Modified Polymetallic Zeolite-Based Catalysts for Hydroprocessing Diesel Oil Fraction and Tetradecane

Corresponding email: Erdos.Ongarbaev@kaznu.kz

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6746

Tuktin, B., Omarova, A., Saidilda, G., Nurzhanova, S., Tungatarova, S., Ongarbayev, Y., 2024. Modified Polymetallic Zeolite-Based Catalysts for Hydroprocessing Diesel Oil Fraction and Tetradecane. International Journal of Technology. Volume 15(4), pp. 812-823

| Balga Tuktin | D.V.Sokolsky Institute of Fuel, Catalysis and Electrochemistry, 142 Kunaev Str., Almaty, 050010, Kazakhstan |

| Aizhan Omarova | Faculty of Chemistry and Chemical Technology, Al-Farabi Kazakh National University, 71 Al-Farabi Pr., Almaty, 050040, Kazakhstan |

| Galymzhan Saidilda | D.V.Sokolsky Institute of Fuel, Catalysis and Electrochemistry, 142 Kunaev Str., Almaty, 050010, Kazakhstan |

| Saule Nurzhanova | D.V.Sokolsky Institute of Fuel, Catalysis and Electrochemistry, 142 Kunaev Str., Almaty, 050010, Kazakhstan |

| Svetlana Tungatarova | D.V.Sokolsky Institute of Fuel, Catalysis and Electrochemistry |

| Yerdos Ongarbayev | Faculty of Chemistry and Chemical Technology, Al-Farabi Kazakh National University, 71 Al-Farabi Pr., Almaty, 050040, Kazakhstan |

According to international standards, motor fuels require limits on the content of sulfur, benzene, aromatic and olefinic hydrocarbons. To achieve this goal, it is necessary to create new, active and selective catalysts and improve technologies for deep hydrotreating and hydroprocessing. Tetradecane and diesel oil fraction hydroprocessing on modified zeolite-containing Ni(Co)-Mo(W)/Al2O3-ZSM-5 catalysts were studied under varying process conditions. The novelty of the work lies in the synthesis of new catalysts based on ZSM-5 type zeolite, modified with metals Ni(Co)-Mo(W) and active additives of rare earth metals and phosphorus. After hydrotreating the diesel oil fraction on the catalyst KT-3, the pour point decreases from -27 to -57°C, the sulfur level decreases from 0.141 to 0.059%, and the yield of the liquid phase is 92.2%. The lowest content of residual sulfur (0.005%) is observed on the KT-4 catalyst at 400°C. Electron microscopic examinations have demonstrated that the modified zeolite-containing catalysts are distributed in a highly dispersed manner, and the metal components in the active phase are primarily in the oxidized state, generating associate clusters on the surface, the dispersion, structure and state of which is influenced by the catalyst components' characteristics. The developed modified zeolite-containing catalysts have multifunctional properties and simultaneously carry out the reactions of hydrocracking, hydroisomerization, hydrodesulfurization and dehydrogenation.

Catalyst; Diesel fraction; Hydroprocessing; Motor fuel; Tetradecane

The

efficient use of petroleum feedstock is potentially achieved by catalytic

processing of hydrocarbons into practical important products. In this context,

a key source of energy is diesel fuel, which is economical, environmentally

friendly, practical, and generally effective in many industrial processes

requiring large amounts of energy. Diesel engines are capable of providing stable

and reliable power for a variety of industrial applications.

The

growing trend of performance requirements for motor fuel underscores the need

to develop new technological and environmental solutions for oil refining. This fuel is the main component of plastics,

synthetic fibers, resins, rubbers, dyes, surfactants, and pharmaceutical

products.

Hydrotreating stage in petroleum raw material

processing ensures the production of clean motor fuel that meets environmental standards. Further intensification of

production relies on developing new, more active, and selective catalysts. In

this context, an important and topical issue is the formation of efficient

catalytic systems for hydroprocesses. Zeolite catalysts, particularly when based on highly silica

zeolite of the pentasil family, are a promising material in the petrochemical

and oil refining industry (Suhartono et al.,

2023). These catalysts are widely used due to the unique microporous structure

and acid-base properties, which enable the conversion of light alkanes into

valuable products during petrochemical synthesis (Zhang

et al., 2023).

Various studies

have synthesized hydrocracking catalysts with different zeolites to investigate

the role of modified zeolite-Y in crude oil hydroconversion (Ding et al.,

2021). The results showed that catalysts with high acidity, strong acid

sites, and mesopores could improve crude oil conversion.

A previous study (Huseynova et al.,

2022) provided an overview of zeolite-based catalysts used in the

alkylation of benzene and toluene with olefins, isobutane, and butenes with

butane-butene fractions, gasoline and oil fractions with olefins, as well as

propane-propylene and butane-butylene fractions of catalytic cracking. Developing novel technologies in

this field requires a new generation of catalysts for the processing of

hydrocarbon raw materials. International standards mandate that motor fuel

contains a significant amount of sulfur, benzene, aromatic hydrocarbons, and

olefin hydrocarbons.

Catalytic hydroprocessing of sulfurous and

paraffinic oils, comprising hydrotreatment, hydroisomerization, and

hydrogenation, achieves a high degree of quality for commercial products.

Hydrodesulfurization, a chemical change that removes sulfur from gas and

refined crude products such as gasoline, jet fuel, kerosene, alongside diesel

and fuel, upgrades the octane number of the resolvent streams (Sikkander et al., 2022).

A study by (Majodina et al.,

2023) compared traditional hydroprocessing and recently improved

catalysts, detailing the chemical considerations underlying the selection of

mineral materials used in both. Furthermore, investigations into the electronic

interactions of more economical and abundant metals including Nb, V, and Fe

with other elements and supporting materials have led to a better understanding

of the synergistic effects that help access noble metal-like properties.

To increase the production of petroleum

products, expand the range, and improve quality, it is necessary to change the

existing oil refining technology using highly efficient catalysts. A highly

promising CoMo catalyst for hydrotreating low-pressure diesel fuel on carriers

made of thermally activated aluminum hydroxide was investigated in comparison

with a commonly imported analog (Salnikov et al., 2023). Previous studies

also developed technologies

suitable for processing rehydrated pseudoboehmites from flash-calcined aluminum

hydroxide to prepare

catalysts for hydrotreating light and heavy oil fractions (Bayanov

et al., 2023). Modification with metals enhances

catalyst acidity, improving catalytic performance, conversion, and selectivity/yield

toward the product (Mavai, 2022). To advance the field of study, new multifunctional catalysts are

needed to effectively hydrotreat diesel fractions in a single stage. This

entails removing sulfur-containing compounds, hydrogenating unsaturated and

aromatic compounds, hydroisomerization, and selective hydrocracking of

n-paraffin hydrocarbons (Tuktin et al., 2021).

The development of new and highly efficient

catalysts for hydroimprovement of diesel fractions is crucial (Janardhan, Shanbhag and Halgeri, 2014; Zhang et al., 2010; Saih and Segawa, 2009; Rodriguez-Castellon,

Jimenez-Lopez, and Eliche-Quesada, 2008). A previous study (Fitri et al.,

2022) used citronella oil as a dietary supplement to diesel fuel.

Citronella fractions and oil have shown great potential as bio-additives to

diesel fuel, evidenced by acceptable density and viscosity in tested various

concentrations (0.1 - 0.5%). Co-Ni/HZSM-5 catalyst with a hierarchical

porous structure was tested for hydrocracking of vegetable oils at a

temperature of 400°C, and a

pressure of 20 bar for 2 hours. The liquid product had similar hydrocarbon

compounds to petroleum diesel fuel, with the most common being pentadecane and

heptadecane (Marlinda et al., 2022).

The influence of technological regimes on the

yield and hydrocarbon composition of products formed during the cracking of

commercial and M-100 fuel oil in the presence of air in the reactor was studied

by (Shakiyeva

et al., 2022). Natural Taizhuzgen zeolite

and Narynkol clay were used to prepare catalysts.

Sulfide catalysts were reportedly obtained

through mechanochemical combination of commercial powders including molybdenum,

cobalt, and nickel (Fedushchak et al., 2019). The study discussed the activity of catalysts

in model hydrodesulfurization reactions of dibenzothiophene and

4,6-dimethyldibenzothiophene as well as in hydrotreating S-components of diesel

fraction. Based on previous reports, the higher activity of Ni-based catalysts

is due to the superior hydrogenizing capacity. Studies by (Altynov et al.,

2023; Aleksandrov, Buhtiyarova and Reshetnikov, 2019) examined the

behavior of CoMo/Al2O3 catalyst in hydrotreating a

straight-run diesel fraction with a high sulfur content (more than 2 wt.%) mixed

with light gas oil in the temperature range of 335 - 365°C at a volumetric feed

rate of 0.8 - 2.5 h-1. Adding gas oil to the straight-run diesel

fraction during hydrotreating has diverse effects based on the temperature and

feed rate of the raw materials (Tanimu et al., 2022).

A study examined catalytic abilities of

trimetallic NiMoWS catalysts supported on aluminum oxide during hydrotreating

of straight-run diesel fraction (Nikul’shina et al., 2019). The results showed

that the oxide precursor’s nature had a significant effect on catalytic

activity. Mixing n-heptane, n-dodecane, tetralin, and decalin with diesel fuel

linearly changes density, viscosity and improves atomization (Wei et al.,

2022). The study by (Jaroszewska et al., 2021) showed that

catalysts containing titanium (HTiMCM-41 and NiMo/HTiMCM-41) improved textural

properties, as well as acidity and binding energy with the metal substrate than

Al-based analogs (HAlMCM -41 and NiMo/HAlMCM-41). Replacing aluminum or

titanium in modifying MCM-41 zeolite significantly affects the properties and

activity of Ni catalysts.

Typical transition metal

sulfides Ni/Co-promoted Mo, as well as W-based bi- and tri-metallic catalysts,

are used for selective removal of sulfur from refractory compounds. The review (Prihadiyono et

al., 2022; Leon et al., 2019) examined three very

specific topics of catalysts to produce ultra-low sulfur diesel. Furthermore, (Winarto et al., 2024) explored a biphasic hydrogenation

approach using solid NR dissolved in a solvent and a hydrogen source (hydrazine

hydrate and hydrogen peroxide) mixed in water. The choice of solvents,

catalysts, and the water-to-solvent volume ratio were examined for the impact on

hydrogenation.

Studies on developing effective catalysts and

technologies to process diesel fractions into valuable chemical products and

motor fuel are crucial (Laredo et al., 2020; Kar, Göksu and Yalman, 2018). The production of high-quality commercial petroleum products can

be achieved using catalysts prepared based on aluminosilicates with a zeolite

structure of the ZSM-5 type for hydrorefining diesel oil fractions (Tuktin et al.,

2022).

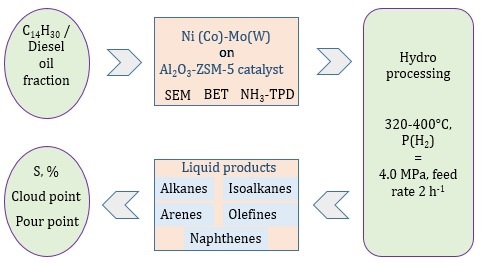

This study investigated hydroprocessing of tetradecane and diesel oil fraction oil on zeolite catalysts modified using

metals of variable valence. A series of new

catalysts with matrix structure Ni(Co)-Mo(W)/Al2O3-ZSM-5

were synthesized as shown in Table 1.

Table

1 Composition

of the developed catalysts

|

No. |

Catalyst sample |

Catalyst components |

|

1 |

KT-1 |

CoO-MoO3-P2O5-La2O3/Al2O3-ZSM-5 |

|

2 |

KT-2 |

CoO-WO3-P2O5-La2O3/Al2O3-ZSM-5 |

|

3 |

KT-3 |

NiO-MoO3-P2O5-La2O3/Al2O3-ZSM-5 |

|

4 |

KT-4 |

CoO-NiO-MoO3-P2O5-La2O3/Al2O3-ZSM-5 |

The synthesis of modified zeolite-based catalysts was performed by saturating a mixture of peptized aluminum hydroxide and zeolite ZSM-5 (China) with aqueous solutions of metal salts. These include (NH4)10W12O41×5H2O (Cherkasy chemical reagents plant, Russia), Ni(NO3)2×6H2O (Ural Chemical Plant, Russia), Co(NO3)3×6H2O (Novosibirsk Rare Metals Plant, Russia), (NH4)6MO7O24×4H2O (Cherkasy chemical reagents plant, Russia), La(NO3)3×6H2O (Novosibirsk Rare Metals Plant, Russia) and modifying additives. After molding, catalysts were dried at 150°C and calcined at 550°C for 5 hours. Before the experiments, catalysts were subjected to preliminarily sulphidation to increase activity in the reactor. The synthesized catalysts were tested through hydroprocessing tetradecane and diesel oil fraction using flow-through installation (Figure 1) with a stationary catalyst bed. The testing conditions included temperature ranging from 320-400°C, hydrogen pressure of 4.0 MPa, and a volumetric feed rate of 2 h-1.

Hydrocarbon composition of reaction products

was analyzed using Khromatek-Kristall and Khromatek-Kristall 5000

chromatographs (Russia). The chromatograph calculates the fractional

composition automatically. For the analysis of hydrocarbons, a glass column 3 m

long, 4 mm in diameter, filled with g-Al2O3 was used. The

integral selectivity (S) of aromatization, dehydrogenation, and cracking was

calculated using the formula S = Y/X, where Y is the yield of products; and X

is the feedstock degree of conversion.

The analysis of sulfur content, pour point, as well as cloud point of diesel oil fraction and products of hydroprocessing was carried out at Oilsert International LLP (Almaty, Kazakhstan). Various methods were used to analyze the physical and chemical characteristics of the developed catalysts. Surface area and porosity were measured by BET method on an AccuSorb unit manufactured by Micromeritics (USA), while electron microscopy was performed using an EM-125K transmission electron microscope (Williams and Carter, 2009). Microdiffraction images were interpreted using standard ASTM tables. To examine the number of acid sites and their strength distribution, the method of temperature-programmed desorption of ammonia was used (Mustafayeva, 2012).

Figure 1 Scheme of a laboratory installation

of

hydroprocessing, where 1 – burette, 2 – pump; 3, 7, 12, 14 – valves; 4, 8 –

pressure gauges; 5 – hydrogen cylinder; 6 – reducer; 9 – reactor; 10 –

refrigerator; 11 – rotameter; 13 – separator; 15 – flask

The development of

new catalysts effective for processing low-solidification diesel oil fractions

into high-octane products is currently a major concern. The original diesel oil fraction

has the following characteristics: pour point -27°C, cloud point -18°C, and a high content of

n-alkanes, which solidifies at higher temperatures compared to branched analogs. In

addition, the sulfur

content is approximately 0.141%.

Tetradecane, an n-alkane, and a component of

diesel oil fraction was used as a hydrocarbon model. The conversion of

tetradecane on the developed modified zeolite-based catalysts was studied by

varying the technological parameters of the process.

During hydroprocessing of n-tetradecane on KT-1 catalyst (Figure 2), the liquid catalysate formed

n-alkanes, isoalkanes,

olefins, aromatic

hydrocarbons, and naphthenes. With an increase in temperature from 320 to 400°C, the degree of

conversion increased from 41.2 to 74.5%. The yield of the liquid phase

decreased from 92.3 to 54.1% with an increase in temperature. In addition, the yield of

isoalkanes and aromatic hydrocarbons on KT-1 catalyst increased from 12.9

to 22.3% and 5.5 to 18.3%, respectively. Based on the results, the content of

olefins and naphthenic hydrocarbons varied insignificantly.

On KT-2 catalyst, hydroprocessing of tetradecane led to an increased content of isoalkanes, rising from 15.0 to 35.3% as the temperature rose from 320 to 400°C, while the amount of aromatic

hydrocarbons decreased from 5.1% to 6.3%. During hydroprocessing

of tetradecane on synthesized catalysts, the highest yield of isoalkanes was

observed on KT-3 catalyst at 400°C. Based on the results, a sharp rise was

observed in the yield of isoalkanes from 17.1 to 37.7% with an increase in

temperature.

Compared to

other catalysts, KT-4 produced a smaller quantity of olefinic hydrocarbons as

reaction products. A rise in the temperature from 320 to 400°C led to a change

in the conversion from 38.8 to 83.4%. Under these conditions, isoalkanes and

aromatic hydrocarbons increased from 13.4 to 30.5% and 6.2 to 19.2%,

respectively, while the naphthenes content decreased from 3.0 to 2.3%.

For all catalysts studied, the degree of tetradecane conversion increased with rising reaction temperature. Based on the results, the developed modified zeolite-based catalysts showed polyfunctional properties, simultaneously facilitating isomerization of n-alkanes, dehydrogenation, and dehydrocyclization.

Figure 2

Results and composition of tetradecane hydroprocessing products using catalysts

CoO-MoO3-P2O5-La2O3/Al2O3-ZSM-5

(KT-1), CoO-WO3-P2O5-La2O3/Al2O3-ZSM-5

(KT-2), NiO-MoO3-P2O5-La2O3/Al2O3-ZSM-5

(KT-3) and CoO-NiO-MoO3-P2O5-La2O3/Al2O3-ZSM-5

(KT-4)

Catalysts were evaluated during hydroprocessing of diesel oil fraction (Figure 3). At a temperature of 400°C, the lowest sulfur content (0.005%) was observed on KT-4 catalyst. The pour point of diesel oil fraction decreased by 15 - 30°C compared to the feedstock after hydroprocessing on the developed catalysts.

Figure 3 Results of diesel oil fraction

hydroprocessing on KT-3 and KT-4

catalysts

KT-3 catalyst produced the most

significant drop in pour point. After hydroprocessing of diesel fraction at

400°C, the pour point dropped to -57°C, and the yield of the liquid phase was

92.2%.

During hydroprocessing of diesel fraction on

the developed catalysts, simultaneous reactions of hydroisomerization,

hydrotreatment, and hydrocracking were observed. For example, after

hydroprocessing of diesel oil fraction on KT-3 catalyst at 400°C, the sulfur

content decreased from 0.141 to 0.059%, and the pour point reduced from -27 to

-57°C. On KT-4 catalyst at 400°C, the reduction reached 0.005% and -55°C respectively.

Catalyst activity is influenced by surface

structure, composition, and state of active sites. Different methods can be

used to investigate the physicochemical traits of catalysts including BET,

temperature-programmed desorption of ammonia, and electron microscopy.

BET analysis showed that the surface area of

the developed catalysts ranged from 221.0-285.0 m2/g and the pore

diameter was between 1.5-3.5 nm. Furthermore, the acid-base characteristics of

catalysts are essential for hydrocarbon processing process. In a previous study

(Wei et al., 2020), Ni-Mo catalysts

supported on Ni-modified ZSM-5 zeolites prepared by co-impregnation method

showed higher stability and isomerization selectivity in n-octane

hydroconversion. This enhanced property was attributed to the synergistic

effect between Brønsted acid sites and Lewis acid sites on catalysts. The

acid-base properties of catalysts were determined through

temperature-programmed desorption of ammonia (Table 2).

Table 2 Acid-base properties of catalysts

|

Catalyst |

Desorption

temperature, 0C |

Desorbed

NH3, 10-4 mole/g catalyst |

|

KT-1 |

195 |

23.4 |

|

KT-2 |

185 |

28.0 |

|

KT-3 |

220 |

32.5 |

|

KT-4 |

225 |

29.6 |

The data showed that acid centers with a desorption temperature of 195°C predominated on the surface of KT-1 The data showed that acid centers with a desorption temperature of 195°C predominated on the surface of KT-1 catalyst, with a concentration of 23.4×10-4 mole/g. The amount of ammonia desorbed from the surface of KT-2 catalyst was 28.0×10-4 mole/g and the concentration of acid sites on KT-3 catalyst was 32.5×10-4 mole/g. On the surface of KT-4 catalyst, ammonia was adsorbed in two forms with Tmax equal to 185 and 225°C. KT-3 catalyst, characterized by the highest concentration of acid sites (32.5×10-4 mole/g) and an average binding energy corresponding to desorption temperature of 220°C, demonstrated high hydroisomerization activity in hydroprocessing of tetradecane and diesel oil fraction. Metals with different degrees of oxidation can be found in the composition of acid sites, attached both inside and on the outer surface of the zeolite cavities, ensuring the multifunctionality of catalytic system.

Catalyst activity is influenced by the

surface structure, phase composition, and the state of modifying additives. In

the study by (Abdullaev et al., 2021), the surface of SSZ-13 zeolite was modified with varying amounts

(1-15%) of tungsten oxide, demonstrating significantly improved selectivity and

yield of propylene from ethylene. This enhancement was attributed not only to

softer and reduced strong acid sites but also to limited diffusion of bulky

products, as confirmed by scanning transmission electron microscopy and

energy-dispersive X-ray spectroscopy (STEM-EDS) data. An electron microscopy

study was carried out to examine the structure and state of active centers in

catalysts promoted by Co, Ni, Mo, and W, among others.

Electron microscopic studies showed that on

the surface of KT-1 catalyst (Figure 4a), extensive accumulations of small

particles were observed with diameter 3.0 - 5.0 nm, corresponding to a mixture

of MoOPO4, La2O3, MoO5, and La2MoO3

phases. Small accumulations of highly dispersed particles with 8.0 - 10.0

nm in size were also found, which could be attributed to La4(P2O7)3.

Furthermore, there were small transparent aggregates with d 20.0 nm related

to LaAlO3 in the

La° mixture. The emergence of

La° could be

connected to redox processes occurring between the active phase components.

The nature of the components in complex

polymetallic catalysts for hydroprocessing of hydrocarbons has a significant

effect on the dispersion and state of active centers. Formations with diameter

4.0 - 6.0 nm, consisting of AlLa3, Co2O3, Co2SiO3,

and La6O11, were prevalent on the surface of KT-1 catalyst (Figure 4b). Cobalt

formed single structures of metallic Co° with a diameter of 2.5 nm on the

surface. Additionally, there were accumulations (d 15.0 nm) of small

particles (d

2.5 nm) consisting of CoSi, CoSi2, and MoPCo2;

lamellar particles (d

15.0 nm) such as MoPCo2Si, CoO, and Mo3Si;

semitransparent structures (d

2.5 nm) namely MoO(OH)2, Co2O3,

MoP2, Co3Al3Si4, and SiP2O7;

alongside particles with d

6.0 - 10.0 nm, including LaP, MoO3, and

Mo3Si. Accumulations containing Co2Mo3O8,

LaP2O7, AlPO4, CoOOH, MoOPO4,

Co(P2O7), and La(MoO4)2 had

particles with different shapes in the range of 50-200 nm in diameter. In

addition, there were particles 4-5 nm in size including La4(P2O7)3,

CoSi, MoP, MoSi2, La6O11, and CoMoP2

Highly

dispersed structures of AlNi, Ni2O3, Mo3O5,

and Mo5Si3 with d 2.0 nm were predominant on the

surface of KT-3 catalyst

(Figure 5). There were well-spaced small accumulations of MoNiSi, Ni2O3,

MoSi2, and M6O11 particles with diameter 6.0 -

10.0 nm. In addition, the oxidized states of nickel Ni2O3

formed single islands, with a size ranging from 5.0 to 10.0 nm (Figure 5a).

KT-3 catalyst was defined by clusters measuring 3.0 - 4.0 nm, formed by fine

particles with d = 0.05 nm, containing NiSi2 and Ni2O3.

Particles with hexagonal faceting and diameters between 15.0 and 30.0 nm were

also found, composed of AlNi2Si, AlNi, La2O3,

MoO(OH)2)2, AlMo3, MoSi2, and Al3La

(Figure 5b). The discovered structures of AlNi2Si, AlMo3,

AlNi, MoSi2, and LaAlO3 NiSi2 indicated the

incorporation of metal components from the active phase into the zeolite

structure with the formation of new centers that could work as Lewis acid

centers.

During

hydroprocessing on polyfunctional catalysts with dehydrogenating,

hydrogenating, and acidic abilities, n-alkane dehydrogenation occurs first on

the metal centers, and the olefin produced on the acid center is converted into

a carbonium ion, which is easily isomerized (Tuktin et al., 2019). Mo5O7(OH)2, MoO3,

NiMO4, CoOOH, NiOOH, AlLa3, P and La, MoNiP, Ni2O3

particles with diameter ranging from 10.0 - 15.0 nm along the edge of dense and

large aggregates were discovered on the surface of KT-4 catalyst (Figure 6a). Additionally,

numerous loose formations of Mo3O5, Mo5Si3,

Mo6O11, Al3Ni,

Ni2O3, and PLa2 were observed with diameter of

3.0 - 5.0 nm. There were also clusters of AlNi2Si and Mo3O5

particles with diameters of 3.5 - 4.0 nm (Figure 6b).

Electron microscopy studies showed that particles

on the surface of the developed catalysts were highly dispersed, with sizes ranging

from 2.0 to 10.0 - 20.0 nm depending on the nature of the modifier metal and

the amount of zeolite introduced. All the studied catalysts were characterized

by the incorporation of modifier metals into the matrix structure with the

formation of CoSi, CoSi2, MoPCo2Si, Co3Al3Si4,

Mo3Si, Co2Si, Mo5Si3, AlNi, MoNiSi,

MoSi2, AlNi2Si, and W(Si, Al)2. These

structures can function as Lewis acid sites, while the phosphorus-containing

centers including SiP2, PLa2, MoNiP, LaP, and Co2P

are also quite strong acidic centers. The modification of catalysts leads to

the formation of highly dispersed heteronuclear clusters of complex

composition, which are active in hydrotreatment and hydroisomerization reactions

of diesel oil fraction (Gackowski et

al., 2020).

Studies have identified several types of surface

structures found on the surface of these catalysts, differing significantly in

size and chemical state of components. For instance, a small amount of

hierarchical Y zeolite (10 %) mixed with alumina, nickel nitrate, and

molybdenum oxide in the light diesel fuel hydrocracking catalyst, played a key

role in selectively hydrogenating naphthalene and further ring-opening activity.

The mesoporous structure of zeolite provided an effective interface and

improved the accessibility of acid sites for bulk reagents (Zhang et al., 2020).

According to electron microscopy data, the active

phase catalyst components are mostly in the oxidized state, creating associate

clusters on the surface. The dispersion, structure, and nature of the modifying

additives in catalyst determine the active state.

In conclusion, this study evaluated

hydroprocessing of tetradecane and diesel oil fraction using new modified zeolite-based

Ni(Co)-Mo(W)/Al2O3-ZSM-5 catalysts under varying process

conditions. The developed catalysts used in hydroprocessing diesel oil fraction showed polyfunctional properties, simultaneously facilitating hydrocracking, hydroisomerization,

hydrodesulfurization, and dehydrogenation reactions. These results suggest that modification using

metals with variable valence allows proper control of hydroisomerization,

hydrodesulfurization, and hydrocracking activity of catalysts in

hydroprocessing of diesel oil fraction, facilitating the production of fuel

with low sulfur and pour point.

The authors are grateful to the

Committee of Science, the Ministry of Science and Higher Education of the Republic

of Kazakhstan for funding this study through the project “ARO8857065 Creation of scientific

foundations for the development of new efficient catalysts and technology for

deep hydroprocessing of vacuum gas oil to produce high-quality motor fuel” (2020-2022).

Abdullaev, M.U., Lee, S., Kim, T.-W., Kim, C.-U., 2021. Tungsten

Oxide-Modified SSZ-13 Zeolite as an Efficient Catalyst for

Ethylene-To-Propylene Reaction. Catalysts, Volume 11,

p. 553

Aleksandrov,

P.V., Buhtiyarova, G.A., Reshetnikov, S.I., 2019. Study of The Influence of

Coker Gas Oil to The Straight-Run Gas Oil on The Process of Hydrotreating in

The Presence of CoMo/Al2O3 catalyst. Russian Journal of Applied

Chemistry, Volume 92,

pp. 1077–1083

Aljajan, Y., Stytsenko, V., Rubtsova, M., Glotov, A.,

2023. Hydroisomerization Catalysts for High-Quality Diesel Fuel Production. Catalysts, Volume 13, p. 1363

Altynov, A., Bogdanov, I., Lukyanov, D., Kirgina, M., 2023. Natural

Gas Liquids into Motor Gasolines: Methodology for Processing on a Zeolite

Catalyst and Development of Blending Recipes.

ChemEngineering, Volume 7, p. 93

Bayanov, V.A., Gizetdinova, A.F., Vishnevskaya, A.L.,

Tagandurdyeva, N.A., Kleymenov, A.V., Trafimov A.V., 2023. Processing Promising

Supports for Hydroprocessing Catalysts Based on Flash-Calcined Aluminium

Hydroxide. Oil & Gas Chemistry, Volume 2, pp. 59–62

Ding, L., Sitepu, H., Al-Bogami, S.A., Yami, D.,

Tamimi, M., Shaik, K., Sayed, E., 2021. Effect of Zeolite-Y Modification on Crude-Oil Direct

Hydrocracking. ACS Omega, Volume 6,

pp. 28654-28662

Fedushchak,

T.A., Uimin, M.A., Maikov, V.V., Mikubaeva, E.V., Akimov, A.S., Morozov, M.A.,

Zhuravkov, S.P., Petrenko, T.V., Vosmerikov, A.V., Zhirov, N.A., Kogan, V.M.,

2019. Two-Component

Ni(Co)-Promoted MoS2 Bulk Catalysts and Their

Hydrodesulphurising Ability in Model Reactions and Diesel Fraction

Hydrotreatment. Chemistry of Sustainable Development, Volume 27, pp. 71–77

Fitri,

N., Riza, R., Akbari, M.K., Khonitah, N., Fahmi, R.L., Fatimah, I., 2022.

Identification of Citronella Oil Fractions as Efficient Bio-Additive for Diesel

Engine Fuel. Designs, Volume

6, p. 15

Gackowski, M., Podobinski, J.,

Broclawik, E., Datka, J., 2020. IR and NMR Studies of the Status of Al and Acid

Sites in Desilicated Zeolite Y. Molecules,

Volume 25, pp. 31

Huseynova, G., Muxtarova, G., Aliyeva, N., Gastimova, G., Rashidova, S., 2022. Zeolite-Containing Catalysts in Alkylation

Processes. Catalysis Research, Volume

2(3, pp. 1–12

Janardhan,

H.L., Shanbhag, G.V., Halgeri, A.B., 2014. Shape-Selective Catalysis by

Phosphate Modified ZSM-5: Generation of New Acid Sites with Pore Narrowing. Applied Catalysis A: General, Volume

471, pp. 12–18

Jaroszewska,

K., Lewandowski, M., Góra-Marek, K., Grzechowiak, J., Djéga-Mariadassou, G.,

2021. Hydrodesulfurization of 4,6-Dimethyldibenzothiophene and the Diesel Oil

Fraction on NiMo Catalysts Supported over Proton-Exchanged AlMCM-41 and

TiMCM-41 Extrudates. Catalysts,

Volume 11, p. 1086

Kar, Y., Göksu, D.S., Yalman, Y., 2018.

Characterization of Light Diesel Fraction Obtained from Upgraded Heavy Oil. Egyptian Journal of Petroleum, Volume

27, pp. 1301–1304

Laredo, G.C., Pérez-Romo,

P., Águeda-Rangel, R., Escobar, J., Vega-Merino, P., 2020. Detailed Characterization of Light Cycle Oil

for BTX Production Purposes. International Journal of Petroleum and

Petrochemical Engineering, Volume 6, Issue 3, pp. 1–12

León, J.N.D., Kumar, C.R., Antúnez-García, J., Fuentes-Moyado, S., 2019. Recent Insights in Transition Metal Sulfide

Hydrodesulfurization Catalysts for the Production of Ultra Low Sulfur Diesel: A

Short Review. Catalysts,

Volume 9, p. 87

Majodina, S., Poswayo, O., Dembaremba, T.O., Tshentu,

Z.R., 2023. Towards Improvement of Hydroprocessing Catalysts - Understanding

The Role of Advanced Mineral Materials In Hydroprocessing Catalysts. Minerals

and Mineral Materials, Volume 2, p. 13

Marlinda, Al-Muttaqii, M.,

Roesyadi, A., Prajitno, D.H., 2022. Formation Of Hydrocarbon Compounds During

the Hydrocracking of Non-Edible Vegetable Oils With Cobalt-Nickel Supported On

Hierarchical HZSM-5 Catalyst. In IOP Conference Series: Earth and Environmental

Sciences, Volume 67, p. 012022

Mavai,

J., 2022. Methanol Synthesis and Converted into Hydrocarbons Over Zeolite

Catalyst a Review. Journal of Emerging

Technologies and Innovative Research, Volume 9, pp. 221–256

Mustafayeva,

R.M., 2012. Zeolite-Containing Catalysts in The Processes of

Obtaining Aromatic Hydrocarbons.

Azerbaijan: Baku

Nikul’shina,

M.S., Mozhaev, A.V., Lancelot, C., Blanchard, P., Lamonier, C., Nikul’shin,

P.A., 2019. Hydrotreating of Straight-Run Diesel Fraction Over Mixed Nimows/Al2O3 Sulfide Catalysts. Petroleum Chemistry, Volume 59, pp. 529–534

Prihadiyono,

F.I., Lestari, W.W., Putra, R., Aqna, A.N.L., Cahyani, I.S., Kadja, J.T.M.,

2022. Heterogeneous Catalyst Based on Nickel Modified into Indonesian Natural

Zeolite in Green Diesel Production from Crude Palm Oil. International Journal of Technology, Volume 13 (4), pp. 931–943

Rodriguez-Castellon,

E., Jimenez-Lopez, A., Eliche-Quesada, D., 2008. Nickel And Cobalt Promoted

Tungsten and Molybdenum Sulfide Mesoporous Catalysts For Hydrodesulfurization. Fuel, Volume 87, pp. 1195–1206

Saih,

Y., Segawa, K., 2009. Catalytic Activity of CoMo Catalysts Supported on

Boron-Modified Alumina for the Hydrodesulphurization of Dibenzothiophene and

4,6-Dimethyl Dibenzothiophene. Applied Catalysis A, Volume 353, pp. 258–265

Salnikov, V.A., Polyakov, N.A., Nevolina, S.A.,

Korotkova, N.V., Reznichenko, I.D., Ovchinnikov, K.A., 2023. A Promising

Catalyst for Hydrotreating Diesel Fuels on A Carrier Made of Thermally

Activated Aluminum Hydroxide. Oil &

Gas Chemistry, Volume 2, pp. 49–52

Shakiyeva, T.V., Sassykova, L.R., Khamlenko, A.A.,

Dzhatkambayeva, U.N., Sassykova, A.R., Batyrbayeva, A.A., Zhaxibayeva, Z.M.,

Ismailova, A.G., Sendilvelan, S., 2022. Catalytic Cracking of M-100 Fuel Oil:

Relationships Between Origin Process Parameters and Conversion Products. Chimica Techno Acta, Volume 9(3), p.

20229301

Sikkander, A. M., Kavitha, K., Ramanachiar, R.,

Anitha, V., Sasikala, S., Sivaraj, C., Balu, T.N., Mishra, S.R., Yasmeen, K.,

2022. Hydrodesulphurization of Petroleum. Petroleum

and Chemical Industry International, Volume 5 (3), pp. 150–152

Suhartono,

Romli, A., Hari Prabowo, B., Kusumo, P., Suharto, 2023. Converting Styrofoam

Waste into Fuel Using a Sequential Pyrolysis Reactor and Natural Zeolite

Catalytic Reformer. International Journal

of Technology, Volume 14 (1), pp. 185–194

., 2022. Metal-Free

Catalytic Oxidative Desulfurization of Fuels. A Review. Energy & Fuels, Volume 36 (7), pp. 3394–3419

Tuktin, B., Zhandarov, E., Nurgaliyev, N.,

Tenizbayeva, A., Shapovalov, A., 2019. Hydrotreating of Gasoline and Diesel Oil

Fractions Over Modified Alumina/Zeolite Catalysts. Petroleum Science and Technology, Volume 37, pp. 1770–1776

Tuktin, B.T., Omarova, A.A., Saidilda, G.T., Sassykova,

L.R., 2022. Modified Zeolite Catalysts for Efficient Processing Of N-Hexane and

Gasoline Fraction. Rasayan Journal of

Chemistry, Volume 15, pp. 2442–2449

Tuktin, B.T., Temirova, A.M., Omarova, A.A.,

Myltykbaeva, Z.K., Anisimov, A.V., 2021. Aromatization of Low-Molecular-Weight

Hydrocarbons on Modified Zeolite Catalysts. Theoretical

Foundations of Chemical Engineering, Volume 55, pp. 1016–1022

Wei, Q., Zhang, P., Liu,

X., Huang, W., Fan, X., Yan, Y., Zhang, R., Wang, L., Zhou, Y., 2020. Synthesis

of Ni-Modified ZSM-5 Zeolites and Their Catalytic Performance in n-Octane

Hydroconversion. Frontiers

in Chemistry, Volume 8, p. 586445

Wei,

Y.J., Zhang, Y.J., Zhu, X.D., Gu, H.M., Zhu, Z.Q., Liu, S.H., Sun, X.Y., Jiang,

X.L., 2022. Effects of Diesel Hydrocarbon Components on Cetane Number and

Engine Combustion and Emission Characteristics. Applied Sciences, Volume 12, p. 3549

Williams,

D.B., Carter, C.B., 2009. Transmission

Electron Microscopy. New York, USA:

Springer

Winarto,

D.A., Liza, C., Fathurrohman, M.I., Masa, A., Chalid M., 2024. Study of Solvent

and Catalyst in Diimide Biphasic Hydrogenation System of Natural Rubber. International Journal of Technology,

Volume 15 (2), pp. 414–424

Zhang,

D., Duan, A., Zhao, Z., Xu, C., 2010. Synthesis, Characterization and Catalytic

Performance of NiMo Catalysts Supported on Hierarchically Porous Beta-KIT-6

Material In The Hydrodesulfurization of Dibenzothiophen. Journal of

Catalysis, Volume 274, pp.

273–286

Zhang, M., Qin, B., Zhang, W., Zheng, J., Ma,

J., Du, Y., Li, R., 2020. Hydrocracking of Light Diesel Oil over Catalysts with

Industrially Modified Y Zeolites. Catalysts, Volume 10, p. 815

Zhang, W., Fang, D., Huang, G., Li, D., Zheng, Y.,

2023. Research and Application Development of Catalytic Redox Technology for

Zeolite-Based Catalysts. Catalysts, Volume 13, p. 1197