A Review on Aero-Acoustics and Heat Transfer in Impinging Jets

Corresponding email: h.assoum@bau.edu.lb

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.7020

Zohbi, B.E., Hassan, M.E., Afyouni, N., Meraim, K.A., Sakout, A., Assoum, H.H., 2024. A Review on Aero-Acoustics and Heat Transfer in Impinging Jets. International Journal of Technology. Volume 15(5), pp. 1398-1419

| Bilal El Zohbi | Lasie UMR CNRS 7356, La Rochelle University, La Rochelle, France, 17031 La Rochelle |

| Mouhammad El Hassan | Mechanical Engineering Department, Prince Mohammad Bin Fahd University, Al Khobar, KSA, 1664 Al Khobar 31952 |

| Nour Afyouni | Lasie UMR CNRS 7356, La Rochelle University, La Rochelle, France, 17031 La Rochelle |

| Kamel Abed Meraim | Lasie UMR CNRS 7356, La Rochelle University, La Rochelle, France, 17031 La Rochelle |

| Anas Sakout | Lasie UMR CNRS 7356, La Rochelle University, La Rochelle, France, 17031 La Rochelle |

| Hassan Hasan Assoum | Mechanical Engineering Department, Beirut Arab University, Lebanon, 11 - 50 - 20 Riad El Solh 11072809 |

A summary of key discoveries regarding the

industrial applications of impinging jets on a vertical plate. The summary

explores the link between the dynamics and heat transmission on one hand and

the relationship between heat exchange and acoustic coupling on the other hand.

The objective of this research work is to investigate the vortex dynamics and

heat transfer mechanisms in impinging jets. The jet impingement technique finds

widespread use in the industry, it serves purposes such as drying, cooling, and

heating. The impinging jet system involves directing a fluid jet with

high-velocity onto a surface. The jet impingement results in high heat exchange

rates and mass transfer rates, making it an attractive technique in various

industrial processes. To investigate these mechanisms, a combination of

experimental and computational methods was used, including flow visualization

and numerical simulations. The study of vortex dynamics in impinging jets is

crucial for understanding the heat transfer mechanisms involved. The flow

characteristics of impinging jets, such as the Reynolds number (Re) of the jet,

the distance from the blowing mouth to the impinged wall, and the geometry of

the blowing mouth, significantly affect the vortex dynamics and heat transfer

rates. Therefore, optimizing these parameters can result in significant

improvements in heat transfer efficiency. Several methods were proposed to

enhance heat transfer, these methods can affect the flow dynamic, the surface

of impingement, the nozzle’s shape and size, and the impingement parameters

such as the impact distance and the jet angle. For example, investigations have

identified that optimal heat transfer took place at an inclination angle

between 40 and 90 degrees. In addition, studies have reported enhancement in

heat transfer with diamond orifices that reached up to 17%. The key findings of

this paperwork include the identification of optimal impingement parameters

that maximize heat transmission rates and the understanding of the significant

relationship between the dynamics of the flow and the acoustic emissions. For

instance, studies showed that synthetic jets can enhance convective heat

transfer by 3 times compare to natural convection. The correlation between the

flow dynamic and the heat transmission on one side, and the flow dynamics and

acoustic emission on the other side, emphasizes the researcher to present

acoustic-thermal coupled studies on the impinging jet; this topic needs more

effort to understand the relation between the two phenomena. The conclusion

highlights the significance of previous findings in industrial applications,

suggesting control mechanisms capable of reducing noise and enhancing heat

transmission.

Aero-acoustics; Flow control: Heat transfer; Impinging jets; Vortex dynamics

Most impinging jets present complex flow dynamics as

shown by several authors (Dairay et al., 2015; Duda, Lagor, and

Fleischer, 2008; Beaubert and Viazzo, 2003). Despite

the large number of experiments and studies conducted on impinging jets in the

past decades (Matsuda,

Fukubayashi, and Hirose, 2017), this research topic is still

one of the most active research areas in thermofluid because of its fundamental

and applied importance (Moghadam, 2017). One of the most active research areas is the

mechanism of heat transmission in jets impinging at subsonic speeds. It is of

high importance due to its widespread use in the industry, like cooling of

turbine blades, annealing of glass, and drying of papers, among others.

Quite a few geometric and flow

properties affect the performance of heat transmission in impinging jets,

including the Reynolds number (Re) of the jet, geometry of the blowing mouth,

flow regime, angle at which the jet is impinging in addition to the distance

separating the blowing mouth and the wall being impinged, etc. (He and Liu 2018a;

2018b; El Hassan and Nobes, 2018; Nuntadusit et al., 2012; Gardon and

Akfirat, 1965).

It is important

to note that the complexity of this flow is mainly determined by certain

characteristics (Weidman,

2017; Zerrout, Khelil, and Loukarfi, 2017). These characteristics include the

development of boundary layers along the impinged wall's surface, as well as

the presence of jet instabilities and their interaction with the impinged wall.

Therefore, a thorough understanding of the flow dynamics and its correlation

with the transfer mechanisms is of high importance in order to define proper

flow control techniques both passive and active for particular industrial uses (Nastase and Bode, 2018; Hong and Cho, 2005; Hwang, Lee, and Cho, 2001).

This paperwork presents a literature summary of the

latest experimental and numerical investigations on jet flows impinging a

plate. The first industrial applications of impinging jets are represented.

Second, the link between the dynamics of the flow and the transmission of heat

in addition to the control methods that enhance heat transfer are the main

topics of this literature review. Third, the impact of the aero-acoustics on

the transfer of heat is discussed. Finally, perspectives on further analysis of

impinging jets and the development of control systems suitable for

industrial uses are proposed. Therefore, it is of interest to understand the

underlying phenomenon between the flow dynamics and heat transfer on one side,

in addition to the relation between aero-acoustics and heat transfer on the

other side, in order to find a control mechanism capable of enhancing heat

transfer and reducing the produced aero-acoustics.

Industrial

Applications of Impinging Jets

Jet Impingement technique finds widespread use in the industry,

including cool cooling down of electrical components and turbine blades, glass

tempering, cryosurgery freezing of tissues, and paper drying, among others.

In gas turbines, the blades are subject to extremely high temperatures

due to the combustion of fuel. Therefore, if the blades are not adequately

cooled, they can deform or even melt, which can lead to engine failure. The

impinging jets can be designed to create different flow patterns on the surface

of the blade, such as radial or crossflow (Zuckerman and Lior, 2007; Chambers et al., 2005). These flow patterns can be optimized to provide maximum

cooling while minimizing the amount of coolant required. Overall, impinging

jets are a highly effective cooling technique for turbine blades, and they are

commonly used in modern gas turbines to ensure reliable and efficient

operation. To assess the effectiveness of jet impingement in various

industrial applications, multiple experiments and numerical studies have been

conducted (Forster and Weigand, 2021; Liu and Feng, 2011).

Moreover, impinging jets are often utilized and employed for cooling

electrical equipment, such as computer chips and power electronics. Electronic

devices generate heat during operation, and if this heat is not dissipated

properly, it can reduce the device's performance and even cause damage. Several

experiments were conducted to identify the performance of impinging jets in cooling

electrical components (Kercher

et

al., 2003; Cheng, Tay, and Hong, 2001). Results from previous studies show that higher jet speeds with larger

jet diameters led to a substantial rise in rates of heat transfer. Moreover,

the utilization of microjet cooling devices suggests that they can adhere to

traditional jet correlations with necessary adjustments made to correlation

parameters. The usage of cooling devices that employ microjets may be

particularly appealing in situations that require localized cooling, as they

can be targeted toward specific hot areas within a system.

Solar energy technologies have shown great potential as a replacement

for fossil fuels in electricity generation. However, solar collectors often

suffer from overheating and poor heat transfer, which can limit their

performance. To address this issue, cooling applications like jet impingement

cooling can be used to improve heat exchange rates and boost performance as

prescribed by Ewe

et

al. (2022). It is important to highlight the potential of jet impingement cooling

for improving the efficiency and reliability of solar energy systems and

provide valuable insights into the key factors that influence its performance.

Authors mentioned that, by optimizing different factors like the velocity of

the jet, the jet/surface separation distance, the shape of the nozzle, and the

rate of coolant flow, it is possible to enhance the effectiveness and

efficiency of jet impingement cooling. Moreover, jet impingement cooling can

also be used for other solar energy applications, such as cooling solar cells,

inverters, and battery systems.

Impinging jets are also found in drying processes where jets of air or

other gases having The high-velocity are directed onto the surface of a

material to be dried. The impact of the jets can help to break up surface

moisture and promote faster drying. Turkan et al. (2019) examined the thermal properties of a continuous industrial

drying process for semi-porous textile composites; impinging jets were employed

as a mean of enhancing the drying rate of a moist porous solid. The authors

aimed to investigate the effect of various parameters, such as nozzle-to-target

distance and jet velocity, on the heat exchange rate and drying rate of the moist

porous solid. The moist porous solid drying rate was found to be significantly

enhanced by impinging jets compared to natural convection drying.

In some food products freezing, refrigerant jets with high-velocities

are addressed onto the food product surface to be frozen. The impact of the

jets can promote faster and more efficient heat transfer, resulting in faster

freezing times and higher-quality frozen food products as stated by Anderson

and Singh (2006). Marazani,

Madyira, and Akinlabi (2017) provided an overview of research on impinging jets used for

fast freezing and cooling systems, including experimental, computational, and

theoretical models. It examines the key factors that govern the performance of

these systems.

Based on the literature review on impinging jets in different industrial applications, further understanding of the dynamics of the flow and its relationship with the transmission of heat in such flows would be helpful for system optimization and for developing proper control methods for heat transfer enhancement.

The

Interaction Between The Dynamics Of The Flow And Resultant Heat Transmission In

Impinging Jets

Dairay et al.

(2015) mentioned that impinging jets are

characterized by four main regions, as illustrated in Figure 1:

Ø

Region I, where

the flow is initiated to then reach the potential core's apex downstream from

the blowing mouth exit. This area, referred to as the potential core region

located in the flow central portion, maintains a consistent velocity where the

speed of the jet stays constant and equals to the blowing mouth exit speed.

Ø

Region II

develops downstream from region I where the centerline jet velocity is lower

than in the jet core and the flow starts to spread in the transversal

direction.

Ø

Region III

where the jet is diverted from the axial direction. This region contains the

stagnation region near the impinging plate.

Ø

Region IV, also

called the wall jet region, is where the driven flow thickens as the flow

boundary layer starts to develop within the impinging wall.

Figure 1 Flow jet regions of jet impinging a solid wall

3.1. Large Coherent Structures in Impinging Jets:

Many experimental and numerical investigations were done for the

purpose of analyzing the correlation between vortex dynamics and the transfer

of heat at the wall. In this section, some of these studies are discussed.

Experimental investigations of the near-wall vortical structures in

impingement jets have been extensive (El

Hassan et

al., 2013; 2012; Hall and Ewing, 2006; Jambunathan et al., 1992; Martin,

1977). For example, Didden and Ho (1985) analyzed the unsteady separation of the boundary layer that

occurs when the flow impinges on a solid surface. The authors noted that

primary vortices develop in the jet shear layer and are advected radially in

the near-wall flow (region IV), while vortices rotating oppositely conveyed

along the radial axis and located closer to the wall are also observed, which

are referred to as secondary vortices. However, the emergence of these

secondary vortices occurs downstream of where the primary vortices were

initially detected. The viscous-inviscid interaction theory, as described by Didden

and Ho (1985), elucidated the mechanism behind the

impinging jet flow's unsteady separation. The primary vortices, situated in the

flow inviscid area, generate a fluctuating pressure gradient downstream,

resulting in an upward fluid motion. Consequently, an unstable boundary between

the viscous and inviscid areas emerges, which leads to the roll-up of an

oppositely rotating vortex. This vortex is associated with an unsteady boundary

layer separation caused by the shear-layer instability. While, the previous

experimental studies provided valuable insights into the vortical structures

formed near the wall, the study conducted by Martin (1977)

is limited due to the advancements in

both experimental and computational techniques since then. Moreover, the

analysis regarding the boundary layer separation conducted by Didden

and Ho (1985) could include simplifications in the

assumptions that could affect the accuracy of the proposed mechanism.

Moreover, over the past twenty years, several computational

investigations have been conducted to enhance our understanding of the

formation of large coherent structures in impinging jet flows (Lodato,

Vervisch, and Domingo, 2009; Beaubert and Viazzo, 2003; Tsubokura et al., 2003). The main focus of the author's work is to compare the

vortical structures of planes and round jets. Specifically, their simulations

identify secondary small coherent structures near the wall. In their LES study,

Hadžiabdic and Hanjalic (2008) investigated a turbulent jet with a Reynolds number of 23000 and a

separation length between the blowing mouth exit and the wall being impinged

H/D = 2. The authors' findings suggest that the predominant flow dynamics event

controlling the flow is the vortex roll-up taking place at the wall being

impinged. This event is closely linked to the creation of oppositely rotating

smaller vortices and the unstable boundary layer detachment phenomenon, all of

which directly influence the distribution of the mean heat exchange. Besides

the valuable insights into the dynamics of large coherent structures in

impinging jets provided by the previous computational investigations. However,

the accuracy of the conducted simulations depends on factors like turbulent

model, resolution of the grid, and boundary layer conditions, all of which have

a direct influence on the fidelity of the predicted flow characteristics.

3.2. The Transfer of Heat at The Impingement Wall:

To investigate the relationship between flow dynamics and the transfer

of heat, the authors recommend examining the pattern of the average heat

transfer and the primary velocity metrics within the studied flow, as suggested

by Dairay

et

al. (2015). On the impingement plate, the coefficient of the mean heat

transmission (h) is defined as the heat flux density (Qp) divided by

the variance in temperature between the mean wall temperature (Tw)

and the jet impinging temperature (Tj), where the radial distance

from the jet axis is represented by 'r'. The mean Nusselt number (

As previously mentioned, there are quite a few geometric and flow

factors that can control the performance of heat transfer of impacting jets

including, the Reynolds number (Re) of the jet, shape of the blowing mouth from

which the jet is issued, flow regime, angel of impingement, and distance

separating the plate from the nozzle’s exit, etc. Gardon and Akfirat (1965) demonstrated that the heat transfer rises as the Reynolds

number grows, while maintaining a descriptively comparable geometry. Two peaks

in the local mean heat transfer were observed after surpassing Re 2800 at

around radial distances of 0.5 and 2. Figure 2 illustrates the two local maxima of the mean heat exchange

for various Reynolds numbers at a distance from the blowing mouth to the

surface being impinged equal to 2. Lee and Lee (1999) found that the magnitudes of the 2 local peaks rise with increasing

Re. Other experimental investigations have explored the impact of nozzle type (Roux et al. 2011), nozzle to plate distance (He

and Liu, 2018a; Baughn, and James, 1989) and confinement (Ashforth-Frost,

Jambunathan, and Whitney, 1997) on mean heat exchange. It can be inferred from these

investigations that the secondary maximum in the Nu distribution is more

pronounced when using a convergent nozzle instead of a long tube for small

separations between the blowing mouth of the nozzle and the impinged plate (H/D

< 4). Despite being a common configuration in practical applications, the

installment of a plate with confinement can restrict the transfer of heat on

the impingement surface (Figure 3).

In order to understand the emergence of primary and secondary peaks in

the distribution of the mean Nusselt number, many investigations were done. Chung

and Luo (2002) and Chung,

Luo, and Sandham (2002) studied the relationship between the vortex patterns and the

fluctuation of heat transmission using Direct Numerical Simulations (DNS).

Results revealed that the changes in stagnation heat transmission are primarily

due to the impact of the primary vortices that emerge from the blowing mouth

exit. The nearly periodic variations in the impingement heat exchange are

caused by the quasi-periodic production of the primary vortices as a result of

Kelvin-Helmholtz instability, although more complex and non-linear changes

occur as Reynolds numbers increase. According to Lee

and Lee (1999), the primary peak is linked to the accelerated radial flow at the

nozzle's edge.

Roux

et

al. (2011) linked the primary peak shown in the distribution of the mean Nusselt

number to the increase in turbulence intensity that happens as a result of

shear layer impingement. Several authors focused on understanding the emergence

of the secondary peak in the distribution of the mean Nusselt number, as for

most authors, the primary peak in heat transfer rate in jet impingement is

primarily caused by the impingement of the primary vortices. However, many

authors disagreed in determining the origin of the secondary peak.

According to Gardon and Akfirat, (1965), the appearance of a second optimum in the

Jambunathan

et

al. (1992) proposed that the formation of annular structures, which are generated

by the jet shear layer, is responsible for the experience of a second peak in

the distribution of the mean Nusselt number. They suggested that these

structures contribute to the intensification of heat exchange in the region of

the secondary peak. Additionally, several other studies, such as those

conducted by Buchlin (2011), and Roux et al. (2011) and Vejrazka

et

al. (2005), supported the idea that a presence of a second extreme in the

distribution of Nusselt number is closely linked to the large-scale vortical

structures that form in the jet flow (region II).

In Popiel

and Trass (1991) authors used smoke-wire flow visualizations to obtain a more

profound understanding of the typical vortex pattern in both free and impinging

circular subsonic jets. They observed a development of smaller near-wall

vortices in the vicinity where a second peak in the mean distribution of heat

transmission is detected. These structures were found to be related to the large-scale

vortical structures, and the authors suggested that they could be in charge of

enhancing heat transmission in that region. On the other hand, according to Chung

and Luo (2002), the distribution of Nusselt numbers, which measure heat

exchange far from the area of jet/wall contact, is affected by the smaller

near-wall vortices, also known as secondary vortices, that result from the

primary vortices and the wall jets interactions.

However, additional research is required to completely comprehend the underlying mechanisms of the secondary maximum occurrence. Hadžiabdic and Hanjalic (2008) and Uddin, Neumann, and Weigand (2013) both used LES to investigate the link between heat transmission and vortical structures in turbulent jet impingement. Hadziabdic and Hanjalic found a correlation between the mean Nusselt number second extreme and the location of the secondary vortex, while Uddin, Neumann, and Weigand (2013) observed regions of significant heat transfer, referred to as cold spots, which were directly related to radially elongated coherent structures. Table 1 presents a summary of the key findings from previous studies that examine the direct connection between heat transfer and flow dynamics. The collection of experimental and computational investigations presented in this section provides a thorough comprehension of the intricate relationship between flow dynamics and heat transmission in impinging jet flows. However, it is crucial to critically evaluate the conducted studies to draw reliable conclusions that can effectively guide future research.

Figure 2 Local Nusselt number for

different Reynolds numbers at H/D = 2.

Figure 3 Jet impingement confinement plate is installed

Table 1 Summary of the main studies on the relationship between heat transfer

and flow dynamics

|

Paper |

Objectives |

Methods |

Results |

|

Gardon and

Akfirat, (1965) |

To examine how turbulence impacts the

transfer of heat characteristics when a jet impinges a solid surface. |

·Re-examined

the velocity measurements and turbulence distributions. |

·2 distinct

spikes in the local mean heat transfer were noticed after surpassing Re 2800 at around radial distances of 0.5 and 2. ·The 2nd

peak in the average Nu distribution can be assigned to the fact that the

laminar boundary layer is transitioned to a turbulent boundary layer. |

|

Lee and Lee

(1999) |

To explore the features of heat

transmission when a jet impinges on a flat surface symmetrically to examine

the impacts of various flow characteristics such as Re, the separation that

exists between the blowing mouth and the impinged flat surface, and the

diameter of the blowing mouth on the rate of heat transfer within the

stagnation region. |

·Utilized

thermo-chromic liquid crystal (TLC) and digital image processing techniques. ·Re ranging

from 5,000 to 30,000. The separation distance between the plate and the

nozzle used is H/D = 2, 4, 6, and 10. |

·The heat

transfer rate rises as Re grows, nozzle diameter decreases, and H/D decreases. ·The

primary peak is linked to the accelerated radial flow at the nozzle's edge.

The 2nd peak contributed to the boundary layer transition from a

smooth, laminar boundary layer to a turbulent one. |

|

Cooper et al.

(1993) |

To provide hydrodynamic data for impinging

jet flow conditions that can be used for turbulence-model evaluation. Also to

assess the performance of turbulence models for impinging jet flows. |

·Two

Reynolds numbers were studied experimentally (2.3 x 10^4 and 7 x 10^4), at

different separation distances between the impinged wall and the blowing

mouth (varying from 2 to 10). ·Computational

simulations to compare with experimental data. |

·Models

that exhibit poor (or good) predictions of the mean flow also demonstrate

corresponding poor (or good) predictions for the turbulence data. ·The

secondary peak can also appear in a fully turbulent boundary layer, calling

into question the study done by Lee and Lee (1999). |

|

Roux et al. (2011) |

To examine how acoustic excitation affects

both the flow parameters and the transfer of heat when a jet strikes a solid

flat surface. |

·Circular

nozzle that produced a laminar jet that impinged onto a flat plate. ·Thermocouples

to measure surface temperature. ·Particle

Image Velocimetry (PIV). ·The jet

was subjected to acoustic excitation by a loudspeaker. |

·The

coefficient of heat transfer rises when the excitation amplitude and

frequency are increased. ·In the

near-wall region, the size and number of vortices of the jet have changed due

to excitations. ·Authors

linked the primary peak to the increase in turbulence intensity that happens

when the shear layer impacts the solid flat surface. The second peak is

linked to the smaller-scale vortical structure formed near the solid flat

surface. |

|

Chung and Luo (2002) |

To investigate the unstable transfer of

heat-induced when a jet impinges on a flat plate from a confined nozzle

configuration. The authors aim to comprehend how both vortical structures

(primary and secondary vortices) formed when the jet impacts the flat surface

influence the distribution of Nu. |

·Applied

Direct Numerical Simulations (DNS) to simulate the dynamics of the flow and

the transfer of heat. ·Reynolds

numbers are varied and two separation distances between the plate and the

blowing mouth (nozzle) are tested to investigate the effects on the heat

transmission. |

·The

quasi-periodic generation of primary vortices which results from the

Kelvin-Helmholtz instabilities was responsible for the nearly periodic

fluctuations observed in heat transmission of the jet impingement. ·As the

Reynolds numbers increased, the fluctuations became more chaotic and

non-linear. ·The

changes in the stagnation transfer of heat are primarily due to the impact of

the Kelvin-Helmholtz vortices that emerge from the blowing mouth exit. ·The 2nd optimum in the distribution of mean Nusselt

number is linked to secondary vortices formed as a fact of primary

vortices/wall interaction. |

Table 1 Summary of the main studies on the relationship between heat transfer

and flow dynamics (Cont.)

|

Paper |

Objectives |

Methods |

Results |

|

Jambunathan et

al. (1992) |

To review and critically analyze

experimental data concerning the heat exchange rate when a jet impacts a

solid surface in turbulent conditions, encompassing Re within the range of

5,000-124,000. The authors aim to derive a correlation for the Nusselt number

that accurately predicts heat transfer coefficients for this system. |

·Experimental

data from various literature sources were collated and critically reviewed. ·Extrapolation

of data was implemented to obtain coefficients of wall jet heat transmission.

|

·Up to a

certain value and at a certain distance from the stagnation point the Nu does not depend on the distance separating the

blowing mouth and the solid surface. ·The

authors derived a new correlation for the Nusselt number able to accurately

predict heat exchange coefficients for the system. ·The

formation of annular structures, which are generated by the jet shear layer,

is responsible for experiencing a 2nd peak in the distribution of

the average Nu. |

|

Hadžiabdic and

Hanjalic (2008) |

To investigate the vortical and turbulence

patterns in jet impinging a solid wall and examine their relation with the

heat transfer at specific locations. |

·Large-Eddy

Simulations (LES) to generate instantaneous velocity and temperature fields

of a round jet issued from a long pipe and impinges normally on a solid wall

at Re = 20,000 and a separation distance between the impinged plate and the

orifice equals to 2.

|

·The

predominant flow dynamics event controlling the flow is the vortex roll-up

taking place at the wall being impinged. ·The

primary flow dynamics event is linked to the creation of opposing smaller

vortices and the intermittent separation of the boundary layer, both of which

directly influenced the distribution of the average Nu. ·A direct

link between the mean Nu second extreme and the location of the secondary

smaller vortical structure is found. |

|

Uddin,

Neumann, and Weigand (2013) |

To examine the flow properties and the

characteristics of heat transmission when a cold jet strikes normally on a

heated plate to clarify the factors that contribute to the emergence of the 2nd

optimum in the radial distribution of the target wall Nu. |

·Large-Eddy

Simulations (LES) were employed for Re varying between 13,000 and 23,000,

estimated based on the jet's diameter and bulk velocity. The non-dimensional

separation between the blowing mouth and the surface of the impingement was

set at 2.

|

·The 2nd

optimum in the radial distribution of Nu at the target wall is due to the

formation of a secondary vortex that promotes the transfer of heat from the

stagnation zone toward the impingement wall. ·The

authors observed regions of significant heat transfer, referred to as cold

spots, which were directly related to radially elongated coherent structures. |

Control Methods To Enhance Heat Transfer In Impinging

Since striking jets are widely used for industrial

purposes, the enhancement of heat exchange in striking jets is of significant

importance. Several studies proposed control mechanisms for the enhancement of

heat transmission by impinging jets.

The control of the heat exchange between the flow and the

plate consists generally of controlling the flow on one hand or varying the

surface properties on the other hand. One of the methods to control the flow

dynamic was proposed by Cho, Lee, and Kim

(1998),

who added a coflowing stream around the main nozzle periphery. This method

leads to disturbing the shear layer and enhances the heat transmission on the

plate by up to 20%. Another flow control was proposed by Zumbrunnen and Aziz

(1993)

who demonstrated that the convective heat transfer coefficient for intermittent

flows is two times that of the steady flow. In addition, they examined the

effect of the frequency of intermittency on the convective heat transmission

enhancement and found a monotonical dependence between the two parameters.

Several studies found the advantage of oscillating jets

on the heat transfer compared to stationary jets. This proposition was proved

by Camci and Herr

(2002).

Liu and Sullivan

(1996) studied

the heat transmission for a jet excited with its natural frequency and the

subharmonics, for an impact ratio H/D < 2. The authors found that the excitation

of the jet can raise or reduce the heat transmission, depending

on the excitation frequency: a frequency near to the natural frequency produces

random vortical structures, which are responsible for the transfer enhancement.

However, the excitation with the subharmonic gives a stable vortex pairing

which generates the unsteady separation of the surface boundary layer and

results in a reduction in the transfer of heat rate. Similar work was made by Poh et al. (2004),

who demonstrated that, after testing different Reynolds numbers, impact ratio

H/d, and pulsation frequency f, the configuration of Re=300, f=5 Hz, and H/d=9

gives the maximum heat exchange.

Hwang, Lee, and Cho (2001)

proposed control of the vortex structures by acoustic excitation, they found that

for Strouhal numbers equal to 2.4 and 3 (blowing case), the length of the

potential core of the jet increases and the turbulence intensity decreases,

which leads to reduction of the local heat transfer and the formation of

secondary peak. However, for Strouhal number equal 1.3 (suction case), the flow

has a shorter potential core and higher turbulence intensity, and then stronger

heat transfer.

All the

previous studies explore various flow control techniques like coflowing

streams, intermittent flows, and oscillating jets capable of enhancing heat

transfer in impinging jet systems. Even though, these methods show promising

increases in heat transmission rates, it is very important to evaluate their

practicality and efficiency for previously mentioned industrial applications.

The transfer

of heat in impinging jets depends on the geometry of the nozzle. Lee and Lee (2000) studied

the effect of the aspect ratio (AR) of an elliptic nozzle on heat exchange

enhancement. Experiments were carried out for 5 values including AR = 1

(axisymmetric jet). For a small impact distance, the heat exchange rate

increases when the aspect ratio increases. Similar work was made by Koseoglu and Baskaya (2010),

who tested the aspect ratio for both elliptic and rectangular jets, and found

that the transmission of heat increases in the stagnation point when the aspect

ratio increases, for both types of jet. Gao, Sun, and Ewing (2003)

examined the performance of adding triangular tabs to the round nozzle. Different

nozzle-to-plate distances have been examined. This system was found to give

rise to the transfer of heat rate by more than 25% for small impact distance.

Other

methods of heat enhancement consisting of controlling the surface properties

were proposed by Rallabandi et

al. (2010) and

de Lemos and

Fischer (2008).

de Lemos and Fischer (2008) simulated

numerically the effect of the presence of the porous layer on the impacted

plate on the convective heat transfer. They found that the presence of the

porous layer causes the disappearance of the second peak in the Nusselt number,

and the total heat transfer is enhanced for a certain range of layer thickness,

porosity, and thermal conductivity ratio between the layer and the plate. Rallabandi et al. (2010) Examined

the effect of having element roughness on the heat transmission enhancement for

impinging jet, using staggered and inclined ribs, and porous foam material.

They found a 50 to 90% increase in heat change due to axial ribs, and a well

noticed rise in the coefficient of heat exchange when the porous foam was used.

In the same context, Ekkad and

Kontrovitz (2002) examined

the effect of surface dimples on heat exchange. The results obtained were

normalized by those of the plane plate to compare the changes in heat that

occurred. It was found that the dimpled surface has a lower heat exchange

coefficient than the non-dimpled one. Another enhancement method consisting of

a micro structured impingement surface was investigated by Ndao et al. (2012).

The surface consists of 64 circular pin fins with a diameter of 125 and a

height of 230

. A pitch of 250

with an enhancement area ratio

A_Total/A_base =2.44has been chosen. They demonstrated an enhancement of 200%

in the heat transfer compared to a plate without fins.

Surface

properties described by previous investigations such as porous layers, ribbed

surfaces, dimples, and micro-structured surfaces, provide innovative approaches

to enhance the rates of heat transfers. However, it is of vital importance to

assess the manufacturability, cost-effectiveness, and durability of

implementing such modification on the surface for practical uses.

The heat

transmission is also related to the impact angle between the jet and the plate,

this topic was been studied by Beitelmal, Saad, and Patel (2000).

Experiments were carried out for different parameters like the spacing between

the wall of impingement and the blowing mouth, the Reynolds number, and the

impact angle. The results show the Nusselt number’s dependence on the impact

angle for different Re and impact ratios. It shows that the highest Nusselt

decreases when the angle of inclination at which the jet is impinging

decreases, for all configurations, in addition to a shift in the diagrams to

the left side of the plate.

Deberland and Rhakasywi

(2014)

examined how

the shape of the orifice in an impinging synthetic jet affects the cooling

performance pf a heated surface. Results showed that square orifices which

covers a larger area and having a higher entrainment rate, resulted in a

greater temperature drop and better heat transfer performance when compared to

circular orifices.

Nguyen et al. (2009a) Investigated experimentally the

convective transfer of heat for a confined and submerged impinging Al2O3-water

nanofluid jet. The authors have tested different parameters such as Re, Pr,

impact ratio, and size of Al2O3 particles. They found

that, for specific values of impact distance and particle volume fraction, the

use of nanofluids can enhance the heat exchange. In addition, for a particle

volume fraction higher than 6%, the use of nanofluids was found not appropriate

for transfer enhancement. Another study based on nanofluids was proposed by (Barewar, Tawri, and Chougule, 2019; Septiadi et al., 2019),

who compared the heat exchange between a ZnO nanofluids jet and a water jet,

and demonstrated a considerable enhancement in the coefficient of heat exchange

for ZnO nanofluids coolant.

Klein and Hetsroni (2012) Proposed

a control mechanism that consisted of the actuating slab in the impinging

plate. The study was carried out for steady impinging laminar microjets. They

found that this mechanism can increase heat transfer by up to 34%. A passive

control mechanism which consists of air-augmented ducts were investigated

experimentally and numerically by Nuntadusit, Wae-hayee, and Kaewchoothong (2018).

Different duct diameters and lengths have been tested. The results show that

the air-augmented duct increases the heat transfer by 25.42% compared to the conventional

jet.

Furthermore,

Ai, Xu, and Zhao (2017)

studied experimentally the heat transfer in the case of movable nozzle.

Different nozzle velocities have been tested using a stepper motor. The results

were compared to the fixed nozzle case. It was found that the nozzle movement

enhances convection by increasing the transfer rate and the uniformity of

temperature distribution. The increase in heat transfer can reach more than

40%ncomparing to the fixed nozzle.

Nuntadusit et al. (2012) studied

the effect of the twist ratio in swirling imping jet on the heat transfer.

Experiments were carried out for 5 ratios. Authors have found that the maximum

enhancement is acquired at a low ratio of 3.64. Kaewchoothong et al. (2014) investigated

experimentally and numerically the performance of expansion pipe nozzle with

holes in the enhancement of heat exchange. Different impact distances and a

number of holes were examined. Results revealed that the existence of holes can

enhance the change of heat up to 6.4% for 4 holes at an impact ratio of 4.

Dynamically, the presence of holes allows the ambient air to enter the duct and

reduce its entrainment with the main jet.

More

recently, Nimmagadda, Lazarus, and Wongwises (2019) studied

the consequences of the magnetic field on the heat transmission of a water jet

impinging on a stationary and vibrating plate. Results show an enhancement in

the heat transmission in the case of the stationary plate by 36.18% in the

presence of the magnetic field of Ha = 80. However, opposite results were

obtained in the case of the vibrating plate and a reduction in the heat

transmission was observed. Furthermore, Diop et al. (2022) investigated

the result of adding mist to the flow of the heat exchange behavior. Different

impact ratios and velocity inlet have been tested, the results show an

enhancement in the case of the presence of the mist, which reaches 21% and 32%

for a mist mass flow rate of 3 mg/s and 6 mg/s, respectively. Table 2 presents

a summary of previous studies on the control methods used in the enhancement of

heat exchange.

Overall, further research is needed for optimization of previously mentioned methods for specific industrial uses. Factors like energy efficiency, manufacturability, scalability, and cost-effectiveness should be considered especially when dealing with the industry.

Heat Transfer

and Self-Sustained Tones in Impinging Jets

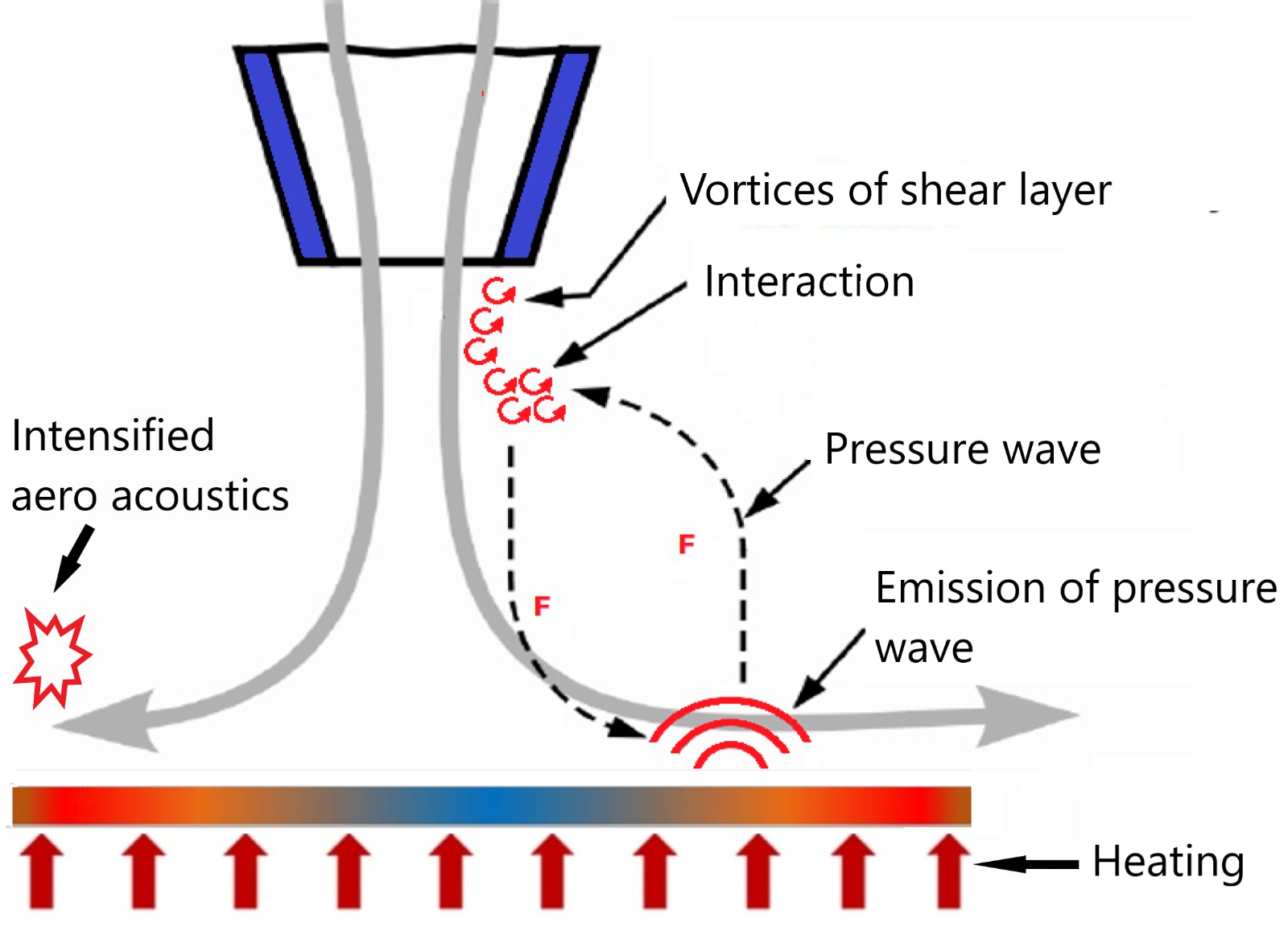

When a turbulent flow strikes a rigid wall, the

fluid-solid interaction can generate, in certain configurations Rockwell and

Naudascher (1979),

acoustic waves which lead to acoustic discomfort. The acoustic waves, called

self-sustaining tones, are generated by the wall pressure fluctuations which

propagate backward as pressure oscillations, called feedback loops, disturb the

shear layer and produce the self-sustaining tones Ho and Nosseir

(1981).

The first theory about aerodynamic noise Lighthill (1954) proves the

direct relation between the turbulence and the emitted noise, and models

mathematically the propagated wave taking the turbulence as a source of sound.

This theory emphasizes the effort to describe the turbulence dynamics to

understand the acoustic emission, as well as to control turbulence structure to

reduce the generated noise (Alkheir et al., 2021; Arya and De, 2021;

Assoum et al. 2021; 2020; Hamdi et al., 2020; Alkheir et al.,

2020; Hamdi et al., 2019; El Hassan and Keirsbulck, 2017; Assoum et

al., 2017; Abed-Meraïm, Assoum, and Sakout, 2016; Assoum, Sakout, and

Abed-Meraim, 2014; Dhamanekar and Srinivasan, 2014; 2013; El Hassan et al., 2012;

Miron et al., 2012; Uzun et al., 2011; Ramakrishnan et al.,

2009; Keirsbulck et al., 2008; Henning et al., 2008; Zhang, 2000).

Whereas, the previous studies on the heat transmission by impinging jet

(mentioned in section 3) found a direct link between the change of heat and the

turbulence dynamics. This indicates the presence of an indirect relation

between the acoustic field and heat transfer since the two phenomena are

related to the turbulence behavior of the jet. From this point, several works

have been proposed as acoustic-heat coupled studies of impinging jets.

Two scenarios can be distinguished in this domain: the

enhancement of the heat exchange using the acoustic excitation, and the control

of the acoustic emission by heating or cooling the impingement plate. In this

context, Seeley et al.

(2006)

studied the effect of acoustic resonance on heat transfer enhancement, using

synthetic jets obtained from two piezoelectric resonators. Based on CFD and

acoustics models, they found that the synthetic jet increase the convection

heat exchange more than 3 times that of natural convection. Similar work has

been proposed by Arik (2007), which

tested the effect of a synthetic jet, obtained from acoustic abatement with

sine waves, on heat enhancement. Experiments were carried out at different operating

frequencies between 3 and 4.5 kHz, and different parameters such as the impact

ratio and the heater power, to find the best combination that gives the maximum

heat exchange. In addition, the study also compared two different sizes of

heaters. The results indicate that the enhancement can vary from 4 to 10 times

compared to natural convection. Acoustic measurements revealed a noise level

exceeding 65 dB, which prompted the authors to suggest exploring alternative

techniques for generating the synthetic jet.

Oppositely, Gustavsson et

al. (2010)

investigated the consequences of the temperature of a jet on the acoustic

generation, for jets impinging at supersonic speeds. This work is similar to that

of Lepicovsky et

al. (1988).

In a previous test, the authors proved that the acoustic frequency varies with

the jet temperature. The configuration was chosen to simulate a hot jet as used

in aircraft landing, so a large-scale facility consisting of a 36.2 mm diameter

nozzle and an operating temperature of up to 1030K was used. It was found that

the temperature does not eliminate the tones, but transforms them to a

high-frequency broadband noise. In the continuation of their study, the authors

compared three geometric configurations on the acoustic emission for a

supersonic jet with a Mach number equal to 1.5 and different temperatures. The

three configurations were: normal impingement, oblique impingement, and jet

blast deflector impingement. Results indicate that, differently from the normal

impingement, oblique and jet blasts did not produce tones at low temperatures,

however, the tones appeared at elevated temperatures. In addition, the unsteady

load was found important at high impact distance, this is due to the reversed

flow from the surface, entrainment in the shear layer of the main jet because

of jet spreading, and interaction between the main jet and the deck surface

which lead to grazing wall jet.

Table 2

Summary of previous studies on the control methods used in the enhancement of

heat transfer

|

Control |

Metrology |

Method |

Main

results | |

|

Cho, Lee, and Kim

(1998) |

Co-flowing

streams around the main jet. |

HWA,

Thermocouple. |

A

coflowing stream was added to a circular jet impacting a heated wall. The

measurements of velocity and temperature were obtained by hot wire and

thermocouples respectively. |

Changing

in the jet characteristics and enhancement of about 20% in heat transfer. |

|

Zumbrunnen and

Aziz (1993) |

Intermittent flow. |

Hot film probe, thermocouple. |

Rotating wheels with blades

were used to create intermittent circular jets. The measurements of velocity

and temperature by hot fil probe and thermocouples respectively. |

Enhancement in heat exchange by

a factor of 2 compared to steady jet. |

|

Camci and Herr

(2002) |

Self-oscillating

jet. |

Hot film

probe, thermocouple. |

A feedback

tube creates the self-oscillation of a circular jet. Velocity

and temperature measurements by hot fil probe and thermocouples respectively. |

The

oscillation enhances the heat transfer. |

|

Liu and Sullivan

(1996) |

Acoustic excitation of the jet. |

Temperature-sensitive

fluorescent technique, hot film sensor. |

Circular jet excited using

speaker impinging on a heated plate. Velocity and temperature

measurements by hot film sensor and fluorescent paint, video recording using

CCD camera. |

Enhancement in heat exchange

when the jet is excited by its natural frequency. Reduction in the heat exchange

when the jet is excited with subharmonic frequency. |

Table 2

Summary of previous studies on the control methods used in the enhancement of

heat transfer (Cont.)

|

Authors |

Control |

Metrology |

Method |

Main results |

|

Poh et al.

(2004) |

Flow pulsations. |

Finite Volume CFD. |

A circular oscillating jet impinging on a heated plate

was simulated using Fluent 6.0. |

Best heat performance at Re=300, f=5Hz, and H/D=9. |

|

Lee and Lee

(2000) |

Changing

the aspect ratio of the elliptic jet. |

Thermochromic

liquid crystal thermometry, smoke wire technique. |

An

elliptic jet with different AR impinging on a heated plate was used. CCD

cameras were used for temperature visualization of liquid crystals. Smoke

wire with cameras was used for flow visualization. |

The

heat transfer increases with increasing the aspect ratio for small impact

distance. |

|

Koseoglu and

Baskaya (2010) |

Changing the inlet geometry. |

3D low Reynolds number k-? model. Thermochromic liquid crystal technique, LDA. |

Elliptic, circular, and rectangular jets impacting a

heated plate were tested. Numerical and experimental work was carried on to

obtain velocity and temperature data. |

Increasing AR of all types of nozzle with equal section

area leads to an enhancement in the heat transfer. |

|

Gao, Sun, and

Ewing (2003) |

Adding

triangular tabs to the round nozzle. |

Infrared

thermography, AN anemometry, and HWA. |

6,

10, and 16 tabs were added to a circular nozzle. Velocity

and temperature measurements by AN2000 anemometer and IR camera respectively. |

More

than 25% enhancement in the heat exchange. |

|

de Lemos and

Fischer (2008) |

Adding a cover of porous material to the plate. |

CFD. |

Simulation of rectangular jet striking a heated plate

covered with a porous material layer |

Decrease the peak in the Nusselt number distribution. Enhancement in heat flux for values certain values of

layer thickness, porosity, and thermal conductivity ratio. |

|

Rallabandi et

al. (2010) |

Adding

ribs to the plate. |

Transient

liquid crystal, mass flowrate sensor. CFD.

|

Staggered

and inline ribs were added to the impingement plate, and jets with different

aspect ratios and flow channels were used. |

50-90%

increase in heat transfer in both configurations |

|

Ekkad and

Kontrovitz (2002) |

Adding dimples to the plate. |

Liquid crystal thermometry. |

Inline and staggered dimples were tested using an image

processing system (RGB camera, CCD camera …). |

TheThe heat exchange is reduced compared to the case without

dimples. |

|

Ndao et al. (2012) |

Adding

pin fin structures to impingement surface. |

CFD. |

A

simulation of a circular jet impinging a plate with micro pins was carried

out. |

200%

increase in the heat exchange rate. |

|

Beitelmal, Saad,

and Patel (2000) |

Inclination of impinging plate. |

Thermocouples. |

The impacted surface was inclined between 45 and 90

degrees. The temperature was measured using thermocouples. |

Shifting in the region of maximum heat transfer |

|

Nguyen et al.

(2009b) |

Using

of Al2O3-Water nanofluid. |

Thermocouples. |

36

nmAl2O3 particle water nanofluid was projected on a

heated plate. The temperature measurements were carried out using

thermocouples. |

Nanofluid

particles with a volume fraction higher than 6% were found not suitable for

heat transfer enhancement. |

|

Barewar, Tawri,

and Chougule (2019) |

Using nanoparticles with a water jet. |

Thermocouples. |

DI water and ZnO nanofluids with different

concentrations were added to a circular jet striking a heated copper plate. |

Significant enhancement in the case of using ZnO

nanofluids. |

Table 2

Summary of previous studies on the control methods used in the enhancement of

heat transfer (Cont.)

|

Authors |

Control |

Metrology |

Method |

Main results |

|

Klein and

Hetsroni (2012) |

Using actuating slab. |

IR thermography. |

Circular jet impacting a heated plate with an actuating

slab that moves up and down. |

34% enhancement in the coefficient of heat change. |

|

Nuntadusit, Wae-hayee,

and Kaewchoothong (2018) |

Using

of swirling jet. |

TLC

and bleu dye technique. |

A

swirling jet impinging a heated plate in a rig test was used. Different twist

ratios were tested. |

Enhancement

in heat exchange was acquired for a swirl number of 0.4. |

|

Ai, Xu, and Zhao

(2017) |

Moving nozzle. |

Thermocouples. |

Stepper motors with regulating speed were used to

create a jet with a movable nozzle. The heated plate was fixed and

thermocouples were used to measure the temperature. |

Increase in the heat transmission and temperature

uniformity at higher nozzle velocity. |

|

Kaewchoothong et

al. (2014) |

Expansion

pipe nozzle with air entrainment holes. |

CFD. |

A

numerical simulation of a system consisting of an expansion pipe blowing

mouth with a different number of air entrainment holes was performed to test

the performance of the system on the heat exchange characteristics. |

Enhancement

up to 6.4% in case of 4 holes and impact ratio of 4. |

|

Nimmagadda, Lazarus,

and Wongwises (2019) |

Magnetic field around the plate. |

CFD. |

The multi-physical simulation was carried out to study

the impact of the magnetic field on the heat exchange in the case of a water

jet striking on a fixed and vibrating plate. |

Enhancement in the heat transfer in the case of fixed

plate up to 36.18% with a magnetic field of 80 Ha. Reduction in the heat exchange rate in the case of

vibrating plate. |

|

Diop et al. (2022) |

Mist

adding. |

Thermocouples. |

A

mist with different concentrations was added to a jet hitting a heated plate.

Thermocouples were utilized to compute the surface temperature. |

The

addition of mist increases the heat transfer rate by 21% for a mist

concentration of 3mg/s and 32% for a concentration of 6 mg/s. |

A coupled

study was investigated by Bhapkar,

Srivastava, and Agrawal (2013),

who studied the outcomes of operating parameters including orifice dimensions,

Reynolds number, impact distance, stock number, and inclination angle on both

acoustic fields, and transfer of heat, for a circular synthetic jet impacting a

heated plate. The objective was a little different from the studies presented

above. The authors were interested in finding a configuration that gives the

maximum heat transfer enhancement and low acoustic noise. They proved that the

maximum heat transmission was obtained for an inclination angle between 40 and

90 degrees, for all impact distances. Furthermore, the authors compared an

elliptic jet to a circular, rectangular, and square jet with the same

equivalent diameter, to find the out-turn of utilizing an orifice shape on the

acoustic emission and heat exchange Bhapkar,

Srivastava, and Agrawal (2014).

They found that, for the elliptic jet, an aspect ratio of 1.4 gives a maximum

heat transfer at an impact ratio of 3. Compared to other orifice shapes, the

elliptic one has the best performance for an impact ratio lower than 6.

However, for higher impact distances, circular and square orifices are better.

Finally, the author highlighted the strong correlation between acoustic and

heat transfer behavior, which needs more effort to relate the two phenomena.

A similar study was made by Mangate and

Chaudhari (2015)

who studied two other shapes: diamond and oval orifices. The excitation

frequency of the synthetic jet was taken in the range of 100 to 250 Hz, and the

impact ratio was between 0 and 16. They calculated the average heat transfer

coefficient and the sound pressure level in order to inspect the acoustic

properties in addition to the properties of heat transfer. Results show an

enhancement in the heat transmission with a value of 17% for the diamond

orifice and 7% for the oval orifice compared to the circular jet at the

operating frequency of 200 Hz. However,

there is a decrease in sound pressure level of 7% for both orifices, as

compared to the circular jet. These findings are highly significant in terms of

achieving an optimal balance between heat enhancement and noise reduction.

Recently, Mrach et al. (2020) studied the

effect of the plate temperature on the acoustic noise produced in the event of

a rectangular jet impacting a slotted plate. This configuration corresponds to

a slot noise listed in Rockwell and

Naudascher (1979).

The authors found a change in the sound pressure level by 10% when the plate

was heated, in addition to the change in the acoustic spectrum during the heating

process. This study indicates a high correlation between thermal and acoustic

characteristics of impinging jets, and needs further work to understand the

change in the turbulence dynamic due to the plate heating.

Based on previous studies in this section,

continued research in this area is essential for having the potential to

improve both the fundamental understanding of the complex relationship between

flow dynamics, heat transmission, and acoustics, especially in practical uses

of impinging jet systems where many factors are capable of influencing the

system’s performance.

In conclusion, this review paper has provided valuable

insights into impinging jet flow dynamics and their important role in various

industrial applications. Controlling the flow dynamics by adjusting the design

of the nozzle, the impingement distance, and flow rates, enhancement and

improvement in heat transfer rates on the performance of previously mentioned

industrial applications can be achieved. Synthetic jets were found to enhance

convective heat transfer by over 300% compared to natural convection. Also,

maximum heat transfer was achieved at inclination angles between 40 and 90

degrees of impinging jet. Additionally, heat transmission improved by 17% when

jet impinges from a diamond orifices and the sound pressure levels decreased by

7% compared to jets impinging from a circular orifice. Moreover, this paperwork

highlights the need for further research to explore the complex relationship

between aero-acoustics emissions and heat transfer of jet impingement.

Therefore, understanding the acoustic implications in industrial systems is

very important to address concerns that are directly related to ensuring

acoustic comfort in practical applications. As a result, future research in

this field must focus on developing advanced computational techniques and

conducting extensive experimental studies in addition to exploring control

strategies to have more advanced knowledge in fluid dynamics, heat transfer,

and aero-acoustics. This will pave the way for more efficient and sustainable

industrial processes.

Abed-Meraïm, K., Assoum, H., Sakout, A., 2016. Transferts Energetiques Entre Le Champ Turbulent D’un Jet Impactant De Ventilation Et Le Champ Acoustique Genere. In: 3rd International Conference on Energy, Materials, Applied Energetics and Pollution, pp. 952–957

Ai, X., Xu, Z.G., Zhao, C.Y., 2017. Experimental Study on Heat Transfer of Jet Impingement with a Moving Nozzle. Applied Thermal Engineering, Volume 115, pp. 682–691

Alkheir, M., Assoum, H.H., Afyouni, N.E., Abed Meraim, K., Sakout, A., El Hassan, M., 2021. Combined Stereoscopic Particle Image Velocimetry Measurements in a Single Plane For an Impinging Jet Around a Thin Control Rod. Fluids, Volume 6(12), p. 430

Alkheir, M., Mrach, T., Hamdi, J., Abed-Meraim, K., Rambault, L., El Hassan, M., 2020. Effect of Passive Control Cylinder on the Acoustic Generation of a Rectangular Impinging Jet on a Slotted Plate. Energy Reports, Volume 6, pp. 549–553

Anderson, B.A., Singh, R.P., 2006. Modeling the Thawing of Frozen Foods Using Air Impingement Technology. International Journal of Refrigeration, Volume 29(2), pp. 294–304

Arik, M., 2007. An Investigation into Feasibility of Impingement Heat Transfer and Acoustic Abatement of Meso Scale Synthetic Jets. Applied Thermal Engineering, Volume 27 (8–9), pp. 1483–1494

Arya, N., De, A., 2021. Acoustic Characteristics of Supersonic Planar Impinging Jets. arXiv. Available online at: http://arxiv.org/abs/2108.03379, Accessed on MM DD, YY

Ashforth-Frost, S., Jambunathan, K., Whitney, C.F., 1997. Velocity and Turbulence Characteristics of a Semiconfined Orthogonally Impinging Slot Jet. Experimental Thermal and Fluid Science, Volume 14(1), pp. 60–67

Assoum, H., Sakout, A., Abed-Meraim, K., 2014. Étude De Sons Auto-Entretenus: Transferts Énergétiques Entre L’énergie Cinétique Turbulente Et Le Champ (Acoustique Study Of Self-Sustained Sounds: Energy Transfers Between Turbulent Kinetic Energy And The Acoustic Field). In: Congrès Français d'Acoustique, pp. 1797–1801

Assoum, H.H., El Hassan, M., Hamdi, J., Alkheir, M., Meraim, K.A., Sakout, A., 2020. “Turbulent Kinetic Energy and Self-Sustaining Tones in an Impinging Jet Using High Speed 3D Tomographic-PIV. Energy Reports, Volume 6, pp. 807–811

Assoum, H.H., Hamdi, J., Abed-Meraim, K., El-Hassan, M., Hammoud, A., Sakout, A., 2017. Experimental Investigation the Turbulent Kinetic Energy and the Acoustic Field in a Rectangular Jet Impinging a Slotted Plate. Energy Procedia, Volume 139, pp. 398–403

Assoum, H.H., Hamdi, J., Alkheir, M., Abed Meraim, K., Sakout, A., Obeid, B., El Hassan, M., 2021. Tomographic Particle Image Velocimetry and Dynamic Mode Decomposition (DMD) in a Rectangular Impinging Jet: Vortex Dynamics and Acoustic Generation. Fluids, Volume 6(12), p. 429

Barewar, S.D., Tawri, S., Chougule, S.S., 2019. Heat Transfer Characteristics of Free Nanofluid Impinging Jet on Flat Surface with Different Jet to Plate Distance: An Experimental Investigation. Chemical Engineering and Processing - Process Intensification, Volume 136, pp. 1–10

Baughn, J.W., Shimizu, S., 1989. Heat Transfer Measurement from a Surface with Uniform Heat Flux and a Impingemnet Jet. Journal of Heat Transfer, Volume 111, pp. 1096–1098

Beaubert, F., Viazzo, S., 2003. Large Eddy Simulations of Plane Turbulent Impinging Jets at Moderate Reynolds Numbers. International Journal of Heat and Fluid Flow, Volume 24 (4), pp. 512–519

Beitelmal, A.H., Saad, M.A., Patel, C.D., 2000. The Effect of Inclination on the Heat Transfer between a Flat Surface and an Impinging Two-Dimensional Air Jet. International Journal of Heat and Fluid Flow, Volume 21(2), pp. 156–163

Bhapkar, U.S., Srivastava, A., Agrawal, A., 2013. Acoustic and Heat Transfer Aspects of An Inclined Impinging Synthetic Jet. International Journal of Thermal Sciences, Volume 74, pp. 145–155

Bhapkar, U.S., Srivastava, A., Agrawal, A., 2014. Acoustic and Heat Transfer Characteristics of an Impinging Elliptical Synthetic Jet Generated by Acoustic Actuator. International Journal of Heat and Mass Transfer, Volume 79, pp. 12–23

Buchlin, J.M., 2011. Convective Heat Transfer in Impinging- Gas- Jet Arrangements. Journal of Applied Fluid Mechanics, Volume 4(2), pp. 137–149

Camci, C., Herr, F., 2002. Forced Convection Heat Transfer Enhancement Using a Self-Oscillating Impinging Planar Jet. Journal of Heat Transfer, Volume 124(4), pp. 770–782

Chambers, A.C., Gillespie, D.R., Ireland, P.T., Dailey, G.M., 2005. The Effect of Initial Cross Flow on the Cooling Performance of a Narrow Impingement Channel. Journal of Heat Transfer, Volume 127(4), pp. 358–365

Cheng, Y., Tay, A.A., Hong, X., 2001. An Experimental Study of Liquid Jet Impingement Cooling of Electronic Components with and without Boiling. Advances in Electronic Materials and Packaging, Volume 2001, pp. 369–375

Cho, H.H., Lee, C.H., Kim, Y.S., 1998. Characteristics of Heat Transfer in Impinging Jets by Control of Vortex Pairing. In: Turbo Expo: Power for Land, Sea, and Air, Volume 78651, p. V004T09A060

Chung, Y.M., Luo, K.H., 2002. Unsteady Heat Transfer Analysis of an Impinging Jet. Journal of Heat Transfer, Volume 124(6), pp. 1039–1048

Chung, Y.M., Luo, K.H., Sandham, N.D., 2002. Numerical Study of Momentum and Heat Transfer in Unsteady Impinging Jets. International Journal of Heat and Fluid Flow, Volume 23(5), pp. 592–600

Cooper, D., Jackson, D.C., Launder, B.E., Liao, G.X., 1993. Impinging Jet Studies for Turbulence Model Flow-Field Experiments. International Journal of Heat and Mass Transfer, Volume 36, 2675–2684

Dairay, T., Fortuné, V., Lamballais, E., Brizzi, L.E., 2015. Direct Numerical Simulation of a Turbulent Jet Impinging on a Heated Wall. Journal of Fluid Mechanics, Volume 764, pp. 362–394

de Lemos, M.J., Fischer, C., 2008. Thermal Analysis of an Impinging Jet on a Plate With and Without a Porous Layer. Numerical Heat Transfer, Part A: Applications, Volume 54 (11), pp. 1022–1041

Deberland, C., Rhakasywi, D., 2014. The Effect of Orifice Shape on Convective Heat Transfer of an Impinging Synthetic Jet. International Journal of Technology, Volume 4(3), pp. 232–239

Dhamanekar, A., Srinivasan, K., 2013. Hysteresis Effects in the Impinging Jet Noise. In: Proceedings of Meetings on Acoustics, Volume 19(1), p. 030121

Dhamanekar, A., Srinivasan, K., 2014. Effect of Impingement Surface Roughness on the Noise from Impinging Jets. Physics of Fluids, Volume 26(3), p. 036101

Didden, N., Ho, C.M., 1985. Unsteady Separation in a Boundary Layer Produced by an Impinging Jet. Journal of Fluid Mechanics, Volume 160, pp. 235–256

Diop, S.N., Dieng, B., Warore, A., Mbodj, S., 2022. A Study on Heat Transfer Characteristics by Impinging Jet within a Few Amounts of Mist. International Journal of Thermofluids, Volume 13, p. 100130

Duda, J.C., Lagor, F.D., Fleischer, A.S., 2008. A Flow Visualization Study of the Development of Vortex Structures in a Round Jet Impinging on a Flat Plate and a Cylindrical Pedestal. Experimental Thermal and Fluid Science, Volume 32, pp. 1754–1758

Ekkad, S.V., Kontrovitz, D., 2002. Jet Impingement Heat Transfer on Dimpled Target Surfaces. International Journal of Heat and Fluid Flow, Volume 23(1), pp. 22–28

El Hassan, M., Assoum, H. H., Martinuzzi, R., Sobolik, V., Abed-Meraim, K., Sakout, A., 2013. Experimental Investigation of the Wall Shear Stress in a Circular Impinging Jet. Physics of Fluids, Volume 25(7), p. 4811172

El Hassan, M., Assoum, H.H., Sobolik, V., Vétel, J., Abed-Meraim, K., Garon, A., Sakout, A., 2012. Experimental Investigation of the Wall Shear Stress and the Vortex Dynamics in a Circular Impinging Jet. Experiments in Fluids, Volume 52(6), pp. 1475–1489

El Hassan, M., Keirsbulck, L., 2017. Passive Control of Deep Cavity Shear Layer Flow at Subsonic Speed. Canadian Journal of Physics, Volume 95 (10), pp. 894–899

El Hassan, M., Nobes, D. S., 2018. Experimental Investigation of the Vortex Dynamics in Circular Jet Impinging on Rotating Disk. Fluids, Volume 7(7), p. 223

Ewe, W.E., Fudholi, A., Sopian, K., Solomin, E., Yazdi, M.H., Asim, N., Fatima, N., Pikra, G., Sudibyo, H., Fitriasari, W., Kuncoro, A.H., Nandar, C.S.A., Abimanyu, H., 2022. Jet Impingement Cooling Applications in Solar Energy Technologies: Systematic Literature Review. Thermal Science and Engineering Progress, Volume 34, p. 101445

Forster, M., Weigand, B., 2021. Experimental and Numerical Investigation of Jet Impingement Cooling onto a Concave Leading Edge of a Generic Gas Turbine Blade. International Journal of Thermal Sciences, Volume 164, p. 106862

Gao, N., Sun, H., Ewing, D., 2003. Heat Transfer to Impinging Round Jets with Triangular Tabs. International Journal of Heat and Mass Transfer, Volume 46(14), pp. 2557–2569

Gardon, R., Akfirat, J.C., 1965. The Role of Turbulence in Determining the Heat-Transfer Characteristics of Impinging Jets. International Journal of Heat and Mass Transfer, Volume 8(10), pp. 1261–1272

Gustavsson, J., Ragaller, P., Kumar, R., Alvi, F., 2010. Temperature Effect on Acoustics of Supersonic Impinging Jet. In: 6th AIAA/CEAS Aeroacoustics Conference, p. 3785

Hadžiabdic, M., Hanjalic, K., 2008. Vortical Structures and Heat Transfer in a Round Impinging Jet. Journal of Fluid Mechanics, Volume 596, pp. 221–260

Hall, J.W., Ewing, D., 2006. On the Dynamics of the Large-Scale Structures in Round Impinging Jets. Journal of Fluid Mechanics, Volume 555, pp. 439–458

Hamdi, J., Assoum, H. H., Alkheir, M., Abed-Meraïm, K., Cauet, S., Sakout, A., 2020. Analysis of the 3D Flow of an Impinging Jet on a Slotted Plate Using TR-Tomo PIV and Proper Orthogonal Decomposition. Energy Reports, Volume 6, pp. 158–163

Hamdi, J., Assoum, H., Abed-Meraïm, K., Sakout, A., 2019. Analysis of the Effect of the 3C Kinematic Field of a Confined Impinging Jet on a Slotted Plate by Stereoscopic PIV. European Journal of Mechanics - B/Fluids, Volume 76, pp. 243–258

He, C., Liu, Y., 2018a. Jet Impingement Heat Transfer of a Lobed Nozzle: Measurements Using Temperature-Sensitive Paint and Particle Image Velocimetry. International Journal of Heat and Fluid Flow, Volume 71, pp. 111–126

He, C., Liu, Y., 2018b. Large-Eddy Simulation of Jet Impingement Heat Transfer Using a Lobed Nozzle. International Journal of Heat and Mass Transfer, Volume 125, pp. 828–844

Henning, A., Kaepernick, K., Ehrenfried, K., Koop, L., Dillmann, A., 2008. Investigation of Aeroacoustic Noise Generation by Simultaneous Particle Image Velocimetry and Microphone Measurements. Experiments in Fluids, Volume 45(6), pp. 1073–1085

Ho, C.M., Nosseir, N.S., 1981. Dynamics of an Impinging Jet: The Feedback Phenomenon. Journal of Fluid Mechanics, Volume 105, pp. 119–142

Hong, S.K., Cho, H.H., 2005. The Review of Studies on Heat Transfer in Impinging Jet. International Journal of Air-Conditioning and Refrigeration, Volume 13, pp. 196–205

Hwang, S.D., Lee, C.H., Cho, H.H., 2001. Heat Transfer and Flow Structures in Axisymmetric Impinging Jet Controlled by Vortex Pairing. International Journal of Heat and Fluid Flow, Volume 22(3), pp. 293–300

Jambunathan, K., Lai, E., Moss, M., Button, B.L., 1992. A Review of Heat Transfer Data for Single Circular Jet Impingement. International Journal of Heat and Fluid Flow, Volume 13(2), pp. 106–115

Kaewchoothong, N., Wae-Hayee, M., Vessakosol, P., Niyomwas, B., Nuntadusit, C., 2014. Flow and Heat Transfer Characteristics of Impinging Jet from Expansion Pipe Nozzle with Air Entrainment Holes. Advanced Materials Research, Volume 931, pp. 1213–1217

Keirsbulck, L., Hassan, M.E., Lippert, M., Labraga, L., 2008. Control of Cavity Tones Using a Spanwise Cylinder. Canadian Journal of Physics, Volume 86(12), pp. 1355–1365

Kercher, D.S., Lee, J.B., Brand, O., Allen, M.G., Glezer, A., 2003. Microjet Cooling Devices for Thermal Management of Electronics. IEEE Transactions on Components and Packaging Technologies, Volume 26(2), pp. 359–366

Klein, D., Hetsroni, G., 2012. Enhancement of Heat Transfer Coefficients by Actuation against an Impinging Jet. International Journal of Heat and Mass Transfer, Volume 55 (15–16), pp. 4183–4194

Koseoglu, M.F., Baskaya, S., 2010. The Role of Jet Inlet Geometry in Impinging Jet Heat Transfer, Modeling and Experiments. International Journal of Thermal Sciences, Volume 49(8), pp. 1417–1426

Lee, J., Lee, S.J., 1999. Stagnation Region Heat Transfer of a Turbulent Axisymmetric Jet Impingement. Experimental Heat Transfer, Volume 1999, pp. 137–156

Lee, J., Lee, S.J., 2000. The Effect of Nozzle Aspect Ratio on Stagnation Region Heat Transfer Characteristics of Elliptic Impinging Jet. International Journal Of Heat And Mass Transfer, Volume 43(4), pp. 555–5575

Lepicovsky, J., Ahuja, K.K., Brown, W.H., Salikuddin, M., Morris, P.J., 1988. Acoustically Excited Heated Jets. NASA Contractor Report 4129

Lighthill, M.J., 1954. On Sound Generated Aerodynamically {II}. {Turbulence} as a Source of Sound. In: Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences, Volume 222 (1148), pp. 1–32

Liu, T., Sullivan, J.P., 1996. Heat Transfer and Flow Structures in an Excited Circular Impinging Jet. International Journal of Heat and Mass Transfer, Volume 39 (17), pp. 3695–3706

Liu, Z., Feng, Z., 2011. Numerical Simulation on the Effect of Jet Nozzle Position on Impingement Cooling of Gas Turbine Blade Leading Edge. International Journal of Heat and Mass Transfer, Volume 54 (23–24), pp. 4949–4959

Lodato, G., Vervisch, L., Domingo, P., 2009. A Compressible Wall-Adapting Similarity Mixed Model for Large-Eddy Simulation of the Impinging Round Jet. Physics of Fluids, Volume 21(3), p. 035102

Mangate, L.D., Chaudhari, M.B., 2015. Heat Transfer and Acoustic Study of Impinging Synthetic Jet Using Diamond and Oval Shape Orifice. International Journal of Thermal Sciences, Volume 89, pp. 100–109

Marazani, T., Madyira, D.M., Akinlabi, E.T., 2017. Investigation of the Parameters Governing the Performance of Jet Impingement Quick Food Freezing and Cooling Systems – A Review. Procedia Manufacturing, Volume 8, pp. 754–760

Martin, H., 1977. Heat and Mass Transfer between Impinging Gas Jets and Solid Surfaces. Advances in Heat Transfer, Volume 13, pp. 1–60

Matsuda, S., Fukubayashi, T., Hirose, N., 2017. Characteristics of the Foot Static Alignment and the Plantar Pressure Associated with Fifth Metatarsal Stress Fracture History in Male Soccer Players: A Case-Control Study. Sports Medicine—Open, Volume 3, p. 27

Miron, P., Vétel, J., Garon, A., Delfour, M., El Hassan, M., 2012. Anisotropic Mesh Adaptation on Lagrangian Coherent Structures. Journal of Computational Physics, Volume 231 (19), pp. 6419–6437

Moghadam, M.Z., 2017. Numerical Modeling of Conjugate Heat Transfer of a Rotary Disk. In: Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, Volume 231 (3), pp. 425–431

Mrach, T., Alkheir, M., El Hassan, M., Assoum, H.H., Etien, E., Abed-Meraim, K., 2020. Experimental Study of the Thermal Effect on the Acoustic Field Generated by a Jet Impinging on a Slotted Heated Plate. Energy Reports, Volume 6, pp. 497–501

Nastase, I., Bode, F., 2018. Impinging Jets - A Short Review on Strategies for Heat Transfer Enhancement. In: E3S Web of Conferences, Volume 32, p. 01013

Ndao, S., Lee, H.J., Peles, Y., Jensen, M.K., 2012. Heat Transfer Enhancement from Micro Pin Fins Subjected to an Impinging Jet. International Journal of Heat and Mass Transfer, Volume 55 (1–3), pp. 413–421

Nguyen, C.T., Galanis, N., Polidori, G., Fohanno, S., Popa, C.V., Le Bechec, A., 2009. An Experimental Study of a Confined and Submerged Impinging Jet Heat Transfer Using {Al2O3}-Water Nanofluid. International Journal of Thermal Sciences, Volume 48(2), pp. 401–411

Nimmagadda, R., Lazarus, G.A., Wongwises, S., 2019. Effect of Magnetic Field and Nanoparticle Shape on Jet Impingement over Stationary and Vibrating Plates. Journal of Numerical Methods for Heat & Fluid Flow, Volume 29(12), pp. 4948–4970

Nuntadusit, C., Wae-Hayee, M., Bunyajitradulya, A., Eiamsa-Ard, S., 2012. Visualization of Flow and Heat Transfer Characteristics for Swirling Impinging Jet. International Communications in Heat and Mass Transfer, Volume 39(5), pp. 640–648