Deep Eutectic Solvents and Natural Deep Eutectic Solvents for Extraction and Purification of Proteins from Animal and Botanical Sources - A Review

Corresponding email: andreyheriedzal@gmail.com

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.6925

Kumoro, A.C., Wardhani, D.H., Kusworo, T.D., Djaeni, M., Ping, T.C., Alhanif, M., 2024. Deep Eutectic Solvents and Natural Deep Eutectic Solvents for Extraction and Purification of Proteins from Animal and Botanical Sources - A Review. International Journal of Technology. Volume 15(5), pp. 1420-1437

| Andri Cahyo Kumoro | 1. Department of Chemical Engineering, Faculty of Engineering, Universitas Diponegoro, Semarang, 50275, Indonesia 2. Institute of Food and Remedies Biomaterials (INFARMA), Faculty of Engineering, Uni |

| Dyah Hesti Wardhani | 1. Department of Chemical Engineering, Faculty of Engineering, Universitas Diponegoro, Semarang, 50275, Indonesia 2. Institute of Food and Remedies Biomaterials (INFARMA), Faculty of Engineering, Uni |

| Tutuk Djoko Kusworo | Department of Chemical Engineering, Faculty of Engineering, Universitas Diponegoro, Semarang, 50275, Indonesia |

| Mohamad Djaeni | Department of Chemical Engineering, Faculty of Engineering, Universitas Diponegoro, Semarang, 50275, Indonesia |

| Tan Chin Ping | Department of Food Technology, Faculty of Food Science and Technology, Universiti Putra Malaysia, Serdang, 43400, Malaysia |

| Misbahudin Alhanif | 1. Department of Chemical Engineering, Faculty of Engineering, Universitas Diponegoro, Semarang, 50275, Indonesia 2. Institute of Food and Remedies Biomaterials (INFARMA), Faculty of Engineering, Uni |

The

rising global population has led to an escalating demand for affordable,

high-quality proteins intended for human consumption. Different efforts have

been made to develop efficient and greener solvents for protein production.

Most proteins are produced from raw plant and animal parts, but the use of the

residues in commercial-scale protein production is very scarce. Therefore, this

research aims to collect an overview of deep eutectic solvents (DESs) and

natural deep eutectic solvents (NADESs) for protein extraction and

purification. In this context, solvent type and operating parameters should

also be selected to modify DESs and NADESs physicochemical characteristics for

the achievement of high protein yield with preserved functional properties. The

results show that appropriate implementation of combined DESs and NADESs with

advanced extraction and purification techniques can improve protein yield and

prevent detrimental effects on the extracted protein and environment. The

application of DESs and NADESs can increase the efficiency of protein

extraction and recovery in various parts of plants and animals by 55.72% and

98.16%, respectively, with purity reaching 99.82%. This research also reviews

safety, environmental impacts, and drawbacks as well as shows feasible future

recommendations for commercial-scale protein production processes. NADESs are safer than petroleum-based solvents but

have higher toxicity than DESs. Magnetic adsorbent and magnetic solid-phase

extraction methods have been shown to reduce labor-intensive steps, resulting

in shorter operating times and superior protein recovery while maintaining

functional properties. Meanwhile, protein producers' knowledge and motivation

to use DES and NADES are strengthened.

Animal and plant parts; Deep eutectic solvent; Extraction; Operating parameter; Protein

Protein is the basic unit of living organisms

acquired from sustainable origins, namely animals, plants, and microorganisms. Since

the world’s population is forecasted to reach 9 billion by 2050, the demand for

affordable high-quality protein is expected to increase (Grudniewska et al., 2018). Therefore, effcient, greener and

sustainable methods for protein production receives a growing interest. The underused

sources have also attracted attention for the preparation of affordable pure

proteins. In this context, the food industries may also adopt

underused plant and animal residues by extracting and refining proteins as

valuable biomacromolecules showing numerous health benefits to reduce

environmental problems and support sustainable development goals.

The

crucial step in using protein is to adopt suitable extraction technologies to

acquire protein from animal or plant matrices. Conventional procedures are techniques

regularly used, such as chemical methods. However, the methods can lead to

reduced extraction yields due to protein degradation (Kumar et al., 2021b). Numerous industries also continue to depend

on traditional methods because of financial viability. Chemical methods are

categorized according to petroleum-based solvents, water, alkalis, organic

solvents, and acids (Bowen et al., 2022; Kumar et al., 2021b). Meanwhile, chemical methods are used

to enhance the retrieval of proteins (Kumar et al., 2021a; Bose et al., 2019). Protein purification methods include

precipitation through the addition of an agent, electrophoresis, ion exchange,

and affnity chromatography (Lin et al., 2021). Conventional acid-based extraction is less

promising due to lower quality of protein (Kumar et al., 2021b). Petroleum-based and solvent-based chemical

methods have been used in the food and pharmaceutical industries for centuries.

However, this solvent has serious problems, those related to low extract yield

and coextraction of unwanted substances, long extraction time, operational

complexity, expensive, toxicity, biodegradability, fammability, safety and

environmental sustainability, denaturation or reduced biological activities (Ling and Hadinoto, 2022; Fuad, Nadzir, and Harun, 2021; de Jesus and Filho, 2020).

Organic

solvents are crucial in protein extraction and precipitation processes, leading

to the production of pure products. Water-based extraction is a widely used

method for obtaining proteins from different sources (Chen et al., 2019a). The process is commonly adopted because of

the elevated solubility and stability of isolated protein, which is mostly

attributed to high content. Protein with the capacity of attaching to lipids

have non-polar or polar side chains and contain aromatic amino acids that

readily dissolve in organic solvents such as ethanol, butanol, and acetone (Qiaoyun et al., 2017). Aqueous two-phase systems, created by

combining polyethylene glycol (PEG) with salts can be used efficiently for

purification and separation of proteins (Asenjo and Andrews, 2011).

Alkalis

such as NaOH and KOH are frequently used to maintain a basic pH and enhance the

yield compared to organic extraction. Altering the pH to a basic level caused

the disulphide linkages to dissolve, leading to an enhancement in recovery and

yield (Contreras et al., 2019). The solubility is enhanced by an elevation

in the pH of solvent due to the ionization of acidic and neutral amino acids at

high pH levels. Therefore, extracting protein in an alkaline environment results

in greater protein yields. In this context, a yield above 90% can be obtained

from soybeans, rapeseed, and other seed commodities through alkaline extraction

at high pH. Alkaline enhances protein extraction and disrupts the structure of

amino acids, lysine and cysteine. This significantly degrades the digestibility

and acceptability of the extracted protein (Kumar et al., 2021b).

To

address this limitation, the food industries have initiated the use of greener

solvents as substitutes for petroleum-based solvents, alkalis, organic

solvents, and acids to manufacture products (Ling

and Hadinoto, 2022; Kumar et al., 2021a; Kumoro

et al., 2019). In addition, ionic liquids (ILs),

deep eutectic solvents (DESs) and analogues from natural sources (sugars,

acids, and amino acids) known as natural deep eutectic solvents (NADESs) are

progressing as advanced agents to decrease the adverse impacts of petroleum-based

solvents (Ling and Hadinoto, 2022). DESs are composed of a quaternary ammonium

salt (QAS) and a hydrogen bond donor (HBD), such as a carboxylic acid or

alcohol. These components are mixed in specific molar ratios to form a eutectic

mixture with a lower melting point (Abbott et al., 2003). Meanwhile, NADESs consist of natural

compounds such as sugar (glucose), organic acids (citric acid), and amino acids

(choline). This compound forms a eutectic mixture with properties similar to

DES but derived from renewable resources (Dai et al., 2013b).

Despite

having comparable physical characteristics to ILs, such as high viscosity, low

volatility, chemical and thermal stability, as well as non-flammability, DESs

are not made of ionic compounds. Non-ionic chemicals can produce DESs (Ling and Hadinoto, 2022), which are more cost-effective with higher

biodegradability (Kudlak, Owczarek, and Namiesnik, 2015). These solvents are environmentally friendly,

easy to synthesize, cheap, biodegradable, and possess low toxicity (Chen et al., 2018).

The

use of DESs and NADESs as an environmentally friendly solvent for extracting

valuable compounds has gained significant interest in recent years. This is due

to the distinct characteristics, including customizable properties,

versatility, ease of preparation, unique super-molecular structure that shows

strong attraction to different compounds, high solubility, and stabilizing

capability (Zannou and Koca, 2022; Dai et al., 2013a). The majority of investigations on extraction

have mostly focused on bioactive small compounds (Pratiwi et al., 2020; de Faria et al., 2017). Several reviews have been published

on the latest developments in extraction of bioactive small compounds using

DESs. Bonacci et al. (2020) gave an example showing the ability to

extract DESs from tiny molecules such as phenolic compounds. The use of choline

chloride glycerol DESs resulted in a significantly higher recovery yield of

oleuropein (~88,287 ppm) from olive oil processing wastes. This was achieved in

10 minutes, which is twice the usual water extraction method requiring 30

minutes. The research reported by de Faria et

al. (2017) also observed similar performance of DES. In

this context, higher recovery of polyphenols and flavonoid compounds was

obtained from saffron processing wastes compared to conventional solvents such

as aqueous methanol, aqueous ethanol, and water. Mulia

et al. (2015) have also succeeded in extracting mangostin

with the highest yield of 2.6% (w/w) from dried mangosteen skin using NADESs.

This was obtained using a mixture of choline chloride and 1,2-propanediol with

a mole ratio of 1:3.

Even

though DESs and NADESs extraction of small bioactive compounds is highly practical,

the investigation of biological macromolecules, such as proteins, oils and

carbohydrates, has gained attention (Ling and Hadinoto, 2022; Mulia et al., 2018). Considering the distinct physicochemical

characteristics of proteins in comparison to other small or large molecules,

the function of DES and NADESs should be reported in extracting proteins

derived from animals and plants. The selection of solvents depends on factors

such as the solubility of protein, extraction efficiency, and desired

properties of solvents. There are differences in protein from animals and

plants due to variations in biochemical composition, cellular structure, and

properties. Animal protein extraction includes methods such as aqueous, organic

solvent, or enzymatic digestion, depending on the tissue type and desired

protein (Malva et al., 2018). Meanwhile, plant protein extraction requires

additional steps to break down cell walls, such as mechanical disruption or

enzymatic treatment, followed by aqueous or buffer solutions (Wang, Liu, and Lu, 2013). Extraction from animals and plants with

greener and environmentally friendly solvents is interesting for further

analysis.

In

this research, extraction of DES and NADESs from animals and plants is

presented. The review commenced with a discussion of the fundamental and

physicochemical characteristics of DESs and NADESs suitable for protein

extraction processes. The main results and trends observed in solvent-based

protein extraction were discussed with the safety and environmental aspects.

Ionic

liquids (ILs) are used as solvents for reaction or extraction processes and

provide numerous advantageous characteristics, such as high boiling point,

broad liquid range, selective dissolving capacity, excellent thermal stability,

non-flammable and molecular structure variety (Morais et al., 2020). However, the preparation is very

complicated, requiring high equipment, manufacturing costs, and laborious

recovery from the mixture with the target analyte (Ling and Hadinoto, 2022). To overcome the limitation, DESs are developed

as a new generation of advanced greener solvents.

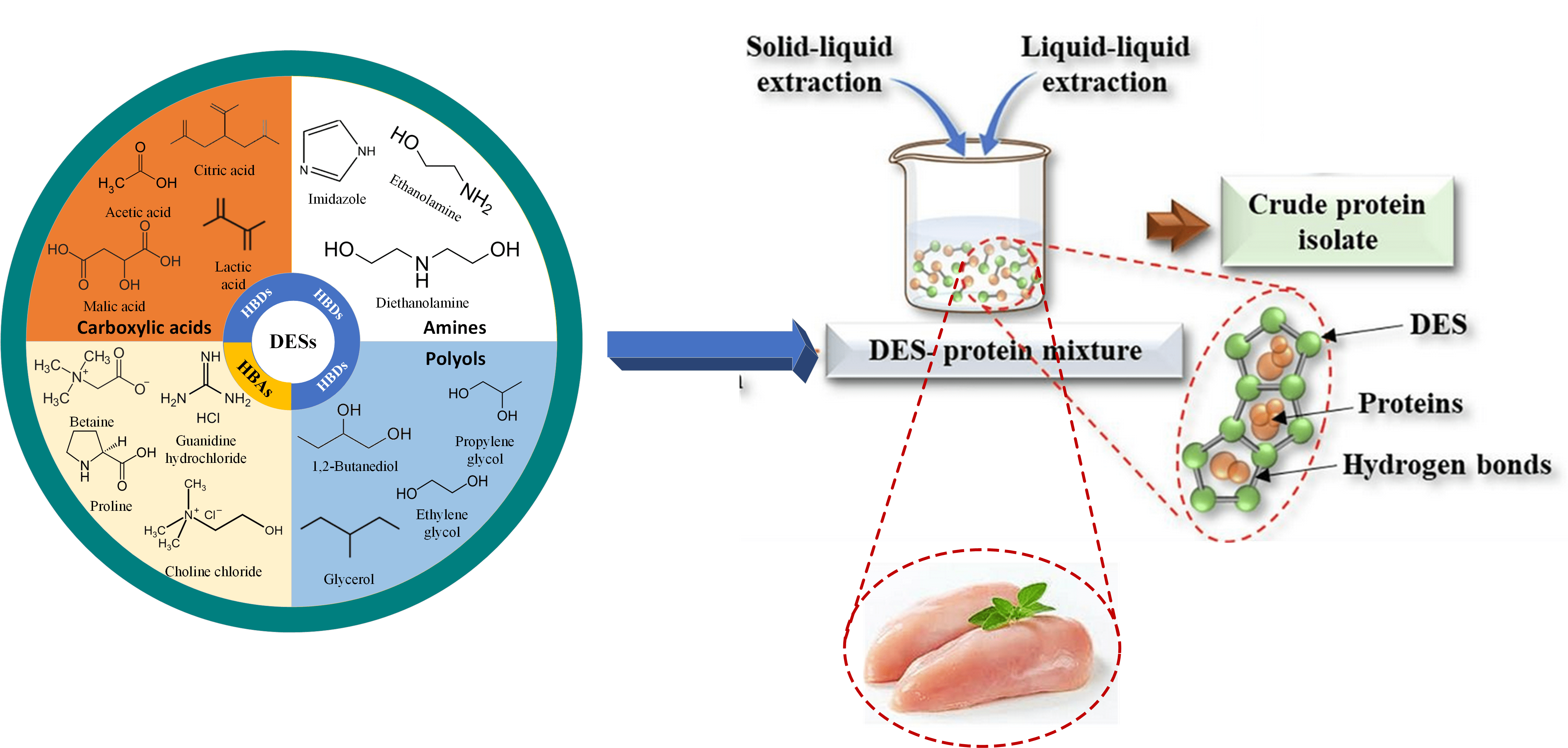

As a

eutectic mixture, DES can be synthesized partially or completely from non-ionic

compounds, which function as hydrogen bond donors (HBDs) such as betaine,

choline chloride, guanidine hydrochloride and proline, as well as hydrogen bond

acceptors (HBA) including amine groups (ethanolamine, dimethylamine, and

imidazole), polyols (ethylene glycol, propylene glycol, and glycerol), and

carboxylic acids (acetic, citric, maleic, and lactic acids) (Saini et al., 2022). Meanwhile, NADESs consist of natural

compounds such as sugar (glucose), organic acids (citric acid), or amino acids

(choline). This compound forms a eutectic mixture with properties similar to

DESs but derived from renewable resources (Dai et al., 2013b). The preparation comprises sequential

procedures, such as size reduction, heating, evaporation, and low-temperature

drying (Saini et al., 2022). After careful selection of the prerequisite

substances, homogenization is carried out at ideal conditions (i.e., <100°C)

to attain a eutectic mixture and equilibrate the resulting solution with

ambient conditions (Mišan et al., 2020). Therefore, the physicochemical

characteristics of DESs are equivalent to ILs as a perfect substitute. The

macromolecular structures are appropriate for protein extraction concerning

solubility, affnity, and stability (Landa-Castro et al., 2020). The influence of the composition of HBAs and

HBDs on the characteristics is explained in Section 4.

DESs

and NADESs can exist as binary or ternary mixtures. In addition, NADESs possess simpler preparation procedures, better

efficiency, selectivity, biodegradability, thermal stability, and

sustainability (Ijardar, Singh, and Gardas, 2022). Based on chemical compositions and formulas,

DESs are grouped into four classes (Abbott et al., 2004).

3. DESs and

NADESs Physicochemical Characteristics Related to Extraction Process

Even though the physical

characteristics of DESs are closely similar to the conventional ILs, the

chemical characteristics are significantly different. The influential

physicochemical characteristics are melting point, freezing temperature,

polarity, solubility, miscibility, pH, density, viscosity, interfacial tension,

refraction index, and ionic conductivity (Omar and Sadeghi, 2022b). The anion size, equilibrium molar ratio of

HBA/HBD, alkyl chain length, and molecular mass of HBA/HBD at the melting point

determine the physicochemical characteristics (Omar and Sadeghi,

2022a). However, viscosity and polarity possess

significant effects on extraction performance (Tolmachev et al.,

2022). Interfacial tension also has a remarkable

effect on liquid-liquid and ultrasound-assisted extraction processes (Kumoro et al.,

2022).

The fluidity of DESs is mainly

characterized by viscosity (Omar and Sadeghi, 2022b), influencing the solubility of target

samples. In this context, the biomacromolecules are more soluble in

less-viscous DESs. Temperature, type of HBAs and HBDs, HBA/HBD molar ratio, and

molecular mass greatly affect viscosity. Meanwhile, an increase in temperature

appreciably decreases viscosity due to hydrogen bond network cleavage between

HBA and HBD as well as the reduction of internal resistance of molecules (Ling and Hadinoto,

2022). DESs possess higher viscosity when sugar,

carboxylic acid and metallic compounds are selected as the HBD, while less

viscous type can be prepared using ethylene glycol, glycerol, and phenol (Ling and Hadinoto,

2022). After water addition, the viscosity

decreases, facilitating better mixing and mass transfer leading to a higher

extraction performance. An extreme amount of water ceases the advantageous

characteristics of DES. Therefore, an appropriate water quantity should be selected

to prevent the disruption of hydrogen bond interactions among DES-forming

substances (Ling et al.,

2020).

Polarity, which is closely related to

Hansen’s solubility parameter (HSP) is a theoretical method used as an

introductory tool to estimate the solubility of target biomacromolecules in

different solvents and select the most appropriate DESs and NADESs for

extraction from respective natural sources (El-Kantar et al.,

2019). Since DESs are mostly polar substances, the

superior ability to dissolve the target analytes can improve extraction yield (Gullón et al.,

2020). Eutectic solvent polarity is attributed to

the HBDs used for the synthesis and the highest are usually synthesized from

carboxylic acids. In contrast, polyols and sugars result in eutectic solvents

with the lowest polarity (Xu et al.,

2019a). The dilution of DESs with water beyond 50%

causes more hydrogen bond destruction and leads to a decrease in extraction

ability (Dai et al.,

2015).

The density of DESs is higher than

pure water (Omar and Sadeghi,

2022b), with the value ranging from 1.0 to 1.35 g/cm3

at 25oC. However, the density of metallic salts containing DESs lies

between 1.3 to 1.6 g/cm3 (Zhang et al.,

2012), depending on the molecular arrangement,

temperature, HBA/HBD molar ratio, as well as the presence of cavities and

voids. Temperature greatly decreases the density, refraction index, and

acoustic velocity due to the enhancement of ionic movement and unoccupied

volume (Omar and Sadeghi,

2022b).

Surface tension is an important

characteristic of DESs utilization in the interface and colloid system (Kumoro et al.,

2022). In this context, HBDs and HBAs have an

appreciable influence on the surface tension of DESs. Since DESs are highly

hydrophobic, the surface tension is enhanced greatly when the water mole

fraction is higher than 0.9 (Chen et al.,

2019b). However, the surface tension decreases as a

function of solvent concentration when petroleum-based solvents or crystal

water in the salt component are added with an increasing temperature from 20 to

60°C (Chen et al.,

2019b).

The majority of DESs are highly

viscous liquids with large ion sizes and possess low ionic conductivity (below

1 mS/cm at ambient temperature) which limits the application in

isoelectric-based protein precipitation (Omar and Sadeghi,

2022b). The ionic conductivity is influenced by

alkyl chain length of cation, the characteristics of organic salt, HBDs and

HBAs ionic ratio, temperature, and water content (Dai et al.,

2015). Therefore, the conductivity can be improved

by increasing the free volume through the reduction of cation size and the

substitution of HBD with fluorinated substances to reduce viscosity (Abbott, Capper, and Gray, 2006). Another strategy is to increase the

temperature which helps to break the hydrogen bond network and increase ionic

motility (Omar and Sadeghi,

2022b). The tunable physical characteristics,

specifically density, viscosity, ionic conductivity, and freezing point

obtained by a careful selection of biodegradable HBD and HBA couplings make

DESs and NADESs more attractive for specific applications (Zhang et al.,

2012).

4. DESs and

NADESs as Extracting Media for Protein Extraction and Purification

DESs,

formed by the combination of hydrogen bond donors and acceptors, have been

extensively studied for the versatile applications. For instance, Abbott et al. (2003) showed the exceptional solvent properties of

DESs, particularly in extraction of bioactive compounds from natural sources.

The results showed that DESs, such as those composed of choline chloride and

urea, reported superior extraction yields and selectivity compared to conventional

solvents. Similarly, Dai et al. (2013a) suggested the efficiency in catalyzing

various chemical reactions, showing the potential as green reaction media.

Conversely, NADESs are derived from naturally occurring compounds such as

sugars, organic acids, and amino acids, and the efficiency has been reported in

various processes. For example, Socas-Rodríguez et

al. (2021) investigated the use as extraction solvents

for bioactive compounds from different matrices. The research showed that

NADESs offered a greener alternative to conventional solvents, with comparable

or improved extraction efficiency. Generally, DESs and NADESs offer promising

prospects as efficient and greener solvents across various industries. The

unique properties, coupled with the renewable and sustainable nature, position

solvents as viable alternatives, contributing to the development of more

sustainable processes.

Efficiency

and yield when using DES or NADES can vary depending on the specific

application and the characteristics of solvent system. These eco-friendly

solvents offer several advantages contributing to improved efficiency and yield

in various processes, including extraction, synthesis, and catalysis. According

to Smith, Abbott, and Ryder (2014), solvents possess unique properties in

enhancing the efficiency and yield of chemical processes. The properties

include the ability to enhance solubility, provide selective extraction,

operate under mild reaction conditions, and offer recyclability. By leveraging

the characteristics, DES and NADES have shown potential to facilitate higher

yields and improved efficiency compared to conventional solvents (Smith, Abbott, and Ryder, 2014).

To

elaborate on a specific example, extraction of bioactive compounds is

considered from plant material using NADESs. Choi et

al. (2011) reported the use in understanding cellular

metabolism and physiology, emphasizing the potential for efficient extraction

of target compounds from natural sources. The selected method includes

preparing the NADESs by mixing components such as choline chloride and organic

acids in specific ratios, followed by extraction of bioactive compounds from

plant material at an appropriate temperature. The resulting extract can be

analyzed using analytical techniques to quantify yield and purity. Moreover, Dai et al. (2015) discussed the tailoring of properties,

including the addition of water, to optimize performance in various

applications. This optimization process enhances efficiency and yield by

fine-tuning solvent characteristics to suit specific extraction or synthesis

requirements.

In

the case of protein extractions, the most used DESs belong to type III and

comprise ChCl as HBA and amines, amide, carboxylic acids, sugars, and polyols

as HBD (Zhang et al., 2012). Ling and Hadinoto (2022) showed that there were considerable

variations in melting points when the HBA:HBD ratios in ChCl:urea were changed.

A 1:2 ratio resulted in a significantly lower melting temperature of 12oC,

while a 1:1 ratio generated NADESs with a high melting point of 50oC.

Therefore, the choice of HBD component has a major impact on the melting point

of the resulting DES as well as the effect of the molar ratio of HBA and HBD.

For example, the use of ethylene glycol, citric acid, malonic acid, oxalic

acid, xylitol, and glycerol as HBD produced DESs with melting temperatures

ranging from 69 °C to room temperature. In this context, the type of HBD

affects the melting point of the synthesized DESs (Zhang et al.,

2012). An appropriate HBA/HBD molar ratio

in the mixture plays a crucial role in ensuring the suitability of the

resulting DESs to selectively dissolve the targeted proteins and easy solvent

recovery.

4.1. DESs and NADESs for Solid–Liquid

Extraction of Protein from Plant and Animal Parts

The mechanism of DESs and NADESs in

solid-liquid extraction of proteins from plant and animal parts includes a

series of steps. These solvents penetrate the cell structures of plant

materials or animal tissues, disrupting hydrogen bonds and hydrophobic

interactions (Morais et al.,

2020). Within plant or animal material, DESs and

NADESs solubilize proteins through interactions such as hydrogen bonding and

electrostatic interactions (Bowen et al.,

2022). Meanwhile, extraction methods such as shaking or stirring enhance

protein leaching from the solid matrix into solvent phase (Zhou, Fakayode and Li, 2023). Subsequent phase separation techniques, such

as centrifugation or filtration, isolate protein-containing solvent phase from

the solid debris (García et al.,

2015). Protein recovery from solvent phase is also

achieved through precipitation or purification methods, with the possibility of

solvent regeneration for further use (Abbott et al.,

2004). This mechanism shows the potential of DESs

and NADESs as sustainable alternatives for protein extraction, offering

applications in various industries including food, pharmaceuticals, and biotechnology.

Different investigations have also

focused on the usage of biomass residues as tabulated in Table 1. These greener

solvents have proven the ability to achieve higher extraction performance in

terms of product yield and purity. Liu et al.

(2017) prepared DESs by mixing several HBAs, such as

ChCl, glycine, betaine, alanine chloride, acetylcholine chloride, and nicotinic

acid with PEG200 to extract pumpkin seeds protein. The PEG200-based DESs were

mixed with a four-fold volume of ethanol as well as 1 M hydrochloric acid to

control the pH at 4.5 and recover 93.8% of the extracted protein (Table 1).

Currently, extraction of proteins using PEG-based DESs is growing more rapidly.

This is because the extracted proteins are more stable and accepted by Food and

Drug Administration (FDA), which opens wider opportunities for more sustainable

developments in the agricultural, food and pharmaceutical sectors (Morgenstern et

al., 2017). Even though PEG-based DESs show excellent

affnity to protein as well as a remarkable capacity to ease precipitation, more

research is required to ensure the scale-up and practical application at a

commercial scale.

Hernández-Corroto et al. (2020) used highly polar and hydrophilic DESs derived from ChCl and

acetic acid to extract pomegranate peel protein. The resulting extract

contained 19.2 mg protein/g with high antihypertensive activity, which was

stronger than petroleum-based extract. After selecting nine ChCl – diol

mixtures as DESs, Yue et al. (2021) found that ChCl–1,4-butanediol/water mixture

was the perfect solvent for oat protein extraction with an effciency of 55.72%

as well as better stability and foaming capacity (Table 1). DESs derived from multicomponent

mixtures could precipitate protein more rapidly than binary mixtures caused by

high partitioning capacity and polarity.

Chen et al. (2021) prepared DESs by mixing ChCl with glycerol to

extract soy protein with a yield of 10% higher than the acid-based

precipitation method, which reported enhanced heat resistance and

hydrophobicity. An equivalent observation was stated by Lin et al. (2021) when acidic DESs based on ChCl and levulinic acid were used to

extract protein from bamboo shoots. The research observed a more profound

protein yield enhancement (60%) compared to extraction using sodium hydroxide

solution.

With the intention of marine

by-product valorization, Rodrigues et al. (2021) prepared DES by blending betaine and

propylene glycol in a ratio of 1:3 to recover proteins from sardine fish heads

and entrails. A yield of 162.2 mg protein/g fish parts greater than the common

aqueous extraction was obtained. This product contained numerous hydrophobic

amino acids, namely alanine, isoleucine, leucine, and valine that are

applicable to produce less polar DESs. In addition, the resulting extracts

showed stronger antioxidant and antimicrobial capacities. The existence of

hydrophobic DESs components promotes more intensive interactions between the

respective proteins with the cell membrane of the assayed microorganisms.

Rodrigues et al. (2021) extracted protein from sardine processing

residue using betaine–propylene glycol and obtained a yield of 162.2 mg

protein/g fish with higher antioxidant and antimicrobial activities than the

water extract. DESs made from lactic acid and L-cysteine are capable of

recovering keratin from coarse wool residue without altering the polypeptide

structure (Okoro et al.,

2022). Based on those reviewed facts, DESs and

NADESs are capable of extracting valuable proteins and preserving desirable

functional characteristics.

Table 1 Extraction

of proteins from sustainable sources using various DESs and NADESs

|

NADESs/DESs |

Protein Sources |

Process Parameters |

Yields |

References |

|

Solid-liquid extraction (SLE) | ||||

|

ChCl–based NADES with ethylene glycol |

orange peel |

Temp.: 4°C, time: 15 min |

7.7 mg/g FW |

(Panic et al.,

2021) |

|

ChCl–levulinic acid |

basal bamboo shoot (BBS), sheath, tip bamboo shoot (TBS) |

Temp.: 80°C, time: 50 min, solid/liquid ratio (30 mg/mL) |

Protein: 15.46 ± 0.30 mg/g DW, 9.54 ± 0.17 mg/g DW and 39.16 ± 1.22

mg/g DW for BBS, sheath and TBS. |

(Lin et al.,

2021) |

|

ChCl–butanediol |

oat |

Temp.: 80°C, time: 1.5 h |

Total protein yield: 55.72%, extracted protein has high solubility,

foaming capacity, and stability. |

(Yue et al.,

2021) |

|

ChCl–glycerol |

soybean |

Temp.:60°C, time: 3.9 h, liquid/solid ratio: 10.3, stirring speed: 873

rpm, water content: <15 wt.% |

Total protein yield: 34.62%, extracted protein has good heat

resistance and is highly hydrophobic. |

(Chen et al.,

2021) |

|

ChCl–acetic acid

|

pomegranate peels |

Time: 15 min, ChCl:AA molar ratio 1:2 |

Protein yield: 19.2 mg/g of protein with excellent antihypertensive

capacity |

(Hernández-Corroto

et al., 2020) |

|

ChCl–PEG |

pumpkin seed |

Temp.: 43oC, liquid/solid ratio: 28 mL/g, microwave power:

140 W, DES concentration: 28% w/w, precipitation time: 4 min |

Protein yield: 93.95% (w/w) of protein |

(Liu et al.,

2017) |

|

Betaine–propylene glycol (B:PG) |

Sardine processing residues |

Temp.:80°C, time: 18 h, B:PG molar ratio: 1:3, liquid/solid ratio: 80 |

Total protein yield: 162.2 mg/g protein. |

(Rodrigues et

al., 2021) |

|

Liquid-liquid extraction (LLE) | ||||

|

ChCl–glycerol |

BSA |

Temp.: 30oC, DES: 1.3 g, salt solution concentration: 0.9

g/mL |

98.16% of BSA was transferred into the DES-rich phase of ATPS,

back-extraction effciency:32.96% |

(Xu et al., 2016) |

|

Tetrabutylammonium bromide–glycolic acid |

Lysozyme from chicken egg white |

Temp.: 35oC, DES <1.0 g, salt solution concentration

< 0.25 g/mL |

98.16% of lysozyme was transferred into the DES-rich phase of ATPS,

91.73% of the initial activity of lysozyme was retained |

(Xu et al.,

2019b) |

|

[TBAC][PPG400]/ [Pro][Xyl] |

Chymotrypsin |

Temp.: 35oC, [Pro][Xyl]: 1.6 g, Protein: 8 mg,

[TBAC][PPG400]: 1.0 g |

extraction effciency: 97.30% |

(Meng et al.,

2019) |

There are many parameters,

which provide essential roles during biomacromolecules extraction, specifically

proteins using DESs and NADESs, such as temperature, duration, solvent-to-solid

ratio, solid particle size, and pH (Kumoro et al.,

2022). An appropriate selection of temperature,

water content, and pH will alter polarity, solubility, interfacial tension, and

viscosity supporting the achievement of high extraction performance (Huang et al.,

2017).

4.2. DESs for

Liquid-Liquid Extraction of Protein from Plant and Animal Parts

Aqueous two-phase systems (ATPS) are

used to facilitate selective liquid-liquid extraction of proteins by

homogenizing a water-soluble polymer with another inorganic salt, such as

PEG-salt-water mixture and ethylene oxide–propylene oxide or

copolymer–polyoxyethylene detergent at a concentration higher than the critical

value (Xu et al.,

2016). Xu et al.

(2016) prepared an ATPS by mixing ChCl and glycerol

with a salt solution and successfully extracted 98.16% of bovine serum albumin

(BSA) from the DESs phase without any protein conformation changes. Hydrogen

bonding, salting out, and hydrophobic interactions are possible characteristics

facilitating protein uptake (Xu et al.,

2016).

Xu et al.

(2019b) recovered lysozyme (Lyz) from chicken egg

white using DESs-based ATPS derived from tetrabutylammonium bromide (TBAB), glycolic

acid (Gly) and Na2SO4 salt. More than 98% of the lysozyme

was transferred to the DESs-phase with 91.73% of the initial activity

preserved. Similarly, Meng et al. (2019) selected a mixture of tetrabutylammonium

chloride (TBAC), L-proline – xylitol (Pro– Xyl) of 1:6 and polypropylene glycol

400 as DESs and ATPS to extract chymotrypsin from the mixture with BSA and

lysozyme. The result also showed that 97.30% chymotrypsin was accumulated in

the [Pro][Xyl]-rich phase under optimum conditions (pH 7.0, 35oC, 12

minutes shaking). The phase separation capacity of DESs can be improved by

enhancing the alkyl side chain length of carboxylic acids and the addition of a

benzyl group.

Liquid-liquid extraction of proteins

using DESs and NADESs in combination with ATPS includes a sophisticated

mechanism. Solvents penetrate the cellular structures of

plant materials or animal tissues, disrupting intermolecular forces and

solubilizing proteins (Abbott et al.,

2003). Subsequently, the mixture is combined with

an aqueous solution to form a biphasic system, where protein partitions between

the two phases based on the physicochemical properties (Singh and Tavana,

2018). Liquid-liquid extraction methods such as

stirring or shaking facilitate the transfer of protein into solvent-rich phase,

while the remaining sample matrix remains in the aqueous phase. Subsequent

separation methods, such as centrifugation or inversion isolate

protein-enriched phase from the aqueous phase (Mendes et al.,

2023). Protein recovery can be achieved through

precipitation or purification methods, with the potential for solvent

regeneration for reuse. This integrated method obtains the advantages of DESs

and NADESs in combination with ATPS to offer an efficient and sustainable

method for protein extraction from diverse biological sources.

4.3. Protein Purifcation Using DESs and NADESs

The extracted

proteins must be purified to allow food, pharmaceutical, and nutraceutical

industries to commercialize safe products for actual human and animal

consumption. The well-established methods to purify protein are alkali,

ammonium sulphate or acetone precipitation, salting-out, ion exchange,

electrophoresis, and affnity chromatography (Sindhu et al., 2012). However, the established techniques suffer

from limitations, such as protein activity loss, denaturation or complexation,

higher operating costs, and equipment operation difficulty. For example, an

enzyme's activity can be distorted by excessive interaction with a polar

solvent. In this context, a smart purifcation strategy using ATPS can be a

potential alternative method due to shorter purification and phase separation

time, excellent capacity to preserve biological activity, great

biocompatibility, low toxicity, and lower requirement of water (Gai et al., 2011). DESs have also been used as a part of ATPS

to purify protein (Table 2) (Zeng et al., 2016).

Purification process using ATPS offers a

versatile method for separating biomolecules based on differential partitioning

between two immiscible aqueous phases (Albertsson, 1970). This strategy includes the design of

phase-forming components such as polyethylene glycol (PEG) and dextran to

optimize protein partitioning behavior (Singh and Tavana, 2018). After mixing the sample with ATPS, the target

protein preferentially partitions into a phase while impurities remain in the

other, facilitating efficient separation (Hatti-Kaul, 2000). Smart technologies integrated into purification

process enable real-time monitoring of protein, allowing for precise adjustment

of conditions to enhance separation efficiency (Bernau et al., 2022). Meanwhile, separation techniques such as

centrifugation are used to isolate the phases containing the purified protein,

followed by further purification steps when necessary (Du et al., 2022). By obtaining automation and data-driven

optimization, this ATPS-based strategy ensures high yields and purity levels in

biotechnology and pharmaceutical applications.

Table 2

Utilization of DES-based ATPS for protein purification

|

|

ATPS |

Proteins |

Purification rate (%) |

References |

|

Associated with DES |

Betaine: glycerol: H2O (1: 2: 1)

-K2HPO4 |

BSA |

99.82 |

(Li et al., 2016) |

|

ChCl: glycerol (1: 1)-K2HPO4 |

BSA |

98.71 |

(Xu et al., 2016) | |

|

ChCl: glycerol (1: 1)-K2HPO4 |

Trypsin |

94.36 |

(Xu, Wang, and Hou, 2020) | |

|

ChCl: urea (1: 2)-K2HPO4 |

R-phycoerythrin |

92.60 |

Xu, Wang, and Hou, 2020) | |

|

Protein purification by MSPE |

PEG4000–MgSO4 |

BSA |

82.68 |

(Saravanan et al., 2008) |

|

Betaine–K2HPO4 |

BSA |

90 |

(Zeng et al., 2016) |

To

achieve the

objective, Li et al. (2016) adopted betaine as the HBA to compose six

types of DESs using urea, methyl urea, glucose,

sorbitol, glycerol, and ethylene glycol as HBD to extract and purify BSA

from protein mixture. In this context, betaine – urea mixture was found as the

most favorable DESs in combination with ATPS for BSA extraction and

purification from the complex systems where an effciency of 99.82% was

achieved. Moreover, Xu et al. (2015) used DESs derived from ChCl as HBA and

ethylene glycol, glycerol, glucose, and sorbitol as HBD to extract and purify

BSA from the mixture. The result confirmed that ChCl–glycerol mixture at a 1:1

molar ratio was the most favorable DESs. Under optimum pH, temperature, and

time, BSA and trypsin recoveries were 98.71% and 94.36%, respectively.

Meanwhile, Xu, Wang, and Hou (2020) observed that ChCl–urea (1:2) mixture

was the most preferred DESs to extract R-phycoerythrin from red algae. A

ternary mixture of ChCl–urea–K2HPO4 was the suitable ATPS

to purify R-phycoerythrin with a separation effciency of 92.60% (Xu, Wang, and Hou, 2020).

5. Limitations of DESs and

NADESs as Proteins Extraction and Purification Media

Even though many chemicals comply with

the functions of HBD and HBA to form DESs, some of solvents are not appropriate

for protein extraction from natural sources. Therefore, a careful selection

should be carried out to determine the appropriate DESs, specifically those related

to recovery and isolation from the phase (Smith, Abbott, and Ryder, 2014). DESs viscosities and densities decline with

the increase in temperature but the ionic conductivity rises (Lores et al.,

2017). These opposite features can be the critical

problems of viability and adaptability potentially affecting the utilizations

by the industry.

Efficient recovery and isolation are essential

for protein separation from DESs to enable recycling. Xu et al. (2015) observed that recovery

from this solvent was slow since the process occurred under a mass transfer

regime due to high interfacial resistance. Even though salt concentration is modified by mixing DESs with a

freshly ethanolic saline solution mixture, only 32.9% of protein is recovered. Therefore,

more advanced improvements should be addressed to the existing protein back

extraction and DESs recovery techniques to attract more interest from

enterprises (Li et al.,

2016).

6. Safety and

Environmental Aspects Associated with The Utilization of DESs and NADESs

NADESs

are less toxic than petroleum-based solvents, and the adverse effects on human

health remain unclear but solvents are regarded as safe (GRAS).

A previous in vivo research on mice and Wistar rats confirmed that NADESs reported

higher toxicity than DESs, which was rooted in high viscosity values. At high concentrations, solvent becomes very viscous

limiting the circulation and inducing acute effects, liver failure, and

mortality (Benlebna et al., 2018). Ecotoxicity research of DESs reported

disparate sensitivities to the tested ecosystem models, which mainly varied

with the composition of DESs. The results showed that DESs and NADESs toxicity was

affected by some parameters, namely viscosity, HBD/HBA molar ratio, organic

acids content, pH, type of cells or organisms, and synergistic effects.

Previous safety analysis is required before using DESs and NADESs for food and medicinal

applications. Since the characteristics largely depend on the

combinations of the components, a compendious database of toxicological properties of DESs should be set up which supports

the numerous component variations of the mixtures with computational predictive

approximations. In addition, most NADESs

combinations and applications are patented limiting the industrial applications.

7. New Methods for

Solid-Phase Extraction Using DESs and NADESs

The

direct utilization of DESs and NADESs using traditional extraction methods can collaborate

with ultrasound-assisted (UAE) and microwave-assisted extraction (MAE) to

achieve higher protein yield and purity. The application can be expected to

extensively break cell wall structure and ease the release of intracellular

protein from plant and animal matrices (Chemat et al., 2019). Correspondingly, DESs can also be developed

in MAE for the recovery of proteins and show greater performances than

conventional techniques (Bubalo et al., 2016). This pilot strategy possesses various

advantages mainly related to higher efficiency, shorter operation time, and

lower solvent requirement than conventional extraction methods using

petroleum-based solvents.

To enhance extraction performance, magnetic adsorbents can be incorporated into ATPS, which function to adsorb proteins for pure protein recovery (Liu et al., 2012). In magnetic solid-phase extraction (MSPE), nanoparticles are dispersed into extraction medium to adsorb proteins. The analytes are immediately segregated from the magnetic adsorbents with the aid of an external magnetic eld enabling nearly complete recovery of protein molecules and recycling of nano adsorbing particles (Table 3) (Wen et al., 2016). This innovative method eliminates some lengthy and laborious stages, namely centrifugation and filtration, that result in a shorter operating time, and exceptional protein recovery with preserved functional properties and offers an important function in purification procedures (Huang et al., 2015).

Table 3 Application of magnetic

particle-modified DESs for protein purification

|

Target Protein |

Magnetic particle |

DESs/ NADESs |

Extraction capacity (mg.g-1) |

References |

|

chymotrypsin |

Fe3O4@TiO2 |

[ChCl][Xyl](1: 1) |

347.8 |

(Li et al., 2021) |

|

R-phycoerythrin |

MB-NH2@CD |

[BeCh][Tri](1:

2) |

549.87 |

(Xu, Wang, and Hou, 2020) |

|

BSA |

Fe3O4-NH2@GO |

[ChCl] [glycerol] (1: 1) |

44.59 |

(Xu et al., 2015) |

|

BSA |

M-CNT@ |

N-[APTMAC][Xyl](1: 1) |

225.15 |

(Ni et al., 2020) |

|

BSA |

Fe@GO @Amino functional dicationic

ionic liquid |

|

89.7 |

(Wen et al., 2016) |

|

BSA |

Fe@GO |

|

6.7 |

In conclusion, DESs and NADESs were reported to

show higher extraction efficiency, improved bioactivity, better recyclability,

reusability and biodegradability potential, as well as less toxicity than conventional

organic solvents. The collaboration of solvents with green chemistry-based

industrial processes to reclaim valuable substances from plant and animal

sources reported more favourable results compared to the available conventional

solvent extraction processes. In addition, some important process parameters,

namely solid and solvent ratio, temperature, mixing, pH, and duration,

significantly affected the effectiveness of DESs during extraction processes.

From a scale-up and industrial application perspective, the use of DESs

required further research concerning thermal stability, analyte purification,

solvent recovery, operational cost, toxicity, and environmental impacts.

The authors acknowledge Universitas Diponegoro for its financial

assistance under the third-year term of World Class Research Universitas

Diponegoro (Kategori A) with contract No.: 118-17/UN7.6.1/PP/2021.

Abbott,

A.P., Boothby, D., Capper, G., Davies, D.L., Rasheed, R.K., 2004. Deep Eutectic

Solvents Formed between Choline Chloride and Carboxylic Acids: Versatile

Alternatives to Ionic Liquids. Journal of the American Chemical Society,

Volume 126(29), pp. 9142–9147

Abbott,

A.P., Capper, G., Davies, D.L., Rasheed, R.K., Tambyrajah, V., 2003. Novel

Solvent Properties of Choline Chloride/Urea Mixtures. Chemical

Communications, Volume 1, pp. 70–71

Abbott,

A.P., Capper, G., Gray, S., 2006. Design of Improved Deep Eutectic Solvents

Using Hole Theory. Chemphyschem: a European Journal of Chemical Physics and

Physical Chemistry, Volume 7(4), pp. 803–806

Albertsson,

P.-Å., 1970. Partition of Cell Particles and Macromolecules in Polymer

Two-Phase Systems. Advances in Protein Chemistry, Volume 24, pp. 309–341

Asenjo,

J.A., Andrews, B.A., 2011. Aqueous Two-Phase Systems for Protein Separation: A

Perspective. Journal of Chromatography A, Volume 1218(49), pp. 8826–8835

Benlebna,

M., Ruesgas-Ramón, M., Bonafos, B., Fouret, G., Casas, F., Coudray, C., Durand,

E., Cruz Figueroa-Espinoza, M., Feillet-Coudray, C., 2018. Toxicity of Natural

Deep Eutectic Solvent Betaine:Glycerol in Rats. Journal of Agricultural and

Food Chemistry, Volume 66(24), pp. 6205–6212

Bernau,

C.R., Knödler, M., Emonts, J., Jäpel, R.C., Buyel, J.F., 2022. The Use of

Predictive Models to Develop Chromatography-Based Purification Processes. Frontiers

in Bioengineering and Biotechnology, Volume 10, pp. 1–24

Bonacci,

S., Di Gioia, M.L., Costanzo, P., Maiuolo, L., Tallarico, S., Nardi, M., 2020.

Natural Deep Eutectic Solvent as Extraction Media for The Main Phenolic

Compounds from Olive Oil Processing Wastes. Antioxidants, Volume 9(6), p. 513

Bose,

U., Broadbent, J.A., Byrne, K., Hasan, S., Howitt, C.A., Colgrave, M.L., 2019.

Optimisation of Protein Extraction for In-Depth Profiling of The Cereal Grain

Proteome. Journal of Proteomics, Volume 197, pp. 23–33

Bowen,

H., Durrani, R., Delavault, A., Durand, E., Chenyu, J., Yiyang, L., Lili, S.,

Jian, S., Weiwei, H., Fei, G., 2022. Application of Deep Eutectic Solvents in

Protein Extraction and Purification. Frontiers in Chemistry, Volume 10,

pp. 1–10

Bubalo,

M.C., Curko, N., Tomaševic, M., Kovacevic-Ganic, K., Radojcic-Redovnikovic, I.,

2016. Green Extraction of Grape Skin Phenolics by Using Deep Eutectic Solvents.

Food Chemistry, Volume 200, pp. 159–166

Chemat, F., Abert-Vian, M., Ravi, H.K., Khadhraoui,

B., Hilali, S., Perino, S., Tixier, A.-S.F., 2019. Review of

Alternative Solvents for Green Extraction of Food and Natural Products: Panorama, Principles, Applications and

Prospects. Molecules (Basel, Switzerland), Volume 24(16), p. 3007

Chen,

J., Jiang, X., Yang, G., Bi, Y., Liu, W., 2018. Green and Efficient Extraction

of Resveratrol from Peanut Roots Using Deep Eutectic Solvents. Journal of

Chemistry, Volume 2018(1), p. 4091930

Chen,

Q., Chaihu, L., Yao, X., Cao, X., Bi, W., Lin, J., Chen, D.D.Y., 2021.

Molecular Property-Tailored Soy Protein Extraction Process Using a Deep

Eutectic Solvent. ACS Sustainable Chemistry & Engineering, Volume 9(30),

pp. 10083–10092

Chen,

R., Wang, X.-J., Zhang, Y.-Y., Xing, Y., Yang, L., Ni, H., Li, H.-H., 2019a.

Simultaneous Extraction and Separation of Oil, Proteins, And Glucosinolates

from Moringa Oleifera Seeds. Food Chemistry, Volume 300, p. 125162

Chen,

Y., Chen, W., Fu, L., Yang, Y., Wang, Y., Hu, X., Wang, F., Mu, T., 2019b.

Surface Tension of 50 Deep Eutectic Solvents: Effect of Hydrogen-Bonding

Donors, Hydrogen-Bonding Acceptors, Other Solvents, and Temperature. Industrial

& Engineering Chemistry Research, Volume 58(28), pp. 12741–12750

Choi,

Y. H., van Spronsen, J., Dai, Y., Verberne, M., Hollmann, F., Arends, I.W.C.E.,

Witkamp, G.J., Verpoorte, R., 2011. Are Natural Deep Eutectic Solvents the

Missing Link in Understanding Cellular Metabolism and Physiology? Plant

Physiology, Volume 156(4), pp. 1701–1705

Contreras,

M. del M., Lama-Muñoz, A., Manuel Gutiérrez-Pérez, J., Espínola, F., Moya, M., Castro,

E., 2019. Protein Extraction from Agri-Food Residues for Integration in

Biorefinery: Potential Techniques and Current Status. Bioresource

Technology, Volume 280, pp. 459–477

Dai,

Y., van Spronsen, J., Witkamp, G.-J., Verpoorte, R., Choi, Y.H., 2013a. Natural

Deep Eutectic Solvents as New Potential Media for Green Technology. Analytica

Chimica Acta, Volume 766, pp. 61–68

Dai,

Y., Witkamp, G.-J., Verpoorte, R., Choi, Y.H., 2013b. Natural Deep Eutectic

Solvents as a New Extraction Media for Phenolic Metabolites in Carthamus

Tinctorius L. Analytical Chemistry, Volume 85(13), pp. 6272–6278

Dai,

Y., Witkamp, G.-J., Verpoorte, R., Choi, Y.H., 2015. Tailoring Properties of

Natural Deep Eutectic Solvents with Water to Facilitate Their Applications. Food

Chemistry, Volume 187, pp. 14–19

de

Faria, E.L.P., do Carmo, R.S., Cláudio, A.F.M., Freire, C.S.R., Freire, M.G.,

Silvestre, A.J.D., 2017. Deep Eutectic Solvents as Efficient Media for the

Extraction and Recovery of Cynaropicrin

from Cynara Cardunculus L. Leaves. International Journal of Molecular

Sciences, Volume 18(11), p. 2276

De

Jesus, S.S., Filho, R.M., 2020. Recent Advances in Lipid Extraction Using Green

Solvents. Renewable and Sustainable Energy Reviews, Volume 133, p.

110289

Du,

M., Hou, Z., Liu, L., Xuan, Y., Chen, X., Fan, L., Li, Z., Xu, B., 2022.

Progress, Applications, Challenges and Prospects Of Protein Purification

Technology. Frontiers in Bioengineering and Biotechnology, Volume 10,

pp. 1–26

El-Kantar,

S., Rajha, H. N., Boussetta, N., Vorobiev, E., Maroun, R. G., Louka, N., 2019.

Green Extraction of Polyphenols from Grapefruit Peels Using High Voltage

Electrical Discharges, Deep Eutectic Solvents and Aqueous Glycerol. Food

Chemistry, Volume 295, pp. 165–171

Fuad,

F.M., Nadzir, M.M., Harun, A., 2021. Hydrophilic Natural Deep Eutectic Solvent:

A Review on Physicochemical Properties and Extractability of Bioactive

Compounds. Journal of Molecular Liquids, Volume 339, p. 116923

Gai,

Q., Qu, F., Zhang, T., Zhang, Y., 2011. Integration of Carboxyl Modified

Magnetic Particles and Aqueous Two-Phase Extraction for Selective Separation of

Proteins. Talanta, Volume 85(1), pp. 304–309

García, G., Aparicio, S., Ullah, R., Atilhan, M.,

2015. Deep Eutectic Solvents: Physicochemical Properties and

Gas Separation Applications. Energy & Fuels, Volume 29(4), pp.

2616–2644

Grudniewska,

A., de Melo, E.M., Chan, A., Gnilka, R., Boratynski, F., Matharu, A.S., 2018.

Enhanced Protein Extraction from Oilseed Cakes Using Glycerol–Choline Chloride

Deep Eutectic Solvents: A Biorefinery Approach. ACS Sustainable Chemistry

& Engineering, Volume 6(11), pp. 15791–15800

Gullón,

P., Gullón, B., Romaní, A., Rocchetti, G., Lorenzo, J.M., 2020. Smart Advanced

Solvents for Bioactive Compounds Recovery from Agri-Food By-Products: A Review.

Trends in Food Science & Technology, Volume 101, pp. 182–197

Hatti-Kaul,

R., 2000. Methods and Protocols: Methods and Protocols. Humana Press, pp. 1–10

Hernández-Corroto,

E., Plaza, M., Marina, M.L., García, M.C., 2020. Sustainable Extraction of

Proteins and Bioactive Substances from Pomegranate Peel (Punica Granatum L.)

Using Pressurized Liquids and Deep Eutectic Solvents. Innovative Food

Science & Emerging Technologies, Volume 60, p. 102314

Huang,

Y., Feng, F., Jiang, J., Qiao, Y., Wu, T., Voglmeir, J., Chen, Z.-G., 2017.

Green and Efficient Extraction of Rutin from Tartary Buckwheat Hull by Using

Natural Deep Eutectic Solvents. Food Chemistry, Volume 221, pp.

1400–1405

Huang,

Y., Wang, Y., Pan, Q., Wang, Y., Ding, X., Xu, K., Li, N., Wen, Q., 2015.

Magnetic Graphene Oxide Modified with Choline Chloride-Based Deep Eutectic

Solvent for The Solid-Phase Extraction of Protein. Analytica Chimica Acta,

Volume 877, pp. 90–99

Ijardar,

S.P., Singh, V., Gardas, R.L., 2022. Revisiting the Physicochemical Properties

and Applications of Deep Eutectic

Solvents. Molecules, Volume 27(4), p. 1368

Kudlak,

B., Owczarek, K., Namiesnik, J., 2015. Selected Issues Related to The Toxicity

of Ionic Liquids and Deep Eutectic Solvents--A Review. Environmental Science

and Pollution Research International, Volume 22(16), pp. 11975–11992

Kumar,

M., Potkule, J., Patil, S., Saxena, S., Patil, P.G., Mageshwaran, V., Punia,

S., Varghese, E., Mahapatra, A., Ashtaputre, N., Souza, C.D., Kennedy, J.F., 2021a.

Extraction of Ultra-Low Gossypol Protein from Cottonseed: Characterization

Based on Antioxidant Activity, Structural Morphology and Functional Group

Analysis. LWT, Volume 140, p. 110692

Kumar,

M., Tomar, M., Potkule, J., Verma, R., Punia, S., Mahapatra, A., Belwal, T.,

Dahuja, A., Joshi, S., Berwal, M.K., Satankar, V., Bhoite, A.G., Amarowicz, R.,

Kaur, C., Kennedy, J.F., 2021b. Advances in The Plant Protein Extraction:

Mechanism and Recommendations. Food Hydrocolloids, Volume 115, p. 106595

Kumoro, A.C., Hasan, M., Singh, H., 2019. Extraction

of Andrographolide from Andrographis paniculata Dried Leaves Using

Supercritical CO2 and Ethanol Mixture. Industrial & Engineering

Chemistry Research, Volume 58(2), pp. 742–751

Kumoro,

A.C., Wardhani, D.H., Kusworo, T.D., Djaeni, M., Ping, T.C., Azis, Y.M.R.F.,

2022. Fish Protein Concentrate for Human Consumption: A Review of Its

Preparation By Solvent Extraction Methods And Potential For Food Applications. Annals

of Agricultural Sciences, Volume 67(1), pp. 42–59

Landa-Castro,

M., Sebastián, P., Giannotti, M.I., Serrà, A., Gómez, E., 2020.

Electrodeposition of Nanostructured Cobalt Films From a Deep Eutectic Solvent:

Influence Of The Substrate And Deposition Potential Range. Electrochimica

Acta, Volume 359, p. 136928

Li,

H., Wang, Y., He, X., Chen, J., Xu, F., Liu, Z., Zhou, Y., 2021. A Green Deep

Eutectic Solvent Modified Magnetic Titanium Dioxide Nanoparticles for The

Solid-Phase Extraction of Chymotrypsin. Talanta, Volume 230, p. 122341

Li,

N., Wang, Y., Xu, K., Huang, Y., Wen, Q., Ding, X., 2016. Development of Green

Betaine-Based Deep Eutectic Solvent Aqueous Two-Phase System for The Extraction

of Protein. Talanta, Volume 152, pp. 23–32

Lin,

Z., Jiao, G., Zhang, J., Celli, G.B., Brooks, M.S.-L., 2021. Optimization of

Protein Extraction From Bamboo Shoots and Processing Wastes Using Deep Eutectic

Solvents in A Biorefinery Approach. Biomass Conversion and Biorefinery,

Volume 11(6), pp. 2763–2774

Ling,

J.K., Hadinoto, K., 2022. Deep Eutectic Solvent as Green Solvent in Extraction

of Biological Macromolecules: A Review. International Journal of Molecular

Sciences, Volume 23(6). p. 3381

Ling,

J.K.U., Chan, Y.S., Nandong, J., Chin, S.F., Ho, B.K., 2020. Formulation of

Choline Chloride/Ascorbic Acid Natural Deep Eutectic Solvent: Characterization,

Solubilization Capacity and Antioxidant Property. LWT, Volume 133, p.

110096

Liu,

Q., Shi, J., Cheng, M., Li, G., Cao, D., Jiang, G., 2012. Preparation of

Graphene-Encapsulated Magnetic Microspheres for Protein/Peptide Enrichment and

MALDI-TOF MS analysis. Chemical Communications, Volume 48(13), pp.

1874–1876

Liu,

R.-L., Yu, P., Ge, X.-L., Bai, X.-F., Li, X.-Q., Fu, Q., 2017. Establishment of

an Aqueous PEG 200-Based Deep Eutectic Solvent Extraction and Enrichment Method

for Pumpkin (Cucurbita moschata) Seed Protein. Food Analytical Methods,

Volume 10(6), pp. 1669–1680

Lores,

H., Romero, V., Costas, I., Bendicho, C., Lavilla, I., 2017. Natural Deep

Eutectic Solvents in Combination with Ultrasonic Energy As A Green Approach for

Solubilisation of Proteins: Application To Gluten Determination By Immunoassay.

Talanta, Volume 162, pp. 453–459

Malva,

A. Della, Albenzio, M., Santillo, A., Russo, D., Figliola, L., Caroprese, M.,

Marino, R., Díaz-Cruz, J.M., 2018. Methods for Extraction of Muscle Proteins

from Meat and Fish Using Denaturing and Nondenaturing Solutions. Journal of

Food Quality, Volume 2018, p. 8478471

Mendes,

M.S.M., Rosa, M.E., Ramalho, F., Freire, M.G., e Silva, F.A., 2023. Aqueous

Two-Phase Systems as Multipurpose Tools to Improve Biomarker Analysis. Separation

and Purification Technology, Volume 317, p. 123875

Meng,

J., Wang, Y., Zhou, Y., Chen, J., Wei, X., Ni, R., Liu, Z., Xu, F., 2019.

Development of Different Deep Eutectic Solvent Aqueous Biphasic Systems for The

Separation Of Proteins. RSC Advances, Volume 9(25), pp. 14116–14125

Mišan,

A., Nadpal, J., Stupar, A., Pojic, M., Mandic, A., Verpoorte, R., Choi, Y.H.,

2020. The Perspectives of Natural Deep Eutectic Solvents in Agri-Food Sector.

Critical Reviews in Food Science and Nutrition, Volume 60(15), pp.

2564–2592

Morais,

E.S., Lopes, A.M.D.C., Freire, M.G., Freire, C.S., Coutinho, J.A., Silvestre,

A.J., 2020. Use of Ionic Liquids and Deep Eutectic Solvents In Polysaccharides

Dissolution And Extraction Processes Towards Sustainable Biomass Valorization. Molecules,

Volume 25(16), p. 3652

Morgenstern,

J., Baumann, P., Brunner, C., Hubbuch, J., 2017. Effect of PEG Molecular Weight

and PEGylation Degree on the Physical Stability of PEGylated Lysozyme. International

Journal of Pharmaceutics, Volume 519(1–2), pp. 408–417

Mulia, K., Adam, D., Zahrina, I., Krisanti, E.A.,

2018. Green Extraction of Palmitic Acid from Palm Oil using Betaine-based

Natural Deep Eutectic Solvents. International Journal of Technology.

Volume 9(2), pp. 335–-344

Mulia, K., Krisanti, E., Terahadi, F., Putri, S.,

2015. Selected Natural Deep Eutectic Solvents for the

Extraction of mangostin from Mangosteen (Garcinia mangostana L.) Pericarp. International

Journal of Technology, Volume 7(1), pp. 22–30

Ni,

R., Wang, Y., Wei, X., Chen, J., Meng, J., Xu, F., Liu, Z., Zhou, Y., 2020.

Magnetic Carbon Nanotube Modified with Polymeric Deep Eutectic Solvent for The

Solid Phase Extraction of Bovine Serum Albumin. Talanta, Volume 206, p. 120215

Okoro, O. V., Jafari, H., Hobbi, P., Nie, L., Alimoradi,

H., Shavandi, A., 2022. Enhanced keratin Extraction from

Wool Waste Using A Deep Eutectic Solvent. Chemical Papers, Volume 76(5),

pp. 2637–2648

Omar,

K.A., Sadeghi, R., 2022a. Novel Lacmoid-Based Deep Eutectic Solvent Dye as

Writing Ink. Chemical Engineering Research and Design, Volume 180, pp.

50–54

Omar,

K.A., Sadeghi, R., 2022b. Physicochemical Properties of Deep Eutectic Solvents:

A Review. Journal of Molecular Liquids, Volume 360, p. 119524

Panic,

M., Andlar, M., Tišma, M., Rezic, T., Šibalic, D., Cvjetko Bubalo, M., Radojcic Redovnikovic, I., 2021. Natural Deep Eutectic Solvent as A Unique Solvent for

Valorisation of Orange Peel Waste by The Integrated Biorefinery Approach. Waste

Management, Volume 120, pp. 340–350

Pratiwi,

F.A., Utami, T.S., Arbianti, R., 2020. Using Ultrasonic Assisted Extraction to

Produce a Bioinsecticide from Cigarette Butt Waste and Green Solvent to Control

Armyworm Infestation. International Journal of Technology, Volume 11(7),

pp. 1329–1336

Qiaoyun,

C., Xinghong, N., Liang, Z., Zheng, T., Jin, L., Kang, S., Xuan, C., Xinghui,

L., 2017. Optimization of Protein Extraction and Decoloration Conditions for

Tea Residues. Horticultural Plant Journal, Volume 3(4), pp. 172–176

Rodrigues,

L.A., Leonardo, I.C., Gaspar, F.B., Roseiro, L.C., Duarte, A.R.C., Matias,

A.A., Paiva, A., 2021. Unveiling the Potential Of Betaine/Polyol-Based Deep

Eutectic Systems For The Recovery of Bioactive Protein Derivative-Rich Extracts

From Sardine Processing Residues. Separation and Purification Technology,

Volume 276, p. 119267

Saini,

A., Kumar, A., Panesar, P.S., Thakur, A., 2022. Potential of Deep Eutectic

Solvents in The Extraction of Value-Added Compounds from Agro-Industrial

By-Products.

Applied Food Research, Volume 2(2), p. 100211

Saravanan, S., Rao, J.R., Nair, B.U., Ramasami, T., 2008.

Aqueous Two-Phase Poly(Ethylene Glycol)–Poly(Acrylic

Acid) System For Protein Partitioning: Influence of Molecular Weight, pH and

Temperature. Process Biochemistry, Volume 43(9), pp. 905–911

Sindhu,

R., Binod, P., Janu, K.U., Sukumaran, R.K., Pandey, A., 2012. Organosolvent

Pretreatment and Enzymatic Hydrolysis of Rice Straw for The Production of

Bioethanol. World Journal of Microbiology & Biotechnology, Volume

28(2), pp. 473–483

Singh,

S., Tavana, H., 2018. Collagen Partition in Polymeric Aqueous Two-Phase Systems

for Tissue Engineering. Frontiers in Chemistry, Volume 6, pp. 4–10

Smith,

E.L., Abbott, A.P., Ryder, K.S., 2014. Deep Eutectic Solvents (DESs) and Their Applications.

Chemical Reviews, Volume 114(21), pp. 11060–11082

Socas-Rodríguez,

B., Torres-Cornejo, M.V., Álvarez-Rivera, G., Mendiola, J.A., 2021. Deep

Eutectic Solvents for The Extraction of Bioactive Compounds from Natural

Sources and Agricultural By-Products. Applied Sciences, Volume 11(11),

p. 4897

Tolmachev,

D., Lukasheva, N., Ramazanov, R., Nazarychev, V., Borzdun, N., Volgin, I.,

Andreeva, M., Glova, A., Melnikova, S., Dobrovskiy, A., Silber, S. A., Larin,

S., de Souza, R. M., Ribeiro, M. C., Lyulin, S., Karttunen, M., 2022. Computer

Simulations of Deep Eutectic Solvents: Challenges, Solutions, and Perspectives.

International Journal of Molecular Sciences, Volume 23(2), p. 645

Wang,

W., Liu, X., Lu, X., 2013. Engineering Cyanobacteria to Improve Photosynthetic

Production of Alka(E)Nes. Biotechnology for Biofuels, Volume 6(1), p. 69

Wen,

Q., Wang, Y., Xu, K., Li, N., Zhang, H., Yang, Q., Zhou, Y., 2016. Magnetic

Solid-Phase Extraction of Protein by Ionic Liquid-Coated Fe@Graphene Oxide. Talanta,

Volume 160, pp. 481–488

Xu,

K., Wang, Y., Huang, Y., Li, N., Wen, Q., 2015. A Green Deep Eutectic

Solvent-Based Aqueous Two-Phase System for Protein Extracting. Analytica

Chimica Acta, Volume 864, pp. 9–20

Xu,

M., Ran, L., Chen, N., Fan, X., Ren, D., Yi, L., 2019a. Polarity-Dependent

Extraction of Flavonoids from Citrus Peel Waste Using A Tailor-Made Deep

Eutectic Solvent. Food Chemistry, Volume 297, p. 124970

Xu,

P., Wang, Y., Chen, J., Wei, X., Xu, W., Ni, R., Meng, J., Zhou, Y., 2019b.

Development of Deep Eutectic Solvent-Based Aqueous Biphasic System for The

Extraction of Lysozyme. Talanta, Volume 202, pp. 1–10

Xu,

P., Zheng, G.-W., Du, P.-X., Zong, M.-H., Lou, W.-Y., 2016. Whole-Cell

Biocatalytic Processes with Ionic Liquids. ACS Sustainable Chemistry &

Engineering, Volume 4(2), pp. 371–386

Xu,

Y., Wang, Q., Hou, Y., 2020. Efficient Purification of R-phycoerythrin from

Marine Algae (Porphyra yezoensis) Based

on a Deep Eutectic Solvents Aqueous Two-Phase System. Marine Drugs,

Volume 18(12), p. 618

Yue,

J., Zhu, Z., Yi, J., Lan, Y., Chen, B., Rao, J., 2021. Structure and

Functionality of Oat Protein Extracted by Choline Chloride-Dihydric Alcohol

Deep Eutectic Solvent and Its Water Binary Mixtures. Food Hydrocolloids,

Volume 112, p. 106330

Zannou,

O., Koca, I., 2022. Greener Extraction of Anthocyanins and Antioxidant Activity

from Blackberry (Rubus spp) Using Natural Deep Eutectic Solvents. LWT, Volume

158, p. 113184

Zeng,

C.-X., Xin, R.-P., Qi, S.-J., Yang, B., Wang, Y.-H., 2016. Aqueous Two-Phase

System Based on Natural Quaternary Ammonium Compounds for The Extraction of

Proteins. Journal of Separation Science, Volume 39(4), pp. 648–654

Zhang,

Q., De Oliveira Vigier, K., Royer, S., Jérôme, F., 2012. Deep Eutectic

Solvents: Syntheses, Properties and Applications. Chemical Society Reviews,

Volume 41(21), pp. 7108–7146

Zhou,

M., Fakayode, O.A., Li, H., 2023. Green Extraction of Polyphenols via Deep

Eutectic Solvents and Assisted Technologies from Agri-Food By-Products. Molecules,

Volume 28(19), p. 6852