Development and Characterization of Biomass-Based Biocarbon Fillers for Natural Rubber Composites

Corresponding email: purwantiningsih@apps.ipb.ac.id

Published at : 28 May 2025

Volume : IJtech

Vol 16, No 3 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i3.6809

Cifriadi, A, Sugita, P, Wismogroho, AS, Kemala, T , Nikmatin, S, Widayatno, WB, Amal, MI, Jayadi, Firdharini, C & Kinasih, NA 2025, ‘Development and characterization of biomass-based biocarbon fillers for natural rubber composites’, International Journal of Technology, vol. 16, no. 3, pp. 982-992

| Adi Cifriadi | 1. Department of Chemistry, Faculty of Mathematics and Natural Sciences, IPB University, Dramaga, Bogor 16880, Indonesia. 2. Bogor Getas Research Unit, Indonesian Rubber Research Institute, Jalan Sala |

| Purwantiningsih Sugita | Department of Chemistry, Faculty of Mathematics and Natural Sciences, IPB University, Dramaga, Bogor 16880, Indonesia |

| Agus Sukarto Wismogroho | Research Center for Nanotechnology Systems, Research Organization for Nanotechnology and Materials, National Research and Innovation Agency, South Tangerang 15314, Banten, Indonesia |

| Tetty Kemala | Department of Chemistry, Faculty of Mathematics and Natural Sciences, IPB University, Dramaga, Bogor 16880, Indonesia |

| Siti Nikmatin | Department of Physic, Faculty of Mathematics and Natural Sciences, IPB University, Dramaga, Bogor 16880, Indonesia |

| Wahyu Bambang Widayatno | Research Center for Advanced Material, National Research and Innovation Agency, South Tangerang 15314, Banten, Indonesia |

| Muhamad Ikhlasul Amal | Research Center for Advanced Material, National Research and Innovation Agency, South Tangerang 15314, Banten, Indonesia |

| Jayadi | Research Center for Advanced Material, National Research and Innovation Agency, South Tangerang 15314, Banten, Indonesia |

| Cherly Firdharini | Research Center for Advanced Material, National Research and Innovation Agency, South Tangerang 15314, Banten, Indonesia |

| Norma A. Kinasih | Bogor Getas Research Unit, Indonesian Rubber Research Institute, Jalan Salak No.1 Bogor 16128, Indonesia |

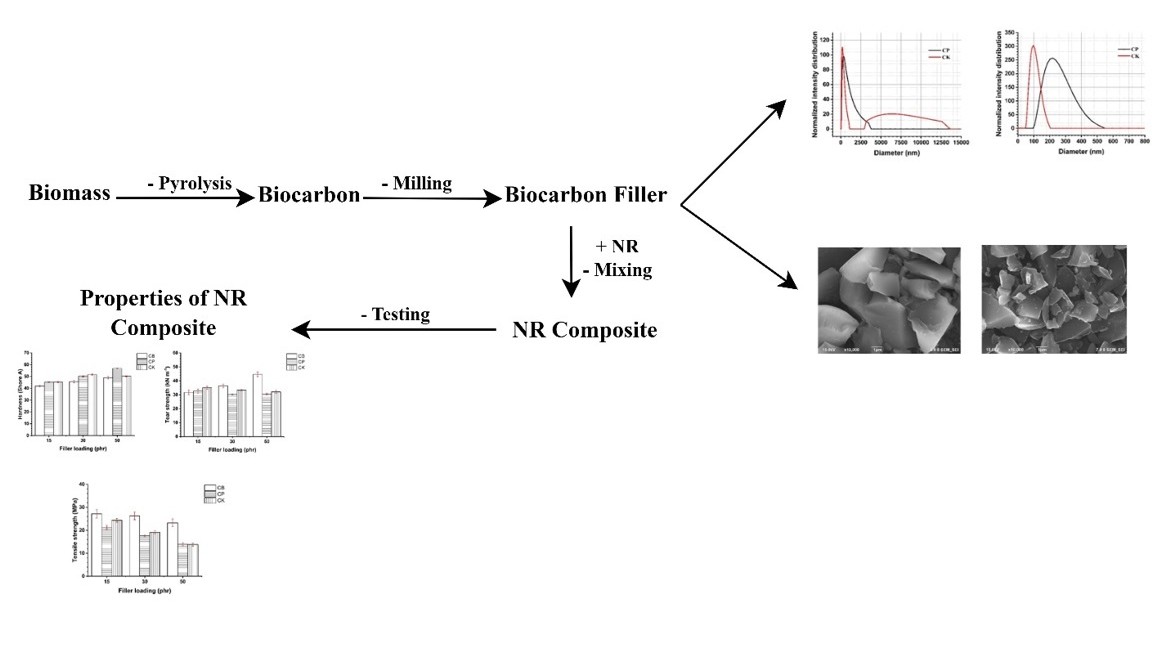

Research on substituting petroleum-based carbon black (CB) fillers in rubber composite with renewable, environmentally friendly, and sustainable fillers based on biomass is increasingly essential to develop. Meanwhile, biomass-based biocarbon faces challenges in rubber composites due to poor surface activity and fluctuating particle size features. Therefore, this study aimed to develop biomass-based biocarbon fillers (cassava starch and tamarind wood) for natural rubber (NR) composites. Pyrolysis and ball mill methods were applied to achieve this. The chemical and physical properties of biocarbon were determined by the particle size analyzer (PSA), specific surface area (SSA) analyzer, and field emission scanning electron microscopes (FE-SEM). In the process, the mechanical properties of biocarbon-filled NR composite were characterized using the ASTM D5289-12 standard. The results showed that the chemical and physical properties of biocarbon filler derived from cassava starch were significantly similar to those of CB N990. It is important to note that the chemical properties of biocarbon filler derived from tamarind wood were lower than those of cassava starch biocarbon and commercial CB N990. On the other hand, the mechanical properties of tensile and tear strength of tamarind wood-filled NR composite at 15 phr (parts per hundred rubber) were significantly equivalent to CB N990-filled NR composite. Based on the result, biocarbon filler derived from tamarind wood in NR composites was discovered to be promising at 15 phr of filler content for substituting petroleum-based carbon black N990 fillers.

Biomass-based biocarbon; Filler; Mechanical properties; Natural rubber composite

Filler is commonly used to enhance mechanical and dynamic properties. as well as to reduce material costs. This material can be in the form of fibers or particulates. Carbon black (CB) is the most widely used in the rubber industry, specifically in the tire and automotive sectors (Zweid et al., 2021). It is produced through incomplete combustion of petroleum and requires high energy consumption, wherein two metric tons of petroleum hydrocarbons were required to produce one metric ton of carbon black. The production of carbon black also produces CO2 emissions as much as 8.109 metric tons CO2 emissions (Probst et al., 2012). Higher demand for fossil fuels leads to higher CO2 emissions (Shieddieque et al., 2021). Therefore, biocarbon from biomass feedstock was produced to reduce CO2 emissions of carbon black production. The exploration of new materials such as biocarbon has intensively increased to substitute carbon black, wherein considered on renewable and abundant resource and quite low processing costs (Jiang et al., 2020).

Carbon black in eco-friendly rubber products or rubber composite is increasingly being reduced and even eliminated to minimize CO2 emissions, aligning with the increasing demand for environmentally friendly and sustainable chemicals in the rubber industry. Research focusing on biocarbon derived from biomass as a replacement for carbon black has gained significant interest in addressing these environmental concerns. Biocarbon is a carbon-rich material derived from the pyrolysis of various biomass or biomass wastes, including agricultural and forestry wastes (Jiang et al., 2020). Those derived from a range of biomass material have been studied intensively as a filler in NR or synthetic vulcanizates. These sources coconut fiber and shells (Aguele and Madufor, 2012), birchwood (Peterson et al., 2016), molasses (Moryadee et al., 2018), sawdust (Otoikhian et al., 2019), rice husks (Xue et al., 2019), landscape wood waste (Peterson and Kim, 2020), lignin waste (Jiang et al., 2020), Paulownia elongata and Populus tremuloides wood (Peterson, 2020), leaves (Lay et al., 2020), coffee grounds (Raju et al., 2021), as well as straw fiber waste (Faga et al., 2022). However, using biocarbon as a filler in rubber vulcanizate still presents challenges, including issues related to large particle size, low surface activity, long processing time, impurities, material content, and varying properties (Jiang et al., 2020).

This study proposed comparison of a novel biocarbon material characteristic derived from carbonized wood and non-wood as a filler for natural rubber (NR) composites. Carbonized starch and tamarind wood were characterized, used, and studied in this experiment to substitute carbon black filler. It has still not been reported in the literature. Moreover, the particle size reduction of biocarbon will be explored to overcome the biocarbon particle size problems in the previous study (Jiang et al., 2020).

Natural rubber composites have been widely used to manufacture products that require good elasticity and vibration damping properties, such as tires, rubber seals, rubber isolators, etc. In the manufacturing of natural rubber composites, it commonly used filler in the form of particles or fiber. Biocarbon filler prepared from pyrolysis of starch and tamarind wood was characterized and used to manufacture natural rubber composites. Based on the characteristics of biocarbon filler and the properties of biocarbon-filled natural rubber composites, the correlation was studied to obtain the application of biocarbon in the manufacture of rubber products.

2.1. Production of Rubber Fillers from Biocarbon

Biocarbon based rubber filler made from cassava starch and tamarind wood. Initially, biocarbon was produced through pyrolysis technique at 450 °C for 7 hours (Tomczyk et al., 2020). The particle size reduction of formed biocarbon was held in mortar grinder and planetary ball mill, respectively. The latter process was carried out with weight ratio of biocarbon powder to grinding balls as 1:4.5 and grinding speed of 125 rpm for 2 hours (Naghdi et al., 2017), to obtain similar particle size of commercial carbon black (CB N990) as a comparison.

2.2. Characterization of Biocarbon

Biocarbon powder samples obtained from cassava starch, tamarind wood, and CB N990 were subjected to proximate analysis, including moisture, ash, volatile matter, and bound carbon contents per SNI 1683: 2021 standards. The degree of acidity (pH) of carbon was characterized using the JIS K 1474:2007 standard. Iodine absorption of rubber fillers from biocarbon and CB N990 was evaluated following the SNI 06-3730-1995 procedures. The bulk density of rubber filler from biocarbon was determined following the SNI 06-3730-1995 standard. Furthermore, particle size distribution was investigated using the Dynamic Light Scattering method using a PSA Nanoplus. The specific surface area of biocarbon rubber fillers, including the pore size, porosity, and pore volume, was determined by the static volumetric method using the JW-BK112 instrument. Functional group analysis of the powder fillers was evaluated using the FTIR spectrometry technique (Thermo Scientific Nicolet iS5). Finally, biocarbon particles' microstructure and surface morphology were determined using FESEM (JEOL-JIB-4610F).

2.3. Materials and Manufacture of NR Composite

NR composite was prepared by mixing materials (NR, fillers, and rubber chemicals) according to the standard of the American Society for Testing and Materials (ASTM) 3182 (Figure 1) standard. Type and dosage of NR, fillers, and rubber chemicals were used (Table 1). Dosage of materials is in phr (parts per hundred rubber) unite. Various types of rubber fillers were used namely carbon black N990 (CB), biocarbon derived from cassava starch (CP), and biocarbon derived from tamarind wood (CK).

Figure 1 Manufacturing stages of NR composite

Table 1 Type and dosage Materials for NR composite formula

Note: phr = parts per hundred rubber

2.4. Characterization of NR composite

The curing characteristics of the compound from NR composite were determined based on the ASTM D5289-12 standard method at 150 °C, using an Alfa 2000 moving die rheometer (Alfa Technologies. Akron. USA). The composite was tested for mechanical properties, including hardness, tensile strength, elongation at break and tear strength.

3.1. Chemical Characteristics of the Biocarbon

Table 2 exhibits the chemical characteristics of of biocarbon from cassava starch and tamarind wood and CB N990 as a rubber filler. The proximate value and pH value of the CP was better than CK, as indicated by the higher bonded carbon content and lower moisture, ash, and volatile matter content values. Even the chemical properties of CP was not significantly different from the chemical properties of commercial CB N990. These results indicate that the chemical properties of biocarbon are influenced by the type of biomass feedstock used (Das et al., 2021; Tomczyk et al., 2020).

Table 1 Chemical characteristics of CB N990 and biocarbon from cassava starch (CP) and tamarind wood (CK)

The volatile substances levels of biocarbon shows organic substances bound in charcoal which evaporate on heating without oxygen at a temperature of 950 °C. The test results (Table 2) shows that the volatile matter in CK is greater than CP and CB. Meanwhile, the volatile matter content of CP was not significantly different from CB. The volatile matter content in CK was 18.26%, while CP was 1.96%, and CB was 1.01%. The pyrolysis process of softwood biomass in microwave heating at 2700 Watt resulted 25% of volatile matter content (Wallace et al., 2019). Hence, the not wood raw material as CP produces lower levels volatile matter than CK.

Ash content reflects the mineral percentage in pyrolysis charcoal, determined by heating a sample without oxygen at 800°C. In Table 2, CK's ash content surpasses CP and CB, while CP and CB exhibit comparable ash content. On the other hand, CK's bonded carbon content is lower than CP and CB, with CP and CB showing no significant difference, indicating that tapioca starch-based biomass yields lower ash content and higher bonded carbon content compared to tamarin-based biomass, with similarities to CB.

Table 2 revealed that biocarbon acidity (pH) relates to carbonate and alkaline content, with CK, CP, and CB exhibiting pH values of 8.67, 7.59, and 7.25, respectively. The pH of biocarbon is generally alkaline aligns with the general range (7.1 to 10.5) and is influenced by biomass composition, oxygen functional groups, and carbonate content (Ronsse et al., 2013). Pyrolysis reduced carboxyl groups, deprotonating acid groups, leading to an alkaline pH.

3.2. Physical Characteristics of the Biocarbon

Table 3 presents the physical characteristics of cassava starch-derived biocarbon, resembling commercial CB N990 in particle size, surface area (evaluated via BET and Langmuir methods), total pore volume, and average pore diameter. In contrast, tamarind wood biocarbon exhibits smaller particle size, pore diameter, and surface area than cassava starch and commercial CB N990. The bulk density values indicate that tamarind wood particles are more easily broken-down during grinding compared to cassava starch.

Table 2 Physical characteristics of CB N990 and biocarbon from cassava starch (CP) and tamarind wood (CK)

The experimental results show that the milling process can produce a biocarbon particle size of 220.1 nm and 130 nm for cassava starch and tamarind wood, respectively. It successively degraded the particle size of cassava starch and tamarind wood to 61.9% and 83.7% compared to this original size. The particle size distribution of CP and CK biocarbon had 2 widely particles size distributions (Figure 2(a)) and become narrower and more uniform after the milling treatment, the particle size distribution in the biocarbon is narrower and more uniform (Figure 2(b). Previous studies have reported that utilizing a planetary ball mill yielded biocarbon particles as small as 60 nm (Naghdi et al., 2017).

Figure 2 Size and distribution of biocarbon particles. (a) before milling and (b) after milling

The absorption capacity of iodine in biocarbon particles obtained from cassava starch, tamarind wood, and CB N990 was 160.56 mg g-1, 463.04 mg g-1, and 109.6 mg g-1. These results showed that biocarbon particles from tamarind wood have a larger surface area than others. It was in line with the report that biocarbon from tamarind wood had a smaller particle size than cassava starch.

Using the BET method. biocarbon from cassava starch showed a surface area of 10.780 m2 g-1 while that from tamarind and CB N990 measured 297.078 m2 g-1 and 14.939 m2 g-1. Based on the Langmuir method, biocarbon particles from cassava starch recorded a surface area of 4.353 m2 g-1, while tamarind wood and CB N990 measured 416.388 m2 g-1 and 4.353 m2 g-1. These results showed that biocarbon particles from tamarind wood can interact with composite matrix in a large contact surface area compared to other samples.

The volume and pore diameter of particles was determined the pore type and correlated to particles surface area. Smaller particle pore diameter indicated a larger particle surface area. Table 3 shows that CK had larger pore volume values and smaller pore diameters of CP and CB. Furthermore, CB, CP, and CK had an average pore diameter value of 12.567 nm, 11.634 nm, and 2.378 nm, respectively. These pore size diameter was (2<(d)<50) nm, which classified as mesoporous types. CK had the smallest pore size diameter, so it had particle surface area, compared to CP and CB.

3.3. Carbon Surface Activity

The FTIR spectra of biocarbon fillers from cassava starch, tamarind wood, and commercial carbon from CB N990 are depicted in Figure 3. The functional groups formed on the surface of biocarbon particles are affected by the temperature of the pyrolysis process, C/H ratio, specific surface area, and ash content (Janu et al., 2021). Notably, biocarbon produced at pyrolysis temperatures of 300 and 450 °C had the same molecular functional groups on the surface. On the contrary, when subjected to higher pyrolysis temperatures, specific functional groups like alcohols, phenols, aromatics, ketones, and even aldehydes were no longer detected (Janu et al., 2021). Other studies also showed that the aliphatic, hydroxyls, and aromatic groups in biocarbon gradually diminish with increasing pyrolysis temperatures ranging from 400 to 1000 °C (Suman et al., 2021).

Figure 3 Spectra FTIR CB N990, biocarbon from cassava starch and tamarind wood

Alcohol, aromatic, and ketone functional groups were detected in CP and acids form alcoholic, aromatic, and alkene functional groups were detected in CK. Meanwhile, Functional groups was detected in CB i.e. alkyne, alkene, carbonyl, alcohol, and aromatic functional groups. The functional group of alkyne and alkene were only presence in CB, but not in CP or CK. Alkyne and alkene functional groups have double bonds on the carbon atom which are predicted to be more reactive for interactions with the NR matrix in the composite. This result correlates with the results of testing the strength properties of the material which are better according to the results in Figure 4 (tear and tensile strength). The NR composite containing CB N990 had higher strength properties compared to the composite containing biocarbon from cassava starch and tamarind wood.

3.4. Carbon Surface Morphology

The results of surface morphology testing (Figure 4) reveal that CB N990 particles were spherical, forming aggregates and agglomerates form, while biocarbon particles were non-spherical flakes. These formations show that the interactions between CB N990 particles were stronger than those from cassava starch or tamarind wood. According to the FESEM image, the particle size of biocarbon from cassava starch and tamarind wood was larger than the size of the aggregate of CB N990. The aggregate size of CB N990 was less than 1 m, while the particle size of biocarbon was larger than 1

m. The biocarbon particles were non-spherical and exhibited non-uniform shapes, with irregular arrangement and distribution, resulting in empty spaces.

(a) (b) (c)

Figure 4 FESEM image of the filler particles of CB N990 (a). biocarbon from cassava starch (b). and tamarind wood (c) at 10.000x magnification

3.5. Curing Characteristics of the Rubber Compound

The torque maximum (MH) and torque difference (MH-ML, ML (torque minimum)) values are curing characteristics of NR compounds, which significantly change with increasing filler content. The composite-containing biocarbon fillers had higher MH and (MH-ML) values than those with CB N990 (Table 4). The MH value represents the maximum crosslinks formed during vulcanization (Shi et al., 2019), while the (MH-ML) value or torsion delta indirectly correlates with the total crosslink density of the rubber compound (Shi et al., 2019). These values reflect the torque magnitude influenced by factors such as mobility of rubber molecular chains (Puspitasari and Cifriadi, 2022; Kazemi et al., 2022), interactions between rubber molecules and filler particles (Puspitasari and Cifriadi, 2022; Sowinska-Baranowska and Maciejewska, 2021), and interactions between filler particles (Sowinska-Baranowska and Maciejewska, 2021). Additionally, in composite with higher filler content, the size and shape of the filler particles were predicted to affect the torque value. Smaller particles with greater surface areas and non-spherical shapes tend to impede the mobility of rubber molecular chains, resulting in higher torque values.

Table 3 Curing characteristics of rubber compound on various types and amounts of fillers

Note: Torque maximum (MH), torque minimum (ML), torque difference (MH-ML), optimum cure time (t90), scorch time value (ts2)

In the process of producing finished rubber or rubber composites, determining the correct vulcanization time is a very important factor, which referred to optimum cure time (t90). Table 4 exhibits that the rubber composite containing CK filler had faster t90 and ts2 than CP and CB filled rubber composite. This effect can be possibly related to the acidity (pH) of biocarbon materials and carbon black N990, wherein acidic rubber compound chemicals can react with alkaline accelerators resulting in degradation of t90 and ts2.

3.6. Mechanical Properties of NR composite

Based on the NR composite formula (Table 1), filler type and content were studied on mechanical properties of NR composites. ZnO and stearic acid are rubber chemicals for activator agent on sulfur vulcanization system, while MBTS is used for accelerator agent on sulfur vulcanization process. Carbon double bond in the structure molecules of NR (Winarto et al., 2024) reacted with Sulphur to produce sulfide crosslink on the NR molecule chains through the vulcanization process (Figure 5).

Figure 5 Reaction NR with sulphur

The mechanical properties of various NR composites are shown in Figure 6. Several factors include particle size, surface area, structure, shape, surface activity, filler concentration, and degree of dispersed particles in the polymer matrix can influence of polymer composite (Mulyani et al., 2023; Robertson and Hardman, 2021). The hardness value of the NR composite containing biocarbon filler was higher than the parameter value of the NR composite containing CB N990, while the values of tensile strength and elongation at break expressed the opposite ones. Compared to the NR composite containing CB N990, formulations with 15, 30, and 50 phr of biocarbon derived from the tamarind wood experienced a decrease in tensile strength values of 10.3%, 26.6%, and 40.3%, respectively. Furthermore, for those containing 15, 30, and 50 phr of biocarbon from cassava starch, the tensile strength values dropped by 22%, 33%, and 40.7%.

NR composite containing 15 phr of biocarbon had a higher tear strength than NR-filled CB N990. However, the composites containing CB N990 had a greater tear strength than the NR composites containing 30 and 50 phr biocarbon. This phenomenon was attributed to the characteristics of the filler as shown in Tables 2 and 3, the functional groups on the filler particles as detailed in Figure 3, and the surface morphology of the particles in the NR composite matrix. The higher carbon content of the material, as demonstrated in Table 2, along with its functional groups (specifically alkyne and alkene groups), is attributed to this effect. The reinforcement mechanism of CB in rubber composites suggests that the functional groups on the surface of CB particles react with the composite matrix, thereby enhancing strength through reactions involving double bonds, sulfur, olefins, and radicals (Fan et al., 2020). It accounts for the superior strengthening properties of CB N990 over biocarbon in NR composite despite having a larger particle size and smaller surface area. Therefore, the surface activity of the filler, facilitating stronger interactions with the composite matrix, played a crucial role in enhancing its strengthening properties.

Figure 6 Mechanical properties of NR composite with variations in the type and amount of filler, (a) hardness, (b) tear strength, (c) tensile strength, and (d) elongation at break

Surface morphology of CB N990 particles (Figure 3) tends to form aggregations and agglomerates in the composite matrix while biocarbon particles do not tend to do so. It shows that the filler particles forming aggregates and agglomerates have stronger interactions. Therefore, the interaction strength between the fillers and the fillers and composite matrix can influence the mechanical properties of the composite (Kim et al., 2020). In addition, the holes between the biocarbon particles had potential material damage when subjected to mechanical loads (Ojogbo et al., 2021). Hence, the tensile strength of NR composite filled 30 and 50 phr of CB N990 were lower than those of composite containing biocarbon.

Hardness was influenced by matrix materials (Nasruddin and Susanto, 2020; Hafad, 2020), rubber fillers (Khalaf, 2022; Puspitasari and Cifriadi, 2022), and softeners (Nun-Anan et al., 2021; Murniati et al., 2020). The hardness properties of rubber composite showed a relationship between strengthening (Othman et al., 2022; Kim et al., 2020) and viscoelastic properties (Bakošová and Bakošová, 2022; Moonart and Utara, 2019), which alternately affected the hardness. Figure 4(a) showed that the hardness properties of rubber composite were influenced by viscoelastic properties, wherein hardness did not significantly increase along with the filler loading. Moreover, the hardness of NR composite containing biocarbon was higher than CB N990 according to the particle size of the filler.

A novel biocarbon material characteristic derived from carbonized starch and tamarind wood as a filler for natural rubber (NR) composites were studied in this experiment to substitute carbon black filler. It has still not been reported in the literature. Moreover, rubber composite produced in this experiment has a specific and different NR composite formula. Thus, the properties of carbonized starch and tamarind wood-filled NR composite could not be compared with the result of previous research.

In conclusion, using pyrolysis and ball mill methods produced biocarbon particles from cassava starch and tamarind wood with nanometer-scale dimensions of 220 nm and 130 nm, respectively. Biocarbon filler derived from tamarind wood had distinctive chemical and physical properties, featuring a larger particle surface area than cassava starch and CB N990. Regarding mechanical properties, the NR composite containing 15 phr biocarbon filler from tamarind wood showed tensile and tear strength properties significantly equivalent to formulations with CB N990. Based on the particle size, biocarbon filler derived from tamarind wood in NR composites was discovered to be promising at 15 phr of filler content for substituting petroleum-based carbon black N990 fillers.

The authors are grateful to the Directorate General of Higher Education, Research, and Technology, The Ministry of Education, Culture, Research, and Technology of the Republic of Indonesia, for funding the 2023 Doctoral Dissertation Research Scheme under contract No. 15871/IT3. D10/PT.01.02/P/T/2023 on April 13. 2023.

Aguele, F & Madufor, C 2012, ’Effects of carbonised coir on physical properties of natural rubber composites‘, American journal of polymer science, vol. 2, no. 3, pp. 28-34, https://doi.org/10.5923/j.ajps.20120203.02

Bakošová, D & Bakošová, A 2022, ’Testing of rubber composites reinforced with carbon nanotubes‘, Polymers, vol. 14, no. 15, article 3039, https://doi.org/10.3390/polym14153039

Das, SK, Ghosh, GK, Avasthe, RK & Sinha, K 2021, ’Compositional heterogeneity of different biochar: effect of pyrolysis temperature and feedstocks’ Journal of Environmental Management, vol. 278, no. 2, article 111501, https://doi.org/10.1016/j.jenvman.2020.111501

Faga, MG, Duraccio, D, Di Maro, M, Pedraza, R, Bartoli, M, d’Ayala, GG, Torsello, D, Ghigo, G & Malucelli, G 2022,‘Ethylene-Vinyl Acetate (EVA) containing waste hemp-derived biochar fibers: mechanical, electrical, thermal and tribological behavior‘, Polymers, vol. 14, no. 19, article 4171, https://doi.org/10.3390/polym14194171

Hafad, SA 2020, ‘Improving mixtures of natural and synthetic rubber with carbon black‘ International Research Journal of Advanced Engineering and Science, vol 5, no. 4, pp. 248-252

Janu, R, Mrlik, V, Ribitsch, D, Hofman, J, Sedlá?ek, P, Bielská, L & Soja, G 2021, ’Biochar surface functional groups as affected by biomass feedstock, biochar composition and pyrolysis temperature‘, Carbon Resources Conversion, vol. 4, pp. 36-46, https://doi.org/10.1016/j.crcon.2021.01.003

Jiang, C, Bo, J, Xiao, X, Zhang, S, Wang, Z, Yan, G, Wu, Y, Wong, C & He, H 2020, ’Converting waste lignin into nano-biochar as a renewable substitute of carbon black for reinforcing styrene-butadiene rubber’, Waste management, vol. 102, pp. 732-742, https://doi.org/10.1016/j.wasman.2019.11.019

Khalaf, ESA 2022, ’Studying the effect of silica on some physico-mechanical properties and morphological behavior of bagasse filled styrene butadiene rubber´, Science Journal of Chemistry, vol. 10, no. 3, pp. 73-80, https://doi.org/10.11648/j.sjc.20221003.13

Kim, DY, Park, JW, Lee, DY & Seo, KH, 2020, ’Correlation between the crosslink characteristics and mechanical properties of natural rubber compound via accelerators and reinforcement’, Polymers, vol. 12, no. 9, pp. 78-80

Lay, M, Rusli, A, Abdullah, MK, Hamid, ZAA & Shuib, RK 2020, ’Converting dead leaf biomass into activated carbon as a potential replacement for carbon black filler in rubber composites’, Composites Part B: Engineering, vol. 201, article 108366, https://doi.org/10.1016/j.compositesb.2020.108366

Moonart, U & Utara, S 2019, ’Effect of surface treatments and filler loading on the properties of hemp fiber/natural rubber composites‘, Cellulose, vol. 26, no. 12, pp. 7271-7295, https://doi.org/10.1007/s10570-019-02611-w

Moryadee, P, Tuamkeaw, S & Saowapark, T 2018, ’Effect of modified molasses carbon filler on mechanical properties of natural rubber vulcanizates’, Current Applied Science and Technology, vol. 18, no. 3, pp. 145-155, https://doi.org/10.14456/cast.2018.11

Mulyani, RWE, Nuruddin, A, Suprijanto & Sunendar Purwasasmita, B 2023, ’Silica-chitosan nanocomposite coatings for enhancing hydrophilicity of polyester fabric‘, International Journal of Technology, vol. 14, no. 4, pp. 761-769, https://doi.org/10.14716/ijtech.v14i4.4786

Murniati, R, Rahmayanti, HD, Utami, FD, Cifriadi, A, Iskandar, F & Abdullah, M 2020, ‘Effects of magnetically modified natural zeolite addition on the crosslink density, mechanical, morphological, and damping properties of SIR 20 natural rubber reinforced with nanosilica compounds‘, Journal of Polymer Research, vol. 27, pp. 1-13, https://doi.org/10.1007/s10965-020-2013-0

Naghdi, M, Taheran, M, Brar, SK, Rouissi, T, Verma, M, Surampalli, RY & Valero, JR 2017, ’A green method for production of nanobiochar by ball milling-optimization and characterization’, Journal of Cleaner Production, vol.164, pp. 1394-1405, https://doi.org/10.1016/j.jclepro.2017.07.084 .

Nasruddin, N & Susanto, T 2020, ’Study of the mechanical properties of natural rubber composites with synthetic rubber using used cooking oil as a softener’, Indonesian Journal of Chemistry, vol. 20, no. 5, pp. 967-978, https://doi.org/10.22146/ijc.42343

Nun-Anan, P, Hayichelaeh, C & Boonkerd, K 2021, ’Effect of a natural processing aid on the properties of acrylonitrile-butadiene rubber: study on soybean oil fatty acid from seed crop‘, Polymers, vol. 13, no. 20, article 3459, https://doi.org/10.3390/polym13203459

Ojogbo, E, Tzoganakis, C & Mekonnen, TH 2021, ’Effect of extrusion, batch-mixing, and co-coagulation on the dispersion of CNCs in natural rubber-CNC nanocomposites‘, Composites Part A: Applied Science and Manufacturing, vol. 149, article 106580, https://doi.org/10.1016/j.compositesa.2021.106580

Othman, NH, Mustapha, M, Sallih, N, Ahmad, A, Mustapha, F & Ismail, MC 2022, ’The effect of residual solvent in carbon? based filler reinforced polymer coating on the curing properties, mechanical and corrosive behaviour‘, Materials, vol. 15, no. 10, article 3445, https://doi.org/10.3390/ma15103445

Otoikhian, K, Adeniyi, A, Dada, A & Ighalo, J 2019, ’Assessment of carbonised wood-flour fillers on the mechanical properties of natural rubber vulcanisates’, European Journal of Sustainable Development Research, vol. 3, no. 4, pp. 1-10, https://doi.org/10.29333/ejosdr/5860

Peterson, SC & Kim, S 2020, ’Reducing biochar particle size with nanosilica and its effect on rubber composite reinforcement’, Journal of Polymers and the Environment, vol. 28, no. 1, pp. 317-322, https://doi.org/10.1007/s10924-019-01604-x

Peterson, SC 2020, ’Coppiced biochars as partial replacement of carbon black filler in polybutadiene/natural rubber composites’, Journal of Composites Science, vol. 4, no. 4, article 147, https://doi.org/10.3390/jcs4040147

Peterson, SC, Chandrasekaran, SR & Sharma, BK 2016, ’Birchwood biochar as partial carbon black replacement in styrene–butadiene rubber composites’, Journal of elastomers & plastics, vol. 48, no. 4, pp. 305-316, https://doi.org/10.1177/0095244315576241

Probst, N, Löffler, M & Lloyd, A 2012, ’Pyrolysis carbon black, an op-portunity for the rubber industry’, KGK. Kautschuk, Gummi, Kunststoffe, vol. 65, no. 11-12, pp. 20-29

Puspitasari, S & Cifriadi, A 2022, ’Carbon black and lignin hybrid filler in designing nr based cushion gum composite formulation’, Journal of Engineering and Technological Sciences, vol 54, no. 2, article 220213, https://doi.org/10.5614/j.eng.technol.sci.2022.54.2.13

Raju, G, Khalid, M, Shaban, MM & Azahari, B 2021, ’Preparation and characterization of eco-friendly spent coffee/ENR50 biocomposite in comparison to carbon black’, Polymers, vol. 13, no. 16, article 2796, https://doi.org/10.3390/polym13162796

Robertson, CG & Hardman, NJ 2021, ’Nature of carbon black reinforcement of rubber: Perspective on the original polymer nanocomposite’, Polymers, vol. 13, no. 4, article 538, https://doi.org/10.3390/polym13040538

Ronsse, F, Van Hecke, S, Dickinson, D & Prins, W 2013, ’Production and characterization of slow pyrolysis biochar: influence of feedstock type and pyrolysis conditions’, Gcb Bioenergy, vol. 5, no. 2, pp. 104-115, https://doi.org/10.1111/gcbb.12018

Shi, G, Wang, W, Lu, H, Wang, G, Yang, F & Rui, X 2019, ’Study of crosslink structure and dynamic mechanical properties of magnetorheological elastomer: Effect of vulcanization system’, Journal of Intelligent Material Systems and Structures, vol. 30, no. 8, pp. 1189-1199, https://doi.org/10.1177/1045389X19835940

Shieddieque, AD, Mardiyati, RS & Widyanto, B 2021, ’Preparation and characterization of sansevieria trifasciata fiber/high-impact polypropylene and sansevieria trifasciata fiber/vinyl ester biocomposites for automotive applications’, International Journal of Technology, vol. 12, no. 3, pp. 549-560, https://doi.org/10.14716/ijtech.v12i3.2841

Sowi?ska-Baranowska, A & Maciejewska, M 2021, ’Influence of the silica specific surface area and ionic liquids on the curing characteristics and performance of styrene–butadiene rubber composites’, Materials, vol. 14, no. 18, article 5302, https://doi.org/10.3390/ma14185302

Suman, S, Yadav, A, Jain, T & SK, AA 2021, ’Study in the changes on the functional groups present in biomass during pyrolysis process’, In: IOP Conference Series: Materials Science and Engineering, vol. 1146, article 012023, https://doi.org/10.1088/1757-899X/1146/1/012023

Tomczyk, A, Soko?owska, Z & Boguta, P 2020, ’Biochar physicochemical properties: pyrolysis temperature and feedstock kind effects’, Reviews in Environmental Science and Bio/Technology, vol. 19, pp. 191-215, https://doi.org/10.1007/s11157-020-09523-3

Wallace, CA, Afzal, MT & Saha, GC 2019, ’Effect of feedstock and microwave pyrolysis temperature on physio-chemical and nano-scale mechanical properties of biochar’, Bioresources and Bioprocessing, vol. 6, no.33, pp. 1-11, https://doi.org/10.1186/s40643-019-0268-2

Winarto, DA, Liza, C, Fathurrohman, MI, Masa, A & Chalid, M 2024, ’Study of solvent and catalyst in diimide biphasic hydrogenation system of natural rubber’, International Journal of Technology, vol. 15, no. 2, pp. 414-424, https://doi.org/10.14716/ijtech.v15i2.6683

Xue, B, Wang, X, Sui, J, Xu, D, Zhu, Y & Liu, X 2019, ’A facile ball milling method to produce sustainable pyrolytic rice husk bio-filler for reinforcement of rubber mechanical property’, Industrial Crops and Products, vol. 141, article 111791, https://doi.org/10.1016/j.indcrop.2019.111791

Zweid, MN, Ubaid, AQ & Kamas, AS 2021, ’Study of thermal conductivity and hardness test of carbon black / polymer micro composite’, Journal of Physics: Conference Series, vol. 1892, no. 1, https://doi.org/10.1088/1742-6596/1892/1/012003