Effect of Wetting-Drying Cycles on Swelling-Shrinkage Behavior and Microstructures of Tropical Residual Expansive Soil

Corresponding email: christy.anandha@ui.ac.id

Published at : 17 Jul 2025

Volume : IJtech

Vol 16, No 4 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i4.7005

| Christy A. Putri | 1. Departement of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia. 2. Departement of Civil Engineering, Faculty of Civil Engineering and Planning, Trisakti Un |

| Widjojo A. Prakoso | Departement of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Wiwik Rahayu | Departement of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Agustino Zulys | Departement of Chemistry, Faculty of Mathematics and Natural Science, Universitas Indonesia, Depok 16424, Indonesia |

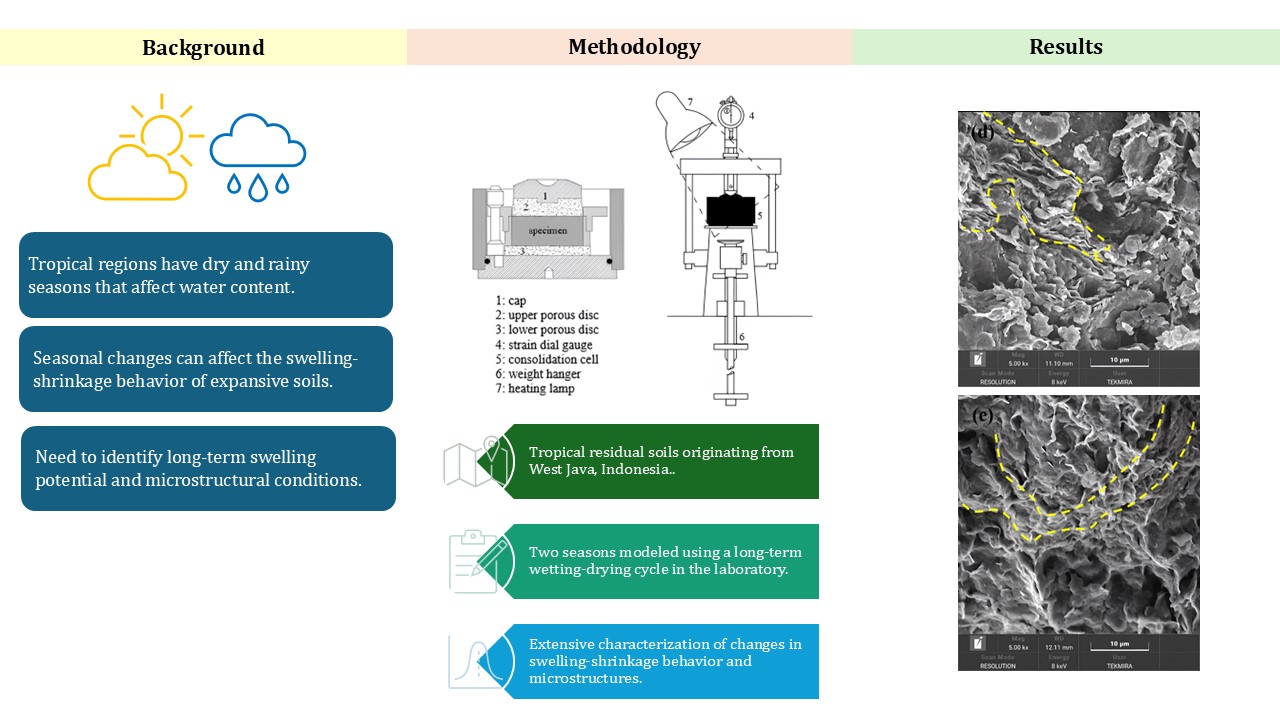

Expansive soil is one of the problematic soils that has swelling and shrinking behavior due to fluctuations in water content. So far, the potential content of Montmorillonite clay minerals, dry density, and water content are known to be factors that cause swelling potential in expansive soils. The dry and rainy seasons significantly affect soil water content in tropical climates. This study modeled the influence of the tropical climate on the test, namely testing the wetting and drying cycles on tropical residual soils originating from West Java, Indonesia, using a modified oedometer. The specimens are reformed and are compacted at maximum dry density and optimum moisture content based on the Standard Proctor compaction The test results show that the wetting-drying cycle produces a different swelling behavior from the initial swelling conditions. Ultimately, as the wetting-drying cycle progresses, the specimens exhibit a consistent swelling potential of approximately 10% after going through the third cycle, which can be considered as reaching an equilibrium state. The wetting-drying cycle causes the specimen to lose its initial microstructural condition and, at the same time, reorients and rearranges the clay particle sheets. Eventually, microstructural evolution influences the behavior during the wetting-drying cycle through the resulting swelling and shrinkage potential.

Expansive soils; Residual; Swelling behavior; Wetting-drying cyclic

Several natural factors, such as rainfall (Rahardjo et al., 2016) and earthquakes (Faisal et al., 2023), as well as soils with specific behaviors such as clayshale (Lesmana et al., 2022), collapsible soils (Zhao et al., 2024), liquefiable soils (Bahsan et al., 2021), and expansive soils (Muntohar et al., 2020), can result in building damage and even structural failure, which causes losses. One of the damages that often occurs in Indonesia is due to expansive soils because of its wide distribution. Expansive soils are problematic soils that can swell and shrink due to fluctuations in water content. This behavior directly affects changes in soil volume, with expansion occurring when the water content increases and the soil volume expands. In contrast, shrinkage will occur when the water content decreases, decreasing the soil volume. In the case of geotechnical engineering, the swelling and shrinkage of expansive soils result in damage and failure of underground structures, such as road damage, reduced bearing capacity of the foundation, and slope failure. Identification of swelling potential and swelling pressure was carried out to determine the magnitude of changes in volume and resulting lifting force which can be used as information and an initial description of expansive soil behavior at a location. The existence of seasonal differences in expansive soil locations will result in changes in water content. Under these circumstances, it is essential to consider climatic factors when identifying mechanical properties, because climate is one of the fundamental factors that influence the swelling behavior in soil (Day, 1999). Therefore, it is essential to model the wetting-drying cycle to identify long-term swelling potential. To date, considerable work has been done to identify the mechanical properties of expansive soils, considering changes in rainy and dry climates through wetting-drying cycle modeling.

Kalkan (2011) researched wetting-drying cycles using full shrinkage of clayey soil from Turkey. The test results showed a decrease in the swelling potential due to an increase in the wetting-drying cycle given. Results that tend to be the same are shown by Estabragh et al. (2015) and Bensallam et al. (2014). Where each researcher used soil dominated by the mineral Smectite and a mixture of Kaolin-Bentonite in their tests However, the research results of Osipov et al. (1987) showed the opposite, involving four types of clay with different microstructural conditions. The test results indicate an increase in the swelling potential and an increase in the given wetting-drying cycle. Increased swelling potential was also shown in soils dominated by Kaolin clay minerals (Day, 1999). The results of previous research indicate that the swelling potential generated at the beginning of the test has a different value at the end of the wetting-drying cycle, either lower or higher. In addition, it also shows that the swelling potential tends to be constant after experiencing several wetting-drying cycles. This behavior is shown by all materials with shrinkage methods and the amount of load given. Previous studies did not analyze the microstructural conditions resulting from the wetting-drying cycles during testing.

Vilarrasa et al. (2016) and Schanz and Tripathy (2009) stated that expansive soil characteristics are approximated by a dual structure that recognizes the presence of two porosity levels. This condition is also demonstrated by Bentonite, an artificial clay material that also has swelling and shrinkage behavior (Seiphoori et al., 2014). Pore sizes with a diameter of less than 0.1 mm are gaps in the clay aggregate. These pores are located between the particles, which are said to be microstructures formed due to active clay minerals. Active clay is formed from a mineral arrangement with a 2:1 structure, which consists of one Octahedral (O) sheet sandwiched by two Tetrahedral (T) sheets and is referred to as TOT. The combination of clay particles is referred to as aggregate, whereas the gaps that form between them are referred to as macropores. Schematics of the two porosity levels in expansive soils can be seen in Figure 1.

Figure 1 Schematic representation of the two structural level

This study observed swelling and shrinkage behavior on expansive soil in the tropics using a modified oedometer test. The form of modification carried out in the test is in the form of increasing mildly the temperature of the sample. Changes in the rainy and dry seasons in the tropical area are modeled as a wetting-drying cycle given to the sample. This research aimed to investigate how microstructural changes during the wetting-drying cycle can impact the long-term mechanical properties of tropical residual soils, specifically their swelling-shrinkage potential and swelling pressure.

The soil used in the test was a residual tropical soil originating from Cikarang – West Java, Indonesia. The physical properties of the material are presented in Table 1. These properties were determined through tests conducted according to the ASTM Standards. The standardized test results were then used to evaluate the following criteria. Based on the degree of swelling criteria, including Vand der Merwe’s criteria and Chen’s criteria, the soil has very high swelling potential if it is classified using the value of clay content and PI (Van der Merwe, 1964) and LL and F200 (Chen, 1965). Meanwhile, based on the XRD test results, the material's mineral content is Quartz, Kaolin, Illite, and Montmorillonite.

Table 1 Soil properties

The Standard Proctor compaction test results were used as a reference when preparing specimens for this research. Specimens were prepared at maximum density and optimum water content conditions, and they were prepared using soil material passing sieve #4 and added a certain amount of water to achieve the planned water content. This research used an oedometer testing apparatus to observe expansive soil's behavior and mechanical properties, referring to ASTM D4546 (2004) (Method C). The soil sampling ring with a diameter of 6 cm and a height of 2 cm was filled with a certain amount of previously prepared soil material and then compacted until reaching the planned density. The ring containing the compacted material was then placed between two pore stones and inserted into the consolidation cell, as shown in Figure 2(a). The five specimens were given a load of 31.4 kPa during the wetting-drying cycle.

The swelling and shrinkage potential was determined by measuring changes in height over a 24-hour period. The testing procedure commenced with a wet cycle, during which the specimen in the consolidation cell was soaked in water to allow for expansion. Once swelling ceased, the specimen transitioned to a dry cycle. During the dry cycle, the water in the consolidation cells was removed, and then the temperature was increased to model the dry season where the material originated. The testing equipment used in this study can be seen in Figure 2(b). In the wet cycle, the temperature during testing was laboratory room temperature 27 ± 2°C. During the dry cycle, the temperature was increased to 34 ± 2°C to model the wetting-drying cycle using a heating lamp directed at the top of the specimen in the consolidation cell. Monitoring was carried out every two days using a digital thermometer to ensure constant temperature during testing. Equilibrium in the wet cycle could be achieved within ± 4 days. Meanwhile, the dry cycle required a much longer time, namely 40-45 days, to reach equilibrium. Observations were made on five specimens with the same initial conditions but with different numbers of wetting-drying cycles, as given in Table 2.

After the cycle was completed, the load was then increased periodically to determine the swelling pressure (SP) on each specimen due to the application of a different number of wetting-drying cycles. Swelling potential (%S) and shrinkage potential (%Sh) were observed during the wetting-drying cycles applied. After receiving the wetting-drying cycle, microstructural condition and Cation Exchange Capacity (CEC) were identified using Scanning Electron Microscope (SEM) testing and the ammonium acetate exchange method (Chapman, 1965), respectively.

Table 2 Test mapping of the specimen

Figure 2 Modified oedometer test; (a) Location of the specimen in the consolidation cell, (b) Testing equipment.

The axial deformation resulting from the wetting-drying cycle of the five specimens is depicted in Figure 3. The observations of the specimens were conducted for a duration of over 300 days, encompassing up to 8 cycles. Each specimen produced a different initial %S, although it was formed and received the same amount of stress during the test. When the dry cycle was applied, shrinkage did not occur immediately. When the water was removed, and the temperature was increased, the specimen underwent creep swelling, and shrinkage occurred after 2 to 3 days. The time needed for the specimen to completely shrink was approximately the same, specifically 40 to 45 days. The swelling-shrinkage potential of each specimen was measured and recorded during testing, as shown in Table 3. Test results for sample S5 are also available in the analysis of expansive soil in three locations in West Java (Putri et al., 2024).

Figure 3 Swelling shrinkage behavior of each specimen

Table 3 Swelling-shrinkage potentials, swelling pressure, and CEC of each specimen

The resulting swelling potential is summarized in Figure 4(a). The potential differed when the specimens swelled for the first time (cycle 0). The potential swelling pattern looks random but tends to increase from S1 to S5 specimens. An increase in the wetting-drying cycle given to each specimen increased the swelling potential for S2 to S5 specimens in the initial cycle. In S2, the swelling potential was equal to 8.48% due to one wetting-drying cycle received. The same pattern was also shown by specimen S3, where applying two wetting-drying cycles resulted in a swelling potential of up to 9.76%. Meanwhile, at a higher number of cycles, S4 and S5 show a constant swelling potential after receiving the third wet-dry cycle, around 9% to 10%.

The shrinkage potential that occurs in each specimen because of the wetting-drying cycle is given in Table 3 and the shrinkage pattern for each specimen can be seen in Figure 4(b). The shrinkage potential generated by each specimen did not have a specific pattern at the beginning of the cycle. However, after experiencing three wetting-drying cycles, the potential for shrinkage continued to decrease. Specimens 1 and 2 had no shrinkage potential to compare. Specimen S3 showed an increase in the shrinkage potential because of two cycles given successively. In contrast, a different pattern was shown by the S4 and S5. The potential for shrinkage generally decreased after passing the third cycle and showed a constant value between 9% and 10%.

Figure 4. (a) swelling potential for each wetting-drying cycle (b) shrinkage potential for each wetting-drying cycle

The swelling pressure generated by each specimen is given in Figure 5(a). The test results indicate that there was an increase in swelling pressure with each subsequent cycle until the S4 specimen underwent four wetting-drying cycles. In the S1, the swelling potential that occurred is 125.6 kPa. The increase in swelling pressure after 1, 2, and 4 cycles became 196.2 kPa, 255.01 kPa, and 313.92 kPa, respectively. However, the resulting swelling pressure tended to be constant until the S5 underwent eight wetting drying cycles, where the resulting swelling pressure was 304.11 kPa. Meanwhile, the relationship between CEC and swelling potential can be seen in Figure 5(b). The number of wetting-drying cycles affects swelling potential even though the CEC tends to be the same (S1, S2, and S3). At a high number of cycles, S4 and S5 show a correlation that tends to be linear between CEC and the final swelling potential. With a CEC of 35 meq/100, S4 produces a swelling potential of 10.5%. Meanwhile, with a lower CEC of 23.8 meq/100 grams, S5 produces a swelling potential of 9%.

Figure 5 Properties after wetting-drying cyclic (a) Swelling pressure (b) CEC vs final swelling potential

Photomicrograph results using SEM for each specimen can be seen in Figure 6. Microstructural conditions look similar because the five specimens from the location were viewed at the same magnification, namely 5000 times. The visible microstructure consists of clay mineral particles arranged in various patterns, which can be attributed to the number of wetting-drying cycles they have undergone. In each image, specific microstructural conditions are highlighted by yellow lines.

The microstructural conditions of S1 showed that the pores formed between the particles were relatively small. In addition, sheets of clay particles are stacked horizontally in a random arrangement, as indicated by the yellow line in Figure 6(a). After experiencing one wetting-drying cycle, the specimens showed the disappearance of the initial structural conditions, as indicated in Figure 6(b). Sheets of particles were no longer visible, but the microstructural conditions appeared to resemble agglomerated (part circled with yellow line) and randomly arranged particles. After experiencing two cycles, as seen in Figure 6(c), the microstructural conditions of the S3 showed the formation of clay mineral sheets again, and lumps of particles were still visible in the specimen’s microstructure. Both microstructural conditions are marked with several yellow lines. As a result of 4 cycles, the microstructural conditions began to show the particle sheets very clearly, and they had a horizontal arrangement orientation or a laminar structure, as seen in Figure 6(d). The photomicrograph results of the S5, which underwent eight wetting-drying cycles, showed an increasingly clear laminar structure, as seen in Figure 6(e). Yellow lines in both images frame the laminar structure of both specimens.

Figure 6 Microstructure evolution of the specimen (a) S1; (b) S2; (c) S3; (d) S4; (e) S5

5. Discussion

5.1. Swelling Potential

The abundance of negative charge on the surface of clay mineral particles results in the interaction between clay and water, which plays a significant role in physical soil changes, such as changes in volume, which result in swelling and shrinking behavior in expansive soils. Swelling phenomena are physical-chemical processes in the mineral structure and clay particles (Lei et al., 2014; Schoonheydt and Johnston, 2006). When the water content increases, the expansion begins with the basal spacing between the TOT sheets in clay minerals 2:1. The thickening occurs because of the arrangement of water molecules, which attempts to balance the charge on the TOT surface. This condition is called crystal swelling, the first stage of the swelling process in expansive soil.

When the crystal swelling is fulfilled, the negative charge on the particle's surface will attract cations to balance the charge. In this condition, some cations are strongly bonded on the surface of the clay particles. However, if the cation is weakly bound to the particle's surface, the cation tends to diffuse from a higher concentration to a lower concentration. This movement produces repulsive forces between clay particles due to the Diffuse Double Layer (DDL) mechanism that occurs (Kyokawa, 2021). This mechanism is also known as osmotic swelling. The swelling potential produced by the specimen is the result of these two mechanisms, where the potential for osmotic swelling is higher than that of crystal swelling. The abundance of negative charges on the surface of mineral clays can be balanced by attracting cations. CEC refers to the soil's ability to exchange cations in DDL. The value of CEC is not solely used for binding water molecules, but it can also strengthen existing bonds within the microstructure

Microstructure is a factor that influences the swelling potential that occurs. Figure 4 shows that five specimens with the same initial conditions produced different swelling potentials at the start of testing. Even though each specimen was forming under the same initial conditions, this diversity is influenced by how the weathering process occurs and the stress history of the rocks that form it (Kuila and Prasad, 2013) then it can effect on mineral content, texture, and microstructure (Wang and Wei, 2015; Peng et al., 2012). Microstructure is the relationship between clay particles that form a specific orientation and affects the interactions between particles (Wang and Wei, 2015). This condition cannot be avoided even with the same compaction effort. Particles with random structural conditions will have a higher expansion potential than structures with a specific orientation. This behavior can happen because, in a random structure, it will cause the DDL to overlap and increase the force between the particles (Kyokawa, 2021). By reviewing the components present in expansive soils more specifically, it is difficult to replicate the specimen identically (Lopez-Lara et al., 2018) because there is a micro-influence from the formation of the particle structure that occurs.

5.2. Swelling Behavior

The wetting-drying cycle applied to each specimen shows differences in the swelling potential at the beginning and end of the observation. The results of long-term cycles show that the swelling potential tends to be constant after being given three wetting-drying cycles, as happened to specimens S4 and S5. Similar behavior is also shown by expansive soils in India and laboratory-prepared soils, which are mixtures of Kaolin and Bentonite (Estabragh et al., 2015; Tripathy and Subba Rao, 2009) and several other studies in 4 season countries, as seen in Table 4. Based on previous studies, research on expansive soils with wetting-drying cycles shows the same results. The long-term behavior will produce a constant swelling potential value after 3-4 wetting-drying cycles. This behavior can be said that the specimen is in a state of equilibrium. An equilibrium condition occurs when the swelling potential has the same value as the shrinkage potential under the same physicochemical conditions (Estabragh et al., 2015).

As previously explained, the swelling potential is a hydration process at the level of clay mineral structure and particles due to wetting. When the process is complete, the swelling will not occur again. Shrinkage does not occur immediately when the drying process is carried out; creep swelling occurs over time. Then, at some point, periodic shrinkage continues to occur. This condition occurs due to water being a load in the consolidation cell. When water is removed, the load received by the specimen is reduced so that creep swelling can occur. When the water content in the specimen continues to decrease, periodic shrinkage occurs.

The swelling and shrinkage behavior that occurs during the wetting-drying cycle impacts the micro condition of the specimen. Specimens may undergo increases or decreases in swelling potential as they approach equilibrium. Furthermore, the final swelling potential may vary slightly but is generally similar in value. These conditions are influenced by several internal factors, where the composition of the soil, clay minerals, and the type of structure of particles significantly affect how the equilibrium conditions will be generated (Bensallam et al., 2014; Basma et al., 1996).

Table 4 Details of the previous study

This behavior shows that the same physical properties can produce different swelling potentials due to a wetting-drying cycle. If we look at the chemical properties, the CEC values tend to be the same even though each specimen receives a different number of wetting-drying cycles. CEC is a natural property of soil that is not influenced by changes in microstructure.

5.3. Microstructure

The number of wetting-drying cycles received resulted in microstructural evolution, as shown in specimens S1 to S4 and tests on marine clay and expansive soils in Jordania (Basma et al., 1996; Osipov et al., 1987). Meanwhile, specimens S4 and S5 showed a linear correlation between CEC and final swelling potential, as shown in Figure 5(b). These conditions indicate that CEC can represent the final swelling potential of specimens with certain microstructural conditions. As shown in Figure 5, specimens S4 and S5 have different microstructural conditions from the others. The two specimens have a laminar microstructure, which shows that microstructure influences the resulting swelling potential.

Microstructure conditions show a layered structure with a broad cross-section and visually in the form of thin sheets, which are the morphological type of clay minerals (She et al., 2020). During the wetting-drying cycle, the soil experiences energy changes from increasing and decreasing temperature. Not all energy stored during the dry cycle is released when the specimen undergoes a wet cycle. The stored energy can drive the soil particles through the exchangeable cations. This movement can affect the condition of the specimen's microstructure during the wetting-drying cycle. The first wetting-drying cycle experienced by the specimen eliminates the initial conditions of its microstructure, which is affected by the energy difference within it. Then, as the number of wetting drying cycles increases, the microstructure is re-oriented and forms a new structural arrangement (Sayem and Kong, 2016; Kalkan, 2011) which is different from its initial state.

Microstructural changes affect the swelling-shrinkage potential behavior that occurs during the wetting-drying cycle. In general, wetting-drying cycles increase the swelling potential and decrease the shrinkage potential. Results of the SEM conducted show that the microstructural conditions have changed and tend to form a laminar structure. This condition is the influence of microstructural evolution, where the arrangement of the particles affects the amount of swelling and shrinkage produced due to the resulting pore size (Tang et al., 2022; Azizi et al., 2020; Monroy et al., 2010; Alonso et al., 1999). The study results show that an increase in the wetting-drying cycle that is carried out one day will not impact the resulting swelling potential. Equilibrium is reached when the microstructure forms a laminar structure formed by the most effective energy during the wetting-drying cycle (Tessier, 1990). The resulting swelling behavior shows that swelling potential is strongly influenced by microstructural conditions. Meanwhile, the character and magnitude of changes in each specimen depend on the initial microstructure's characteristics and the bond structure formed (Osipov et al., 1987).

5.4. Swelling Pressure

The swelling pressure increased from the specimen without a cycle (S1) to the fourth cycle (S4), from 125.6 kPa to 304.1 kPa. The results showed that the swelling pressure after the fourth (S4) to eighth cycles (S5) tends to be constant at 310 kPa, as seen in Figure 5. This condition is influenced by the microstructural conditions, which tend to be the same so that the reaction to a given load almost does not change with the addition of a given cycle.

Microstructural conditions with a laminar arrangement indicate the uniformity of structure and space between particles. There are Van der Waals attractions (Du et al., 2021) and repulsive forces that appear in the spaces between clay particles. Van der Waals force is the ability of attraction between particles, where the closer the distance between the particles, the strength increases. These conditions indicate that the specimen's density increases when the microstructural conditions form a laminar arrangement. This condition causes the space between the clay mineral sheets to become smaller. As a result, the same ions will have positions that are getting closer, thus giving a greater repulsive force between the mineral sheets (Pusch, 2006). Seeing the microstructural changes that occur, the swelling pressure is quite sensitive to microstructural changes during the hydration process. The increasingly compacted microstructure conditions result in a more significant load to return the specimen to its original state.

Based on the research, microstructural conditions played a critical role in expansive soils’ swelling-shrinking behavior and mechanical properties. It is not enough to identify the swelling potential that occurs in expansive soils using the initial conditions of the specimens. The variability of microstructural conditions due to particle orientation resulted in different swelling potentials in the specimen, even under the same initial conditions. Microstructural evolution occurred because of wetting-drying cycles experienced by the sample. As the wetting-drying cycle increases, the initial microstructural conditions disappear, reorientation occurs, and a new arrangement of particles forms into a laminar structure. The evolution to form a laminar structure reduced the imbalance in the microstructure so that the CEC value could represent the final swelling potential. Under these microstructural conditions, both the swelling potential and the swelling pressure showed values that tend to be constant, respectively 10% and 300 kPa. Therefore, it is proposed that the wetting-drying cycle is a factor to be considered in analyzing the long-term behavior of swelling and shrinkage of expansive soils.

The research described in this paper was financially supported by PUTI Q2 from Universitas Indonesia (Contract No NKB-1351/UN2.RST/HKP.05.00/2022).

Alonso, E, Vaunat, J & Gens, A 1999, 'Modelling the mechanical behaviour of expansive clays', Engineering Geology, vol. 54, pp. 173-183, https://doi.org/10.1016/S0013-7952(99)00079-4

ASTM D422 2002, 'Standard test method for particle-size analysis', Annual Book of Standards, West Conshohocken, vol. 8, pp. 1-8, https://doi.org/0.1520/D0422-63R07

ASTM D4318 2004, 'Standard test methods for liquid limit, plastic limit, and plasticity index of soils', Annual Book of Standards, West Conshohocken, vol. 8, pp. 1-20

ASTM D4546 2004, 'Standard test methods for one-dimensional swell or collapse of soils', Annual Book of Standards, West Conshohocken, vol. 8, pp. 1-10

ASTM D698 2004, 'Standard test methods for laboratory compaction of soil standard effort', Annual Book of Standards, West Conshohocken, vol. 8, pp. 1-13

ASTM D854 2004, 'Standard test methods for specific gravity of soil solids by water pycnometer', Annual Book of Standards, West Conshohocken, vol. 8, pp. 1-7

Azizi, A, Musso, G & Jommi, C 2020, 'Effects of repeated hydraulic loads on microstructure and hydraulic behaviour of a compacted clayey silt', Canadian Geotechnical Journal, vol. 57, pp. 100–114, https://doi.org/10.1139/cgj-2018-0505

Bahsan, E, Andreatama, B, Prakoso, WA, Soepandji, BS, Dwinanti, R & Marthanty, R 2021, 'Applying the Drucker-Prager failure criterion for representing soil behavior using smoothed particle hydrodynamics', International Journal of Technology, vol. 12, no. 5, pp. 965–974, https://doi.org/10.14716/ijtech.v12i5.5217

Basma, AA, Al-Homoud, AS, Malkawi, AIH & Al-Bashabsheh, MA 1996, 'Swelling-shrinkage behavior of natural expansive clays', Applied Clay Science, vol. 11, pp. 211–227, https://doi.org/10.1016/S0169-1317(96)00009-9

Bensallam, S, Bahi, L, Alaoui, M, Ejjaaouani, H & Shakhirev, V 2014, 'The effect of surcharge pressure on the cyclic vertical deformations for expansive clayey soils in Morocco', Geosciences Journal, vol. 18, pp. 81-87, https://doi.org/10.1007/s12303-013-0043-x

Chapman, H 1965, 'Cation?exchange capacity', Methods of Soil Analysis: Part 2 Chemical and Microbiological Properties, vol. 9, pp. 891-901, https://doi.org/10.2134/agronmonogr9.2.c6

Chen, FH 1965, 'The use of piers to prevent the uplifting of lightly loaded structures founded on expansive soils', Proceedings of International Research and Engineering Conference on Expansive Clay Soils, Texas, pp. 152-171

Day, RW 1994, 'Swell-shrink behavior of compacted clay', Journal of Geotechnical Engineering, vol. 120, no. 3, pp. 618-623, https://doi.org/10.1061/(ASCE)0733-9410(1994)120:3(618)

Day, RW 1999, Geotechnical and Foundation Engineering: Design and Construction, McGraw-Hill Professional

Du, J, Zhou, A, Lin, X, Bu, Y & Kodikara, J 2021, 'Prediction of swelling pressure of expansive soil using an improved molecular dynamics approach combining diffuse double layer theory', Applied Clay Science, vol. 203, article 105998, https://doi.org/10.1016/j.clay.2021.105998

Estabragh, A, Parsaei, B & Javadi, A 2015, 'Laboratory investigation of the effect of cyclic wetting and drying on the behaviour of an expansive soil', Soils and Foundations, vol. 55, no. 2, pp. 304–314

Faisal, A, Anshari, A, Nazri, F, & Kassem, M 2023, 'Near-collapse probability of RC frames in Indonesia under repeated earthquakes containing fling-step effect', International Journal of Technology, vol. 14, no. 2, pp. 339-350, https://doi.org/10.14716/ijtech.v14i2.4989

Kalkan, E 2011, 'Impact of wetting–drying cycles on swelling behavior of clayey soils modified by silica fume', Applied Clay Science, vol. 52, no. 4, pp. 345-352, https://doi.org/10.1016/j.clay.2011.03.014

Kuila, U & Prasad, M 2013, 'Specific surface area and pore?size distribution in clays and shales', Geophysical Prospecting, vol. 61, pp. 341–362, https://doi.org/10.1111/1365-2478.12028

Kyokawa, H 2021, 'A double structure model for hydro-mechano-chemical behavior of expansive soils based on the surface phenomena of mineral crystals', Engineering Geology, vol. 294, article 106366, https://doi.org/10.1016/j.enggeo.2021.106366

Lei, X, Wong, H, Fabbri, A, Limam, A & Cheng, YM 2014, 'A thermo-chemo-electro-mechanical framework of unsaturated expansive clays', Computers and Geotechnics, vol. 62, pp. 175-192, https://doi.org/10.1016/j.compgeo.2014.07.004

Lesmana, R, Rahayu, W, Bahsan, E & Soepandji, BS 2022, 'Stabilization of weathered clay shale using propylene glycol and potassium chloride as an embankment material alternative', International Journal of Technology, vol. 13, no. 4, pp. 717-726, https://doi.org/10.14716/ijtech.v13i4.1883

Lopez-Lara, T, Hernandez-Zaragoza, J, Carreon-Freyre, D, Cerca, M, Rojas-Gonzalez, E, Minor Franco, A, Martinez-Barrera, G & Salgado-Delgado, R 2018, 'Spatial microstructural ordering of expansive clay minerals', Advances in Civil Engineering, vol. 2018, article 9217365, https://doi.org/10.1155/2018/9217365

Monroy, R, Zdravkovic, L & Ridley, A 2010, 'Evolution of microstructure in compacted London Clay during wetting and loading', Géotechnique, vol. 60, pp. 105-119, https://doi.org/10.1680/geot.8.P.125

Muntohar, AS, Diana, W, Tafalas, MY & Bimantara, NR 2020, 'The behavior of the flexible plate–supported with SiCC-mortar column on expansive soil', International Journal of Technology, vol. 11, no. 1, pp. 123-132, https://doi.org/10.14716/ijtech.v11i1.1213

Osipov, V, Bik, NN & Rumjantseva, N 1987, 'Cyclic swelling of clays', Applied Clay Science, vol. 2, no. 4, pp. 363-374, https://doi.org/10.1016/0169-1317(87)90042-1

Peng, X, Zhang, ZB, Wang, LL & Gan, L 2012, 'Does soil compaction change soil shrinkage behaviour?', Soil and Tillage Research, vol. 125, pp. 89-95, https://doi.org/10.1016/j.still.2012.04.001

Pusch, R 2006, 'Mechanical properties of clays and clay minerals', Developments in Clay Science, vol. 1, pp. 247-260, https://doi.org/10.1016/S1572-4352(05)01006-8

Putri, AP, Prakoso, WA, Rahayu, W & Zulys, A 2024, 'Long-term swelling potential of tropical residual expansive soils', Manuscript submitted for publication

Rahardjo, H, Satyanaga, A & Leong, EC 2016, 'Effects of rainfall characteristics on the stability of tropical residual soil slope', E3S Web of Conferences, vol. 9, article 15004, https://doi.org/10.1051/e3sconf/20160915004

Sayem, HM & Kong, L-W 2016, 'Effects of drying-wetting cycles on soil-water characteristic curve', DEStech Transactions on Environment, Energy and Earth Sciences, In: 2016 International Conference on Power Engineering & Energy, Environment (PEEE 2016)

Schanz, T & Tripathy, S 2009, 'Swelling pressure of a divalent?rich bentonite: Diffuse double?layer theory revisited', Water Resources Research, vol. 45, no. 5, https://doi.org/10.1029/2007WR006495

Schoonheydt, RA & Johnston, CT 2006, 'Surface and interface chemistry of clay minerals', Developments in Clay Science, vol. 1, pp. 87-113, https://doi.org/10.1016/S1572-4352(05)01003-2

Seiphoori, A, Ferrari, A & Laloui, L 2014, 'Water retention behaviour and microstructural evolution of MX-80 bentonite during wetting and drying cycles', Géotechnique, vol. 64, pp. 721-734, https://doi.org/10.1680/geot.14.P.017

She, J, Lu, Z, Duan, Y, Yao, H & Liu, L 2020, 'Experimental study on the engineering properties of expansive soil treated with Al13', Scientific Reports, vol. 10, pp. 1-9, https://doi.org/10.1038/s41598-020-70947-6

Tang, C-S, Cheng, Q, Gong, X, Shi, B & Inyang, HI 2022, 'Investigation on microstructure evolution of clayey soils: A review focusing on wetting/drying process', Journal of Rock Mechanics and Geotechnical Engineering, vol. 15, no. 1, pp. 269-284, https://doi.org/10.1016/j.jrmge.2022.02.004

Tawfiq, S & Nalbantoglu, Z 2009, 'Swell-shrink behavior of expansive clays', In: 2nd International Conference on New Developments in Soil Mechanics and Geotechnical Engineering, Near East University, Nicosia, North Cyprus

Tessier, D 1990, 'Behaviour and microstructure of clay minerals', Soil Colloids and Their Associations in Aggregates, Springer

Tripathy, S & Subba Rao, KS 2009, 'Cyclic swell–shrink behaviour of a compacted expansive soil', Geotechnical and Geological Engineering, vol. 27, pp. 89-103, https://doi.org/10.1007/s10706-008-9214-3

Van Der Merwe, D 1964, 'The prediction of heave from the plasticity index and percentage clay fraction of soils', The Civil Engineer in South Africa, vol. 6, pp. 103-107

Vilarrasa, V, Rutqvist, J, Blanco Martin, L & Birkholzer, J 2016, 'Use of a dual-structure constitutive model for predicting the long-term behavior of an expansive clay buffer in a nuclear waste repository', International Journal of Geomechanics, vol. 16, no. 6, https://doi.org/10.1061/(ASCE)GM.1943-5622.0000603

Wang, G & Wei, X 2015, 'Modeling swelling–shrinkage behavior of compacted expansive soils during wetting–drying cycles', Canadian Geotechnical Journal, vol. 52, pp. 783–794, https://doi.org/10.1139/cgj-2014-0059@cgj-ec.2015.01.issue-4

Zhao, X, Cui, Y, Zhang, R, Tian, G, Satyanaga, A & Zhai, Q 2024, 'Experimental investigation of the collapsibility of loess subjected to water invasion', Bulletin of Engineering Geology and the Environment, vol. 83, no. 33, pp. 1–7, https://doi.org/10.1007/s10064-023-03532-6