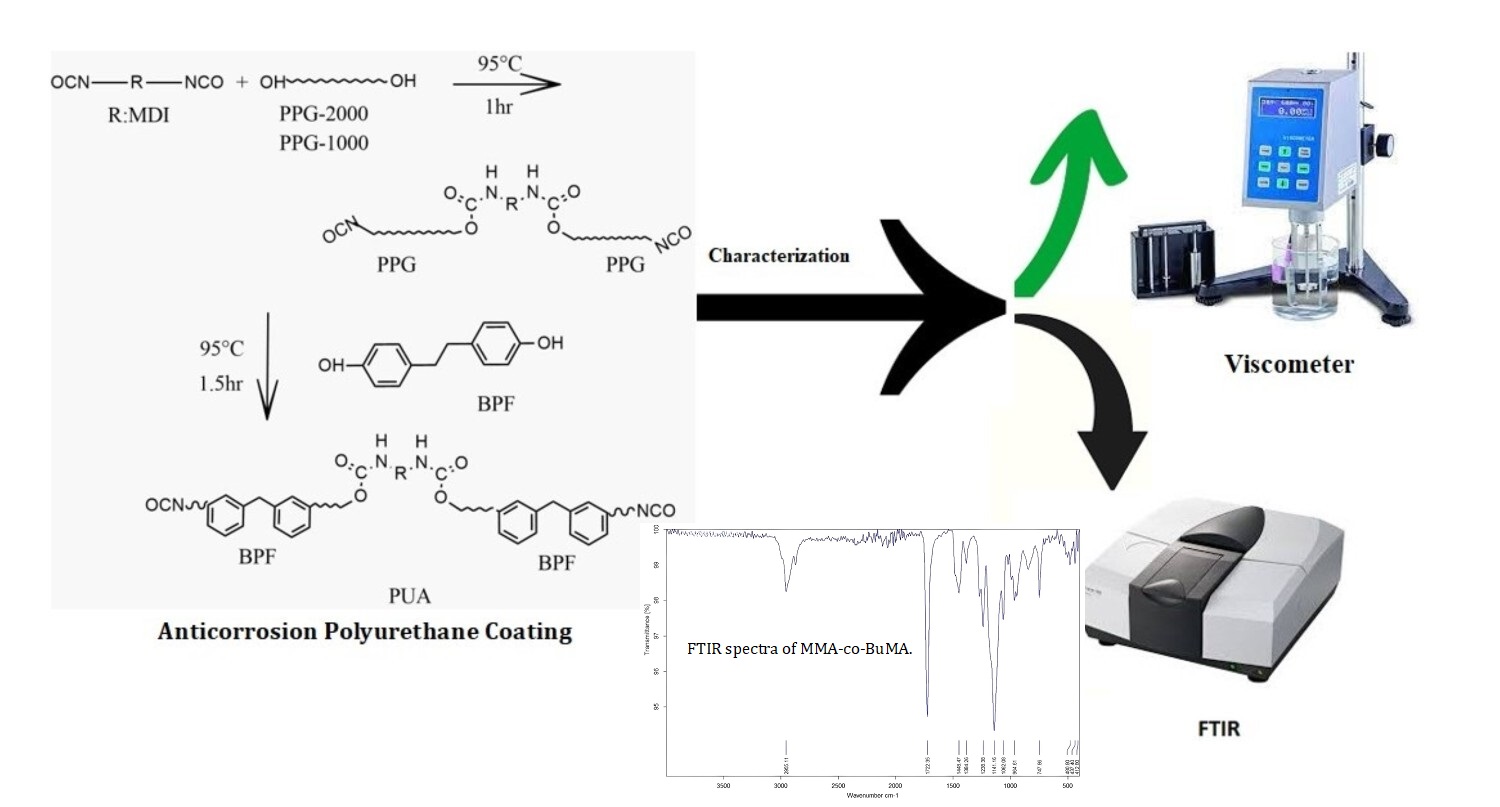

Figure 1 depicts the reaction method used to prepare the prepolymer. Table 1

displays the samples that were made. The resulting PU was clear and liquid,

with viscosities of 120 mPa-s and 464.4 mPa-s at 5 and 50 rpm, respectively.

Table 1 Crystal size of heterogeneous catalyst using Debye-Scherrer Equation.

|

|

Wt

(g) |

Wt

(%) |

|

Polyols, OH |

|

|

|

GP 2000 |

168.5 |

82.2 |

|

GP 4000 |

21.6 |

10.5 |

|

Total |

190.1 |

92.7 |

|

Mole of OH

(gm/ mole) |

0.0896 | |

|

Isocyanate,

NCO |

|

|

|

IPDI |

8.5 |

4.1 |

|

HDI |

6.4 |

3.1 |

|

Total |

14.9 |

7.3 |

|

Mole of NCO

(gm/mole) |

0.0762 | |

|

NCO/OH |

0.85 |

|

Figure 1 The reaction scheme for the preparation of PU.

2.3. Synthesis of poly(methyl methacrylate-co-butyl

methacrylate) (AK)

The copolymerization

of methyl methacrylate (MMA) in conjunction with butyl methacrylate (BuMA) in

feed (5/5) was prepared by the bulk polymerization technique. The two monomers

MMA and BuMA were added to a 250 mL three-necked flask. Using an automatically

regulated water bath in an atmosphere of nitrogen, benzoyl peroxide was introduced

to the flask and mechanically stirred for 3 h at 500 rpm and 82oC.

The copolymer obtained was analyzed using FTIR to confirm its structure and

functional groups. The MMA-co BuMA was liquid and transparent in appearance

with viscosities of 432 mPa-s and 600 mPa-s at 5 and 50 rpm, respectively.

2.4. Preparation of polyurethane/acrylic hybrids (PU/AK)

Polyurethane/acrylic

hybrids were prepared by mixing process at temperatures 60oC and 600

rpm. Further details about the PU/AK hybrids are given in Table 2.

Table 2 The composition of the PU/AK hybrids.

|

Samples |

Polyurethane

polymer Wt., (gm) |

Poly MMA-co

BuMA Wt., (gm) |

|

PU |

100 |

0 |

|

PU/AK-5 |

95 |

5 |

|

PU/AK-10 |

90 |

10 |

|

PU/AK-20 |

80 |

20 |

|

PU/AK-30 |

70 |

30 |

|

PU/AK-40 |

60 |

40 |

2.5. Preparation of PU and PU/AK hybrid films

PU and PU/AK films

were created by casting the solution onto a flat surface and allowing it to

cure for five days at room temp. The films were stored in a desiccator at room

temperature for subsequent characterization and measurement.

2.6. Preparation of the PUC and PU/AKC coatings

To prepare the PUC

and PU/AKC coatings, the weight percentages of the coating ingredients can be

found in Table 3. In all formulations, the solid content of PU or PU/AK

accounted for 27% of the total mixture. Xylene and polyols (GP-3000 and

GP-2100) were combined in a vial and mixed for 10 minutes at a speed of 500

rpm. After adding the plasticizer ESOL N100 and the anti-foam BYK-054, the

mixture was stirred for five minutes. Calcium carbonate (filler) and TiO2-R-996

(pigment) were added to the mixture and continued to mix for 30 minutes at 1200

rpm. Finally, DBTL (catalyst) is added during the application of the coating on

the metal.

Table 3 The composition of the PU/AK hybrids.

|

Raw materials |

Weight percent |

|

PU or PU/AK |

27 |

|

Xylene |

6.45 |

|

GP-3000 |

9.24 |

|

GP-2100 |

4.5 |

|

ESOL N100 |

4.5 |

|

BYK-054 |

0.35 |

|

Calcium carbonate |

40.16 |

|

TiO2-R-996 |

4 |

|

DBTDL |

0.4 |

|

Total |

100 |

2.7. Application of the PU and PU/AK as coatings

Before applying the

coating, the metal samples with dimensions of 9.0 cm x 0.9 cm x 15 cm were

subjected to abrasive blasting and cleaning. The coating, which was based on PU

and PU/AK, was applied using a film applicator to achieve a wet film thickness

of 75 mm. The samples were then allowed to cure at room temperature for a

period of 6 days.

2.8. Tests

FTIR spectra were

obtained with a Bruker Tensor 37 FTIR spectrometer. The Y-axis, which

represents the percentage of transmittance difference between the signals,

might be utilized in calculating the transmittance %. Additionally, software

that automatically calculates and shows the % transmittance vs wavenumber (or

wavelength) for the whole spectrum is included with the majority of modern FTIR

spectrometers. The viscosity (h) of the PU, AC, and PU/AC hybrids was

measured using a Brookfield viscometer, Spindle 2, at speeds of 5 and 50 rpm at

25°C. The thixotropy index was obtained using equation 1;

To determine the contact angle between the

water droplets and the sample surface, a CAHN DCA-322 contact angle measuring

device was employed. It was run at 25°C with a water drop and a velocity of 100

lm/s. A little syringe was used to deposit a drop of water on the surface to be

investigated, and the contact angle was measured by watching the water drops

form on the monitor.

The

findings were obtained by averaging three measurements performed on separate

portions of the film. The tensile properties of the cast films were evaluated

using an MTS 10/M tensile testing system with a crosshead speed of 50 mm/min. A

minimum of four values were averaged, and a 1-kN load cell was utilized.

Furthermore, an indentation Barcol hardness tester was used to evaluate the

hardness in accordance with ASTM B648-10. Pull-off testing was used to

determine the degree of adhesion between the metal and hybrid polymers in

accordance with ASTM D4541. Tests for corrosion resistance were carried out on

coated panels using salt (10% NaCl), base (10% NaOH), acid (37% HCl and H2SO4),

solvent resistance (xylene, MEK, and ethanol) (ASTM D5402-93), and water

resistance (D1647-89). A temperature of 25°C was used to record the dry

times.

3.1. FTIR analysis

The success of the addition polymerization of isocyanate (NCO) with

polyol (OH) was evaluated by FTIR spectroscopy as shown in Figure 2. According

to the FTIR spectrum of pure isocyanate (Figure 2a), the observed that the

transmittance of NCO peak at 2243 cm-1 was 95%, which decreased to

15% at 2261 cm-1, as shown in Figure 2b for polyurethane, which was

attributed to the consumption of OH group of polyols (GP 2000 and GP 4000) for

80% of the NCO during the addition polymerization. The new peaks observed in

Figure 2b for the polyurethane polymers were at 2867-2930 cm-1 for

CH2, and at CH3, and 1091 cm-1 for the ether

group (C–O–C) due to the polyol groups. The structure of PU is shown in Figure

1.

The FTIR spectrum of poly MMA-co BuMA is shown in Figure 3. The FTIR

spectrum of the copolymer showed a peak at 1732 cm-1 for the

carbonyl group, peaks at 2960 and 3437 cm-1 for CH stretching, and a

peak at 1273 cm-1 for the (C–O–C) ester group. The structure of the

copolymer is shown in Figure 4.

Figure 2 FTIR spectra of (a): pure isocyanate and (b) PU

Figure 3 FTIR spectra of MMA-co-BuMA

Figure 4 Structure of Poly MMA-co-BuMA

3.2. Viscosity and thixotropic

index (TI)

The effect of the content of poly (MMA-co-BuMA) on the viscosity of the

polyurethane/acrylic hybrid at speeds of 5 and 50 rpm is shown in Figure 5. The

viscosities of PU were 464 mPa-s and 120 mPa-s, while the viscosities of poly (MMA-co-BuMA)

(AK) were 432 mPa-s and 600 mPa-s at 5 and 50 rpm, respectively. Generally, the

rheology study of the polymer indicated that the viscosity of the polymer

decreased as the rpm increased because of the shear-thinning nature of the

polymer (Wang et al., 2020). The viscosity of PU/AK increased with increasing AK content in the

PU/AK hybrids. PU/AK-5 had the lowest viscosities of 453 mPa-s and 110 mPa-s at

5 and 50 rpm, respectively, while PU/AK-40 had the highest viscosities of 770

mPa-s and 180 mPa-s at 5 and 50 rpm, respectively. The higher molecular weight

of the hybrids may be the cause of the increase in viscosity (Nanda et al., 2005).

Figure 5 The viscosity of

PU/AK hybrids at speeds of 5 and 50 rpm.

The thixotropic index (TI)

is a significant factor in controlling the quality of a polymer for coating

applications. The thixotropic index of PU was 3.87, while it was 0.72 for AC,

as shown in Figure 6. The mixing of AK with PU to produce a hybrid polymer

increased the TI from 3.87 to 3.9 for PU/AK-20 and PU/AK-30 and to 4.2 for

PU/AK-40, which is greater than the standard for coating applications (TI =

3.0). The thixotropy of the coating influences the formulation and preparation

process of the coatings and in turn, affects the rheological properties of the

coating (Wang

et al., 2022).

Figure 6 The thixotropic index (TI) of PU/AK at different ratios

3.3. Adhesion

Figure 8 The cross-linking between PU and AK in the PU/AK hybrid.

3.4. Mechanical Properties

The

chemical properties of polymers are determined by various factors such as the

type of monomer, material, solvent, temperature, crosslinking, and

concentration. Table 4 shows the impact of AK on the PU/AK hybrid. When AK is

mixed with PU to create a hybrid, it enhances the tensile strength, hardness,

and contact angle, while reducing the elongation at break. The increase in the

mechanical properties of PU/AK is affected by the length of the side chains

through the hydrogen bonds between PU and AK as shown in Scheme 4. For example,

the tensile strength of PU was 75 MPa, while PU/AK enhanced tensile strength to

97 MPa for PU/AK-5 and 201 MPa for PU/AK-40. Furthermore, hardness (shore D)

increased from 45 for PU to 68 for PU/AK-40. The impact test was passed for all

samples except AK, which passed the crosshatch test. PU/AK had better

mechanical properties than PU, AK, and other PU/AK hybrids due to the two kinds

of cross-linking between PU and AK. A number of researchers have reported that

crosslinking the backbone of a polymer is an effective way to increase the

mechanical properties of polymer films (Lei et al., 2015).

Table 4 Mechanical properties of the PU and PU/AK hybrids.

|

|

Tensile

strength, MPa |

Elongation,

% |

Hardness,

shore D |

Contact

angle |

Impacta

test |

Crossb

Hatch |

|

PU |

75 |

200 |

45 |

105 |

Pass |

Pass |

|

PU/AK-5 |

97 |

158 |

50 |

120 |

Pass |

Pass |

|

PU/AK-10 |

164 |

125 |

53 |

132 |

Pass |

Pass |

|

PU/AK-20 |

180 |

110 |

58 |

140 |

Pass |

Pass |

|

PU/AK-30 |

186 |

106 |

63 |

145 |

Pass |

Pass |

|

PU/AK-40 |

201 |

95 |

68 |

147 |

Pass |

Pass |

a: A test used to assess the

adhesion of paint coatings and provides an instant assessment of the quality of

the bond to the substrate.

b: A test used for

assessing the durability and resilience of powder coatings.

3.5. Chemical and corrosion resistance

Table 5 illustrates the

impact of the AK component on the chemical and corrosion characteristics of

hybrid coatings (PU/AKC). These characteristics include resistance to solvents,

acids, alkaline substances, water, and salt coatings. The results indicate that

the polyurethane coating is effective against alkaline, water, and ethylene

glycol solutions. However, the addition of AK in the PU coating enhances

corrosion and chemical resistance. The hybrid coating PU/AKC5 (5% AK) is

suitable and slightly suitable for most chemical and corrosion treatments.

Increasing the AK content to 10% increased the corrosion resistance of the

coating hybrid. Out of all the evaluated samples, PU/AKC10 showed the best

resistance to chemicals and corrosion. Table 5 illustrates how the hybrid

coating's resistance to chemicals and corrosion was reduced when the amount of

AK in the hybrids increased. The coating's adherence to the metal is what

causes its corrosion resistance to grow and decrease (Negim

et al., 2020; Wang et al., 2019; Kozakiewicz, 2015; Madbouly and Otaigbe,

2005).

The study coated PU

with a 5:5 acrylic copolymer containing methyl and butyl methacrylate, prepared

from isocyanates and polyols with a 0.85 NCO/OH ratio. FTIR characterization

was used to investigate mechanical properties and chemical and corrosion resistance

of the PU/AK hybrid films. Polyurethane (PU) was prepared from a mixture of

isocyanates (IPDI and HDI) and different polyols (GP-4000 and GP-2000) using

the polyaddition technique, while acrylic copolymer (AK) was synthesized by a

bulk technique based on methyl methacrylate and butyl methacrylate. Polyurethane and coating hybrids were created

by mixing PU with varying amounts of AK in order to investigate how AK content

affected the hybrid films' mechanical and physical characteristics as well as

their resistance to chemicals and corrosion. AK and UP together improved the

mechanical and physical characteristics of the polyurethane/acrylic hybrids

because they include functional groups that come from PU and AK, such as NCO,

NH, carbonyl, and ester groups, which may cause cross-linking between UP and

AK. The tensile strength, adhesion, hardness, and contact angle of the PU and

AK hybrids were all higher than those of the pure PU and AK. But when the AK

concentration rose, the tensile strength, adhesion, contact angle, and hardness

all improved while the elongation at break reduced. This is primarily explained

by the polymeric network that PU and AK cross-linked to produce the hybrid

polymer. However, the coating hybrids exhibited the best chemical and corrosion

resistance when the PU/AKC hybrids contained 10% AK. PU/AK hybrid polymers

could offer enhanced anticorrosion resistance and mechanical properties, making

them ideal for various industries. They are suitable for protective coatings on

metals, construction adhesives, aircraft components, marine environments,

bridges, pipelines, electronic components, and industrial packaging materials.

These properties make them suitable for durability, chemical resistance,

mechanical strength, and anticorrosion protection in various industries. Future

research on polyurethane-acrylic hybrids as anticorrosion coatings should focus

on long-term durability, aging studies, eco-friendly alternatives, and

industrial application, aiming for sustainable solutions.

The work was financially supported by the Ministry of

Science and Education of the Republic of Kazakhstan: Program-targeted financing

from competitive procedures for 2023-2025. Project No. (BR21882301) entitled

“Comprehensive solution to current issues related to geology, production, and

processing of mineral and hydrocarbon raw materials”. We thank Professor Anwar

Usman. Department of Chemistry, Faculty of Science, Universiti Brunei

Darussalam Jalan Tungku Link, Gadong BE1410, Negara Brunei Darussalam for his

consultation in conducting this study.

Conflicts of interest

The authors declare no

conflicts of interest.

Akhanova, N.Y., Negim, El., Yerlanuly, Y.,

Batryshev, D.G., Eissa, M.M., Schur, D.Y., Ramazanov, T.S., Al Azzam, K.M.,

Muratov, M.M., Gabdullin, M.T. 2024. Influence

Of Fullerene Content on The Properties of Polyurethane Resins: A Study of

Rheology and Thermal Characteristics. Heliyon, Volume 10(12), p. E33282.

https://doi.org/10.1016/j.heliyon.2024.e33282

Alshabebi, A.S., Alrashed, M.M., El-Blidi, L., Haider, S., 2024.

Preparation of Bio-Based Polyurethane Coating from Citrullus Colocynthis Seed

Oil: Characterization and Corrosion Performance. Polymers, Volume16(2),

p. 214. https://doi.org/10.3390/polym16020214

ASTM D 2572-19, Standard Method of Test for Isocyanate Group in Urethane

Materials or Prepolymer. ASTM D 2572-19

Bartman, M., Balicki, S., Ho?ysz, L., Wilk, K.A., 2023. Surface

Properties of Graffiti Coatings on Sensitive Surfaces Concerning Their Removal

with Formulations Based on the Amino-Acid-Type Surfactants. Molecules,

Volume 28(4), p. 1986. https://doi.org/10.3390/molecules28041986

Bender, R., Féron, D., Mills, D., Ritter, S., Bäßler, R., Bettge, D., De

Graeve, I., Dugstad, A., Grassini, S., Hack, T., Halama, M., Han, E., Harder,

T., Hinds, G., Kittel, J., Krieg, R., Leygraf, C., Martinelli, L., Mol, A.,

Neff, D., Nilsson, J.-O., Odnevall, I., Paterson, S., Paul, S., Prosek, T.,

Raupach, M., Revilla, R.I., Ropital, F., Schweigart, H., Szala, E., Terryn, H.,

Tidblad, J., Virtanen, S., Volovitch, P., Watkinson, D., Wilms, M., Winning,

G., Zheludkevich, M., 2022. Corrosion Challenges Towards a Sustainable Society.

Materials and Corrosio, Volume 73(11), pp. 1730–1751. https://doi.org/10.1002/maco.202213140

Bichu, Y.M., Alwafi, A., Liu, X., Andrews, J., Ludwig, B., Bichu, A.Y.,

Zou, B., 2023. Advances in Orthodontic Clear Aligner Materials. Bioactive

Materials, Volume 22, pp. 384–403.

https://doi.org/10.1016/j.bioactmat.2022.10.006

Bui, T.M.A., Nguyen, T.V., Nguyen, T.M., Hoang, T.H., Nguyen, T.T.H.,

Lai, T.H., Tran, T.N., Hoang, V.H., Le, T.L., Dang, T.C., Vu, Q.T., Nguyen-Tri,

P., 2020. Investigation of Crosslinking, Mechanical Properties and Weathering

Stability of Acrylic Polyurethane Coating Reinforced by SiO2

Nanoparticles Issued from Rice Husk Ash. Materials Chemistry and Physics,

Volume 241, p. 122445. https://doi.org/10.1016/j.matchemphys.2019.122445

Butler, L.N., Fellows, C.M., Gilbert, R.G., 2004. Effect Of Surfactant

Systems on The Water Sensitivity of Latex Films. Journal of Applied Polymer

Science, Volume 92(3), pp. 1813–1823. https://doi.org/10.1002/app.20150

Cao, Y., Liu, Z., Zheng, B., Ou, R., Fan, Q., Li, L., Guo, C., Liu, T.,

Wang, Q., 2020. Synthesis of Lignin-Based Polyols Via Thiol-Ene Chemistry for

High-Performance Polyurethane Anticorrosive Coating. Composites Part B:

Engineering, Volume 200, p. 108295.

https://doi.org/10.1016/j.compositesb.2020.108295

Deng, Y., Bai, W., Chen, J., Zhang, X., Wang, S., Lin, J., Xu, Y., 2017.

Bio-Inspired Electrochemical Corrosion Coatings Derived from Graphene/Natural

Lacquer Composites. Royal Society of Chemistry (RSC) Advances, Volume

7(71), pp. 45034–45044.

https://doi.org/10.1039/C7RA08536B

https://doi.org/10.1002/app.35662

https://doi.org/10.1080/00218464.2016.1177793

Hu, J.Y., Zhang, S.S., Chen, E., Li, W.G., 2022. A Review on Corrosion

Detection and Protection of Existing Reinforced Concrete (RC) Structures. Construction

and Building Materials, Volume 325, p. 12671. https://doi.org/10.1016/j.conbuildmat.2022.126718

Ito, N.M., Gouveia, J.R., Vidotti, S.E., Ferreira, M.J.G.C., Santos,

D.J.D., 2020 Interplay of Polyurethane Mechanical Properties and Practical

Adhesion of Flexible Multi-Layer Laminates. The Journal of Adhesion,

Volume 96(14), pp. 1219–1232. https://doi.org/10.1080/00218464.2019.1580580

Jiang, F., Zhao, W., Wu, Y., Dong, J., Zhou, K., Lu, G., Pu, J., 2019.

Anti-Corrosion Behaviors of Epoxy Composite Coatings Enhanced Via Graphene

Oxide with Different Aspect Ratios. Progress in Organic Coatings. Volume

127, pp. 70–79. https://doi.org/10.1016/j.porgcoat.2018.11.008

Kozakiewicz, J., 2015. Developments in Aqueous Polyurethane and

Polyurethane-Acrylic Dispersion Technology. Part I. Polyurethane dispersions. Polimery,

Volume 60(09), pp. 525–535. https://doi.org/10.14314/polimery.2015.525

Kurpanik, R., Lechowska-Liszka, A., Mastalska-Pop?awska, J., Nocu?, M.,

Rapacz-Kmita, A., ?cis?owska-Czarnecka, A., Stodolak-Zych, E., 2022. Effect of

Ionic and Non-Ionic Surfactant on Bovine Serum Albumin Encapsulation and

Biological Properties of Emulsion-Electrospun Fibers. Molecules, Volume

27(10), p. 3232. https://doi.org/10.3390/molecules27103232

Lawal, S.L., Afolalu, S.A., Ogedengbe, T.S., 2023. Overview of Corrosion

and its Consequences in the Oil and Gas Industry. In: 2023 2nd International Conference

on Multidisciplinary Engineering and Applied Science (ICMEAS). 2023 2nd

International Conference on Multidisciplinary Engineering and Applied Science

(ICMEAS), pp. 1–4. https://doi.org/10.1109/ICMEAS58693.2023.10429890

Lei, L., Xia, Z., Ou, C., Zhang, L., Zhong, L., 2015. Effects Of

Crosslinking on Adhesion Behavior of Waterborne Polyurethane Ink Binder. Progress

in Organic Coatings, Volume 88, pp. 155–163. https://doi.org/10.1016/j.porgcoat.2015.07.002

Leitsch, E.K., William, H.H., John M.T., 2016. Polyurethane/Polyhydroxyurethane

Hybrid Polymers and Their Applications as Adhesive Bonding Agents. International

Journal of Adhesion and Adhesives, Volume 64, pp. 1–8.

https://doi.org/10.1016/j.ijadhadh.2015.09.001

Lovato, M.J., del-Valle, L.J., Puiggalí, J., Franco, L., 2023.

Performance-Enhancing Materials in Medical Gloves. Journal of Functional

Biomaterials, Volume 14(7), p. 349. https://doi.org/10.3390/jfb14070349

Madbouly, S.A., Otaigbe, J.U., 2005. Rheokinetics of Thermal-Induced

Gelation of Waterborne Polyurethane Dispersions. Macromolecules, Volume

38(24), pp. 10178–10184. https://doi.org/10.1021/ma0511088

Marathe, R.J., Gite, V.V., 2016. Encapsulation of 8-Hq as a Corrosion

Inhibitor in Pf and Uf Shells for Enhanced Anticorrosive Properties of

Renewable Source Based Smart Pu Coatings. Royal Society of Chemistry (RSC)

Advances, Volume 6(115), pp. 114436–114446. https://doi.org/10.1039/C6RA21684F

Maurya, A.K., de-Souza, F.M., Gupta, R.K., 2023. Polyurethane and Its

Composites: Synthesis to Application. Polyurethanes: Preparation,

Properties, and Applications, Volume 1: Fundamentals pp. 1–20. https://doi.org/10.1021/bk-2023-1452.ch001

Nacas, A.M., Ito, N.M., De-Sousa-JR, R.R., Spinacé, M.A., Dos-Santos,

D.J., 2017. Effects of NCO:OH Ratio on the Mechanical Properties and Chemical

Structure of Kraft Lignin–Based Polyurethane Adhesive. The Journal of

Adhesion, Volume 93(1–2), pp.18–29.

Nanda, A.K., Wicks, D.A., Madbouly, S.A., Otaigbe, J.U., 2005. Effect of

Ionic Content, Solid Content, Degree of Neutralization, and Chain Extension on

Aqueous Polyurethane Dispersions Prepared by Prepolymer Method. Journal of

Applied Polymer Science, Volume 98(6), pp. 2514–2520. https://doi.org/10.1002/app.22141

Negim, E.-S., Bekbayeva, L., Omurbekova, K., Ibrahim, M.N.M., 2019.

Effect of Polyol on Physico-Mechanical Properties of Polyurea Film. In:

AIP Conference Proceedings, Volume 2124(1), p. 020051. https://doi.org/10.1063/1.5117111

Negim, E.S., Ketegenov, T., Narimanov, A., Zhangaliyev, M., Rafikova,

H., Irmukhametova, G., Iskakov, R., Mun, G., 2016. Development of Polyurethane

Dispersion Based on Aromatic Isocyanat: Influence of NCO/OH Ratio on

Physico-Mechanical Properties of PUD. International Journal of Biology and

Chemistry, Volume 9(1), pp. 73–78. https://doi.org/10.26577/2218-7979-2016-9-1-73-78

Negim, E.-S., Omurbekova, K., Bekbayeva, L., Abdelhafiz, A., 2020.

Effect Of NCO/OH Ratio on the Physico-Mechanical Properties of

Polyurethane-Polyurea Hybrid Spray Coatings. Egyptian Journal of Chemistry,

Volume 63(11), pp. 4503–4508. https://doi.org/10.21608/ejchem.2020.23845.2416

Negim, E.-S., Yeligbayeva, G., Al-Azzam, K.M., Irmukhametova, G.,

Bekbayeva, L., Kalugin, S.N., Uskenbayeva, S., 2024. Synthesis,

Characterization, and Application of Polyurethane/2-Hydoxyethyl Methacrylate

Hybrids as Additives to Unsaturated Polyester Resins. Polymer Bulletin,

Volume 81(5), pp. 4459–4475. https://doi.org/10.1007/s00289-023-04918-y

Patil, C.K., Jung, D.W., Jirimali, H.D., Baik, J.H., Gite, V.V., Hong,

S.C., 2021. Nonedible Vegetable Oil-Based Polyols in Anticorrosive and

Antimicrobial Polyurethane Coatings. Polymers, Volume 13(18), p. 3149.

https://doi.org/10.3390/polym13183149

Peruzzo, P.J., Anbinder, P.S., Pardini, O.R., Costa, C.A., Leite, C.A.,

Galembeck, F., Amalvy, J.I., 2010. Polyurethane/Acrylate Hybrids: Effects of

The Acrylic Content and Thermal Treatment on the Polymer Properties. Journal

of Applied Polymer Science, Volume 116(5), pp. 2694–2705. https://doi.org/10.1002/app.31795

Ramezanzadeh, B., Ghasemi, E., Mahdavian, M., Changizi, E., Moghadam,

M.M., 2015. Characterization Of Covalently-Grafted Polyisocyanate Chains onto

Graphene Oxide for Polyurethane Composites with Improved Mechanical Properties.

Chemical Engineering Journal, Volume 281, pp. 869–883.

https://doi.org/10.1016/j.cej.2015.07.027

Solovyeva, V.A., Almuhammadi, K.H., Badeghaish, W.O., 2023. Current

Downhole Corrosion Control Solutions and Trends in the Oil and Gas Industry: A

Review. Materials, Volume 16(5), p. 1795.

https://doi.org/10.3390/ma16051795

Son, S.J., Kim, K., Lee, Y., Lee, D., Kim, H.D., 2011. Effect Of Acrylic

Monomer Content on the Properties of Waterborne Poly (Urethane?Urea)/Acrylic

Hybrid Materials. Journal of Applied Polymer Science, Volume 124(6), pp.

5113–5121.

Susai, R., Tuan, A.N., Saeid, K., Mahdi, Y.,

Yongxin, L., 2020. Corrosion

Protection at the Nanoscale. ? Elsevier Science Publishing Co Inc, pp.

500–507

Syrmanova, K., Negim, E., Kaldybekova, J.,

Tuleuov, A.M., 2016. Epoxylitane

?ompositions Modification with Using Thermoplastic Polyurethane. Oriental

Journal of Chemistry, Volume 32(1), pp. 01–07.

http://dx.doi.org/10.13005/ojc/320101

Ur-Rahman, O., Shi, S., Ding, J., Wang, D., Ahmad, S., Yu, H., 2018.

Lignin Nanoparticles: Synthesis, Characterization and Corrosion Protection

Performance. New Journal of Chemistry, Volume 42(5), pp. 3415–3425. http://dx.doi.org/10.1039/C7NJ04103A

Vakili, M., Koutník, P., Kohout, J., 2024. Addressing Hydrogen Sulfide Corrosion in Oil and

Gas Industries: A Sustainable Perspective. Sustainability, Volume 16(4), p. 1661. https://doi.org/10.3390/su16041661

Wang, G., Zhou, Z., Chen, M., Wang, J., Yu, Y., 2023. UV-Curable

Polyurethane Acrylate Pressure-Sensitive Adhesives with High Optical Clarity

for Full Lamination of TFT-LCD. American Chemical Society (ACS)

Applied Polymer Materials, Volume 5(3), pp. 2051–2061.

https://doi.org/10.1021/acsapm.2c02092

Wang, W., Hu, Y., Li, L., Zeng, J., Yao, Y., 2022. Effect of Various

Polymer Additives on the Rheology and Thixotropy of Organic Vehicles. Journal

of Materials Science: Materials in Electronics, Volume 33(15), pp.

12002–12015. https://doi.org/10.1007/s10854-022-08161-5

Wang, X., Xu, Q., Yu, H., Xu, J., 2019. Synthesis of High-Solid,

Low-Viscosity Hydroxy Acrylic Resin Modified with Hydroxyl Acrylic Resin using

4-tert-Butylcyclohexyl Acrylate (TBCHA). Journal of Saudi Chemical Society,

Volume 23(7), pp. 992–998. https://doi.org/10.1016/j.jscs.2019.04.005

Yan, T., Balzer, A.H., Herbert, K.M., Epps, T.H., Korley, L.T.J., 2023.

Circularity in Polymers: Addressing Performance and Sustainability Challenges

using Dynamic Covalent Chemistries. Chemical Science, Volume 14(20), pp.

5243–5265. https://doi.org/10.1039/D3SC00551H

Yeligbayeva, G., Moldabayeva, G.Z., Azzam, K.M.A., Bekbayeva, L., Negim,

E-.S., Shalash, M., Usman, A., 2024. Synthesis, Characterization, and

Applications of Anticorrosion Polyurethane Coating: The Effect of Bisphenol

F. International Journal of Technology. Volume 15(5),

pp. 1258-1270. https://doi.org/10.14716/ijtech.v15i5.7022

Zhang, J., Ge, D., Wang, X., Wang, W., Cui, D., Yuan, G., Wang, K.,

Zhang, W., 2021. Influence of Surfactant and Weak-Alkali Concentrations on the

Stability of O/W Emulsion in an Alkali-Surfactant–Polymer Compound System. American

Chemical Society (ACS) Omega Journal, Volume 6(7), pp. 5001–5008.

https://doi.org/10.1021/acsomega.0c06142

Zhang, X., Kim, Y., Kim, D., Liu, M., Erramuspe, I.B.V., Kaya, G.B.,

Wang, X., Kim, T., Via, B.K., Cho, H., 2020. Shape-Stabilized Phase Change

Material by a Synthetic/Natural Hybrid Composite Foam with Cell-Wall Pores. American

Chemical Society (ACS) Applied Energy Materials, Volume 4(1), pp.

416–424. https://doi.org/10.1021/acsaem.0c02341

Zhu, X., Jiang, X., Zhang, Z., Kong, X.Z., 2008. Influence of

Ingredients in Water-Based Polyurethane–Acrylic Hybrid Latexes on Latex

Properties. Progress in Organic Coatings, Volume 62(3), pp. 251–257.

https://doi.org/10.1016/j.porgcoat.2007.12.006