Sustainable Porous Silica Material Extracted from Volcanic Ash of Mount Sinabung Indonesia as Corrosion Inhibitor

Corresponding email: lisnawaty@unimed.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6740

Simatupang, L., Siburian, R., Ginting, E., Pakpahan, B.M.T., Simatupang, K.A.P., Siagian, D.G., Laoli, E.R., Goei, R., Tok, A.I.Y., 2024. Sustainable Porous Silica Material Extracted from Volcanic Ash of Mount Sinabung Indonesia as Corrosion Inhibitor. International Journal of Technology. Volume 15(4), pp. 880-889

| Lisnawaty Simatupang | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V, Medan Sumatera Utara, 20221, Indonesia |

| Rikson Siburian | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, 20155, Medan, Indonesia |

| Elfrida Ginting | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V, Medan Sumatera Utara, 20221, Indonesia |

| Binsar Maruli Tua Pakpahan | Department of Mechanical Engineering, Faculty of Engineering, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V, Medan Sumatera Utara, 2022, Indonesia |

| Kristian Adinata Pratama Simatupang | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V, Medan Sumatera Utara, 20221, Indonesia |

| Dea Gracella Siagian | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V, Medan Sumatera Utara, 20221, Indonesia |

| Edward Relius Laoli | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V, Medan Sumatera Utara, 20221, Indonesia |

| Ronn Goei | School of Materials Science and Engineering, Nanyang Technological University, 50 Nanyang Avenue, 639798, Singapore |

| Alfred Iing Yoong Tok | School of Materials Science and Engineering, Nanyang Technological University, 50 Nanyang Avenue, 639798, Singapore |

This study investigated the

potential of porous silica material extracted from volcanic ash of Mount

Sinabung, Indonesia, as a corrosion inhibitor. The new material was subjected

to comprehensive analysis using the X-Ray Diffraction (XRD), Fourier Transform

Infrared Spectroscopy (FTIR), Search Engine Marketing (SEM), and Atomic

Absorption Spectrophotometry (AAS). Corrosion test was conducted by coating the

metal surface with synthesized silica. XRD data showed the presence of

amorphous silica, while SEM indicated a rough and irregular pore cavity. Based

on AAS characterization, the concentration of silica in the Mount Sinabung

volcanic ash was 79.23 % (v/v) with a yield of 29.73 %(w/w). Furthermore,

coated and uncoated iron plates, with grit variations of 800, 1200, 1500, and

2000, were tested against HCl 15 % (v/v) and NaCl 3.5 % (w/v)

as model corrosive solutions. The SEM results showed that coated plates had

fewer holes and cracks formation while the XRD analysis of the same samples

presented a slight decrease in the intensity of iron phase. Among silica-coated

iron plates, the 1500 grit variation had the lowest corrosion rate and the

highest corrosion inhibitor efficiency in both HCl 15 % (v/v)

and NaCl 3.5 % (w/v) corrosive solutions, recording efficiencies

of 26.3 and 91.8 %, respectively.

Corrosion inhibitor; Grit; Natural silica; Silica coated iron; Volcanic ash

Mount Sinabung is one of

the active volcanoes in Indonesia, located in the North Sumatera Province.

According to The Indonesia Disaster Control Bureau (BNPB) data, Mount Sinabung

has emitted approximately 250 million tons of ash since the eruption in 2010. A

previous study discovered that the main component of volcanic ash was SiO2

(74.3%) (Karolina et al., 2020; Lubis et

al., 2019). Silica content is higher compared to other volcanoes in

the country, such as Mount Merapi (63.3 %) or Mount Kelud (70.6 %) (Nakada et al., 2019).

The abundance of volcanic ash

and high silica content presents significant potential for the production of silica-based material.

Silica has various applications in the pharmaceutical, ceramics, paints,

coatings, and chemical industries. This is due to the numerous advantageous

properties, including high porosity, mechanical strength, thermal stability, pore

surface area, stability in acidic environments, non-swelling characteristics,

and resistance to microbial attack (Salleh et

al., 2021; Boonmee and Jarukumjorn, 2020; Pan, Li, and Mao., 2020; Mainier et

al., 2018a; El-Fargani et al., 2017; Verma and Khan, 2016; Anderson

and Segall, 2011). These attributes support the potential for the

cost-effective production of silica-based composite material applied by various

niche (Beleuk-a Moungam et al., 2022;

Prabha et al., 2021; Silvana and Sunardi,

2020; Iguchi et al., 2012).

Several studies have reported the use of

volcanic ash, including its application as a base material for geopolymers and

in the synthesis of nano-silica (Hasanah et al.,

2021; Sinuhaji et al., 2018; Karolina et al., 2015).

Investigation has been conducted on the preparation of volcanic ash from Mount

Sinabung, a basic material for creating silica-based adsorbents. This study

also comprises the characterization of volcanic ash, modification of silica

surfaces for composite material, and its application in heavy metal adsorption (Simatupang and Devi, 2016). Based on previous

work, the characterization showed that the resulting silica gel was amorphous,

with a surface area of 375 m2/g and a pore diameter of 1.5 nm (Simatupang et al., 2020). The substantial

pore surface area renders silica gel suitable for adsorption purposes.

The common problem faced by

industrialized nations is metal corrosion, a process driven by oxidation

reactions, thereby leading to degradation in the quality of metal. Corrosion

could be caused by moisture, acids, salt, and high ambient temperatures (Pan et al., 2020; Yeganeh, Omidi, and Eskandari, 2018;

Javaherdashti, 2000). However, the process can be controlled by slowing

down oxidation (Assassi and Benharrats, 2021; Chasse,

Scardino, and Swain, 2020; Wang et al., 2020; Onyeachu et al., 2019;

Tansug et al., 2014). The adhesion

strength between the coating material and the ferrous metal surface is

influenced by the level of surface roughness. The rough iron plate specimens

produced areas with an unstable surface structure that experienced greater

corrosion due to the uneven distribution of the passive layer.

Several materials previously used as

corrosion inhibitor, include polyaniline, metal alloy, and imidiazole.

Furthermore, inhibitor material characteristics are surface area, small pore

size and heteroatom with N and O, lone pair electrons, as well as metal with

lower potential reduction standard (Mulyani et

al., 2023; Ningrum et al., 2023; Riyanto

et al., 2023; Assassi and Benharrats,

2021).

Sodium silicate is a chemical compound

that is often used as corrosion inhibitor due to its environmentally

friendliness and low cost (Mulyani et al.,

2023; Da-Silva, Saji, and Aoki, 2022; Saji, 2019). In coating

application, a mixture of silica from natural sand and rice husk ash serves as

a natural inhibitor for reinforcing concrete structures (Marzorati, Verotta, and Trasatti, 2019; Awizar et al., 2013). This study was

conducted specially to optimize the use of Sinabung volcanic ash as silica

precursor and coating material for corrosion inhibitor to protect the ferrous

metal from corrosion.

2.1. Preparation of Silicate from

Volcanic ash

The preparation

of silicate comprised

soaking 20 g of volcanic ash in 37 % (v/v) HCl (E-Merck)

for 2 hours at a temperature of 95°C with continuous stirring. After

filtration, the residue was rinsed in distilled water until reaching pH 7, then dried in an oven at 120 °C

for 6 hours. The dried volcanic ash was extracted with a 4, 6, or 8 M NaOH

solution (E-Merck) and boiled while stirring until the mixture thickened. The mixture was

then placed in a

furnace at 750 °C for 3 hours. After cooling, 200 mL of distilled water was

added, and the mixture was left overnight before being filtered. A total of 20 mL of Na2SiO3

solution was placed into a plastic container, and a few drops of 3M HCl

solution were added while stirring to form a white gel and neutral pH. Silica gel was filtered and rinsed

with distilled water, followed by drying in an oven at 120 °C. Silica yield from volcanic ash was calculated using Equation 1.

%

silica =

The schematic representation of the preparation of silica from volcanic ash is shown in Figure 1.

Figure 1 A Schematic Representation of the

Preparation of Silica from Volcanic Ash

Atomic Absorption Spectroscopy

(AAS)Z-2000 series was performed to determine silica content in the Na2SiO3

solution. FTIR SHIMADZU, Rigaku ZSX, XRD Perkin Elmer 3110 Shimadzu XRD 6000,

and SEM Zeiss type EPOMH 10 Zss were used to characterize the physicochemical

properties of material.

2.2. Corrosion

Testing of Iron Samples

Iron plate 3 × 3 cm2 with a thickness of 3

mm was used for corrosion testing. The samples were pre-treated with sandpaper

of varying grit numbers 800, 1200, 1500, and 2000 to smoothen and remove

scratches on the surface. Each iron plate grit was soaked in Inhibitor for 5 days.

Subsequently, the uncoated and coated iron plates were dipped in a corrosive

solution containing 15 % (v/v) HCl and 3.5 % (w/v)

NaCl for 96 hours. The HCl solution represents an acidic environment while NaCl

represents a salty atmosphere conducive to corrosion. Sets of silica-coated and

uncoated iron plates were analyzed using SEM and XRD before and after corrosion

tests.

Peaks at 3356.89 cm-1,

3454.12 cm-1, and 3446.02 cm-1, showed the presence of OH

strain vibrations from Si-OH, as presented in Figure 2. Furthermore, Si-O

asymmetric stretching vibrations in Si-O-Si were characterized by band

absorptions at 1184.45 cm-1 and 1095.57 cm-1, represented

by a wide and sharp peak in the 1000-1100 cm-1 wavenumber range. A

peak was observed at wave numbers 796.42 cm-1 and 789.21 cm-1,

which showed Si-O-Si stretching vibrations. The presence of the Si-O-Si

functional group was confirmed by the peaks observed at 326.46 cm-1,

attributed to the bending vibration, in both 6M and 8M NaOH solutions.

The XRD pattern, as presented in Figure 2, showed that silica

gel produced from the 3 variations of NaOH was amorphous, characterized by a

broad peak at = 23.36°;

= 22.68°;

= 23.40°, with the highest intensity

being

= 23.40°. The diffraction pattern, with a peak, widened around

=

20-24°, indicated a low crystallinity amorphous structure (Simatupang et al., 2018).

SEM image showed the existence of rough and irregular pore

cavities, as presented in Figure 3. The presence of amorphous silica was also

confirmed by the XRD results. Non-crystalline or amorphous silica possesses

pores with atoms or molecules arranged in random and irregular patterns, as

well as complex spherical structures.

Figure 2 (1) FTIR spectra of silica gel prepared using (A) 4M NaOH, (B) 6M NaOH, and (C) 8M NaOH, and (2) XRD pattern spectra of silica gel prepared using (A) 4M NaOH, (B) 6M NaOH, and (C) 8M NaOH

Figure 3 SEM Image of Silica Gel

Prepared Using (a) 4M NaOH, (b) 6M NaOH, (c) 8M NaOH

The concentration of NaOH and the length

of the extraction time affect silica formation process. The AAS data showed

that the highest silica content was discovered when volcanic ash was extracted

with 8M NaOH solution. This concentration resulted in a 79.23% (v/v) Na2SiO3

and a gel yield of 29.73% (w/w). The purpose of using 8M NaOH is due to the

higher concentration of NaOH, leading to greater extraction power.

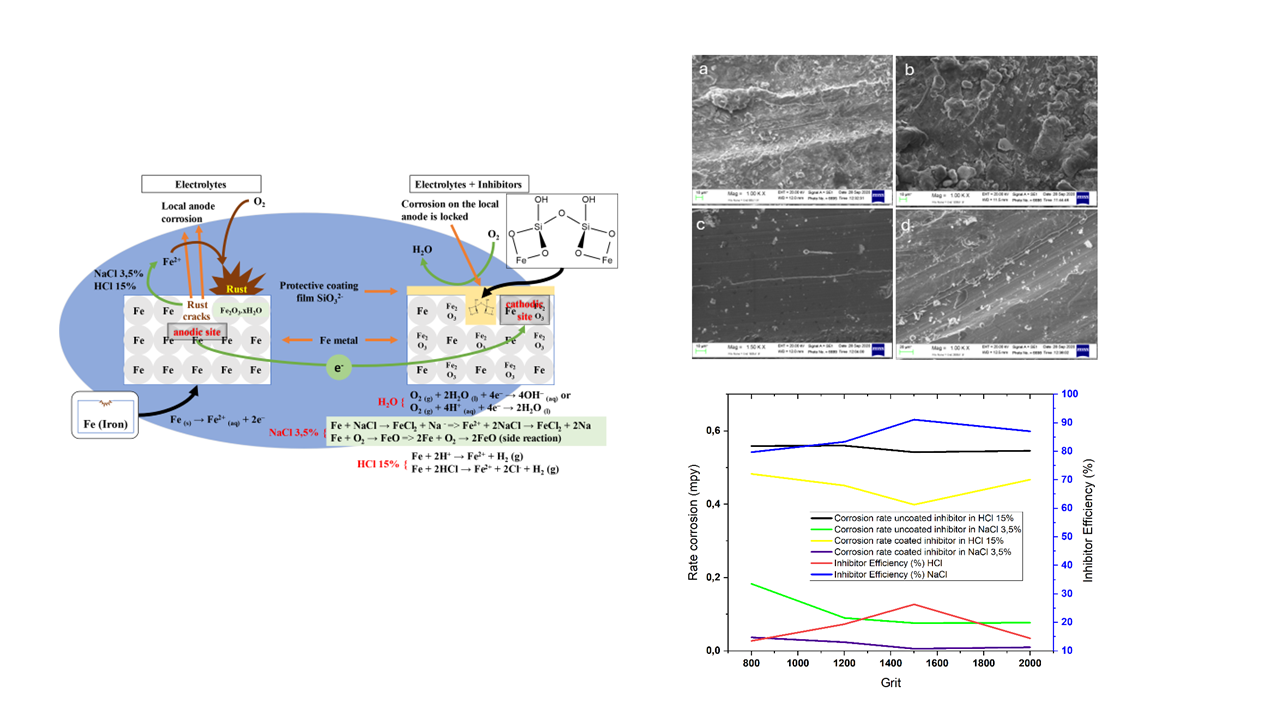

The sets of silicate-coated and uncoated iron plates were subjected to corrosion test using a corrosive solution containing 15 % HCl (v/v) and 3.5 % NaCl (w/v). The results were analyzed using SEM (Figures 4 and 5).

Figure 4 (1) SEM images grit of iron plate uncoated before treatment (a) 800 (b)

1200 (c) 1500 (d) 2000; (2) SEM images uncoated, in HCl 15 % (v/v;

(3) SEM images uncoated, in NaCl 3.5 % (w/v)

Figure 5 (1) SEM images of grit of iron plate coated before treatment, showing

(a) 800, (b) 1200, (c) 1500, and (d) 2000 grit levels; (2) SEM images of coated

iron plate after exposure to 15 % HCl (v/v); and (3) SEM

images of coated iron plate after exposure to 3.5 % NaCl (w/v)"

Figure 5

shows the morphology of iron plate after coating with silicate. The 1500-grit

iron plate has the smoothest surface compared to the other grits, which results

in a more even thickness of silicate layer. The morphology appeared to be less

perforated and fewer lumps were formed compared to uncoated iron plates with

inhibitor. This is in accordance with the theory that samples with the addition

of inhibitor will crack less, showing a smaller corrosion rate (Devianto et al., 2023; Goyal et al., 2020).

Based on the analysis data, it was observed that silicate is effective as

corrosion inhibitor.

The

reaction mechanism scheme is shown in Figure 6. Sodium silicate has an anodic

inhibitory capacity in a neutral medium. This implied that the SiO2

species migrated to the anode region of the metal surface, reacting with Fe2+

ions and forming a protective layer of iron silicate (FeSiO3).

Silicate was effective as inhibitor by reacting with OH-, thereby reducing

corrosion reaction in neutral solutions and decreasing corrosion rate. The new

peak that appeared after immersion at 2 = 30-40° was FeOOH- (Ningrum et al., 2023).

Figure 6 Mechanism of

silicate inhibition reaction

XRD patterns for all grit both uncoated and coated iron plates

in NaCl 3.5% (w/v) can be seen in Figure 7 showing that the peak on iron plate

was lower in intensity than the peak on iron plate before treatment.

The existence of a lower

intensity peak after immersion in corrosion solution showed sediment. The Fe

peak of the 2000 grit iron plate at 2 = 40-50° was sharper compared to the

1200 and 1500 grit. Furthermore, the

level of surface smoothness affected corrosion rate, with a new peak appearing at

= 20-30° for the

series of samples after immersion in NaCl 3.5% (w/v). The

intensity of each iron plate showed a

reduction in iron corrosion rate and a slight decrease in grit size variation, showing effective inhibition by

silicate inhibitor.

Corrosion test of iron plate was analyzed

for corrosion rate using the weight-loss method (Malaret, 2022). Where the CR is corrosion rate (mpy), W is mass loss (g), A is surface area (cm2), t is the exposure time (hour), D is density (g/cm3), C

is constant

3.45 x 106.

Based on Table 1, the 1500 grit iron plate, whether

silica-coated or uncoated, had lowest corrosion rate of 3.399 mpy and 0.006

mpy, alongside highest inhibitor efficiency of 26.3% and 91.1% respectively.

These results surpass those of a previous study utilizing tobacco extract and

sodium silicate as inhibitor in a3.5% NaCl (w/v) corrosive solution, which

achieved efficiencies of 24 - 69% and 79.55%, respectively.

Table 1 Data of Corrosion Rate and Inhibitor Efficiency for each Grit

of Iron Plate

|

No |

Grit |

Corrosion

Solution |

Corrosion

rate uncoated

iron (mpy) |

Corrosion

rate silicate-coated iron (mpy) |

Inhibitor

Efficiency (%) |

|

1 |

800 |

HCl

15% |

0.559 |

0.483 |

13.5 |

|

2 |

1200 |

0.560 |

0.451 |

19.4 | |

|

3 |

1500 |

0.542 |

0.399 |

26.3 | |

|

4 |

2000 |

0.546 |

0.467 |

14.4 | |

|

5 |

800 |

NaCl

3.5% |

0.183 |

0.037 |

79.7 |

|

6 |

1200 |

0.090 |

0.024 |

83.3 | |

|

7 |

1500 |

0.076 |

0.006 |

91.1 | |

|

8 |

2000 |

0.077 |

0.010 |

87.0 |

Figure 8 Corrosion Rate and Inhibitor Efficiency for each Grit

of Iron Plate uncoated silica inhibitor and coated silica inhibitor in

corrosive solutions

In conclusion, the highest silica

content from volcanic ash of Mount Sinabung was observed when 8M NaOH was used,

with a Na2SiO3 concentration of 79.23 v% (v/v)

and a yield of 29.73v% (w/w). According to the

characterization results by FTIR, the synthesized silica gel has -OH and Si-O

functional groups from Si-OH and Si-O-Si, respectively. XRD analysis suggested

that the as-synthesized silica gel had an amorphous structure. Micrograph SEM

showed rough and irregular pore cavities, while the effect of surface grit

variations on the performance of sodium silicate inhibitor synthesized in 15 %

HCl (v/v) and 3.5 % NaCl (w/v)

solutions, was lower corrosion rates. The lowest corrosion rate was observed on

the 1500 grit iron plate, and the addition of silica as inhibitor reduced the

rate in HCl 15 % (v/v) and NaCl 3.5 % (w/v)

corrosive solutions, leading to inhibitor efficiencies of 26.3 % and 91.8 %,

respectively.

The

authors acknowledge financial support from Universitas Negeri Medan for the

Financial Year 2021-2022 under Applied Product Research, Contract Numbers:

008/UN33.8/PL.PNBP/2021 and 104/UN33.8/KEP/PPKM/PT/2022.

Anderson,

K., Segall, P., 2011. Physics-based Models of Ground Deformation and Extrusion

Rate at Effusively Erupting Volcanoes. Journal of Geophysical Research:

Solid Earth, Volume 16(B7), pp. 1–20

Assassi,

F., Benharrats, N., 2021. Synthesis, Characterizations and Application of

Polyaniline-paint as Anticorrosion Agent. Inorganic and Nano-Metal Chemistry,

Volume 51(6), pp. 805–813

Awizar,

D.A., Othman, N.K., Jalar, A., Daud, A.R., Rahman, I.A., Al-Hardan, N.H., 2013.

Nanosilicate Extraction from Rice Husk ash as Green Corrosion Inhibitor. International

Journal of Electrochemical Science, 8(2), 1759–1769

Beleuk-a

Moungam, L.M., Lemougna, P.N., Kaze, R.C., Mohamed, H., Deutou-Nemaleu, J.G.,

Billong, N., Kamseu, E., Mvondo-Ze, A.D., Kenfack, I.T., 2022. Synthesis of

Volcanic Ash-based Porous Inorganic Polymers Using Biomass as Pore Inducing

Agent: Phase Evolution and Descriptive Microstructure. Silicon, Volume

14(6), pp. 2595–2608

Boonmee,

A., Jarukumjorn, K., 2020. Preparation and Characterization of Silica

Nanoparticles from Sugarcane Bagasse Ash for using as a Filler in Natural

Rubber Composites. Polymer Bulletin, Volume 77(7), pp. 3457–3472

Chasse,

K.R., Scardino, A.J., Swain, G.W., 2020. Corrosion and Fouling Study of

Copper-based Antifouling Coatings on 5083 Aluminum Alloy. Progress in

Organic Coatings, Volume 141, p. 105555

Da-Silva,

P.B., Saji, V.S., Aoki, I.V., 2022. Rapid and Eco-friendly One-step Synthesis

of Dodecylamine-encapsulated Mesoporous Silica Nanocontainers. Microporous

and Mesoporous Materials, Volume 341, pp. 112109

Devianto,

H., Nurdin, I., Widiatmoko, P., Silvia, D., Prakarsa, C., 2023. Tobacco Extract

for Inhibition of Carbon Steel Corrosion in H2S-contained NaCl Solution. International

Journal of Technology, Volume 14(5), pp. 1167–1176

El-Fargani,

H., Lakhmiri, R., El-Farissi, H., Albourine, A., Safi, M., Cherkaoui, O., 2017.

Removal of Anionic Dyes by Silica-chitosan Composite in Single and Binary Systems:

Valorization of Shrimp co-product “Crangon-Crangon” and “Pandalus Borealis.” Journal

of Materials and Environmental Science, Volume 8(2), pp. 724–739

Goyal,

M., Vashist, H., Kumar, S., Bahadur, I., Benhiba, F., Zarrouk, A., 2020. Acid

Corrosion Inhibition of Ferrous and Non-ferrous Metal by Nature Friendly

Ethoxycarbonylmethyltriphenylphosphonium Bromide (ECMTPB): Experimental and MD

Simulation Evaluation. Journal of Molecular Liquids, Volume 315, p.

113705

Hasanah,

M., Sembiring, T., Sebayang, K., Humaidi, S., Rahmadsyah, Saktisahdan, T.J.,

Handoko, F., Ritonga, S.I., 2021. Extraction Of Silica Dioxide (SiO2)

From Mount Sinabung Volcanic Ash with Coprecipitation Method. In: IOP

Conference Series: Materials Science and Engineering, Volume 1156(1), p. 012015

Iguchi,

M., Surono, Nishimura, T., Hendrasto, M., Rosadi, U., Ohkura, T., Triastuty,

H., Basuki, A., Loeqman, A., Maryanto, S., Ishihara, K., Yoshimoto, M., Nakada,

S., Hokanishi, N., 2012. Methods for Eruption Prediction and Hazard Evaluation

at Indonesian Volcanoes. Journal of Disaster Research, Volume 7(1), pp.

26–36

Javaherdashti,

R., 2000. How Corrosion Affects Industry and Life. Anti-Corrosion Methods

and Materials, Volume 47(1), pp. 30–34

Karolina,

R., Syahrizal, S., Putra, M.A., Prasetyo, T.A., 2015. Optimization of the use

of Volcanic Ash of Mount Sinabung Eruption as the Substitution for Fine

Aggregate. Procedia Engineering, Volume 125, pp. 669–674

Karolina,

R., Syahrizal., M.A.P., Handana., Wijaya, B., 2020. Utilization of Volcanic Ash

of Mount Sinabung as a Substitute for Cement to Flexure Strength of Geopolymer

Concrete. Icosteerr 2018, pp. 332–337

Lubis,

M., Sukeksi, L., Harahap, M.B., Ginting, M., Wici, H., Ayu, G.E., 2019. Use of

Silica Gel from Volcanic Ash as Chitosan Composite Membrane’s Filler. Asian

Journal of Chemistry, Volume 31(10), pp. 2303–2305

Mainier, F.B., Figueiredo, A.A.M., de-Almeida Junior, A.A.M.,

Almeida-Junior, B.B., 2018a. Proposal of the use Sodium Silicate as a Corrosion

Inhibitor in Hydrostatic Testing of Petroleum Tanks using Seawater. International

Journal of Advanced Engineering Research and Science, Volume 5(6), pp.

33–38

Malaret,

F., Yang, X.S., 2022. Exact Calculation of Corrosion Rates by the Weight-loss Method.

Experimental Results, Volume 3, p. E13

Marzorati,

S., Verotta, L., Trasatti, S.P., 2019. Green Corrosion Inhibitors from Natural

Sources and Biomass Wastes. Molecules, Volume 24(1), p. 48

Mulyani,

R.W.E., Nuruddin, A., Suprijanto, Sunendar-Purwasasmita, B., 2023.

Silica-Chitosan Nanocomposite Coatings for Enhancing Hydrophilicity of

Polyester Fabric. International Journal of Technology, Volume 14(4), pp.

761–769

Nakada,

S., Zaennudin, A., Yoshimoto, M., Maeno, F., Suzuki, Y., Hokanishi, N., Sasaki,

H., Iguchi, M., Ohkura, T., Gunawan, H., Triastuty, H., 2019. Growth process of

the lava dome/flow complex at Sinabung Volcano during 2013–2016. Journal of

Volcanology and Geothermal Research, Volume 382, 120–136

Ningrum,

E.O., Khoiroh, I., Nastiti, H.I., Affan, R.A., Karisma, A.D., Agustiani, E.,

Surono, A., Suroto, H., Suprapto, S., Taji, L.S., Widiyanto, S., 2023. Surface

Coating Effect on Corrosion Resistance of Titanium Alloy Bone Implants by

Anodizing Method. International Journal of Technology, Volume 14(4), pp.

749–760

Onyeachu,

I.B., Obot, I.B., Sorour, A.A., Abdul-Rashid, M.I., 2019. Green Corrosion

Inhibitor for Oilfield Application I: Electrochemical Assessment of

2-(2-pyridyl) Benzimidazole for API X60 Steel Under Sweet Environment in NACE

Brine ID196. Corrosion Science, Volume 150, pp. 183–193

Pan,

C., Chen, N., He, J., Liu, S., Chen, K., Wang, P., Xu, P., 2020. Effects of

Corrosion Inhibitor and Functional Components on the Electrochemical and

Mechanical Properties of Concrete Subject to Chloride Environment. Construction

and Building Materials, Volume 260, p. 119724

Pan,

C., Li, X., Mao, J., 2020. The Effect of a Corrosion Inhibitor on the

Rehabilitation of Reinforced Concrete Containing Sea Sand and Seawater. Materials,

Volume 13(6), p. 1480

Prabha,

S., Durgalakshmi, D., Rajendran, S., Lichtfouse, E., 2021. Plant-derived Silica

Nanoparticles and Composites for Biosensors, Bioimaging, Drug Delivery and

Supercapacitors: a Review. Environmental Chemistry Letters, Volume

19(2), pp. 1667–1691

Riyanto,

Jazuli, M.M., Sahroni, I., Musawwa, M.M., Cahyandaru, N., Wahyuni, E.T., 2023.

A Simple Technique for the Corrosion Inhibition of Underwater Cannonball from a

Shipwreck. International Journal of Technology, Volume14(4), pp. 843–853

Saji,

V.S., 2019. Supramolecular Concepts and Approaches in Corrosion and Biofouling

Prevention. Corrosion Reviews, Volume 37(3), pp. 187–230

Salleh,

S.Z., Yusoff, A.H., Zakaria, S.K., Taib, M.A.A., Seman, A.A., Masri, M.N.,

Mohamad, M., Mamat, S., Sobri, S.A., Ali, A., Ter-Teo, P., 2021. Plant Extracts

as Green Corrosion Inhibitor for Ferrous Metal Alloys: A Review. Journal of

Cleaner Production, Volume 304, p. 127030

Silvana,

S., Sunardi, S., 2020. Synthesis and Characterization of Si02/Zn0

Nanocomposites from Zinc Waste and Mount Merapi Volcanic Ash. Journal of

Scientific and Applied Chemistry, Volume 23(10), pp. 365–369

Simatupang,

L., Devi., 2016. The preparation and characterization of Sinabung volcanic ash

as silica based adsorbent. Jurnal Pendidikan Kimia (Journal of Chemistry

Education), Volume 8(3), pp. 159–163

Simatupang,

L., Siburian, R., Sitanggang, P., Doloksaribu, M., Situmorang, M., Marpaung,

H., 2018. Synthesis and Application of Silica Gel Base on Mount Sinabung’s Fly

Ash for Cd(II) Removal with Fixed Bed Column. Rasayan Journal of Chemistry,

Volume 11(2), p. 819–827

Simatupang,

L., Situmorang, M., Marpaung, H., Siburian, R., 2020. Fabrication of

Silica-based Chitosan Biocomposite Material from Volcanic Ash and Shrimp Husk

by Sol Gel Method for Adsorbent of Cadmium (Ii) Ions. Indian Journal of

Chemical Technology, Volume 27(5), pp. 387–394

Sinuhaji,

P., Sembiring, T., Magfirah, A., Piliang, AF., Nababan, S.M., 2018. Analysis of

Composition; Topography of Volcanic Materials Erupted from Mount Sinabung, Karo

Regency, Indonesia. In: Journal of Physics: Conference Series, Volume

1116(3), p. 032035

Tansug,

G., Tüken, T., Giray, E.S., Findikkiran, G., Sigircik, G., Demirkol, O., Erbil,

M., 2014. A New Corrosion Inhibitor for Copper Protection. Corrosion Science,

Volume 84, pp. 21–29

Verma,

D.K., Khan, F., 2016. Corrosion Inhibition of Mild Steel in Hydrochloric Acid

using Extract of Glycine Max Leaves. Research on Chemical Intermediates,

Volume 42(4), pp. 3489–3506

Wang, X., Jing, C., Chen, Y., Wang, X., Zhao, G., Zhang, X., Wu, L., Liu, X., Dong, B., Zhang, Y., 2020. Active Corrosion Protection of Super-hydrophobic Corrosion Inhibitor Intercalated Mg–Al Layered Double Hydroxide Coating on AZ31 Magnesium Alloy. Journal of Magnesium and Alloys, Volume 8(1), pp. 291–300

Yeganeh, M., Omidi, M., Eskandari, M., 2018. Superhydrophobic Surface of AZ31 Alloy Fabricated by Chemical Treatment in the NiSO4 Solution. Journal of Materials Engineering and Performance, Volume 27(8), pp. 3951–3960