Managing Circularity in Industrial Ecosystems: Introducing the Concept of Circular Maturity and its Application in NLMK Group

Corresponding email: 9056591561@mail.ru

Published at : 29 Dec 2023

Volume : IJtech

Vol 14, No 8 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i8.6836

Babkin, A., Shkarupeta, E., Malevskaia-Malevich, E., Pogrebinskaya, E., Batukova, L., 2023. Managing Circularity in Industrial Ecosystems: Introducing the Concept of Circular Maturity and its Application in NLMK Group. International Journal of Technology. Volume 14(8), pp. 1769-1778

| Aleksandr Babkin | Peter the Great St. Petersburg Polytechnic University, Polytechnicheskaia Str., 29, Saint Petersburg, 195251, Russia |

| Elena Shkarupeta | 1. Peter the Great St. Petersburg Polytechnic University, Polytechnicheskaia Str., 29, Saint Petersburg, 195251, Russia, 2. Voronezh State Technical University, 20-letiia Oktiabria Str., 84, Voronezh |

| Ekaterina Malevskaia-Malevich | Peter the Great St. Petersburg Polytechnic University, Polytechnicheskaia Str., 29, Saint Petersburg, 195251, Russia |

| Ekaterina Pogrebinskaya | 1. Financial University Under the Government of the Russian Federation, Leningradsky ave., 49, Moscow, 125167, Russia, 2. Sechenov University, Trubetskaya str, 8, Building 2, Moscow, 119991, Russia |

| Louise Batukova | Siberian Federal University, Svobodny ave., 79, Krasnoyarsk, 660041, Russia |

The primary objective of this research endeavor is

the conceptualization and operationalization of the 'Circular Maturity'

construct within the context of industrial ecosystems. A comprehensive

evaluative framework is developed, designed to assess circularity in alignment

with thresholds that are environmentally, socially, and economically

acceptable, commonly encapsulated as ESG results. This framework incorporates a

multifaceted system for the governance of circularity, integrating diverse

measures, functions, principles, strategies, business models, and circular

solutions across various stages of the value chain. Utilization of information,

finances, resources, human capital, platforms, and collaborative mechanisms is

envisaged to mitigate external risks and challenges. Key driver projections,

namely circular potential, circular activity, and

circular efficiency are formulated for the governance of circularity and the

enhancement of circular maturity at the corporate level. The applicability and

efficacy of the proposed framework are validated through a case study involving

the industrial ecosystem of Novolipetsk Metallurgical Combinate (NLMK) in

Russia.

Circular maturity; Circularity; Industrial ecosystem; NLMK

As Earth's biocapacity approaches its limits, and with climate policies and regulations on carbon emissions tightening globally (Berawi, 2020), coupled with the volatility in prices and demand for fossil resources, it becomes crucial to transition from a linear to a circular model of production and consumption in industrial ecosystems (Khaykin and Babkin, 2022). Numerous studies have considered circularity in industrial ecosystems at different levels (Krmela, Simberová, and Babica, 2022; Ilyina, 2022; Kulibanova et al., 2022; Shkarupeta and Ilyina, 2022), proposing approaches to assessing circularity (Khan et al., 2023; Kuzior, Arefiev, and Poberezhna, 2023; The Circularity Gap Report, 2022; Vinante et al., 2021; Bogdanovich-Irina, Kistaeva-Natalia, and Egorova-Svetlana, 2020; Mayer et al., 2019; Haas et al., 2015) and circular maturity (Uztürk and Büyüközkan, 2022), as well as analyzing mechanisms of transition from linear economy to closed-loop economy (Pichlak and Szromek, 2022; Doszhan et al., 2022; Gileva and Shkarupeta, 2022; Surovitskaya, 2021; Umarova, 2021; Liu and Stephens, 2019).

On the other hand, however, no comprehensive studies

have been carried out on circularity management in industrial ecosystems aimed

at improving their circular maturity at the corporate level. For this reason,

the given problem requires careful, further thorough exploration.

Managing circularity in industrial ecosystems is

understood as an array of measures ensuring positive dynamics of circular

maturity in industrial ecosystems, accounting for the risks and challenges of

the external environment based on specific functions, principles, strategies,

business models, circular solutions, and technologies introduced at different

stages of the value chain using information, finances, resources, human

capital, platforms, and collaborative mechanisms to achieve a high circularity index,

a complex of long-term ESG effects, ultimately creating a mature circular

ecosystem. We thoroughly explored the concept of industrial ecosystems based on

sustainable business models incorporating eco-innovation and circularity in the

context of the transition to Industry 5.0 in our earlier papers (Babkin, and Shkarupeta, 2022; Babkin et al., 2022;

Babkin et al., 2021).

Circular maturity serves as a metric to quantify the

level of circular development within an industrial ecosystem. It is defined as

an aggregate indicator that characterizes the degree of circularity in the

ecosystem, taking into account the adoption of circular principles, factors,

strategies, and circular business models. Key drivers projected to influence

circular maturity in an industrial ecosystem include circular potential,

circular activity, and circular efficiency.

In general, the existing techniques for assessing

circularity allow classifying metrics related to the generally accepted

principles, such as resource consumption and recovery (Zaytsev

et al., 2021), circular product design, and waste generation.

Sufficient metrics are yet to be devised for certain areas (for example,

employee training, economic indicators, etc.). In addition, existing studies

assessing the circular maturity of industrial ecosystems at the corporate level

have certain limitations. This primarily concerns the system of indicators for

assessing the circular maturity of ecosystems. Integral indicators describe

recycling and symbiosis within the ecosystem from different perspectives but do

not consider the dynamics of circularity in industrial ecosystems (Umarova, 2021). As a result, different estimates

may be obtained for the circular maturity of industrial ecosystems.

Furthermore, the framework for assessing the circularity of an industrial

ecosystem should be equipped with a predictive function determining the

circularity relative to the environmentally, socially, and economically

acceptable thresholds (ESG results), answering four key questions:

• What is the

general level of circular maturity in industrial ecosystems?

• How does the

circular maturity vary over time in an industrial ecosystem?

• Which factors

make the smallest and the greatest contribution to the final index of circular maturity in the industrial ecosystem?

• What are the

challenges facing sustainable ESG practices in industrial ecosystems, and what methods are available for resolving them?

The research

methodology is based on existing theoretical approaches to developing

industrial ecosystems, the nature and the evolution of the circular economy and

the areas under its umbrella, integration of modern literature and cooperation

with experts, a framework for developing industrial ecosystems, techniques, and

procedures for assessing circular maturity at the national, sectoral and

corporate levels. The study fundamentally relies on the dialectical approach,

also using the systemic, complex, interdisciplinary, cross-industry, project,

value, holistic approaches, analysis based on the tools available from the WEF

Strategic Intelligence Platform, content analysis, comparative analysis, method

of taxonomic components, method of strategic maps, integral method, linear

normalization, computational data analysis, desk research, analysis of

published research, qualitative and quantitative data analysis, data-driven

management by exception, ranking, triangulation of aggregated data with other

established sources, benchmarking, etc.

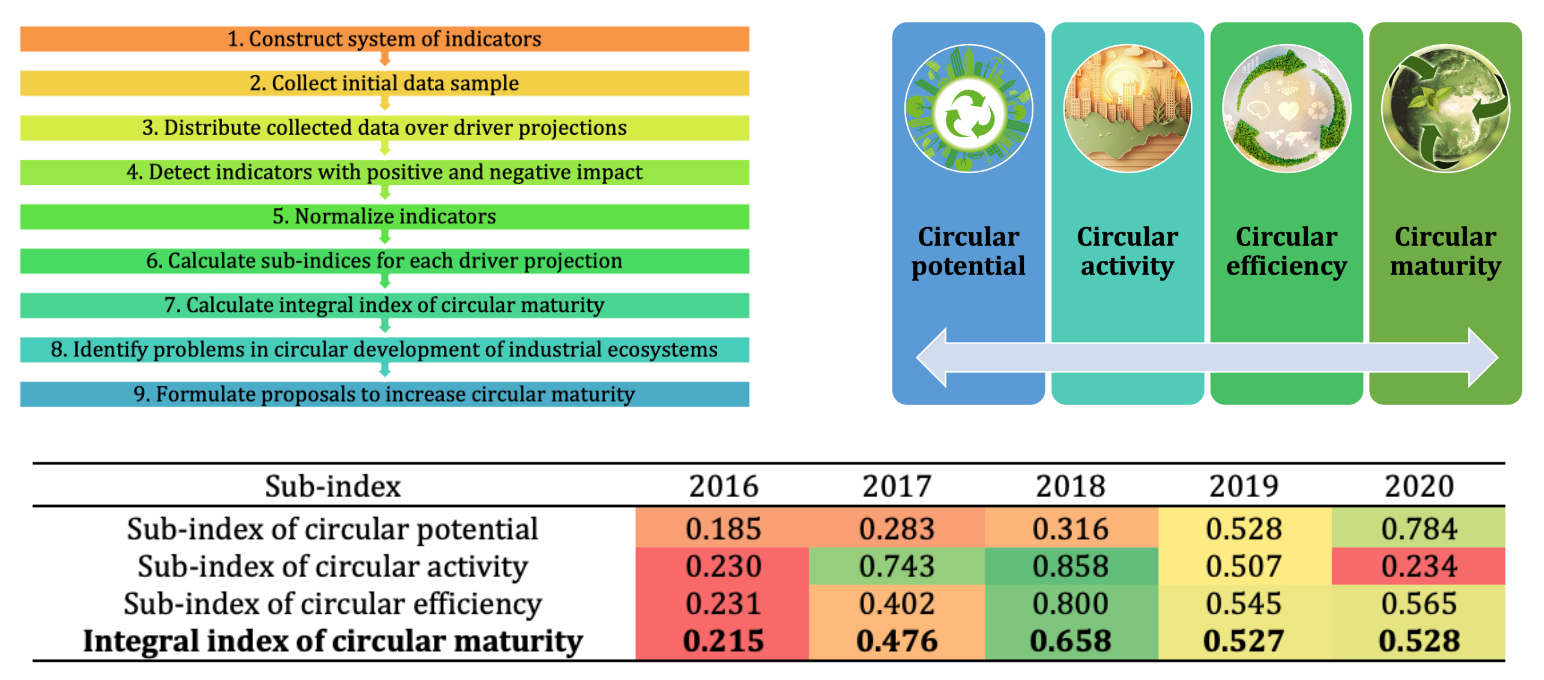

The framework we have developed

for assessing the circular maturity of an industrial ecosystem at the corporate

level includes several stages shown in Figure 1.

Figure 1 Framework for assessing the circular maturity of

the industrial ecosystem at the corporate level

Stage 1. Constructing a system of

indicators.

The proposed system of indicators for

assessing the circular maturity of the industrial ecosystem at the corporate

level (Table 1) includes 13 indicators distributed over three driver

projections: circular potential, circular activity, and circular efficiency.

Table 1 System of Indicators for assessing the circular maturity of the industrial

ecosystem at the corporate level

|

Driver projection |

Indicator |

Notation |

Unit |

|

1 Circular potential |

1.1 Total investments |

X1 |

million USD |

|

1.2 Investment projects in

environmental protection |

X2 |

million USD | |

|

1.3 Cost of employee training |

X3 |

million USD | |

|

1.4 Number of training

conducted: employee training |

X4 |

thousand sessions | |

|

2 Circular activity |

2.1 Current environmental

protection costs |

X5 |

million USD |

|

2.2 Labor productivity |

X6 |

tons of steel per capita | |

|

2.3 Number of suppliers with

measures to improve environmental compliance |

X7 |

% | |

|

2.4 Environmental audits for

suppliers of raw materials and equipment |

X8 |

units | |

|

3 Circular efficiency |

3.1 Lost time injury frequency

rate |

X9 |

coefficient |

|

3.2 Share of recycled water in

total water consumption |

X10 |

% | |

|

3.3 Specific atmospheric

emissions |

X11 |

kg/ton of steel | |

|

3.4 Recycling of secondary raw

materials |

X12 |

% | |

|

3.5 Specific energy intensity |

X13 |

Gcal/ton |

Source:

developed by the authors on the basis of (The Circularity Gap Report, 2022)

The approach based on identifying

three driver projections allows us to balance low scores with respect to one

projection with high scores with respect to another projection. The three

projections compensate for a relatively large number of indicators and improve

the analytic capabilities of the technique developed.

where is the sub-index of circularity for each of

the three estimated projections;

n is the number of indicators;

is the

value of the ith indicator in the tth industrial ecosystem;

is the minimum value of the ith indicator;

is the maximum value of the ith indicator.

Stage 7. Calculating the integral index

of circular maturity.

All projections also have equal weight

for estimating the integral index of circular maturity of industrial ecosystems

(2):

where is the integral index of circularity in industrial ecosystems;

N is the total number of estimated

indicators;

The proposed framework

for assessing the circular maturity of the industrial ecosystem at the

corporate level was validated using the data for the industrial ecosystem of

the NLMK Group for 2016–2020. The NLMK group was chosen for study for several

reasons. As one of the largest international producers of steel, NLMK Group is

aware of its responsibility to society, nature, and future generations. The

sustainable development of the NLMK Group is regulated by a range of internal

documents. The NLMK production facilities are part of a closed-loop economy:

100% of the products can be involved in recycling and reprocessing, and 35% of

the NLMK steel is produced with ferrous scrap. Closed-loop water supply is

organized at fourteen NLMK enterprises. The goal of the 2022 Strategy is to

maintain the share of recycled water supply in terms of production growth at

the level of at least 96% (NLMK, 2022).

The

data for calculating the circular maturity of the industrial ecosystem of the

NLMK Group are given in Table 2. The source of initial data for calculating the

circular maturity was the environmental, social, governance (ESG) databook.

Table 2 Data for calculating the circular maturity

of the industrial ecosystem of the NLMK Group

|

Indicator |

2016 |

2017 |

2018 |

2019 |

2020 |

|

X1 |

558.60 |

592.00 |

680.00 |

1,080.00 |

1,124.00 |

|

X2 |

54.00 |

33.00 |

80.00 |

78.00 |

82.00 |

|

X3 |

3.36 |

4.50 |

4.81 |

5.47 |

19.17 |

|

X4 |

53.40 |

55.40 |

52.50 |

52.90 |

52.90 |

|

X5 |

73.00 |

90.00 |

95.00 |

124.00 |

101.00 |

|

X6 |

482.05 |

501.96 |

503.33 |

448.49 |

461.00 |

|

X7 |

30.00 |

69.00 |

80.00 |

41.00 |

38.00 |

|

X8 |

21.00 |

36.00 |

39.00 |

34.00 |

13.00 |

|

X9 |

0.85 |

1.12 |

0.77 |

0.86 |

1.25 |

|

X10 |

96.30 |

96.40 |

96.50 |

96.60 |

96.60 |

|

X11 |

19.97 |

19.55 |

18.95 |

20.19 |

19.80 |

|

X12 |

90.00 |

91.00 |

93.00 |

99.00 |

99.00 |

|

X13 |

5.60 |

5.49 |

5.47 |

5.64 |

5.55 |

Source: compiled by the authors on the basis

of (NLMK, 2021)

We

computed the arithmetic mean, considering both the positive and negative

influence of the variables, and obtained the following values for the

circularity sub-indices and the integral circularity index of the NLMK Group's

industrial ecosystem (Table 3).

Table 3 Sub-indices of circular maturity and the

integral circularity index in the industrial ecosystem of the NLMK Group

|

Sub-index |

2016 |

2017 |

2018 |

2019 |

2020 |

|

Sub-index of circular potential |

0.185 |

0.283 |

0.316 |

0.528 |

0.784 |

|

Sub-index of circular activity |

0.230 |

0.743 |

0.858 |

0.507 |

0.234 |

|

Sub-index of circular efficiency |

0.231 |

0.402 |

0.800 |

0.545 |

0.565 |

|

Integral index of circular maturity |

0.215 |

0.476 |

0.658 |

0.527 |

0.528 |

The sub-index of circular activity exhibits the greatest

volatility, with the maximum reached in 2018 (0.858) and the minimum in 2016

(0.23). The maximum level of circular activity was observed for the NLMK Group

in 2017 and 2018. The main factor in the negative trend of the declining

sub-index of circular activity was a sharp reduction in the number of

environmental audits conducted for suppliers of raw materials, materials, and

equipment: from 39 in 2018 and 34 in 2019 to 13 in 2020. The sub-index of

circular efficiency also decreased from 0.8 in 2018 to 0.565 in 2020. In this

case, the factors were an increase in lost time injury frequency rate (LTIFR)

from 0.77 in 2018 to 1.25 in 2020, an increase in atmospheric emissions from 18.95

kg/ton of steel in 2018 to 20.19 kg/t of steel in 2019 and 19.8 kg/t of steel

in 2020, increase in energy intensity from 5.47 Gcal/ton in 2018 to 5.64

Gcal/ton in 2019 and 5.55 Gcal/ton in 2020.

The sub-index of circular potential exhibited consistent

positive dynamics during 2016–2020. This is explained by the growth in

investments, both total, for environmental protection and for employee

training. The circular maturity of the NLMK Group's industrial ecosystem

exhibited growth from 2016 to 2018. The maximum circularity index of NLMK

Group's industrial ecosystem was observed in 2018, subsequently decreasing in

2019. The level of circular maturity was maintained at the same level in 2020.

The following factors accelerate circularity in the NLMK

Group's industrial ecosystem: increasing investments, investment projects in

environmental protection, costs of employee training, current environmental

protection costs, the share of recycled water in total water consumption, and

recycling of secondary raw materials. The following factors hinder the circular

development of the NLMK Group: reduction in the number of employees, number of

training conducted, labor productivity, number of suppliers with measures to

improve environmental compliance, environmental audits of suppliers, increase

in LTIFR, and energy intensity of products. A decrease in the circular maturity

of the NLMK Group's industrial ecosystem was observed in 2019 and 2020 due to

external challenges, such as export duties on metal products, volatility of raw

materials markets, and unscheduled repairs at the Lipetsk site aimed at

debottlenecking to increase the production capacity. The ongoing COVID-19

pandemic, disrupting the supply chains, including investment projects, has

required additional resilience from the NLMK Group.

An effective system for managing circularity in industrial ecosystems is essential to address the negative trends and issues mentioned above and to accelerate circularity (Figure 2).

Figure 2 System for

managing circular development in industrial ecosystems

Support subsystems for managing circularity in industrial

ecosystems include information, financial, natural resources, human capital,

and stakeholders. A favorable environment promoting growth is also an important

part of the support subsystem for managing circularity in industrial

ecosystems.

The environmental subsystem includes an increased load on the

Earth's biocapacity, depletion of natural resources, and a considerable

ecological footprint. Other major factors affecting circularity in industrial

ecosystems include economic sanctions, altering the supply chains, and

hindering access to technologies, but also stimulating import substitution and

innovations to replace imported goods in industrial sectors and post-pandemic

recovery of industrial ecosystems. The observed reduction in greenhouse gas

emissions due to the COVID-19 pandemic is projected to have only a moderate

impact on long-term emission trends. Nevertheless, there is a concurrent trend

of tightening climate policies and regulations, particularly regarding carbon

emissions.

The target subsystem for managing circularity in industrial

ecosystems is intended to provide an environmentally safe and socially

equitable space, growth of social welfare, minimize waste and losses, replenish

resources based on more environmentally friendly supply chains, create a mature

circular ecosystem, etc. The circular ecosystem is understood in this study as

a network of organizations cooperating and interacting to promote a favorable

environment for collective transformations enabling entire value chains (or

individual industries or regions) to adopt circular practices.

Management subsystem (entities managing circularity in

industrial ecosystems) includes the actors of the circular ecosystem, as well

as the management of industrial ecosystems, industrial and eco-industrial

parks, clusters, etc. The Managed subsystem (i.e., the object controlled to improve

circularity in the industrial ecosystem) is the circularity evolution in

industrial ecosystems. The levels at which circularity is managed in industrial

ecosystems include the macro level (global, all sectors and industries),

meso-level (national/state, sector, industry), micro-level (company level

including corporations, multinational companies with multiple branches around

the world, integrated structures, production facilities/divisions and assembly

lines for products/processes).

Classical functions have been chosen for the system managing

circularity in industrial ecosystems, including goal setting, planning,

organization, motivation, coordination, regulation, monitoring and evaluation,

and control. The principles for managing circularity in industrial ecosystems

include: the elimination of waste and pollution, circulation of products and

materials at their highest cost, environmental restoration, resource and impact

decoupling, improving efficiency. The stages of managing circularity in

industrial ecosystems include: design, sourcing, production, logistics, markets

and sales, consumption, recycling of disposed products, reverse logistics.

Strategies for managing circularity in industrial ecosystems include:

recycling, efficient resource use, integration of renewable energy sources,

restoration, reconstruction and recycling of products and components, prolonging

the product life, product as service, sharing models, modifying the consumer

behavior.

The circular business models in the management system include

the holistic circular business model canvas, the ReSOLVE framework, the

ENVISAGE model, the GRID business model, hybrid types of circular business

models, industrial symbiosis, as well as five business models with respect to

the value chain (circular supplies, product life extension, reusing waste,

sharing platforms, product as a service). The following circular solutions can

be used for managing circularity in industrial ecosystems (The Circularity Gap Report, 2022): efficient

design and use of information and communication technologies (ICTs) and digital

technologies, circular healthcare system, durable consumer products, effective

design and use of consumer products, circular consumables, chemical-free

practices, reduction of transportation and travel, vehicle design improvement,

resource-efficient technologies, natural solutions for production, reduction of

excess consumption, circular raw materials, infrastructure, vehicles,

durability of machinery, equipment, vehicles, design improvements of vehicles.

Three large groups of technologies can be used to accelerate circularity in

industrial ecosystems: digital, physical, and biological technologies.

The system for managing circularity in industrial ecosystems

must take into account the risks, including the tightening of climate policies

in the world, carbon emission regulations, high costs of circular solutions

(short-term losses for long-term benefits), decrease in fossil resource

exports, volatile prices for fossil resources, etc.

It seems reasonable to establish a digital platform for

accelerating the circular economy in the Russian Federation as part of the

platform subsystem for managing circularity in industrial ecosystems. Such a

platform has already been created at the global level. Since 2018, the Platform

for Accelerating the Circular Economy (PACE) has become a global collaboration

platform for key public and private decision-makers to share vision best

practices and scale the circular economy together. Nearly 100 leaders from

governments, companies and civil society across continents and sectors have

joined the PACE Leadership Group to help accelerate the transition to a

circular economy globally. Collaborative subsystem for managing circularity in

industrial ecosystems allows for the creation and development of formal and

informal communities based on the quintuple helix innovation model (academia +

industry + government + society + environment). The resulting subsystem is

intended for achieving the goals of managing circularity in industrial

ecosystems, i.e., reaching a high level of the circularity index, as well as

establishing a mature circular ecosystem. Effects of managing circularity along

the value chain include direct ESG effects (economic, social, environmental),

spillovers at the macro level, as well as the processing of critical raw

materials, use of biological resources in the industrial sector, product life

extension, and overproduction at the meso- and micro-levels.

The findings of this study align with and extend the existing

body of research on circularity in industrial ecosystems. For instance, the

emphasis on the role of environmental audits resonates with studies that

highlight the importance of supplier engagement in achieving circularity.

However, unlike some studies that report a stable or increasing trend in

circular activities, this research identifies fluctuations in circular maturity

levels attributed to both internal and external factors. The decline in circular

activity and efficiency sub-indices corroborates findings from other studies

that point to the challenges posed by external economic and environmental

factors.

The

study's primary contribution resides in its novel system for managing

circularity in industrial ecosystems, distinguishing it from existing

mechanisms in the industrial economy. This system's potential for generating

synergistic effects is considerable, provided that orchestrated measures are

systematically and coherently implemented across national, sectoral, and

corporate levels. However, the framework is not without limitations. Its

complexity and sensitivity to normalization methods render the estimates

volatile. To enhance the framework's robustness, it is advisable to expand the

sample size and extend the study to other industrial ecosystems beyond the NLMK

Group. While the study focuses on the NLMK Group in Russia, the framework and

findings have broader implications. The challenges and opportunities associated

with managing circularity are not confined to any single geographic or

industrial context. Therefore, the framework could serve as a blueprint for

similar assessments in other industrial ecosystems globally. Future research directions

include the development of a strategic management framework focused on

sustainable ESG practices within the context of circular industrial ecosystems.

Additionally, there is a need to refine managerial practices to better align

with sustainable ESG goals. Such future inquiries could also explore the

applicability of the framework across various sectors, such as construction and

retail, thereby broadening its scope and utility processes.

The

study was supported by the grant of the Russian Science Foundation No.

23-28-01316, «Strategic management of effective sustainable ESG-development of

the multilevel cybersocial industrial ecosystem of type in a circular economy

based on Industry 5.0 concept: methodology, tools, practice».

Babkin, A., Glukhov, V.,

Shkarupeta, E., Kharitonova, N., Barabaner, H., 2021. Methodology for Assessing

Industrial Ecosystem Maturity in the Framework of Digital Technology

Implementation. International Journal of Technology, Volume 12(7), pp.

1397–1406

Babkin, A., Shkarupeta,

E., Kabasheva, I., Rudaleva, I., Vicentiy, A.A., 2022. Framework for Digital

Development of Industrial Systems in the Strategic Drift to Industry 5.0. International

Journal of Technology, Volume 13(7), pp. 1373–1382

Berawi, M.A., 2020.

Managing nature 5.0: The role of digital technologies in the circular economy. International

Journal of Technology, Volume 11(4), pp. 652–655

Bogdanovich-Irina, S.,

Kistaeva-Natalia, N., Egorova-Svetlana, E., 2020. Environmental Indicators as a

Tool For Balanced Development of The Economy. Economy, Volume 13(6),

pp. 7–19

Doszhan, R.D., Zhuparova,

A.S., Kozhakhmetova, a.K., Semerkova, L.N., 2022. Economic Feasibility of

Sustainable Innovations. Models, Systems, Networks In Economics, Technology,

Nature And Society, Volume 3, pp. 42–59

Gileva, T.A., Shkarupeta,

E.V., 2022. Reframing Strategic Management of Enterprise Development in the

Digital Environment: Stages and Tools. -Economy, Volume 97(5), pp. 28–42

Glukhov, V.V., Babkin,

A.V., Shkarupeta, E.V., 2022. Digital Strategizing of Industrial Systems on The

Basis of Sustainable Eco-Innovation and Circular Business Models in The

Transition to Industry 5.0. Economics and Management, Volume 28(10), pp.

1006–1020

Haas, W., Krausmann, F.,

Wiedenhofer, D., Heinz, M., 2015. How Circular is The Global Economy?: An Assessment

of Material Flows, Waste Production, and Recycling in The European Union and

The World in 2005. Journal of Industrial Ecology, Volume 19(5), pp. 765–777

Ilyina, E.A., 2022.

Circular Economy: Conceptual Approaches and Mechanisms of Their Implementation.

Organizer of Production, Volume 30(3), pp. 21–30

Khan, M.A.-A.,

Cardenas-Barron, L.E., Trevino-Garza, G., Cespedes-Mota, A., 2023. Optimal Circular

Economy Index Policy In A Production System With Carbon Emissions. Expert

Systems with Applications, Volume 212, p. 118684

Khaykin, M.M., Babkin,

A.V., 2022. Problems of Economic Security of An Industrial Enterprise Under

Conditions of Modern Geopolitical Realities. Organizer of Production,

Volume 30(4), pp. 165–176

Krmela, A., Šimberová, I.,

Babica, V., 2022. Dynamics of Business Models in Industry-Wide Collaborative

Networks for Circularity. Journal of Open Innovation: Technology, Market,

and Complexity, Volume 8(1), p. 3

Kulibanova, V.V., Theor,

T.R., Ilyina, I.A., Sharakhina L.V., 2022. Development of the ESG Agenda in The

Russian Federation at The Regional Level. Economy, Volume 15(5), pp.

95–110

Kuzior, A., Arefiev, S.,

Poberezhna, Z., 2023. Informatization of Innovative Technologies For Ensuring

Macroeconomic Trends in The Conditions of a Circular Economy. Journal of

Open Innovation: Technology, Market, and Complexity, Volume 9(1), p. 10–20

Liu, Z., Stephens, V.,

2019. Exploring Innovation Ecosystem from The Perspective Of Sustainability: Towards

A Conceptual Framework. Journal of Open Innovation: Technology, Market, and

Complexity, Volume 5(3), p. 48

Mayer, A., Haas, W.,

Wiedenhofer, D., Krausmann, F., Nuss, P., Blengini, G.A., 2019. Measuring Progress

Towards A Circular Economy: A Monitoring Framework For Economy? Wide

Material Loop Closing in The EU28. Journal of industrial ecology, Volume

23(1), pp. 62–76

NLMK, 2021. ESG databook –

2021. Available Online at: https://nlmk.com/download_file.php?FILE_ID=139439&ELEMENT_ID=111273&NAME=ESG++2021&PAGE_URL=%2Fru%2

Fsustainability%2F,,

Accessed on February 05, 2023

NLMK, 2022. Sustainability

Annual Report 2022. Available Online at:

https://nlmk.com/upload/iblock/a67/NLMK_OUR_2022.pdf, Accessed on September 30,

2023

Pichlak, M., Szromek,

A.R., 2022. Linking Eco-Innovation and Circular Economy—A Conceptual Approach. Journal

of Open Innovation: Technology, Market, and Complexity, Volume 8(3), p. 121

Shkarupeta, E.V., Ilyina,

E.A., 2022. Digital Circular Economy: Concept, Model, Strategy, Framework,

Technology. Organizer of Production, Volume 30(4), pp. 9–17

Surovitskaya, G.V., 2021.

The Potential of "End-To-End" Digital Technologies to Improve Quality

Management Systems. Models, Systems, Networks In Economics, Technology,

Nature and Society, Volume 3, pp. 60–70

The Circularity Gap

Report, 2022. Five Years Of The Circularity Gap Report. Available Online at:

https://www.circularity-gap.world/2022, Accessed on February 05, 2023

Umarova, D.T., 2021.

Foreign Experience of Scientific and Technological Integration. Models,

Systems, Networks In Economics, Technology, Nature And Society, Volume 4,

pp. 26–40

Uztürk, D., Büyüközkan,

G., 2022. 2-Tuple Linguistic Model-based Circular Maturity Assessment

Methodology: A Case for Agriculture. IFAC-PapersOnLine, Volume 55(10),

pp. 2036–2041

Vinante, C., Sacco, P.,

Orzes, G., Borgianni, Y., 2021. Circular Economy Metrics: Literature Review and

Company-Level Classification Framework. Journal of Cleaner Production,

Volume 288, p. 125090

Zaytsev, A., Dmitriev, N.,

Rodionov, D., Magradze, T., 2021. Assessment of the Innovative Potential of

Alternative Energy in the Context of the Transition to the Circular Economy. International

Journal of Technology, Volume 12(7), pp. 1328–1338