Enhancement of Asphalt Resilience through Functionalization of Natural Rubber with Glycidyl Methacrylate, Maleic Anhydride, and Divinylbenzene

Corresponding email: tamrin@usu.ac.id

Published at : 28 May 2025

Volume : IJtech

Vol 16, No 3 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i3.6816

Wijaya, NR, Tamrin, Eddiyanto, Laksmono, JA & Ritonga, AH 2025, ‘Enhancement of asphalt resilience through functionalization of natural rubber with glycidyl methacrylate, maleic anhydride, and divinylbenzene’, International Journal of Technology, vol. 16, no. 3, pp. 993-1003

| Nanang Rahmat Wijaya | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Jl. Bioteknologi No.1, Medan 20155, Indonesia |

| Tamrin | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Jl. Bioteknologi No.1, Medan 20155, Indonesia |

| Eddiyanto | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan, Jl. Willem Iskandar, Pasar V, Medan 20221, Indonesia |

| Joddy Arya Laksmono | Research Center for Chemistry, National Research and Innovation Agency (BRIN), PUSPIPTEK, Serpong, Tangerang Selatan 15314, Indonesia |

| Ahmad Hafizullah Ritonga | Institut Kesehatan Medistra Lubuk Pakam, Deli Serdang-20512, Indonesia |

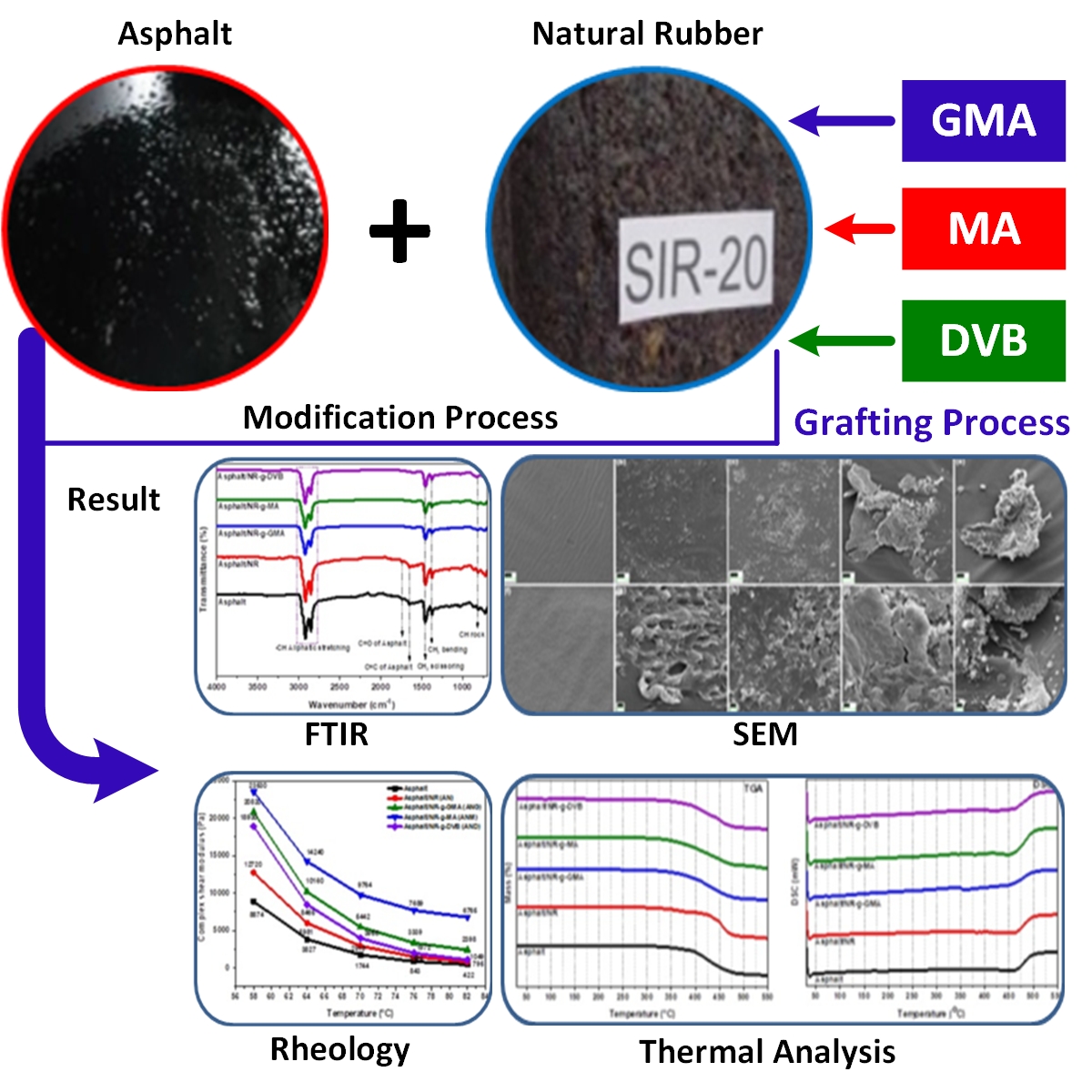

Asphalt is an important construction material in the development of road and transportation infrastructure. However, this material often encounters challenges, such as cracking and deformation due to traffic loads and environmental changes. An effective solution is the modification of Asphalt using functionalized natural rubber (NR). Therefore, this research aimed to enhance Asphalt resilience by using NR functionalized with Glycidyl Methacrylate (GMA), Maleic Anhydride (MA), and Divinylbenzene (DVB), as well as to understand the interactions between the materials. An Internal Mixer with heating, monomer addition, and purification was used for the grafting process of GMA, MA, and DVB onto NR. The functionalized NR was integrated into the Asphalt matrix through heating processes. The results showed that NR functionalized with GMA, MA, and DVB successfully improved the physical, rheological, thermal, and morphological properties of Asphalt. Asphalt/NR-g-GMA sample achieved the highest values at 25°C, with a penetration of 68.7 mm, a softening point of 55.5° with a penetration of 173 cm. Rheological analysis showed an increased post-aging complex shear modulus, particularly in asphalt/NR-g-MA. This result showed superior performance and compatibility, reaching 12.86 kPa at 58°C before aging and 23.63 kPa afterward. Morphological analysis showed a more harmonious surface structure in Asphalt modified with NR-g-GMA. In addition, FTIR analysis showed distinct spectrum changes between Asphalt/NR and the modification with NR-g-GMA, NR-g-MA, and NR-g-DVB, suggesting interactions between asphalt and the functionalized NR. In conclusion, this research showed that functionalized NR caused significant chemical interactions, improving the physical, rheological, thermal, and morphological properties, as well as the durability and resilience of asphalt.

Asphalt; Divinylbenzene; Glycidyl methacrylate; Maleic anhydride; Natural rubber

Asphalt is an important construction material in developing road and transportation infrastructure. The performance of this material plays a significant role in maintaining the integrity and durability of roadways against vehicular loads, temperature fluctuations, and extreme weather conditions. However, asphalt faces persistent challenges, such as wear, cracking, and permanent deformation, due to increasing traffic loads and changing environmental conditions. Addressing these challenges is essential in producing resilience and enduring asphalt (Alhaji and Musa, 2018; Ma et al., 2016). According to previous research, modifying Asphalt has become a significant focus in enhancing performance. This modification aimed to alter the physical, mechanical, and thermal properties to improve resilience and durability (Tamrin et al., 2023; Setiadji et al., 2022; Alas and Ali, 2019; Yaacob et al., 2018). A promising method is using natural rubber (NR) as a modifier. NR is known for its elasticity and has the potential to enhance asphalt performance (Suwarto et al., 2023; Wu et al., 2023). However, the successful integration of NR often encounters challenges related to adhesion and dispersion, which can impact the performance of the mixture due to the different polarity characteristics. In this context, enhancing the interaction between NR and asphalt is important (Jitsangiam et al., 2021; Sari et al., 2020).

Previous research on modification with rubber has been conducted, including Nanjegowda and Biligiri (2023) which integrated recycled crumb rubber. Li et al. (2022b) used an internal de-crosslinking method on crumb rubber to develop a mixture with superior characteristics. Yan et al. (2023) optimized compatibility with thermoset NR using mineral oil as a softener. Wijaya et al. (2022) explored compatibility with NR grafted using Glycidyl Methacrylate (GMA). Furthermore, Alfian et al. (2021) grafted Divinylbenzene (DVB) and GMA comonomers onto cyclized NR, where DVB acted as both a grafting material and a cross-linking agent, forming a network in the resulting copolymer. This research made collective contributions to advancing superior and sustainable road material technology.

An effective strategy to improve asphalt performance is by functionalizing NR using chemical agents. A good chemical agent includes Maleic Anhydride (MA), which forms a bond with hydroxyl groups in NR (Pongsathit and Pattamaprom, 2018). GMA reacts with hydroxyl and carbonyl groups in NR, improving the adhesion and dispersion of NR in asphalt (Radabutra et al., 2022). Shirokikh et al. (2020) successfully produced a stable high-concentration styrene-DVB graft copolymer. Therefore, comprehensive research is important for understanding the impact of functionalization on the thermal, mechanical, and physical properties of asphalt mixtures. In this context, exploring the use of GMA, MA, and DVB to functionalize NR as a modifier is important. GMA and MA can interact with the carbonyl and hydroxyl groups in NR, enhancing adhesion and dispersion, while DVB is a cross-linking agent in the resulting copolymers. The novelty of this research is in the use of NR with GMA, MA, and DVB for asphalt modification. This method goes beyond previous research, which typically used non-functionalized NR, aiming to enhance the interaction between NR and asphalt (Nanjegowda and Biligiri, 2023; Jitsangiam et al., 2021). Therefore, this research aimed to significantly enhance resilience and performance by introducing functionalized NR into the composition. Specifically, the impact of modifying NR with MA, GMA, and DVB was investigated. The primary focus is on evaluating the influence of the modifications on the thermal, mechanical, physical, and morphological properties of asphalt blends.

2.1. Materials

The materials used included asphalt (Penetration 60/70) purchased from PT. Gudang Aspal, Deli Serdang, Indonesia. The Standard Indonesian Rubber (SIR-20) was obtained from PT. Perkebunan Nusantara III, Medan, Indonesia. DVB, MA, GMA, and Dicumyl Peroxide (DCP) are chemical substances sourced from Merck, Darmstadt, Germany.

2.2. Functionalization of NR with GMA, MA, and DVB monomers by the grafting method in the molten state

NR of 30 g was placed in an internal mixer at a temperature of 160°C and a speed of 65 rpm for 10 min. Subsequently, 4.5 g GMA monomer and 0.3 g DCP initiator were added, and then the mixing proceeded for 15 min. The sample was removed from the internal mixer, kept for 15 min, and cut into small pieces. The NR/GMA sample was placed into a round-bottom flask containing 200 mL of xylene and refluxed at 180°C, stirred at 60 rpm until dissolved. This solution was added with 80 mL of acetone to cause a separation from the unreacted GMA and GMA homopolymer. The formed NR-g-GMA precipitate was filtered, washed with 150 mL of methanol (repeated twice), dried in an oven at 85°C for 6 h, cooled, and stored in a desiccator for 24 h. This was followed by weighing the NR-g-GMA sample, similar to the process applied to MA and DVB monomers (Figure 1) (Ritonga et al., 2023, 2022a).

Figure 1 Schematic diagram of (a) the functionalization of NR with GMA, MA, and DVB; (b) Asphalt modified with NR-g-GMA, NR-g-MA, and NR-g-DVB

2.3. Modification of asphalt using NR-g-GMA, NR-g-MA, NR-g-DVB copolymers by blending methods

Asphalt was integrated with NR in a mixing apparatus at a certain ratio, as shown in Table 1. The mixture was blended and heated at a rotation speed of 600 rpm and a temperature of 180°C for 30 min (Luo et al., 2024). Subsequently, the mixing activity was stopped and allowed to cool, resulting in Asphalt/NR (AN). The same method was applied to NR-g-GMA, NR-g-MA, and NR-g-DVB copolymers. The entire samples were characterized according to Figure 1b.

Table 1 Composition of asphalt and NR functionalized with various monomers

2.5. Characterization

The monomers grafting onto NR used an Internal Mixer, namely (Thermo Haake Polydrive). The sample blending process used a hotplate and overhead stirrer (Thermo Fisher Scientific). Penetration at 25oC was inspected following ASTM D5-71, AASHTO T49-68, and SNI 2456-2011 standards, using a 100 g penetrometer tester at 25°C for 5 s. The softening point was examined according to ASTM D36-69, AASHTO T53-74, and SNI 2434-2011 standards using a ring and ball tester. The temperature was determined when the ball contacts the base plate. The ductility at 25 °C was inspected according to ASTM D113-69, AASHTO T51-74, and SNI 2432-2011 standards using a dactylometer tester.

Rheology was analyzed using a Dynamic Shear Rheometer (Matest). Functional groups were analyzed using an FTIR Spectrometer (Agilent/FTIR Cary 630) at wavenumbers 4000 to 650 cm-1. Furthermore, thermal stability and properties were analyzed by TGA/DTA (Hitachi/TG/DTA 7300 series) at 30 to 600°C with a heating rate of 10°C/min and DSC (Hitachi/X-DSC 7000) at 30 to 200°C at 10°C/min under nitrogen flow. Morphology was observed using Scanning Electron Microscopy (SEM)(ZEISS EVO @ MA 10).

3.1. Physical Characteristics of Asphalt Modified with NR-g-GMA, NR-g-MA, and NR-g-DVB

The physical characteristics evaluated include penetration tests, softening points, and ductility of asphalt and the modifications, as shown in Table 2.

Table 2 Penetration, softening point, and ductility of Asphalt and the modifications

Notes: *Requirements

Asphalt penetration was evaluated according to ASTM D5 standards at 25°C under a 100 g load, with 60-70 mm penetration being the preferred choice for tropical climates. Functionalized Asphalt/NR samples exhibited increased penetration in the standard range, with a maximum composition of 85:15 in ANG-3, ANM-3, and AND-3 samples (Kurniawan et al., 2020). The softening point was tested per ASTM D36, and the result showed an increase in SNI standards with the addition of modified rubber, ranging from 2-16% (Li et al., 2022a).

Asphalt ductility was assessed by ASTM D113 and found to meet the minimum standard of 100 cm for all samples, particularly ANG-3, ANM-3, and AND-3, with a ratio of 85:15. NR functionalization enhanced the ductility of the mixture, with GMA monomer-grafted samples showing significant superiority in physical tests. NR functionalized with GMA, MA, and DVB improved the physical properties of asphalt. Penetration, softening point, and ductility tests showed that NR functionalization significantly increased the quality of asphalt, particularly with MA. The result also showed a significant improvement in asphalt durability compared to previous research (Jitsangiam et al., 2021; Radabutra et al., 2022). Functionalizing NR with GMA, MA, and DVB had better performance than previous modifications.

3.2. Rheology Analysis of Asphalt Modified with NR-g-GMA, NR-g-MA, and NR-g-DVB

Rheological testing using DSR was conducted on Asphalt, Asphalt/NR (AN-1), Asphalt/NR-g-GMA (ANG-3), Asphalt/NR-g-MA (ANM-3), and Asphalt/NR-g-DVB (AND-3), as shown in Figure 2.

Figure 2 Rheology of Asphalt, Asphalt/NR, Asphalt/NR-g-GMA, Asphalt/NR-g-MA, and Asphalt/NR-g-DVB in conditions: (a) original (before aging), (b) after short-term aging

Testing aimed to understand the behavior of asphalt and NR-functionalized variants under traffic loads and environmental conditions. The complex shear modulus fluctuates with temperature changes, particularly in the range of 58°C to 82°C. Initially, all samples tend to decrease the complex shear modulus with rising temperature, showing increased stiffness at lower temperatures. AN sample had no significant difference from asphalt, especially beyond 70°C. Furthermore, NR-functionalized samples showed significant differences. ANM sample showed better complex shear modulus values than all, though not significantly different from ANG. After short-term aging, asphalt complex shear modulus significantly increases at all temperatures. ANM samples also showed a significant post-aging increase, suggesting good compatibility of NR-g-MA with asphalt. The samples of AND showed an increase after aging but with less significance than ANM and ANG. This result showed that NR-g-DVB had a better interaction with asphalt. Previous research confirms that NR-modified asphalt increased the complex shear modulus, showing a post-modification with improved stability. Functionalized NR also showed a significant improvement in rheological outcomes compared to non-functionalized NR (Jitsangiam et al., 2021; Li et al., 2023b; Ling et al., 2023; Poovaneshvaran et al., 2020).

3.3. Thermal Analysis of Asphalt Modified with NR-g-GMA, NR-g-MA, and NR-g-DVB

Thermal analysis was conducted on the Asphalt and the modifications, as shown in Figure 3. Table 3 shows the analysis results with the percentage of sample degradation at temperatures of 250°C (T250), and 500°C (T500). Other results, such as the maximum degradation temperature (Tmax), the melting point temperature (Tm), and the decomposition temperature (Td), were also shown. The thermal stability of each sample had no significant difference when compared to conventional asphalt, specifically based on the T500 value. However, the AN sample was known to experience more significant degradation compared to others, as evidenced in T500 and Tmax, which experienced degradation of 1.80 mg/min. The 3 samples have Tm, where the Tm of ANG and ANM differ significantly from AND due to the grafting and cross-linking process. ANM sample produces the same Td and Tmax, caused by the high compatibility and interaction between asphalt and NR-g-MA compared to ANG and AND. This result was consistent with previous research that the presence of NR in small sample asphalt mixtures had no significant effect on thermal stability, but had an impact on changes in the properties (Wijaya et al., 2022; Ryms et al., 2017; Amin and Samy, 2013).

Figure 3 (a) TGA, (b) DTG, (c) DTA, and (d) DSC curves of Asphalt, Asphalt/NR, Asphalt/NR-g-GMA, Asphalt/NR-g-MA, and Asphalt/NR-g-DVB

Table 3 Thermal analysis of asphalt modified with functionalized NR

3.4. FTIR Analysis of Asphalt Modified with NR-g-GMA, NR-g-MA, and NR-g-DVB

Figure 4 shows FTIR spectra of Asphalt, AN, ANG, AND, and ANM samples. The spectrum of asphalt had sharp absorption bands at 2912.5 cm-1 and 2847 cm-1, showing the presence of asymmetric aliphatic hydrocarbon compounds. Asphalt had bands at 1739.5 cm-1 (carbonyl group C=O) and 1645.8 cm-1 (C=C), and the spectrum closely resembles the AN sample, suggesting no interaction with NR. ANG, ANM, and AND samples had spectra similar to asphalt due to an 85:15 ratio of asphalt and NR functionalized. However, these samples lack bands at 1739.5 cm-1 and 1645.8 cm-1, showing interactions between Asphalt and NR-g-GMA, NR-g-MA, and NR-g-DVB. The spectra of the 3 samples show only variations in intensity and no significant differences. FTIR spectra of asphalt are consistent with previous research (Adibi et al., 2024; Ritonga et al., 2022b; Wijaya et al., 2022).

Figure 4 FTIR Spectra of Asphalt, Asphalt/NR, Asphalt/NR-g-GMA, Asphalt/NR-g-MA, and Asphalt/NR-g-DVB

Figure 5 Reaction mechanism for grafting of GMA, MA, and DVB onto NR

Carbonyl groups in NR-g-GMA and NR-g-MA, as shown in Figure 5 significantly impact reactivity and interaction with asphalt. The existence of carbonyl groups, specifically ketone, has been proven by previous research to enhance reactivity. This implies that compounds containing carbonyl groups can easily interact with specific components in asphalt, resulting in stronger interactions. Carbonyl can also form hydrogen bonds with other functional groups, such as hydroxyl, thereby strengthening the interactions ( Zhao et al., 2024; Li et al., 2023a; Radabutra et al., 2022; Pongsathit and Pattamaprom, 2018). These results were found to be consistent with the rheological test. Meanwhile, hydrogen bond formation with asphalt occurs without ketone groups in NR-g-DVB. The interaction between NR-g-DVB and asphalt tended to be weaker compared to NR-g-GMA and NR-g-MA (Xie et al., 2024; Wei et al., 2023).

3.5. Morphological Analysis of Asphalt Modified with NR-g-GMA, NR-g-MA, and NR-g-DVB

The morphology of asphalt and the modifications (AN, ANG, ANM, AND) were analyzed using SEM, as shown in Figure 6. This analysis was conducted at 2000- and 10000-times magnifications to explore the dispersion, modifications, and interactions between components and the entire microstructure.

Figure 6 SEM micrographs of (a) Asphalt, (b) AN, (c) ANG, (d) ANM, (e) AND at 2000 times magnification, and (f) Asphalt, (g) AN, (h) ANG, (i) ANM, (j) AND at 10000 times magnification

At 2000 times magnification, asphalt showed a smooth and homogeneous microstructure. In the AN sample, a distinct surface texture was different from asphalt, showing uneven NR dispersion and numerous voids, thereby suggesting an inhomogeneous mixture. ANG sample shows a different texture, showcasing uniform NR-g-GMA dispersion with a few small voids, signifying a strong interaction. Some areas were smooth, such as asphalt for ANM and samples of AND, while others were not. This result suggests uneven dispersion or agglomerations of NR-g-MA and NR-g-AD due to a less homogeneous blending process. At 10000 times magnification, the ANG sample showed the dominance of NR-g-GMA particles in the asphalt matrix. In general, modification with NR, as shown in previous research, induced changes to the morphology or surface structure (Tamrin et al., 2023; Zhao et al., 2023; Kandil et al., 2022).

In conclusion, this study showed positive results in modifying asphalt with NR functionalized using MA, GMA, and DVB. The resilience of asphalt was effectively enhanced, showing improvements in penetration, softening point, and ductility in samples containing functionalized NR. Asphalt/NR-g-GMA sample achieved the highest values, with a penetration, softening point, and ductility of 68.7 mm, 55.5°C, and 173 cm, respectively, at 25°C. Rheological analysis showed an increased post-aging complex shear modulus, particularly in asphalt/NR-g-MA. This result suggested superior performance and compatibility, reaching 12.86 kPa at 58°C before aging and 23.63 kPa afterwards. Thermal stability remained consistent without significant differences, but asphalt samples with functionalized NR showed an increased melting point temperature from the grafted monomers. FTIR spectra confirmed interactions between asphalt and functionalized NR, as evidenced by the disappearance of carbonyl groups. In addition, morphological analysis showed a more harmonious surface structure in the modification with NR-g-GMA. The result showed that functionalized NR caused significant chemical interactions, thereby improving physical, rheological, thermal, and morphological properties.

The authors would like to thank the Polymer Chemistry Laboratory, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, for providing the laboratory facilities.

Adibi, A, Jubinville, D, Chen, G & Mekonnen, TH 2024, 'In-Situ surface grafting of lignin onto an epoxidized natural rubber matrix: A masterbatch filler for reinforcing rubber composites', Reactive and Functional Polymers, vol. 197, no. 1, article 105856, https://doi.org/10.1016/j.reactfunctpolym.2024.105856

Alas, M & Ali, SI 2019, 'Prediction of the high-temperature performance of a geopolymer modified asphalt binder using artificial neural networks', International Journal of Technology, vol. 10, no. 2, pp. 291–319, https://doi.org/10.14716/ijtech.v10i2.2421

Alfian, Z, Tamrin, T & Nasution, N 2021, 'Addition of divinyl benzene comonomer to glycidyl methacrylate grafting to cyclic natural rubber', IOP Conference Series: Earth and Environmental Science, vol. 912, article 12099, https://doi.org/10.1088/1755-1315/912/1/012099

Alhaji, MM & Musa, A 2018, 'Effect of reclaimed asphalt pavement stabilization on the microstructure and strength of black cotton soil', International Journal of Technology, vol. 9, no. 14, pp. 727–736, https://doi.org/10.14716/ijtech.v9i4.435

Amin, A & Samy, M 2013, 'Preparation and characterization of some hyperbranched polyesteramides/montmorillonite nanocomposites', International Journal of Polymer Science, vol. 2013, no. 1, article 528468, https://doi.org/10.1155/2013/528468

Jitsangiam, P, Nusit, K, Phenrat, T, Kumlai, S & Pra-ai, S 2021, 'An examination of natural rubber modified asphalt: Effects of rubber latex contents based on macro- and micro-observation analyses', Construction and Building Materials, vol. 289, no. 1, article 123158, https://doi.org/10.1016/j.conbuildmat.2021.123158

Kandil, H, Samy, M & El-Nashar, DE 2022, 'Gallate ester of castor oil as a multifunctional additive in HAF carbon black–filled natural rubber composites', Journal of Vinyl and Additive Technology, vol. 28, no. 2, pp. 331–342, https://doi.org/10.1002/vnl.21886

Kurniawan, A, Wirjosentono, B, Tamrin, T, Siregar, AH & Nasution, DA 2020, 'Preparation and characterisations of maleic anhydride-modified-(asphalt, natural rubber, and polystyrene) blends containing sand aggregate', AIP Conference Proceedings, vol. 2267, article 20080, https://doi.org/10.1063/5.0015735

Li, H, Cui, C, Temitope, AA, Feng, Z, Zhao, G & Guo, P 2022a, 'Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application', Journal of Traffic and Transportation Engineering (English Edition), vol. 9, no. 5, pp. 836–863, https://doi.org/10.1016/j.jtte.2022.03.002

Li, J, Jiang, H, Han, F, Lin, Z, Zhao, Z, Jin, X & Liu, Y 2023a, 'Investigation of the effects of chemical modification and oxidative aging on the properties and compatibility of rubber asphalt based on thermodynamic principles', Journal of Cleaner Production, vol. 428, no. 1, article 139070, https://doi.org/10.1016/j.jclepro.2023.139070

Li, J, Xiao, X, Chen, Z, Xiao, F & Amirkhanian, SN 2022b, 'Internal de-crosslinking of scrap tire crumb rubber to improve compatibility of rubberized asphalt', Sustainable Materials and Technologies, vol. 32, no. 1, article e00417, https://doi.org/10.1016/j.susmat.2022.e00417

Li, J, Zhang, X, Wei, H, Zhu, H & Tang, B 2023b, 'Evaluation of volatile organic compounds emissions and rheological properties of Buton rock asphalt modified asphalt', Construction and Building Materials, vol. 408, no. 1, article 133575, https://doi.org/10.1016/j.conbuildmat.2023.133575

Ling, M, Ji, J, Tanvir, H, Fuentes, L & Walubita, LF 2023, 'Simultaneous evaluation of rutting-stripping performance and cracking resistance for asphalt mixtures', Construction and Building Materials, vol. 408, no. 1, article 133581, https://doi.org/10.1016/j.conbuildmat.2023.133581

Luo, X, Muttaqin, F & Zhang, Y 2024, 'Investigating non-petroleum-based biodegradable polymers as eco-friendly and sustainable materials in asphalt modification: A review on natural rubbers and natural oils', Journal of Cleaner Production, vol. 436, no. 1, article 140483, https://doi.org/10.1016/j.jclepro.2023.140483

Ma, D, Zhao, D, Zhao, J, Du, S, Pang, J, Wang, W & Fan, C 2016, 'Functionalization of reclaimed polyethylene with maleic anhydride and its application in improving the high temperature stability of asphalt mixtures', Construction and Building Materials, vol. 113, no. 1, pp. 596–602, https://doi.org/10.1016/j.conbuildmat.2016.03.096

Nanjegowda, VH & Biligiri, KP 2023, 'Utilization of high contents of recycled tire crumb rubber in developing a modified-asphalt-rubber binder for road applications', Resources, Conservation and Recycling, vol. 192, no. 1, article 106909, https://doi.org/10.1016/j.resconrec.2023.106909

Pongsathit, S & Pattamaprom, C 2018, 'Irradiation grafting of natural rubber latex with maleic anhydride and its compatibilization of poly (lactic acid)/natural rubber blends', Radiation Physics and Chemistry, vol. 144, no. 1, pp. 13–20, https://doi.org/10.1016/j.radphyschem.2017.11.006

Poovaneshvaran, S, Mohd Hasan, MR & Putra Jaya, R 2020, 'Impacts of recycled crumb rubber powder and natural rubber latex on the modified asphalt rheological behaviour, bonding, and resistance to shear', Construction and Building Materials, vol. 234, no. 1, article 117357, https://doi.org/10.1016/j.conbuildmat.2019.117357

Radabutra, S, Khemthong, P, Saengsuwan, S, Chanthadand, C, Ponyut, N & Pijarn, N 2022, 'Preparation and characterization of wood-to-wood bonding adhesive by glycidyl methacrylate grafting natural rubber', International Journal of Adhesion and Adhesives, vol. 114, no. 1, article 103093, https://doi.org/10.1016/j.ijadhadh.2022.103093

Ritonga, AH, Jamarun, N, Arief, S, Aziz, H, Tanjung, DA & Isfa, B 2022a, 'The influence of oleic acid and benzoyl peroxide against oleic acid grafted onto LLDPE', Rasayan Journal of Chemistry, vol. 15, no. 1, pp. 190–196, http://dx.doi.org/10.31788/RJC.2022.1516720

Ritonga, AH, Jamarun, N, Arief, S, Aziz, H, Tanjung, DA & Isfa, B 2022b, 'Oleic acid monomer and benzoyl peroxide effect on grafting degree and thermal properties of LLDPE grafted with oleic acid in solvent system', AIP Conference Proceedings, vol. 2638, no. 1, article 020002, https://doi.org/10.1063/5.0104027

Ritonga, AH, Jamarun, N, Arief, S, Aziz, H, Tanjung, DA, & Isfa, B 2023, 'The effect of oleic acid-grafted linear low-density polyethylene as compatibilizer on the properties of linear low-density polyethylene/cyclic natural rubber blends', International Journal of Technology, vol. 14, no. 1, pp. 162–172, https://doi.org/10.14716/ijtech.v14i1.5085

Ryms, M, Denda, H, & Jasku?a, P 2017, 'Thermal stabilization and permanent deformation resistance of LWA/PCM-modified asphalt road surfaces', Construction and Building Materials, vol. 142, no. 1, pp. 328–341, https://doi.org/10.1016/j.conbuildmat.2017.03.050

Sari, TI, Saputra, AH, Bismo, S, & Maspanger, DR 2020, 'Deproteinized natural rubber grafted with polyacrylonitrile (PAN)/polystyrene (PS) and degradation of its mechanical properties by dimethyl ether', International Journal of Technology, vol. 11, no. 1, pp. 15–25, https://doi.org/10.14716/ijtech.v11i1.1942

Setiadji, BH, Wibowo, MA, Jonkers, HM, Ottele, M, Widayat, -, Qomaruddin, M, Sugianto, FH, & Purwanto, HAL 2022, 'Pyrolysis of reclaimed asphalt aggregates in mortar', International Journal of Technology, vol. 13, no. 4, pp. 751–763, https://doi.org/10.14716/ijtech.v13i4.5621

Shirokikh, SA, Kulieva, LE, Koroleva, MY, & Yurtov, EV 2020, 'Effect of the stability of highly concentrated emulsions containing styrene–divinylbenzene mixtures on the structure of highly porous copolymers formed on their basis', Colloid Journal, vol. 82, no. 1, pp. 767–775, https://doi.org/10.1134/S1061933X20060137

Suwarto, F, Parry, T, Thom, N, Airey, G, Abed, A, Rahman, T, & Wititanapanit, J 2023, 'Engineering characterization and environmental analysis of natural rubber latex modified asphalt mixture', Construction and Building Materials, vol. 402, no. 1, article 132970, https://doi.org/10.1016/j.conbuildmat.2023.132970

Tamrin, Ritonga, AH, & Aritonang, B 2023, 'The enhancement of mechanical, physical, and thermal properties of modified asphalt mixture with lignin from mahogany sawdust in the presence of diphenylmethane 4,4?-diisocyanate', International Journal of Adhesion and Adhesives, vol. 125, no. 1, article 103431, https://doi.org/10.1016/j.ijadhadh.2023.103431

Wei, K, Cao, X, Wu, Y, Cheng, Z, Tang, B, & Shan, B 2023, 'Dynamic chemistry approach for self-healing of polymer-modified asphalt: A state-of-the-art review', Construction and Building Materials, vol. 403, no. 1, article 133128, https://doi.org/10.1016/j.conbuildmat.2023.133128

Wijaya, NR, Tamrin, T, Eddiyanto, E, & Laksmono, JA 2022, 'Compatibility of mixtures of asphalts and graft copolymerization of natural rubber onto glycidil methacrylate (NR-g-GMA) in modification of asphalt-rubber', AIP Conference Proceedings, vol. 2659, no. 1, article 070010, https://doi.org/10.1063/5.0129103

Wu, Z, Ge, D, Ju, Z & Xue, Y 2023, 'The performance evaluation of extracted asphalt binder from dry process produced rubber modified asphalt mixture', Construction and Building Materials, vol. 401, no. 1, article 131864, https://doi.org/10.1016/j.conbuildmat.2023.131864

Xie, T, He, Z, Yu, H, Ma, Y, Shi, C, Zhang, C, Ge, J, & Dai, W 2024, 'Evaluation of styrene butadiene rubber asphalt modification mechanism and adhesion effect based on molecular simulation', Fuel, vol. 364, no. 1, article 131023, https://doi.org/10.1016/j.fuel.2024.131023

Yaacob, H, Chang, FL, Jaya, RP, Hainin, MR, Rashid, ASA & Hassan, NA 2018, 'Assessing the bond strength of hot mix asphalt pavement for wearing and binder courses', International Journal of Technology, vol. 9, no. 5, pp. 925–933, https://doi.org/10.14716/ijtech.v9i5.2193

Yan, Y, Guo, R, Liu, Z, Yang, Y & Wang, XY 2023, 'Property improvement of thermosetting natural rubber asphalt binder by mineral oil', Journal of Materials Research and Technology, vol. 24, no. 1, pp. 8807–8825, https://doi.org/10.1016/j.jmrt.2023.05.134

Zhao, X, Li, F, Zhang, X, Qiu, Y, Lei, L, Zhao, Y, Li, F & Xue, Y 2024, 'Viscosity reduction mechanism and rheological properties of ethylene-bis-stearamide and crumb rubber modified asphalt', Construction and Building Materials, vol. 412, no. 1, article 134830, https://doi.org/10.1016/j.conbuildmat.2023.134830

Zhao, Z, Wu, S, Xie, J, Yang, C, Yang, X, Wang, F & Liu, Q 2023, 'Utilization of high contents desulfurized crumb rubber in developing an asphalt rubber pellets modified asphalt', Construction and Building Materials, vol. 402, no. 1, article 133043, https://doi.org/10.1016/j.conbuildmat.2023.133043