The Influence of Surface Modification of Porous Materials to Improve the Efficiency of Separation of Water-Oil Emulsions: A Review

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6736

Soloveva, O., Solovev, S., Shakurova, R., 2024. The Influence of Surface Modification of Porous Materials to Improve the Efficiency of Separation of Water-Oil Emulsions: A Review. International Journal of Technology. Volume 15(4), pp. 937-951

| Olga Soloveva | Institute of Heat Power Engineering, Kazan State Power Engineering University, 420066 Kazan, Russia |

| Sergei Solovev | Institute of Digital Technologies and Economics, Kazan State Power Engineering University, 420066 Kazan, Russia |

| Rozalina Shakurova | Institute of Heat Power Engineering, Kazan State Power Engineering University, 420066 Kazan, Russia |

Water/oil

(W/O) emulsions are formed during oil fields and production development, thereby

reducing the

oil quality. In

order to separate the

emulsions, specialists use

various methods, equipment, and materials. Most emulsions formed during oil

production are stable and persistent, and traditional methods such

as sedimentation and

centrifugation are ineffective in the separation process. Addressing

this challenge, porous materials characterized by selective super-wetting properties are used for the high-quality

separation of stable W/O emulsions. Therefore, this review

presents recent advancements in

highly porous cellular materials that separate W/O emulsions. It further

discusses the features,

limitations, and advantages of using superhydrophobic/superleophilic and

superhydrophilic/superleophobic porous materials such as metallic and polymeric

foams. The influence of the structure and nature of porous materials on the

efficiency of the separation of W/O emulsions is analyzed. Additionally,

this review also explores

methods for modifying highly porous materials to improve selective wettability.

Absorption capacity; Contact angle; Emulsion separation efficiency; Porous material; Separation of emulsions

Water/oil (W/O) emulsions are a common problem during oil production, formed when water is injected into an oil reservoir to increase pressure and displace oil. Although this method is widely adopted for its high efficiency and ease of implementation, it results in the mixing of W/O leading to the formation of undesired W/O emulsions. These emulsions have an effect on the oil quality, corrode equipment, and pollute water and soil. Subsequently, water, acting as a ballast, introduces specific complications in the transportation and processing of oil, making oil dehydration a mandatory stage in the production process. Therefore, there is a pressing need to study effective methods and materials for separating W/O emulsions (Zeng and Taylor, 2020; Poerwadi et al., 2020). These emulsions are characterized by a two-component system of liquids insoluble in each other, while one phase is continuous, and the second is in a dispersed state. There are three types of emulsions, which include direct type (oil in water), reverse type (water in oil), and complex emulsions (water-oil-water or oil-water-oil) (Camelo-Silva et al., 2022; Jhawat Gulia, and Sharma, 2021). Figure 1 shows the classification and types of emulsions.

Figure 1 Classification and types of emulsions

The main properties of W/O and oil/water (O/W) emulsions

are stability, viscosity, water content, and density (Sapei et

al., 2022). In the various industries,

petroleum/water emulsions exhibit specific characteristics, including oil

density of 0.86–1 (mg/L), emulsions viscosity from 1.40·103 to

9.28·104 (mPa·s), emulsion stability from 0 to 3.36·104

(s), and water content varying between 30–90%. Industrial processes also yield

emulsions based on petroleum products which include diesel O/W (density

0.83–0.85 mg/L, viscosity 8.04·105 mPa·s); fuel O/W (density

0.98–1.00 mg/L, stability from 5.9·102 to 1.3·103 s,

water content 76–77%); gasoline/oil (density 0.71–0.76 mg/L, viscosity 1.5·105

mPa·s) etc. (Fingas and Fieldhouse, 2004). Some of the published studies predominantly

focus on the separation of the processes of

various emulsions such as n-hexane/water (95%, 0.6–0.7 g/cm3, 0.3–0.4 mPa·s) (Qiang et al., 2018), ethanol/water (10–40%, 0.6–0.7 g/cm3,

0.9–2 mPa·s) (Cho et al., 2016), pump O/W (40–80%, 0.85–0.95 g/cm3, 60–80

mPa·s) (Liu et al., 2020), toluene/water (0.85–0.9 g/cm3, 0.5–0.6 mPa·s) (Xu et al., 2021), soybean O/W, etc.

The separation of emulsions includes dividing crude oil into oil and aqueous phases, and this demulsification process is carried out in refineries (Acharya

and Potter, 2021). Various methods

contribute to emulsions separation, including mechanical (Semenov, Slavyanskiy, and Mitroshina, 2021;

Portnov et al., 2021; Solovyev et al., 2021), thermal (Santos et al., 2017; Fortuny

et al., 2007), chemical (Wang

et al., 2021a; Sun et al., 2020; Kang et al., 2006), biological (Zahari, Yan, and Rahim, 2022;

Esmaeili et al., 2021; Fajun et al., 2020; Sachdev and Cameotra, 2013), and electrical (Moldes et

al., 2007; Mostefa and Tir, 2004). Methods such as ultrasound and

magnetic fields are recognized for separating or improving the separation of

emulsions methods. These methods can be effectively combined with highly porous cellular materials for the separation of W/O emulsions.

Porous materials play an active role in

separating W/O emulsions, characterized by

high permeability, low density, hydrophobicity, and lightweight (Satria

and Saleh, 2022; Yang et al., 2021a; Qin et al., 2016). These materials, depending on the types, serve as an effective absorbent or

filter material, intensifying the separation of emulsions in the

implementation of thermal separation methods (Wu et

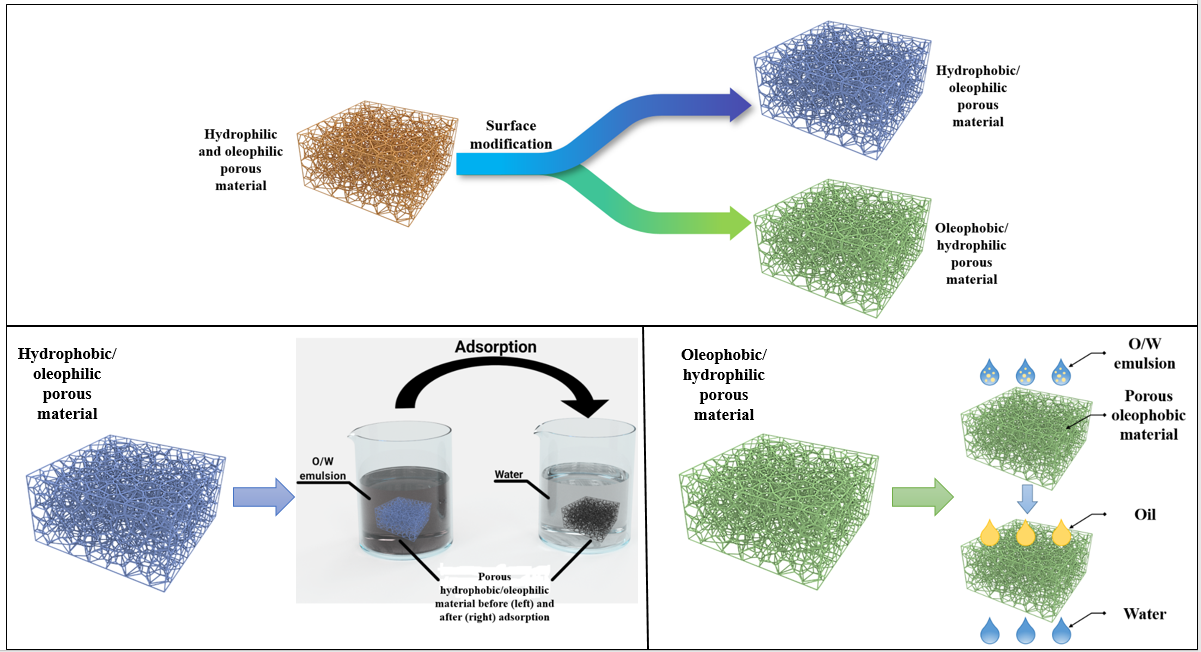

al., 2020a; Yan et al., 2020; Yang et al., 2019). Figure 2 shows diagrams of the process of separating O/W emulsions using porous material, which is used as an absorbent (Figure 2a) or as a filter material (Figure 2b).

Numerous publications focus on the use of porous materials for the

separation of W/O emulsions. Many investigations have solved problems such as the

separation of W/O emulsions using metal (Solov’eva et al., 2021) and polymer (Qiang et al., 2018) foams, studied the adsorption capacity and efficiency of emulsions

separation by hydrophobic (Xue et al., 2021a) and hydrophilic materials, examined the methods for applying a

hydrophobic coating to the surface of porous material (Álvarez-Gil,

Ramirez, and Fernandez-Morales, 2021), synthesized the composite porous materials by surface modification (Cho

et al., 2016),

assessing the influence of the type of modifier and the concentration on water

contact angle (WCA), adsorption capacity, and emulsions separation efficiency (Ahmed, Anis, and Khalil, 2021; Zhang,

Liu, and Qiao, 2020). Investigations also examine factors such as the influence of liquid pH

on adsorption capacity (Alazab and Saleh, 2022). Researchers have studied the

features of emulsion separation using materials such as polyurethane foam,

melamine foam, polydimethylsiloxane foam, nanocellulose sponge, iron foam,

nickel foam, and copper foam. Various surface modifiers (metal nanoparticles,

polymer compounds, carbon nanotubes) and methods of their application

(immersion in solution, polymerization, freeze-drying, sol-gel process, etc.)

have been studied. In addressing these aspects, scientists have solved many

problems related to the separation of W/O emulsions by porous media.

The purpose of this study is to systematize and

classify research results, as well as to identify unsolved problems in this

area. The relevance and novelty of this review lie in providing comprehensive

systematic data on research related to the separation of emulsions. This

information assists specialists by helping in the identification of (i) the

effective use of porous materials to separate certain types of emulsions, and

(ii) synthesizing composite porous materials with the necessary properties to

solve specific engineering problems. In this review, articles focusing on

emulsion separation using metal and polymer porous materials were selected. The

data were classified according to the material of the porous medium (metal,

polymer); wettability of the material (hydrophobic, oleophobic); type of

modifier; method of applying the modifier to the surface of the porous medium;

the influence of the modifier on the properties of porous medium (contact

angle, adsorption capacity).

This systematic

review specifically focuses on metal and polymer porous materials used for

separating emulsions, namely foams made from nickel, iron, polyurethane,

melamine, polydimethylsiloxane, etc. This review discusses two methods for

separating emulsions: filtration and adsorption, which are implemented using

porous materials. Furthermore, the distinctive feature and advantage is the

analysis of the influence of various surface modifiers (metal nanoparticles,

polymer compounds, graphene, etc.) on surface wettability and emulsion

separation characteristics (separation efficiency and adsorption capacity).

Figure 2 Separation

of O/W emulsions using porous materials by adsorption (a) and filtration (b)

Surface

wettability is the fundamental characteristic of materials for emulsion

separation (Wang and Deng, 2019). It is

assessed by measuring WCA.

2.1. Water contact

angle (WCA) in

air

Theoretically,

WCA depends on the interaction between the solid, liquid, and gaseous phases

for a perfectly smooth surface. WCA can be obtained from Young’s

Equation (1) (Jiang, Müller-Plathe, and Panagiotopoulos, 2017):

where – contact angle on a

perfectly smooth surface,

surface tension between a solid and a liquid

solid and gas

and liquid and gas

surface is

considered hydrophilic, at

>90° hydrophobic,

and a surface with contact angle

>150° is called superhydrophobic

(Yang et al., 2021b) (Figure 3).

Young's equation describes the wettability of a perfectly smooth surface, however, the real surface is rough. According to the study by Robert Wenzel, it was reported that water droplets fill the rough structure, thereby increasing the contact area and surface wettability, in which case Equation (2) applies (Sarkar and Kietzig, 2013):

where W – apparent

contact angle, r – the ratio of the contact area of the interface between a

solid and a liquid in the case of a rough surface to the contact area in the

case of a perfectly smooth surface. Applying equation (2) to surfaces with high

roughness or to porous structures, the value of cos

W will be

greater or less than one, which is unacceptable from a mathematical point of

view. In the Cassie-Baxter theory, air pockets under a layer of water are

considered a superhydrophobic environment, which prevents water penetration (Chu,

Feng, and Seeger, 2015). The Cassie-Baxter regime is described by the following contact angle

Equation (3) (Feng and Jiang, 2006):

Figure 3 WCA formed by liquid droplets on a smooth,

solid surface, in the air.

2.2. Contact angle under water or oil

The above wetting regimes are

valid for the case of liquid contact with a solid (smooth or rough) surface in

the air. However, to calculate the contact angle of liquid drop A (LA)

under liquid B (LB) the following Equation (4) is derived (Liu

et al., 2009):

where – surface tensions at the interfaces, respectively: liquid A-gas, liquid B-gas,

and liquid A-liquid B. The angles

A and

B are the contact

angles of fluids A and B with air. Figure 4 shows the modes of surface wetting

with liquid A under liquid B.

Depending on the contact angle, the wettability regime, and the environment (air, water, oil), there are several possible extreme wettability states (Wang et al., 2015; Chen and Xu, 2013), namely: superhydrophilic, superhydrophobic, superolephilic, and superoleophobic wettability in the air; underwater superoleophobicity and underwater superoleophilicity in water; underoil superhydrophilicity and underoil superhydrophobicity (Li et al., 2016a; Wang et al., 2015).

Figure 4 Regimes of wetting a solid surface with

liquid A (LA) in liquid B (LB)

To describe the properties of porous materials used for emulsion

separation and evaluate their effectiveness, the comparison includes

characteristics such as contact angle, absorption capacity, and emulsion

separation efficiency. We consider surfaces with WCA of 0°, 90°, >90° and

>150° to be superhydrophilic, hydrophilic, hydrophobic, and

superhydrophobic, respectively. Surfaces with oil contact angles (OCA) of 0°,

90°, >90° and >150° we consider to be superoleophilic, oleophilic,

oleophobic and superoleophobic, respectively.

Absorption capacity is determined

by immersing the test material in W/O until the material is saturated with

liquid. The test sample is then removed from the liquid, and the mass is

measured. Absorption capacity (Q) is calculated by Equation (5) (Meng

et al., 2017):

where ms and ms,o – the

mass of the test material before and after liquid absorption, respectively.

Absorption capacity is measured in g/g, and the process is influenced by

factors such as porosity and pore size of the adsorbent; pH, density, and

viscosity of a liquid; size of liquid molecules; concentration of dispersed

phase particles (SobolCiak et al., 2021). The wetting regime is

influenced by the porosity and pore size of the adsorbent. As these increase,

the liquid penetration into the porous structure also increases. Porous

materials absorb high-viscosity liquids, such as oil or diesel, better than

low-viscosity liquids, such as hexane, that is, the adsorption capacity is

proportional to the density of the oil (Wang et

al., 2020; Li et al., 2019a). The adsorption capacity of porous material to

droplets of oil in the emulsion varies depending on the pH of the water.

According to a study by (Alazab and Saleh, 2022), the highest adsorption capacity

was achieved in neutral water (31 g/g at pH = 7); in an acidic environment, the

adsorption capacity decreased slightly (30 g/g at pH = 2), in an alkaline

environment, porous material absorbs oil even worse (26 g/g at pH=12).

According to (Ahmed, Anis, and Khalil, 2021), the smaller the size of oil droplets, the

lower the adsorption capacity.

The emulsion separation

efficiency is calculated by Equation (6) (Li et al., 2019b):

where Cfeed – oil concentration in

the initial emulsion, Cfiltrate – oil concentration in the filtrate.

3.1. Metal Foams Used

for Emulsion Separation

Porous metals are actively used in industry to solve various problems

related to filtration and heat transfer (Solovev et al., 2022; Soloveva et al., 2022; Soloveva, Solovev, and Yafizov, 2021; Solovev et al., 2019). These metal foams exhibit

effective absorption of both water and oil well. Therefore, to separate W/O emulsions, hydrophobic coating, for example, HDTMS, hydrophobic silica,

carbon nanoparticles, etc., is applied to the surface of the metal foam. For

instance, the study by (Zhang et al., 2019a) developed nickel foam by

synthesizing the ZnO@Co3O4 hierarchical structure using

hydrothermal method followed by calcination and hydrophobic modification with

HDTMS. The modified foam showed a high WCA of 158°, separation efficiency

varied from 97 to 99%. The following methods are used for coating the surface of metal foam:

electrochemical deposition method (Zhang et al., 2023), immersion deposition method (Eum

et al., 2019),

simple dipping method followed by drying in an oven (Wang et

al., 2021b),

acid dipping and etching method (Álvarez-Gil, Ramirez, and

Fernandez-Morales, 2021), etc. In the study by (Zhang

et al., 2019b) hydrophobic-oleophilic iron foam

was developed by immersion in n-dodecyl mercaptan (NDM). The Fe-NDM foam showed

high hydrophobicity (WCA=145°) and a separation efficiency of O/W emulsions of 98%. Subsequently, coating a metal

foam results in a reduction in cell size and a decrease in the permeability of

the foam. The coating should be as thin as possible while providing high hydrophobic

or oleophobic properties. In the study, (Chen et

al., 2020) proposed a method for applying a superoleophobic

coating, in which a metal felt was immersed in a colloidal suspension of

silicon dioxide, washed, dried, and then annealed at 550°C. The thickness of

the coating layer was about a hundred nanometers, thereby the pore sizes

remained practically unchanged. The resulting material showed high efficiency

in absorbing water from W/O emulsions, maintaining excellent

performance after 30 use cycles.

Metal foams have been extensively examined as an absorbent material for

separating W/O and O/W emulsions. However, using porous

metals as coalescing baffles in gravity-dynamic separators is also known from

the literature. A comparison between plate and highly porous partitions serves

to intensify the process of separation of the emulsion. In a study by (Solov’eva et al., 2021), the influence of the baffle

design on the emulsion separation process was investigated. A comparison

between the plate and highly porous baffles showed that porous baffles provide

more effective separation at low emulsion flow rates, and plate baffles are

more effective at high emulsion flow rates.

Metal foams are characterized by the following advantages, which include high mechanical strength and lightweight, high porosity, and large surface area. However, the widespread application is affected by susceptibility to contamination and corrosion. In emulsion separation, the foam becomes clogged with oil droplets and organic substances, which leads to a decrease in the wettability of the surface and a decrease in separation efficiency. The foam must be washed periodically, for example, with ethanol, to restore the performance. To solve the problem of pollution, scientists are developing foams capable of self-cleaning (Li et al., 2022; Wu et al., 2020b; Kang et al., 2018). Self-cleaning surfaces are characterized by a high static WCA and a small sliding angle, which leads to the so-called self-cleaning effect (Zhang et al., 2013). Another disadvantage of metal foams is corrosion, and hydrophobic and anticorrosive coating is often applied to the surface of the foam to solve this problem (Li et al., 2022).

3.2. Polymer foams used for emulsion separation

In addition to metal foams, polymeric foams are used to separate

emulsions. The most widely used polyurethane (PUF) and melamine foams (MF) are

due to their cost-effectiveness, ease of production, and high wettability.

Polymeric foams are characterized by high hydrophilicity and oleophilicity (Krishnamoorthi et al.,

2021; Wang et al., 2014). Foams are often coated with hydrophobic/oleophilic, less often with

hydrophilic/oleophobic coating to separate emulsions (Jin et

al., 2022; Li et al.,

2018; Li et al.,

2016b). Hydrophobic

coatings increase surface roughness (Hou et al., 2019), thereby ensuring hydrophobicity

of the material (Ejeta et al., 2021). Table 1 shows the

characteristics of polymeric foams modified with various hydrophobic coatings.

Surface modifier affects the adsorption capacity

of porous material. In a study by (Qiang et al., 2018), they synthesized

composite sponges based on polyurethane foam and graphene oxide nanoribbons

(GONR) and modified them with two different silanol groups:

trimethoxyoctadecylsilane (TMOS) and trimethoxysilane (FAS). TMOS-modified foam

became superhydrophobic (WCA=153°) and superoleophilic (OCA = 0°). The foam

treated with FAS achieved superhydrophobicity using WCA of 165 contact angle

with superoleophobic behavior towards specific oils such as diesel, toluene,

and n-hexane. Surface modification influenced the foam adsorption capacity,

with FAS-modified samples showing significantly lower absorption rates for

n-hexane, toluene, gasoline, and diesel compared to samples treated with GONR

and TMOS. The study reported that the surface properties of composites could be

adapted to water or oil by adjusting the end groups of silane molecules.

Hydrophobic coating changes the surface roughness of the foam, forms a

hierarchical structure, and leads to an increase in capillary forces, which

affects the rate of oil adsorption. In a study by (Xue et

al., 2021b)

PU foam was modified with polydimethylsiloxane (PDMS/PU) and copper

terephthalate (CuT-PA/PDMS/PU). CuTPA/PDMS/PU foam had higher roughness than

PDMS/PU foam, and the presence of a hierarchical structure resulted in increased

capillary forces and an 8-fold increase in motor oil adsorption rate compared

with PDMS/PU foam. In another study by (Xu et al., 2021) MF was modified with microporous polymers using

carboxyl (CMP-COOH) and hydroxyl (CMP-OH) groups. Modification with carboxyl

groups provides a higher adsorption capacity of the composite foam, for

comparison: the adsorption capacity of CMP-COOH and CMP-OH foams for toluene

was 75 g/g and 56 g/g, respectively. The modifier concentration also affects

the adsorption capacity. According to the study by (Xue et

al., 2021a)

melamine sponge was modified with MXene and tetradecylamine (TDA) in

different concentrations. Increasing the concentration of both MXene and TDA

increased WCA. The addition of MXene increased oil adsorption capacity compared

to pure melamine sponge.

However, MXene@MS foam continued to absorb water

due to its hydrophilic nature. The addition of TDA reduced the surface energy

of the melamine sponge, increasing hydrophobicity. As a result, TDA@MS and

TDA-MXene@MS composite foams did not absorb water at all and displayed higher

oil adsorption capacity. This indicates that the choice of modifier and its

concentration influence surface roughness, form a microporous hierarchical

structure, bolster capillary forces, and consequently impact oil adsorption

capacity and rate.

In addition to the above modifiers, polymer

foams are modified with reduced graphene oxide (Jamsaz and

Goharshadi, 2020; Zhang, Liu, and Qiao, 2020; Zhou et al., 2019; Cao et al., 2019; Zhang et al., 2017), carbon

nanotubes (Visco et al., 2021), carbon nanofibers (Guo

et al., 2021; Baig,

Alghunaimi, and Saleh, 2019),

carbon black (Chen et

al., 2023; Yang et

al., 2023), etc. Carbon modifiers contributed to a

significant increase in the hydrophobicity of foams (WCA > 150°), and also

improved the mechanical properties.

In addition to polyurethane foam and melamine

foam, less common polymeric foams are known to be synthesized from

polystyrene-divinylbenzene (Zhang et al., 2016),

polylactic acid (Wang et al., 2019), and

polypropylene (Mi et al., 2019).

Traditionally, emulsion separation materials

have been characterized by either hydrophobic or oleophobic properties.

However, contemporary investigation is focusing on developing materials with

opposite wettability, capable of displaying both hydrophobic and oleophobic

properties, depending on the conditions. For example, when the material is

pre-wetted with oil, it exhibits superoleophilic and superhydrophobic

properties. Conversely, when the material is initially wetted with water, it

shows superhydrophilic and superleophobic properties. This behavior is

explained by the presence of hierarchical voids in the material. If the

material has micro- and nano-sized pores, the first infusion liquid, for

example, water, penetrates through the micropores. Laplace forces retain the

second (oil), and the material exhibits superleophobic properties.

Despite the extensive

investigations in using porous materials for separating emulsions, critical

challenges persist including (i) protecting metal porous adsorbers from corrosion

and (ii) cleaning adsorbers from oil contaminants to extend the service life

remain unresolved.

Table 1 Characteristics of polymeric

foams modified with hydrophobic coatings

|

Base material |

Coating material |

WCA |

Oil |

Oil absorption capacity,

g/g |

Ref. |

|

PUF |

Graphene oxide

nanoribbons |

153° |

n-hexane |

34 |

(Qiang et al.,

2018) |

|

Stearic acid |

140° |

n-hexane |

23 |

(Wang and Zheng,

2017) | |

|

Octadecyl

Trichlorosilane |

156° |

n-hexane |

21 |

(Liang et al.,

2019) | |

|

Fe3O4

nanoparticles, |

145° |

n-hexane |

10 |

(Alazab and Saleh, 2022) | |

|

Titanate nanotubes |

128° |

n-hexane |

20 |

(Pan et al.,

2015) | |

|

Polydimethylsiloxane |

157° |

n-hexane |

12.5 |

(Xue et al.,

2021b) | |

|

MF |

Microcrystals MgAl-LDH |

163.2° |

n-hexane |

70.5 |

(He et al.,

2022) |

|

TiO2

nanoparticles |

161.1° |

ethanol |

46 |

(Cho et al.,

2016) | |

|

Polydimethylsiloxane |

157° |

ethanol |

58 |

(Wang et al.,

2020) | |

|

Copper nanoparticle |

148.5° |

pump oil |

90 |

(Li et al.,

2019c) | |

|

Waste epoxy resins |

146.5° |

pump oil |

80 |

(Liu et al.,

2020) | |

|

Conjugated microporous

polymers |

153.92° |

toluene |

73 |

(Xu et al.,

2021) | |

|

Acrylic copolymer/silica |

153.5° |

n-hexane |

78 |

(Li et al.,

2019b) | |

|

Tetradecylamine-MXene |

152° |

toluene |

60 |

(Xue et al.,

2021a) | |

|

Halloysite NP and

SiO2 |

158° |

toluene |

110 |

(Song et al.,

2022) | |

|

PDMS foam |

Graphene |

130.8° |

n-hexane |

10.2 |

(Pan et al.,

2021) |

|

Multiwalled carbon

nanotubes |

157° |

– |

– |

(Zhou et al.,

2023) |

In conclusion, porous materials with selective wettability were actively used to separate O/W and W/O emulsions formed during oil production or as a result of oil spillage. At industrial enterprises, various emulsions were formed, the properties of which depend on the density (0.71 – 1.07 g/mL) and viscosity (from 1 to 3.04·105 mPa·s) of petroleum and oil, as well as water content (10 – 90%). To improve the oil quality and purify wastewater, O/W, and W/O emulsions were separated by adsorption or filtration with porous materials. This review systematically presented the results of the separation of emulsions by porous media, emphasizing the influence of surface modifiers on the separation characteristics. The analysis showed that the type and concentration of the modifier significantly influenced WCA, adsorption capacity, and separation efficiency. The water contact angle (WCA) of PU foam, treated with different hydrophobic coatings, ranged between 1280 and 1570, showcasing hydrophobicity or superhydrophobicity. Additionally, the adsorption capacity for n-hexane fluctuated from 10 to 34 g/g. The viscosity and density of emulsions also affected adsorption capacity. Porous materials absorb high-viscosity liquids (2·103 – 2·105 mPa·s) better than low-viscosity liquids (0.5 – 120 mPa·s). Hydrophobic and oleophilic composites were used for the adsorption of oil from emulsions. Accordingly, these composites are advisable to use for eliminating oil and oil products that spill water. Hydrophobic composites were not suitable for gravitational separation of emulsions, because water naturally settles under oil on the surface of the composite, forming a barrier layer and preventing oil droplets from penetrating the pores. In addition, hydrophobic composites quickly become contaminated with oil during gravitational separation. In this scenario, it was advisable to use hydrophilic and oleophobic porous composites.

This review was funded by the Russian Science

Foundation, Grant Number 21-79-10406, https://rscf.ru/en/project/21-79-10406/.

Acharya, T., Potter, T.A., 2021. CFD Study on Hydrocarbon Mean Residence

Time in a Horizontal Oil–Water Separator. SN Applied Sciences,

Volume 3, pp. 1–10

Ahmed, R.M., Anis, B., Khalil, A.S., 2021. Facile Surface Treatment and

Decoration of Graphene-Based 3D Polymeric Sponges for High-Performance

Separation Of Heavy O/W Emulsions. Journal of Environmental Chemical

Engineering, Volume 9(2), p 105087

Alazab, A.A., Saleh, T.A., 2022. Magnetic Hydrophobic Cellulose-Modified

Polyurethane Filter for Efficient O/W Separation In A Complex Water

Environment. Journal of Water Process Engineering, Volume 50, p. 103125

Álvarez-Gil, L., Ramirez, J., Fernandez-Morales, P., 2021.

Ultra-Hydrophobic Aluminum Foam Development for Potential Application in

Continuous W/O Separation Processes. Surfaces and Interfaces, Volume 26,

p. 101362

Baig, N., Alghunaimi, F.I., Saleh, T.A., 2019. Hydrophobic And

Oleophilic Carbon Nanofiber Impregnated Styrofoam for Oil and Water Separation:

A Green Technology. Chemical Engineering Journal, Volume 360,

pp. 1613–1622

Camelo-Silva, C., Verruck, S., Ambrosi, A., Di Luccio, M., 2022.

Innovation and Trends in Probiotic Microencapsulation by Emulsification

Techniques. Food Engineering Reviews, Volume 14(3), pp. 462–490

Cao, N., Guo, J., Boukherroub, R., Shao, Q., Zang, X., Li, J., Lin, X.,

Ju, H., Liu, E., Zhou, C., Li, H., 2019. Robust Superhydrophobic Polyurethane

Sponge Functionalized with Perfluorinated Graphene Oxide for Efficient

Immiscible O/W Mixture, Stable Emulsion Separation, and Crude Oil

Dehydration. Science China Technological Sciences,

Volume 62(9), pp. 1585–1595

Chen, C., Chen, S., Chen, L., Yu, Y., Weng, D., Mahmood, A., Wang, J.,

Parkin, I.P., Carmalt, C.J., 2020. Underoil Superhydrophilic Metal Felt

Fabricated by Modifying Ultrathin Fumed Silica Coatings for The Separation of

W/O Emulsions. ACS Applied Materials & Interfaces,

Volume 12(24), pp. 27663–27671

Chen, J., Sun, M., Ni, Y. Zhu, T., Huang, J., Li, X., Lai, Y., 2023.

Superhydrophobic Polyurethane Sponge for Efficient W/O Emulsion Separation and

Rapid Solar-Assisted Highly Viscous Crude Oil Adsorption and Recovery. Journal

of Hazardous Materials, Volume 445, p. 130541

Chen, P.C., Xu, Z.K., 2013. Mineral-Coated Polymer Membranes with

Superhydrophilicity and Underwater Superoleophobicity for Effective O/W

Separation. Scientific Reports, Volume 3(1), p. 2776

Cho, E.C., Chang-Jian, C.W., Hsiao, Y.S. Lee, K.C., Huang, J.H., 2016.

Interfacial Engineering of Melamine Sponges Using Hydrophobic TiO2

Nanoparticles for Effective O/W Separation. Journal of the Taiwan

Institute of Chemical Engineers, Volume 67, pp. 476–483

Chu, Z., Feng, Y., Seeger, S., 2015. O/W Separation with Selective

Superantiwetting/Superwetting Surface Materials. Angewandte Chemie

International Edition, Volume 54(8), pp. 2328–2338

Ejeta, D.D., Wang, C.F., Lin, C.H., Kuo, S.W., Chen, J.K., Tsai, H.C.,

Hung, W.S., Hu, C.C., Lai, J.Y., 2021. Preparation of a Main-Chain-Type

Polybenzoxazine-Modified Melamine Sponge Via Non-Solvent-Induced Phase

Inversion for Oil Absorption and Very-High-Flux Separation of W/O

Emulsions. Separation and Purification Technology, Volume 263,

p. 118387

Esmaeili, H., Mousavi, S.M., Hashemi, S.A., Lai,

C.W., Chiang, W.H., Bahrani, S., 2021. Application of Biosurfactants in The

Removal of Oil from Emulsion. In: Green Sustainable Process for Chemical and

Environmental Engineering and Science: Biosurfactants for the Bioremediation of

Polluted Environments, Inamuddin, Adetunji, C.O., (eds.), Elsevier Inc. Amsterdam, Netherlands, pp. 107–117

Eum, K.Y., Phiri, I., Kim, J.W., Choi, W.S., Ko, J.M., Jung, H., 2019.

Superhydrophobic And Superoleophilic Nickel Foam for O/W Separation. Korean

Journal of Chemical Engineering, Volume 36, pp. 1313–1320

Fajun, Z., Zhexi, T., Zhongqi, Y., Hongzhi, S., Yanping, W., Yufei, Z.,

2020. Research Status and Analysis of Stabilization Mechanisms and

Demulsification Methods of Heavy Oil Emulsions. Energy Science &

Engineering, Volume 8(12), pp. 4158–4177

Feng, X.J., Jiang, L., 2006. Design and Creation of

Superwetting/Antiwetting Surfaces. Advanced Materials, Volume

18(23), pp. 3063–3078

Fingas, M., Fieldhouse, B., 2004. Formation Of Water-In-Oil Emulsions

and Application to Oil Spill Modelling. Journal of Hazardous Materials,

Volume 107(1-2), pp. 37–50

Fortuny, M., Oliveira, C.B., Melo, R.L., Nele, M., Coutinho, R.C.,

Santos, A.F., 2007. Effect of Salinity, Temperature, Water Content, And Ph on

The Microwave Demulsification of Crude Oil Emulsions. Energy &

Fuels, Volume 21(3), pp. 1358–1364

Guo, Z., Long, B., Gao, S., Luo, J. Wang, L., Huang, X., Wang, D., Xue,

H., Gao, J., 2021. Carbon Nanofiber Based Superhydrophobic Foam Composite for

High Performance O/W Separation. Journal of Hazardous Materials,

Volume 402, p. 123838

He, R., Liu, S., Wang, R. Fu, T., Zhang, R., Zhang, Q. Zhou, Y., 2022.

In Situ Modification of Melamine Sponge by MgAl-LDH with Super-Hydrophobicity

and Excellent Harsh Environment Tolerance for High Flux Emulsion

Separation. Separation and Purification Technology,

Volume 291, p. 120916

Hou, J., Zhao, G., Zhang, L., Wang, G., Li, B., 2019. High-Expansion

Polypropylene Foam Prepared in Non-Crystalline State and Oil Adsorption

Performance of Open-Cell Foam. Journal of Colloid and Interface Science,

Volume 542, pp. 233–242

Jamsaz, A., Goharshadi, E.K., 2020. Flame Retardant, Superhydrophobic,

and Superoleophilic Reduced Graphene Oxide/Orthoaminophenol Polyurethane Sponge

for Efficient O/W Separation. Journal of Molecular Liquids,

Volume 307, p. 112979

Jhawat, V., Gulia, M., Sharma, A.K., 2021. Pseudoternary Phase Diagrams

used in Emulsion Preparation. In Chemoinformatics and Bioinformatics in the

Pharmaceutical Sciences, Academic Press, Cambridge, Massachusetts, USA, pp.

455–481

Jiang, H., Müller-Plathe, F., Panagiotopoulos, A.Z.,

2017. Contact Angles from Young’s Equation In Molecular Dynamics Simulations. The

Journal of Chemical Physics, Volume 147(8), p. 084708

Jin, L., Gao, Y., Huang, Y. Ou, M., Liu, Z., Zhang, X., He, C., Su, B.,

Zhao, W., Zhao, C., 2022. Mussel-Inspired and in Situ Polymerization-Modified

Commercial Sponge for Efficient Crude Oil and Organic Solvent Adsorption. ACS

Applied Materials & Interfaces, Volume 14(2), pp. 2663–2673

Kang, H., Cheng, Z. Lai, H., Ma, H., Liu, Y., Mai, X., Wang, Y., Shao,

Q., Xiang, L., Guo, X., Guo, Z., 2018. Superlyophobic Anti-Corrosive and

Self-Cleaning Titania Robust Mesh Membrane with Enhanced O/W Separation. Separation

and Purification Technology, Volume 201, pp. 193–204

Kang, W., Jing, G., Zhang, H., Li, M., Wu, Z., 2006. Influence of

Demulsifier on Interfacial Film Between Oil and Water. Colloids and

Surfaces A: Physicochemical and Engineering Aspects, Volume 272(1-2),

pp. 27–31

Krishnamoorthi, R., Anbazhagan, R., Tsai, H.C., Wang, C.F., Lai, J.Y., 2021.

Preparation Of Caffeic acid-Polyethyleneimine Modified Sponge for Emulsion

Separation and Dye Adsorption. Journal of the Taiwan Institute of

Chemical Engineers, Volume 118, pp. 325–333

Li, F., Bhushan, B., Pan, Y., Zhao, X., 2019a. Bioinspired Superoleophobic/Superhydrophilic

Functionalized Cotton for Efficient Separation of Immiscible O/W Mixtures and

O/W Emulsions. Journal of Colloid and Interface Science,

Volume 548, pp. 123–130

Li, J., Wang, Y., Gao, R., Zhang, T.C., Yuan, S., 2022. Superhydrophobic

Copper Foam Modified with Hierarchical Stearic Acid/CuSiO3/Cu(OH)2

Nanocomposites for Efficient W/O Separation. Journal of Environmental

Chemical Engineering, Volume 10(3), p. 107618

Li, J., Xu, C. Zhang, Y., Wang, R., Zha, F., She, H., 2016a. Robust

Superhydrophobic Attapulgite Coated Polyurethane Sponge for Efficient

Immiscible O/W Mixture and Emulsion Separation. Journal of Materials

Chemistry A, Volume 4(40), pp. 15546–15553

Li, M., Bian, C., Yang, G., Qiang, X., 2019b. Facile Fabrication of

Water-Based and Non-Fluorinated Superhydrophobic Sponge for Efficient

Separation Of Immiscible Oil/Water Mixture And Water-In-Oil Emulsion. Chemical

Engineering Journal, Volume 368, pp. 350–358

Li, X., Liu, T., Wang, D., Li, Q., Liu, Z., Li, N., Zhang, Y., Xiao, C.,

Feng, X., 2018. Superlight Adsorbent Sponges Based on Graphene Oxide

Cross-Linked with Poly (Vinyl Alcohol) for Continuous Flow Adsorption. ACS

Applied Materials & Interfaces, Volume 10(25), pp. 21672–21680

Li, Y., Zhang, H., Fan, M., Zhuang, J., Chen, L., 2016b. A Robust

Salt-Tolerant Superoleophobic Aerogel Inspired by Seaweed for Efficient

Oil–Water Separation in Marine Environments. Physical Chemistry Chemical

Physics, Volume 18(36), pp. 25394–25400

Li, Z., Sang, S. Jiang, S.,Chen, L., Zhang, H., 2022. A Self-Detecting

and Self-Cleaning Biomimetic Porous Metal-Based Hydrogel for O/W

Separation. ACS Applied Materials & Interfaces,

Volume 14(22), pp. 26057–26067

Li, Z., Zhang, T., Qiu, F., Yue, X., Yang, D., Li, P., Zhu, Y., 2019c.

Facile One-Step Fabrication of Highly Hydrophobic, Renewable and Mechanically

Flexible Sponge With Dynamic Coating For Efficient O/W Separation. Journal

of the Taiwan Institute of Chemical Engineers, Volume 95, pp. 515–524

Liang, L., Xue, Y., Wu, Q., Dong, Y., Meng, X., 2019. Self-Assembly

Modification of Polyurethane Sponge for Application in O/W Separation. RSC

advances, Volume 9(69), pp. 40378–40387

Liu, M., Wang, S., Wei, Z., Song, Y., Jiang, L., 2009. Bioinspired

Design of a Superoleophobic and Low Adhesive Water/Solid Interface. Advanced

Materials, Volume 21(6), pp. 665-669

Liu, X., Tian, F., Zhao, X., Du, R., Xu, S., Wang, Y.Z., 2020. Recycling

Waste Epoxy Resin as Hydrophobic Coating of Melamine Foam for High-Efficiency

Oil Absorption. Applied Surface Science, Volume 529, p. 147151

Meng, G., Peng, H., Wu, J., Wang, Y., Wang, H., Liu, Z., Guo, X., 2017.

Fabrication Of Superhydrophobic Cellulose/Chitosan Composite Aerogel for O/W

Separation. Fibers and Polymers, Volume 18(4), pp. 706–712

Mi, H.Y., Jing, X., Liu, Y., Li, L., Li, H. Peng, X.F., Zhou, H., 2019.

Highly Durable Superhydrophobic Polymer Foams Fabricated by Extrusion and

Supercritical CO2 Foaming for Selective Oil Absorption. ACS Applied Materials & Interfaces,

Volume 11(7), pp. 7479–7487

Moldes, A.B., Torrado, A.M., Barral, M.T., Domínguez, J.M., 2007.

Evaluation Of Biosurfactant Production from Various Agricultural Residues by

Lactobacillus Pentosus. Journal of Agricultural and Food Chemistry,

Volume 55(11), pp. 4481–4486

Mostefa, N.M., Tir, M., 2004. Coupling Flocculation with Electroflotation

for Waste O/W Emulsion Treatment. Optimization Of the Operating

Conditions. Desalination, Volume 161(2), pp. 115–121

Pan, Y., Zhan, J., Pan, H., Yuan, B., Wang, W., Song, L., Hu, Y., 2015.

A Facile Method To Fabricate Superoleophilic and Hydrophobic Polyurethane Foam

For Oil–Water Separation. Materials Letters, Volume 159, pp.

345–348

Pan, Z., Guan, Y., Liu, Y., Cheng, F., 2021. Facile Fabrication of

Hydrophobic and Underwater Superoleophilic Elastic and Mechanical Robust

Graphene/PDMS Sponge For O/W Separation. Separation and Purification

Technology, Volume 261, p. 118273

Poerwadi, B., Kartikowati, C.W., Oktavian, R., Novareza, O., 2020.

Manufacture of a Hydrophobic Silica Nanoparticle Composite Membrane for O/W

Emulsion Separation. International Journal of Technology. Volume 11(2),

pp. 364–373

Portnov, I.Y., Ponikarov, S.I., Solovyev, S.A., Solovyeva, O.V., 2021.

Separator on The Principle Of Gravitational-Dynamic Separation Of Emulsions

(Water–Oil Type) For Solving Various Problems Of Oil And Gas Production,

Petrochemistry, And Ecology. Chemical and Petroleum Engineering,

Volume 57(1-2), pp. 129–135

Qiang, F., Hu, L.L., Gong, L.X., Zhao, L., Li, S.N., Tang, L.C., 2018.

Facile Synthesis of Super-Hydrophobic, Electrically Conductive and Mechanically

Flexible Functionalized Graphene Nanoribbon/Polyurethane Sponge for Efficient

O/W Separation At Static And Dynamic States. Chemical Engineering

Journal, Volume 334, pp. 2154–2166

Qin, J., Chen, Q., Yang, C., Huang, Y., 2016. Research Process on

Property and Application of Metal Porous Materials. Journal of Alloys

and Compounds, Volume 654,

pp. 39–44

Sachdev, D.P., Cameotra, S.S., 2013. Biosurfactants In

Agriculture. Applied Microbiology and Biotechnology,

Volume 97, pp. 1005–1016

Santos, D., da Rocha, E.C., Santos, R.L., Cancelas, A.J., Franceschi,

E., Santos, A.F., Fortuny, M., Dariva, C., 2017. Demulsification of

Water-In-Crude Oil Emulsions Using Single Mode and Multimode Microwave

Irradiation. Separation and Purification Technology,

Volume 189, pp. 347–356

Sapei, L., Agustriyanto, R., Fitriani, E.W., Levy, Z., Sumampouw, C.,

2022. Enhancement of the Stability of W/O/W Double Emulsion by Chitosan

Modified Rice Husk Silica. International Journal of Technology,

Volume 13(3), pp. 584–595

Sarkar, A., Kietzig, A.M., 2013. General

Equation of Wettability: A Tool to Calculate The Contact Angle For A Rough

Surface. Chemical Physics Letters, Volume 574, pp. 106–111

Satria, M., Saleh, T.A., 2022. Effect of Loading Various

Nanoparticles on Superhydrophobic/Superoleophilic Stearic Acid-Modified

Polyurethane Foams For O/W Separation. Journal of Environmental

Chemical Engineering, Volume 10(6), p. 108577

Semenov, E.V., Slavyanskiy, A.A., Mitroshina, D.P., 2021. Numerical

Analysis of Emulsion Separation Processes in A Continuous Centrifuge. Chemical

and Petroleum Engineering, Volume 57(1-2), pp. 113–121

Sobolciak, P., Popelka, A., Tanvir, A., Al-Maadeed, M. A., Adham, S.,

Krupa, I., 2021. Some Theoretical Aspects of Tertiary Treatment of Water/Oil

Emulsions by Adsorption And Coalescence Mechanisms: A Review. Water,

Volume 13(5), p. 652

Solov’eva, O.V., Solov’ev, S.A., Yafizov, R.R., Ponikarov, S.I., Portnov, I.Y.,

2021. Influence of Design of Baffles in a Gravity-Dynamic Separator Model on

W/O Emulsion Separation Efficiency. Chemical and Petroleum Engineering,

Volume 56(11-12), pp. 884–888

Solovev, S.A., Soloveva, O.V., Akhmetova,

I.G., Vankov, Y.V., Paluku, D.L., 2022. Numerical Simulation of Heat and Mass

Transfer in An Open-Cell Foam Catalyst On Example Of The Acetylene

Hydrogenation Reaction. ChemEngineering, Volume 6(1), p. 11

Solovev, S.A., Soloveva, O.V., Gilmurahmanov, B.Sh., Lamberov, A.A.,

2019. Numerical Investigation of The Ethylbenzene Dehydrogenation Reaction in a

Fixed Bed Reactor with Catalyst Granules of Various Sizes. Journal of

Physics: Conference Series, Volume 1399, p. 055022

Soloveva, O.V., Solovev, S.A., Vankov, Y.V.,

Shakurova, R.Z., 2022. Experimental Studies Of The Effective Thermal

Conductivity of Polyurethane Foams With Different Morphologies. Processes,

Volume 10(11), p. 2257

Soloveva, O.V., Solovev, S.A., Yafizov, R.R.,

2021. Numerical Simulation of The Aerosol Particle Motion in Granular Filters

with Solid and Porous Granules. Processes, Volume 9(2), p. 268

Solovyev, S.A., Solovyeva, O.V., Yafizov, R.R., Ponikarov, S.I.,

Portnov, I.Y., 2021. Study of The Influence of Coalescence Baffle Inclination

Angle On The Intensity Of W/O Emulsion Separation In A Separator Section. Chemical

and Petroleum Engineering, Volume 57(1-2), pp. 19–24

Song, Q., Zhu, J., Niu, X., Wang, J., Dong, G., Shan, M., Zhang, B.,

Matsuyama, H., Zhang, Y., 2022. Interfacial Assembly of Micro/Nanoscale

Nanotube/Silica Achieves Superhydrophobic Melamine Sponge for W/O

separation. Separation and Purification Technology, Volume 280, p.

119920

Sun, H., Wang, Q., Li, X., He, X., 2020. Novel Polyether-Polyquaternium

Copolymer as An Effective Reverse Demulsifier for O/W Emulsions:

Demulsification Performance and Mechanism. Fuel, Volume 263,

p. 116770

Visco, A., Quattrocchi, A., Nocita, D.,

Montanini, R., Pistone, A., 2021. Polyurethane

Foams Loaded with Carbon Nanofibers for Oil Spill Recovery: Mechanical

Properties Under Fatigue Conditions and Selective Absorption In O/W

Mixtures. Nanomaterials, Volume 11(3), p. 735

Wang, G., He, Y., Wang, H., Zhang, L., Yu, Q., Peng, S., Wy, X., Re, T.,

Zeng, Z., Xue, Q., 2015. A Cellulose Sponge with Robust Superhydrophilicity and

Under-Water Superoleophobicity for Highly Effective O/W Separation. Green

Chemistry, Volume 17(5), pp. 3093–3099

Wang, G., Zeng, Z., Wu, X. Ren, T, Han, J., Xue, Q., 2014.

Three-Dimensional Structured Sponge with High Oil Wettability for The Clean-Up of

Oil Contaminations and Separation Of Oil–Water Mixtures. Polymer

Chemistry, Volume 5(20), pp. 5942–5948

Wang, J., Zheng, Y., 2017. O/W Mixtures and Emulsions Separation of

Stearic Acid-Functionalized Sponge Fabricated via a Facile One-Step Coating

Method. Separation and Purification Technology, Volume 181,

pp. 183–191

Wang, N., Deng, Z., 2019. Synthesis Of Magnetic, Durable and

Superhydrophobic Carbon Sponges for Oil/Water Separation. Materials

Research Bulletin, Volume 115, pp. 19–26

Wang, S., Liu, K., Yao, X., Jiang, L., 2015. Bioinspired Surfaces with

Superwettability: New Insight on Theory, Design, And Applications. Chemical

Reviews, Volume 115(16), pp. 8230–8293

Wang, X., Han, Z., Liu, Y., Wang, Q., 2020. Micro-Nano Surface Structure

Construction and Hydrophobic Modification to Prepare Efficient O/W Separation

Melamine Formaldehyde Foam. Applied Surface Science,

Volume 505, p. 144577

Wang, X., Pan, Y., Liu, X. Liu, H., Li, N. Liu, C., Schubert, D.W.,

Shen, C., 2019. Facile Fabrication of Superhydrophobic and Eco-Friendly Poly

(Lactic Acid) Foam for Oil–Water Separation Via Skin Peeling. ACS

Applied Materials & Interfaces, Volume 11(15), pp. 14362–14367

Wang, Y., Fang, S., Wang, X., Wang, Y., Xiong, Y., Duan, M., 2021a.

Synthesis of a Novel Reverse Demulsifier with The Characteristics of

Polyacrylate and Polycation and Its Demulsification Performance. Journal

of Applied Polymer Science, Volume 138(41), p. 51200

Wang, Y., Zhao, S., Guo, Z. Huang, J., Liu, W., 2021b. Multi-Layer

Superhydrophobic Nickel Foam (NF) Composite for Highly Efficient W/O Emulsion

Separation. Colloids and Surfaces A: Physicochemical and Engineering

Aspects, Volume 628, p. 127299

Wu, B., Ye, L., Zhang, Z., Zhao, X., 2020a. Facile Construction of

Robust Super-Hydrophobic Coating for Urea-Formaldehyde Foam: Durable

Hydrophobicity and Self-Cleaning Ability. Composites Part A: Applied

Science and Manufacturing, Volume 132, p. 105831

Wu, M.B., Huang, S., Liu, C., Wu, J., Agarwal, S., Greiner, A., Xu,

Z.K., 2020b. Carboxylated Wood-Based Sponges with Underoil Superhydrophilicity

for Deep Dehydration Of Crude Oil. Journal of Materials Chemistry A,

Volume 8(22), pp. 11354–11361

Xu, L., Zang, Y., Xiao, J., Wu, Y., Pan, Y., Wu, T., Tang, Y., Cui, J.,

Jia, H., Miao, F., 2021. Superhydrophobic Conjugated Microporous Polymer-Coated

Sponges: Synthesis And Application For Highly Efficient O/W Separation And The

Recovery Of Palladium Ions. Separation and Purification Technology,

Volume 261, p. 118291

Xue, J., Zhu, L., Zhu, X., Li, H., Ma, C., Yu, S., Sun, D., Xia, F.,

Xue, Q., 2021a. Tetradecylamine-Mxene Functionalized Melamine Sponge for

Effective O/W Separation And Selective Oil Adsorption. Separation and

Purification Technology, Volume 259, pp. 118106

Xue, J., Zhu, L., Zhu, X., Li, H., Wang, R., Liu, X., Xia, F., Li, X.,

Xue, Q., 2021b. Hierarchical Superhydrophobic Polydimethylsiloxane/Copper

Terephthalate/Polyurethane Sponge for Highly Efficient O/W Separation. Colloids

and Surfaces A: Physicochemical and Engineering Aspects, Volume 630,

p. 127635

Yan, J., Cao, J., Xue, L., Feng, S., Zhang, H., Wang, D., 2020. Thiol

Oxidative Coupling Synthesis of Silicone Foams For O/W Separation. ACS

Applied Polymer Materials, Volume 2(4), pp. 1634–1643

Yang, M., Yang, L., Chen, Z., Ding, Y., Li, M., Wu, Q., Liu, T., Liu,

L., 2023. Superhydrophobic/Superoleophilic Modified Melamine Sponge for O/W

Separation. Ceramics International, Volume 49(7), pp.

11544–11551

Yang, S., Chen, L., Liu, S., Hou, W., Zhu, J., Zhao, P., Zhang, Q.,

2021a. Facile and Sustainable Fabrication of High-Performance Cellulose Sponge from

Cotton For O/W Emulsion Separation. Journal of Hazardous Materials,

Volume 408, p. 124408

Yang, S., Yin, K., Wu, J., Wu, Z., Chu, D., He, J., Duan, J.A., 2019.

Ultrafast Nano-Structuring of Superwetting Ti Foam with Robust Antifouling and

Stability Towards Efficient O/W Emulsion Separation. Nanoscale,

Volume 11(38), pp. 17607–17614

Yang, Y., Ali, N., Bilal, M., Khan, A., Ali,

F., Mao, P., Ni, L., Gao, X., Hong, K., Rasool, K., Iqbal, H. M., 2021b. Robust

Membranes with Tunable Functionalities for Sustainable O/W Separation. Journal

of Molecular Liquids, Volume 321, p. 114701

Zahari, N.Z., Yan, G.P., Rahim, S.A., 2022.

Effects of Single and Consortia Inoculants on the Biodegradation Efficiency of

Crude Oil in Seawater. International Journal of Technology, Volume

13(2), pp. 422–431

Zeng, Z.W.S., Taylor, S.E., 2020. Facile Preparation of Superhydrophobic

Melamine Sponge for Efficient Underwater O/W Separation. Separation and

Purification Technology, Volume 247, p. 116996

Zhang, J., Chen, R., Liu, J., Liu, Q., Yu, J., Zhang, H., Jing, H.,

Zhang, M., Wang, J., 2019a. Construction of ZnO@ Co3O4-Loaded Nickel Foam with

Abrasion Resistance and Chemical Stability For O/W Separation. Surface

and Coatings Technology, Volume 357, pp. 244–251

Zhang, M., Tian, G., Yan, H., Guo, R., Niu, B., 2023. Anticorrosive

Superhydrophobic High-Entropy Alloy Coating On 3D Iron Foam for Efficient O/W

Separation. Surface and Coatings Technology, Volume 468, p.

129756

Zhang, N., Zhong, S., Zhou, X., Jiang, W., Wang, T., Fu, J., 2016.

Superhydrophobic P (St-DVB) Foam Prepared By The High Internal Phase Emulsion

Technique For Oil Spill Recovery. Chemical Engineering Journal,

Volume 298, pp. 117–124

Zhang, R., Wu, Y., Zhang, H., Xue, S., Guo, M., Zhang, T., 2019b. A

Facile Strategy Toward Hydrophobic–Oleophilic 3D Fe Foam for Efficient

Oil–Water Separation. Journal of Materials Science,

Volume 54(20), pp. 13358–13367

Zhang, X., Li, Z., Liu, K., Jiang, L., 2013. Bioinspired Multifunctional

Foam with Self?Cleaning And O/W Separation. Advanced Functional

Materials, Volume 23(22), pp. 2881–2886

Zhang, X., Liu, D., Ma, Y., Nie, J., Sui, G.,

2017. Super-Hydrophobic Graphene Coated

Polyurethane (GN@ PU) Sponge with Great O/W Separation Performance. Applied

Surface Science, Volume, 422, pp. 116–124

Zhang, Z., Liu, H., Qiao, W., 2020. Reduced Graphene-Based

Superhydrophobic Sponges Modified by Hexadecyltrimethoxysilane for Oil

Adsorption. Colloids and Surfaces A: Physicochemical and Engineering

Aspects, Volume 589, p. 124433

Zhou, J., Zhang, Y., Yang, Y., Chen, Z., Jia, G., Zhang, L., 2019. Silk

Fibroin-Graphene Oxide Functionalized Melamine Sponge for Efficient Oil

Absorption and O/W Separation. Applied Surface Science,

Volume 497, p. 143762

Zhou, W., Zhan, B., Chen, Z., Wang, G., Liu, Y.,

2023. Robust 3D Porous Superhydrophobic Foam with Excellent Photothermal Effect

and Joule Heating Effect for Efficient All-Weather Cleanup of Highly Viscous

Crude Oil Spills. Separation and Purification Technology, Volume

320, p. 124117