Characteristics of Treated Monazite in Different Particle Sizes to Upgrade the Rare Earth Elements Content by Using Mechanochemical and Roasting Processes

Corresponding email: reza.ulum@ui.ac.id

Published at : 05 Feb 2024

Volume : IJtech

Vol 15, No 2 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i2.6722

Tjhia, M.A., Yahya, M.N.F., Ulum, R.M., 2024. Characteristics of Treated Monazite in Different Particle Sizes to Upgrade the Rare Earth Elements Content by Using Mechanochemical and Roasting Processes. International Journal of Technology. Volume 15(2), pp. 463-471

| Matthew Alexander Tjhia | Department of Metallurgical and Materials Engineering, Faculty of Engineering, University of Indonesia, Kampus Baru UI, Depok, 16424, Indonesia |

| Muhammad Nur Fakhriy Yahya | Department of Metallurgical and Materials Engineering, Faculty of Engineering, University of Indonesia, Kampus Baru UI, Depok, 16424, Indonesia |

| Reza Miftahul Ulum | Department of Metallurgical and Materials Engineering, Faculty of Engineering, University of Indonesia, Kampus Baru UI, Depok, 16424, Indonesia |

Rare earth metals (REE) constitute one of the most

crucial groups of elements globally.

In Indonesia, deposits of REE have been recognized within

monazite minerals extracted from tin mining operations in Bangka. Nevertheless,

Indonesia has not used these deposits and has instead heavily relied on imports

from other countries. This study aims to recover rare earth metals,

specifically Cerium (Ce), Lanthanum (La), Ytterbium (Yb), and Yttrium (Y), from

monazite sand, a by-product of tin mining. The method employed in this research

is Mechanochemical Decomposition, involving the reaction of monazite samples

with a 33 wt% solid Sodium Hydroxide (NaOH) to convert REE-Phosphate compound

into REE-Hydroxide. The

process begins with sample preparation, involving mechanochemical decomposition

using a ball mill, followed by roasting at 400°C, leaching with distilled

water, and subsequent steps of filtration and drying at 120°C. Various initial

particle sizes, denoted as +65, -65 +100, -100 +140, -140 +170, and -170 mesh,

were used to assess their effect on the recovery and grade of REE. Various

initial particle sizes, denoted as +65, -65 +100, -100 +140, -140 +170, and

-170 mesh, were used to assess their effect on the recovery and grade of REE.

The series of procedures revealed notable improvements in the REE content in

monazite. The highest recovery of Ce, La, Yb, and Y elements reached 46.43%,

70.08%, 22.69%, and 23.31%, while the highest grade of those elements obtained

the values of 4.116%, 1.543%, 0.263%, and 1.681%, respectively. In alignment

with prior research, the recovery of Light Rare Earth Elements (LREEs)

surpasses that of Heavy Rare Earth Elements (HREEs). However, a unique

observation emerges: a diminishing trend in both recovery and grade as particle

sizes become finer. This unexpected phenomenon warrants further investigation

to elucidate the mechanisms governing rare earth metal recovery from monazite

sand under varying particle sizes.

By-product; Monazite; Particle size; REE-Oxide; Roasting

Rare

earth metals (REE) are a mineral group consisting of 17 elements, namely 15

elements of the lanthanide group (La – Lu), Scandium (Sc), and Yttrium (Y)

Trisnawati et al. (2020) reported

that Y, Gd, Er, Dy, and Yb as HREEs2-(SO4)3 products can be recovered

through sulfuric acid leaching, while the result from Prameswara

et al. (2023) showed that Dy and Yb leaching

from solid REE-hydroxide using HCl solution afforded a total of 61.71% Dy and

74.55% Yb recovery.

The processing of REE from monazite can be achieved through chemical

treatment, employing acid and base methods. Two common approaches involve NaOH

digestion or leaching with H2SO4 to extract REE from

monazite

In a few studies, the researcher has used mechanochemical processes,

especially inorganic material. For instance, Bonnaillie et al. used the

mechanochemical method for synthesizing SnO2 nanostructures

2.1. Sample Preparation

Monazite

sand was preliminarily dried at 80°C and subsequently underwent size reduction

through ball milling, with a rotational speed ranging from 67.8 to 71.1 rpm

over a 30-minute duration. The milling process yielded five distinct particle

size fractions, specifically +65 mesh, -65 to +100 mesh, -100 to +140 mesh,

-140 to +170 mesh, and -170 mesh.

2.2. Mechanochemical with NaOH 33wt%

Each

particle size fraction was subjected to a mechanochemical treatment with the

incorporation of 33 wt% sodium hydroxide (NaOH) from Pro Analys Merck 106498.

The purpose of adding NaOH was to react with rare earth element phosphate

(REE-PO4) and produce rare earth element hydroxides (REE-OH). The

mechanochemical process was conducted within a ball mill from NOAH NQM-4,

employing a rotational speed of 650 rpm for a duration of 120 minutes.

2.3. Roasting

Before

the roasting step, the mechanochemically treated samples were subjected to

compaction using a Krisbow Hydraulic Press, thereby increasing the contact

surface area. Subsequently, the roasting procedure was conducted in a Payun

Tech Muffle Furnace within alumina crucibles, sustained at a temperature of

400°C for a duration of 120 minutes. This process served the dual purpose of

finalizing the NaOH and REE-PO4 reaction and facilitating the

oxidation of rare earth elements inherent in the sample.

2.4. Distilled water washing, filtration,

and drying

The roasted product was subjected

to leaching with distilled water at a controlled temperature of 70°C and a

rotational speed of 680 rpm, maintained for a duration of 30 minutes, which was

discussed in the next section as a washing process. The process was conducted

by a Hot Plate Magnetic Stirrer from Thermo Scientific Cimarec SP88857105. The

primary objective of this step was to facilitate the dissolution of the formed

Na3PO4 compound. Following completion of the leaching

process, the mixture was subjected to filtration, yielding a precipitate. This

precipitate was subsequently isolated and subjected to drying at 120°C for 120

minutes using Memmert UN 55 Oven.

2.5.

Characterization

To

identify the REE content in the initial sample, the ICP-OES test was conducted

at Laboratorium Teknologi Bahan Galian Nuklir National Research and Innovation

Agency (BRIN). X-ray Diffraction (XRD) and X-ray Fluorescence (XRF) analyses

were conducted on dried samples as part of a comprehensive characterization

step. The objective of the XRD analysis, undertaken at the Center for Materials

Processing and Failure Analysis (CMPFA) at Universitas Indonesia, and the XRF

is conducted at the Laboratory of the National Research and Innovation Agency

(BRIN), focused on quantifying the concentration increments of key elements,

specifically Cerium (Ce), Lanthanum (La), Ytterbium (Yb), and Yttrium (Y).

These analyses collectively provided essential insights into the composition

and elemental content of the investigated specimens, contributing to a

comprehensive understanding of their properties and potential applications.

3.1. Monazite Raw Sand Characteristics

Following the method outlined by Zhang and Noble,

the initial monazite is characterized using Inductively Coupled Plasma-Optical

Emission Spectroscopy (ICP-OES).

Before the mechanochemical and roasting processes, sample preparation was

carried out on the monazite. Firstly, the monazite was subjected to a drying

process to eliminate any residual moisture present

Table 1 ICP-OES results of initial

monazite samples

|

Elements |

Ce |

La |

Nd |

Pr |

Sm |

Y |

Gd |

Dy |

Sc |

Tb |

Eu |

Yb |

|

Concentration (ppm) |

8927 |

4189 |

2860 |

1750 |

737.3 |

436.4 |

161.8 |

158.3 |

23.7 |

6.8 |

2.8 |

0.14 |

Table 2 XRF results of

the initial monazite sample

|

Particle Size (mesh) |

+65mesh |

-65mesh +100mesh |

-100mesh +140mesh |

-140mesh +170mesh |

-170mesh | |

|

Concentration (wt%) |

Ce |

0.759 |

1.165 |

0.801 |

0.878 |

0.898 |

|

La |

0.174 |

0.279 |

0.203 |

0.218 |

0.206 | |

|

Y |

0.958 |

0.595 |

0.642 |

0.628 |

0.767 | |

|

Yb |

0.154 |

0.089 |

0.082 |

0.089 |

0.102 | |

3.2.

Converting Rare Earth Phosphate to Rare Earth Hydroxide

In order to decompose phosphates in REE, monazite is

milled with the addition of NaOH. The milling process took place in a planetary

ball mill for 120 minutes at 680 rpm, serving two primary purposes: mixing and

milling. Monazite is mixed well with NaOH during milling, while the mechanical

force helps break bonds between REE and phosphates. NaOH will react with

phosphate, producing REE hydroxides and Na3PO4

Besides that, NaOH also reacts with CO2 in the atmosphere,

creating Na2CO3 as a product

3.3. Roasting in

atmospheric condition

This process aims to change hydroxide from mechanochemical to oxide

compound. The method includes heating samples at 400o for 2 hours in the

atmospheric condition. The reaction that occurs during roasting is as shown:

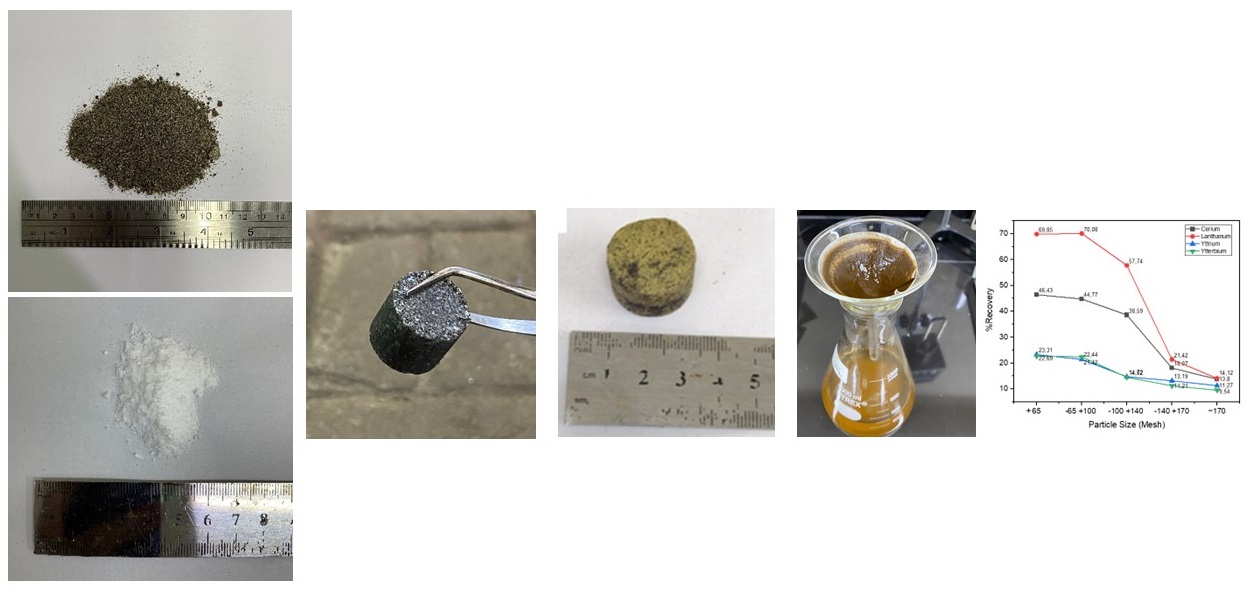

The result shows the change in

morphology and color. The pellets show expansion and shift in color from dark

grey to yellow-greenish. Expansion on +65mesh and -65mesh +100mesh seen are

much more significant than the rest. Lower expansion on -100mesh +140mesh, -140mesh

+170mesh, and -170mesh is caused of

denser pellets. Expansion might occur because of CO2 formation

during the reaction between phosphate and Na2CO3, as

shown in equation 1

The reaction can be validated with XRD,

where REE was found in the oxide form. XRD also shows Na in Na3PO4

and Na2CO3 form, which indicates equations (1) and (2) have

occurred. SnO2, SiO2, Fe3O4, and

FeTiO3 are monazite impurities as a cassiterite by-product, as shown

in Figure 1

Figure 1 XRD results

after the roasting process.

3.4. Leaching

with distilled

water to dissolve Na3PO4

Na (Na2CO3 and Na3PO4)

dissolve in water. Therefore, the by-product will dissolve by agitating the

sample in distilled water, leaving only REE residue

XRD shows that Na is still

present as Na2CO3 and Na3PO4,

indicating insufficient washing time. On the other hand, the REEs and

impurities compound's form doesn't change. The analysis results of the XRD

pattern are shown in Figure 2. Upon completion of the washing and drying

processes, an analysis of the residue revealed an increase in the concentration

levels of elements Ce, La, Y, and Yb. The X-ray Fluorescence (XRF)

characterization results presented in Table 3. demonstrate the observed changes

in element concentrations.

Figure 2 XRD

results after distilled water washing and drying

Table 3 XRF result of the product after distilled water washing and

drying

|

Particel

Size (mesh) |

+65mesh |

-65mesh +100mesh |

-100mesh +140mesh |

-140mesh +170mesh |

-170mesh | |

|

Concentration

(wt%) |

Ce |

2.653 |

4.116 |

3.829 |

1.861 |

1.376 |

|

La |

0.915 |

1.543 |

1.452 |

0.548 |

0.323 | |

|

Y |

1.681 |

1.006 |

1.171 |

0.972 |

0.960 | |

|

Yb |

0.263 |

0.159 |

0.148 |

0.117 |

0.108 | |

3.5 Product Morphology after roasting and after the

leaching process

SEM results with 1000 x magnification of the sample after the roasting process can be seen in Figure 3. Meanwhile, the SEM results with 1000 x magnification of the sample after the washing and drying process can be seen in Figure 4. According to EDS result, in the samples after the washing process with sizes -100mesh +140mesh and -170mesh, the Ce content was 33.17% and 0.92%, respectively. Meanwhile, other samples did not show any REE content.

Figure 3 SEM results after roasting for particle size (a) +65mesh (b) -65mesh +100mesh (c) -100mesh +140mesh (d) -140mesh +170mesh (e) -170mesh

Figure 4 SEM results after washing for particle size (a) +65mesh (b) -65mesh +100mesh

(c) -100mesh +140mesh (d) -140mesh +170mesh (e) -170mesh

Table 4 EDS result of the product after distilled water washing and

drying

|

Particle

Size (mesh) |

+65mesh |

-65mesh +100mesh |

-100mesh +140mesh |

-140mesh +170mesh |

-170mesh | |

|

Concentration

(wt%) |

C |

2.48 |

2.85 |

2.01 |

1.26 |

1.84 |

|

O |

32.87 |

33.21 |

29.31 |

22.68 |

33.45 | |

|

Na |

2.04 |

13.99 |

9.88 |

2.30 |

6.24 | |

|

Mg |

0.19 |

0.11 |

- |

0.52 |

0.78 | |

|

Al |

0.41 |

2.15 |

1.03 |

0.57 |

1.59 | |

|

Si |

2.9 |

16.3 |

9.07 |

1.54 |

5.26 | |

|

S |

0.96 |

2.15 |

1.41 |

0.42 |

1.06 | |

|

Sn |

51.12 |

6.40 |

3.31 |

67.09 |

39.80 | |

|

Ca |

0.81 |

0.25 |

0.24 |

1.29 |

0.07 | |

|

Ti |

0.73 |

2.47 |

1.77 |

0.29 |

0.38 | |

|

Fe |

4.77 |

19.90 |

8.21 |

1.58 |

7.53 | |

|

Ni |

0.71 |

0.21 |

0.60 |

0.46 |

0.48 | |

|

Ba |

- |

- |

- |

- |

0.61 | |

|

Ce |

- |

- |

33.17 |

- |

0.92 | |

%recovery

calculation was done on the final product using REE contents based on equation

(4).

The result of the %recovery calculation from Ce, La, Y, and Yb is present on a graph shown in Figure 5. Based on that picture, the coarser the initial particle size, the higher %recovery will be earned. This phenomenon can be attributed to the fact that samples with finer particle sizes tend to experience greater losses during the processing stages, resulting in higher weight loss percentages.

Figure 5 Effect of initial particle size on (a) %recovery and

(b) %grade of Ce, La, Y, and Yb

Monazite

contains REE, mainly LREE. Sn, Fe, and Ti present as impurities. NaOH is an

effective reagent used for mechanochemical decomposition to remove phosphate

from monazite by reacting and producing Na3PO4. Ce, La,

Yb, and Y had their content increased after the procedure. The highest %grade

of Ce and La achieved at particle size -65mesh +100mesh respectively by 4.116%

and 1.543% each. Yb and Y have the highest %grade at particle size +65mesh,

respectively, by 0.263% and 1.681% each. The highest %recovery of Ce, La, Yb,

and Y was achieved at particle size +65mesh by 46.43%, 70.08%, 22.69%, and

23.31% respectively, which have the final form of CeO2, La2O3,

Yb2O3, and Y2O3.

The authors express their gratitude to the

Center for Materials Processing and Failure Analysis (CMPFA) Department of

Metallurgical and Materials Engineering at Universitas Indonesia for their

supports in conducting this research.

Ahmadi, M., Seyedin, S.H., 2019.

Investigation of NaOH Properties, Production and Sale Mark in the world Modern

Spent Caustic Treatment System View project Investigation of NaOH Properties,

Production and Sale Mark in the world. Journal of Multidisciplinary

Engineering Science and Technology (JMEST), Volume 6(10), pp. 10809–10813

Bünzli, J.-C., Pecharsky, V., 2016.

Handbook on the Physics and Chemistry of Rare Earths. 1st Edition.

Amsterdam: North-Holland

Fortune Business Insight, 2021. Rare

Earth Elements Market Size & Forecast Report [2021-2028],

Fortunebusinessinsight.Com. Available online at: https://www.fortunebusiness

insights.com/rare-earth-elements-market-102943, Accessed on October 3, 2022

Gupta, C.K., Krishnamurthy, N., 2005.

Extractive Metallurgy of Rare Earths. Florida, United States of America: CRC

Press

Habashi, F., 2013. Extractive

Metallurgy of Rare Earths. Canadian Metallurgical Quarterly, Volume

52(3), pp. 224–233

Harjanto, S.,

Virdhian, S., Afrilinda, E., 2013. Characterization of Indonesia Rare

Earth Minerals and Their Potential Processing Techniques Synthesis of Zeolite

Catalyst from Badau Belitung Kaolin View project Logam Tanah Jarang View Project.

Available online at https://www.researchgate.net/publication/265096672,

Accessed on October 15, 2022

Jung, H., Lee, Y.J., Yoon, W.B.,

2018. Effect of Moisture Content on The Grinding Process and Powder Properties

In Food: A Review. Processes, Volume 6(6), p. 69

Kim, W., Bae, I., Chae, S., Shin, H.,

2009. Mechanochemical Decomposition of Monazite to Assist the Extraction of

Rare Earth Elements. Journal of Alloys and Compounds, Volume 486(1–2),

pp. 610–614

Kumari, A.,

Panda, R., Jha, M.K., Lee, J.Y., Kumar, J.R., Kumar, V., 2015. Thermal

Treatment for The Separation of Phosphate and Recovery of Rare Earth Metals

(REMs) from Korean Monazite. Journal of Industrial and Engineering

Chemistry, Volume 21, pp. 696–703

Legendre, F., Poissonnet, S.,

Bonnaillie, P., 2007. Synthesis of Nanostructured SnO2 Materials by Reactive

Ball-Milling. Journal of Alloys and Compounds, Volume 434, pp. 400–404

Lide, D.R., 2005. CRC Handbook of

Chemistry and Physics, Journal of Chemical Technology & Biotechnology.

Available online at https://doi.org/10.1002/jctb.280500215, Accessed on October

3, 2022

Mateti, S., Mathesh, M., Liu, Z., Tao,

T., Ramireddy, T., Glushenkov, A.M., Yang, W., Chen, Y.I., 2021.

Mechanochemistry: A Force in Disguise and Conditional Effects Towards Chemical

Reactions. Chemical Communications, Volume 57(9), pp. 1080–1092

Ministry of Energy and Mineral

Resources, 2020. Booklet Tambang Tanah Jarang (Rare Earth Mining Booklet).

Available online at: https://www.esdm.go.id/id/

booklet/booklet-tambang-tanah-jarang-2020, Accessed on October 14, 2022

Monash Scientific Glass Blowing

Services, n.d. NaOH. Available online at: http://www.monashscientific.com.au/NaOH.htm,

Accessed on May 7, 2023

Prameswara, G.,

Trisnawati, I., Handini, T., Poernomo, H., Mulyono, P., Prasetya, A., Petrus,

H.T.M.B., 2023. Recovery of Critical Elements (Dysprosium and

Ytterbium) from Alkaline Process of Indonesian Zircon Tailings: Selective

Leaching and Kinetics Study. International Journal of Technology, Volume

14(4), pp. 770–779

Prihutami, P., Sediawan, W.B.,

Prasetya, A., Petrus, H.T.B.M., 2021. A Product Diffusion Model for the

Extraction of Cerium and Yttrium from Magnetic Coal Fly Ash Using Citric Acid

Solution. International Journal of Technology, Volume 13(4), pp. 921–930

PubChem, n.d., Sodium Hydroxide.

Available online at: https://pubchem.ncbi.nlm.nih.gov/compound/Sodium-hydroxide,

Accessed on May 11, 2023

Trisnawati, I., Prameswara, G.,

Mulyono, P., Prasetya, A., Petrus, H.T.B.M., 2020. Sulfuric Acid Leaching of

Heavy Rare Earth Elements (HREEs) from Indonesian Zircon Tailing. International

Journal of Technology, Volume 11(4), pp. 804–816

Tsuzuki, T., McCormick, P.G., 2004.

Mechanochemical Synthesis of Nanoparticles. Journal of Materials Science, Volume

39, pp. 5143–5146

Van-Gosen, B.S., Phillip L.V., Keith

R.L., Joseph G., Robert R., 2014. The Rare-Earth Elements — Vital to Modern

Technologies and Lifestyles. USGS Mineral Resources Program, p. 4

Zhang, W., Noble, A., 2020.

Mineralogy Characterization and Recovery of Rare Earth Elements from The Roof

And Floor Materials of The Guxu Coalfield. Fuel, Volume 270, p. 117533